Rokee is a chinese Tooth Gear Couplings Manufacturer, provide Tooth Gear Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Tooth Gear Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Tooth Gear Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

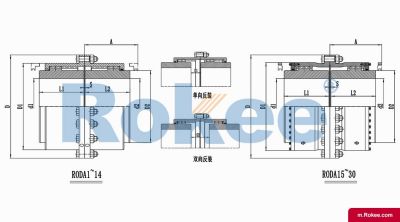

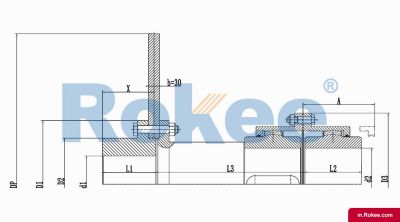

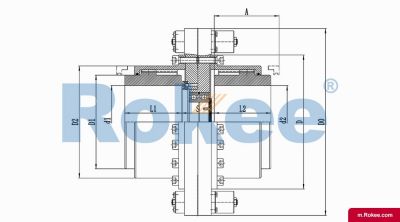

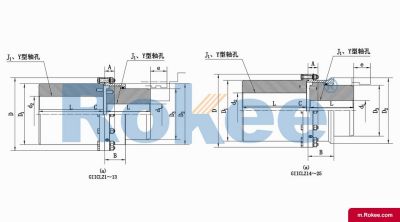

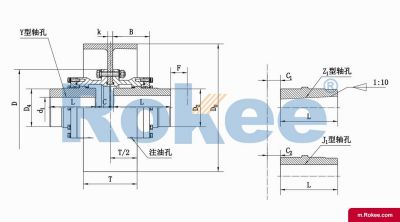

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

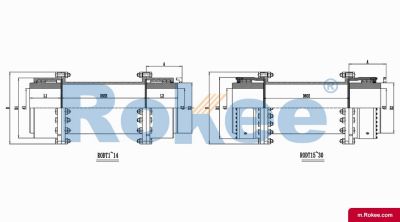

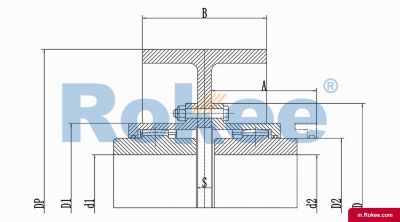

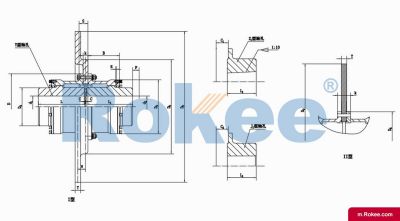

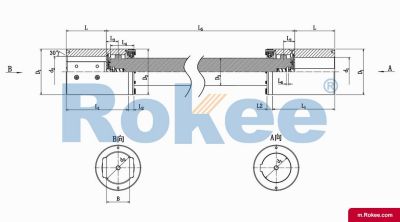

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

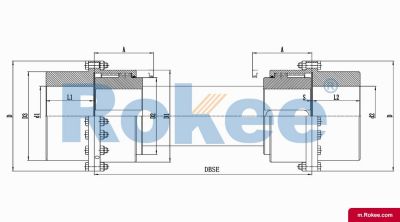

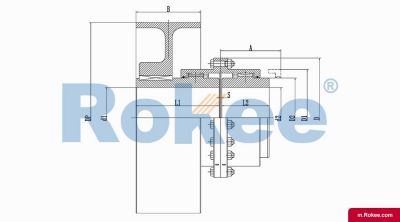

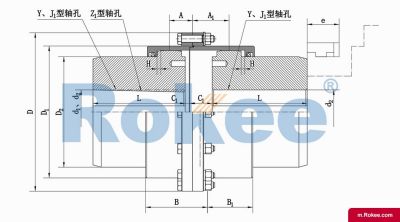

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

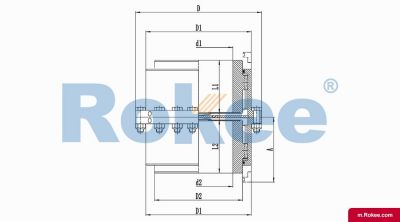

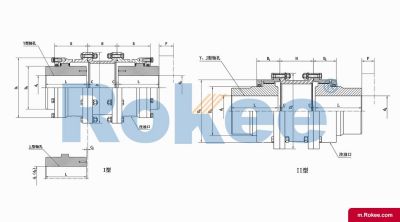

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

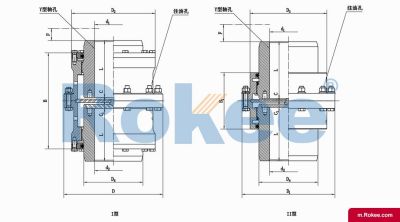

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

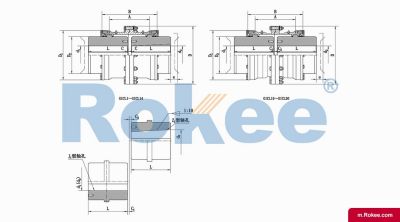

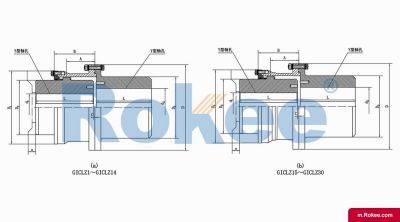

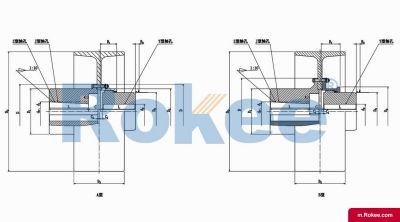

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

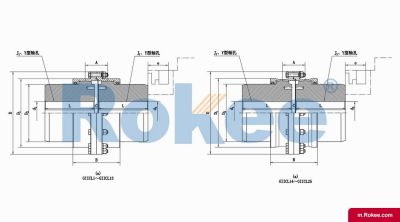

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

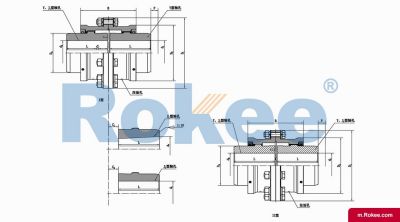

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

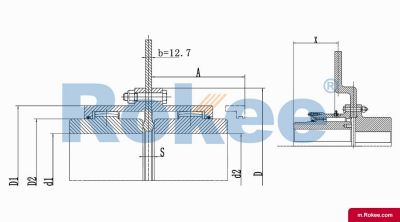

A tooth gear coupling is a movable rigid coupling composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. It utilizes the meshing of internal and external teeth to achieve the transmission of torque and rotational motion between the two halves of the coupling, and has a certain ability to compensate for the relative displacement of the two shafts. The tooth gear coupling is mainly composed of internal gear rings, gear shaft sleeves (external gear shaft sleeves), end caps, and sealing devices. Among them, small-sized tooth gear coupling end caps and inner gear rings usually form an integral structure. tooth gear couplings can be divided into straight tooth gear couplings, drum tooth gear couplings, and special drum tooth gear couplings according to the different axial tooth profiles of their outer gear shaft sleeves. tooth gear couplings also have advantages such as small radial size and wide range of operating speeds. High precision and dynamically balanced tooth gear couplings can also be used for high-speed transmission, such as shaft transmission in gas turbines.

When the tooth gear coupling is in operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear sleeve, which in turn drives the driven shaft to rotate. Due to the meshing of the inner and outer teeth, when there is relative displacement between the two shafts, the tooth surfaces of the inner and outer teeth will periodically slide axially relative to each other. This sliding allows the coupling to adapt to certain angular, radial, and axial displacement compensation, thereby maintaining stable transmission performance. tooth gear couplings are widely used in metallurgy, mining, lifting and transportation, petroleum, chemical, general machinery, and power industries. Especially under heavy loads, large impacts, or conditions where the shaft system is prone to displacement, the tooth gear coupling ensures stable operation of the equipment due to its high load-bearing capacity and good displacement compensation capability.

In terms of maintenance, tooth gear couplings need to maintain good lubrication and sealing conditions to avoid tooth wear and power loss. At the same time, the meshing condition of the coupling teeth should be regularly checked to ensure that its contact area and meshing accuracy meet the specified requirements. If it is necessary to remove the ring gear, special tools must be used and not knocked to avoid damaging the shaft or coupling components.

When selecting a tooth gear coupling, the selection should be based on the actual working conditions and requirements of the transmission system to ensure that the performance of the coupling meets the usage requirements. Installation should be carried out according to the prescribed installation methods and steps to ensure the installation accuracy and alignment requirements of the coupling. During use, the coupling should be regularly inspected and maintained to promptly identify and address potential problems and malfunctions.

In the complex network of industrial transmission systems, couplings serve as the critical link that bridges rotating shafts, ensuring the smooth transfer of torque and motion while accommodating inevitable misalignments. Among the diverse range of coupling technologies available, the tooth gear coupling stands out for its exceptional load-bearing capacity, robust compensation capabilities, and reliable performance in demanding operating conditions. This mechanical component, characterized by the meshing of internal and external gears, has become an indispensable part of heavy-duty machinery across multiple industries, from metallurgy and mining to energy and marine engineering.

The fundamental structure of a tooth gear coupling is defined by a set of core components that work in harmony to achieve torque transmission and misalignment compensation. At the heart of this assembly are two primary elements: the external gear sleeve and the internal gear ring. The external gear sleeve, typically a flanged half-coupling with precision-machined external teeth, is connected to the drive or driven shaft through a keyway connection, ensuring a secure fit that prevents relative rotation during operation. The internal gear ring, an annular component with matching internal teeth, meshes closely with the external gear sleeve, forming the torque-transmitting interface. Complementing these core components are sealing devices, connecting bolts, and a lubrication system, each playing a vital role in maintaining operational integrity. Sealing devices, often in the form of rubber or metallic seals, prevent lubricant leakage and block the ingress of external contaminants such as dust, moisture, and debris, which can cause premature wear and corrosion. Connecting bolts secure the coupling components to the shaft ends, ensuring structural stability even under high torque loads. The lubrication system, which may include oil holes, oil passages, and grease chambers, delivers essential lubricants to the meshing tooth surfaces, reducing friction, minimizing wear, and dissipating heat generated during operation.

The working principle of a tooth gear coupling revolves around the meshing of gears to transmit torque while accommodating axial, radial, and angular misalignments between connected shafts. When the drive shaft rotates, torque is transferred to the external gear sleeve via the keyway connection. This torque is then transmitted to the internal gear ring through the meshing of the external and internal teeth, ultimately driving the driven shaft into rotation. A key characteristic of this design is its ability to compensate for shaft misalignments, which are common in industrial machinery due to factors such as installation errors, thermal expansion, and structural deformation during operation. When misalignments occur, the meshing tooth surfaces undergo periodic axial sliding, a motion that allows the coupling to adapt to positional deviations without compromising torque transmission. This sliding motion, however, underscores the importance of proper lubrication, as inadequate lubrication can lead to increased friction, excessive wear, and reduced coupling lifespan. The efficiency of torque transmission is further enhanced by the multi-tooth contact design, which distributes the load across multiple tooth surfaces, enabling the coupling to handle significantly higher torque loads compared to many other coupling types of similar radial dimensions.

Material selection and manufacturing processes are critical factors that determine the performance, durability, and reliability of tooth gear couplings. Given the demanding operating conditions they often encounter, the core components are typically fabricated from high-strength alloy steels such as 42CrMo and 20CrMnTi. These materials are chosen for their excellent combination of strength, toughness, and wear resistance, properties that are essential for withstanding the high stresses and repeated loading associated with torque transmission. The manufacturing process involves a series of precision operations, starting with forging or casting to shape the basic components, followed by machining to achieve the required dimensional accuracy. The tooth profiles, in particular, require precision machining to ensure smooth meshing and optimal load distribution; the cumulative tooth pitch error is often controlled within 0.025 mm, a tolerance that far exceeds basic industry standards. Heat treatment processes play a crucial role in enhancing the mechanical properties of the components. A common heat treatment sequence involves quenching and tempering to improve the overall toughness of the material, followed by carburizing and quenching to harden the tooth surfaces. This dual heat treatment approach ensures that the tooth surfaces have sufficient hardness to resist wear, while the core remains tough enough to absorb impact loads, preventing brittle fracture.

Tooth gear couplings can be categorized into two main types based on tooth profile design: straight tooth and curved (drum) tooth couplings. Straight tooth couplings feature linear tooth profiles on the external gear sleeve, a design that simplifies manufacturing but limits misalignment compensation capabilities. In applications where angular misalignment is significant, straight tooth couplings may experience edge contact between the teeth, leading to increased wear and reduced performance. As a result, straight tooth couplings are gradually being phased out in many industrial applications, with curved tooth couplings becoming the preferred choice due to their superior performance. Curved tooth couplings, also known as drum gear couplings, feature external teeth machined into a spherical shape, with the center of the sphere aligned with the gear axis. This innovative design increases the tooth contact area and allows for larger angular misalignments compared to straight tooth couplings. The curved tooth profile also improves the contact conditions between the meshing teeth, eliminating edge contact and reducing stress concentrations, thereby enhancing torque transmission capacity and extending service life. Additionally, curved tooth couplings typically have larger tooth backlash, a feature that further facilitates misalignment compensation and reduces the risk of tooth jamming.

Variations of curved tooth couplings have been developed to meet the specific requirements of different industrial applications. For example, some designs incorporate an intermediate connecting pipe, allowing for longer transmission distances between shafts. Others feature adjustable torque-limiting mechanisms, which enable the maximum transmitted torque to be set within a specific range, providing protection for critical machinery components against overload damage. Wide-tooth curved couplings are designed with a larger internal tooth width, enabling them to compensate for greater axial displacements while maintaining torque transmission efficiency. In contrast, narrow-tooth designs offer a more compact structure and lower moment of inertia, making them suitable for applications with limited installation space and high-speed operation. Specialized versions have also been developed for vertical installation scenarios and direct connection to motor shaft extensions, each tailored to the unique constraints and requirements of their intended applications.

In recent years, advancements in materials and manufacturing technologies have expanded the range of tooth gear coupling options, with non-metallic components gaining popularity in certain applications. Nylon tooth gear couplings, for instance, utilize a combination of metal external gear sleeves and MC nylon internal gear rings. The nylon internal gear ring offers several advantages, including excellent self-lubricating properties, good wear resistance, and the ability to absorb vibration and impact. These characteristics make nylon tooth gear couplings particularly suitable for applications such as fans, pumps, and food processing machinery, where low noise, reduced maintenance, and corrosion resistance are important. The elastic deformation of the nylon material also enhances the coupling's misalignment compensation capabilities, further improving operational smoothness. Another emerging trend is the use of 3D printing (fused deposition modeling) for the production of custom tooth gear couplings, especially for small-batch applications where traditional molding methods are economically unfeasible. While 3D-printed couplings offer design flexibility and rapid prototyping capabilities, their performance in terms of strength and durability under heavy loads is still being evaluated and optimized.

The versatility of tooth gear couplings is reflected in their wide range of industrial applications, spanning multiple sectors where reliable torque transmission and misalignment compensation are essential. In the metallurgical industry, they are extensively used in rolling mills, continuous casting machines, and steelmaking equipment, where they handle the high torque loads and frequent start-stop operations characteristic of these processes. The mining industry relies on tooth gear couplings for equipment such as excavators, conveyors, and crushers, where they must withstand harsh operating conditions including dust, vibration, and extreme loads. In the energy sector, precision-balanced tooth gear couplings are used in gas turbines and generators, where high-speed operation and reliable performance are critical for efficient power generation. The marine industry utilizes these couplings in ship propulsion systems, where they connect the engine to the propeller shaft, accommodating misalignments caused by hull flexure during navigation. Other applications include petroleum and chemical processing equipment, lifting and transportation machinery, and industrial pumps and fans, each benefiting from the coupling's ability to operate reliably in demanding environments.

Despite their numerous advantages, tooth gear couplings require proper maintenance to ensure optimal performance and longevity. Regular inspection and lubrication are the cornerstones of effective maintenance. Lubrication intervals depend on operating conditions such as speed, load, and environment; in general, lubricants should be checked and replaced periodically to ensure they remain effective in reducing friction and preventing wear. Common lubricants used include NLGI 2# extreme pressure lithium-based grease for medium and low-speed applications, and specialized oils for high-speed or high-temperature environments. Sealing devices should also be inspected regularly to ensure they are intact and functioning properly, as damaged seals can lead to lubricant loss and contamination. Periodic checks of tooth wear, bolt tightness, and shaft alignment are also essential. Signs of excessive wear, such as pitting, scuffing, or tooth deformation, indicate the need for component replacement or repair. Proper installation, including accurate shaft alignment, is equally important, as excessive initial misalignment can accelerate wear and reduce coupling lifespan.

The performance advantages of tooth gear couplings are numerous, making them a preferred choice for many industrial applications. Their high load-bearing capacity allows them to transmit large torque loads, while their compact radial dimensions make them suitable for applications with limited installation space. The ability to compensate for multiple types of misalignments ensures smooth operation even in imperfectly aligned shaft systems. When properly designed and maintained, tooth gear couplings exhibit excellent durability and long service life, reducing downtime and maintenance costs for industrial operations. Additionally, their wide range of material and design variations allows for customization to meet the specific requirements of different applications, from low-speed, heavy-duty machinery to high-speed, precision equipment.

Like any mechanical component, tooth gear couplings have certain limitations that must be considered during selection and application. One of the primary limitations is their relatively high maintenance requirement compared to some other coupling types, particularly in terms of lubrication and inspection. In high-speed applications, the meshing of teeth can generate noise and vibration, which may require additional damping measures in noise-sensitive environments. Another limitation is the potential for increased wear in harsh environments with high levels of contamination, unless appropriate sealing measures are implemented. Furthermore, the initial cost of tooth gear couplings is often higher than that of simpler coupling types, although this cost is typically offset by their superior performance and longer lifespan in demanding applications.

Looking to the future, the development of tooth gear couplings is likely to focus on enhancing performance, reducing maintenance requirements, and expanding their application range. Advances in material science may lead to the development of new alloys and composite materials with improved strength, wear resistance, and corrosion resistance, enabling couplings to operate in even more extreme environments. The integration of smart monitoring technologies, such as sensors to detect tooth wear, temperature, and vibration, could enable predictive maintenance, allowing for timely repairs before component failure occurs. Additionally, ongoing optimization of design and manufacturing processes, including the use of advanced simulation tools to predict performance under various operating conditions, will continue to improve the efficiency and reliability of tooth gear couplings. As industrial machinery becomes increasingly complex and demanding, the role of tooth gear couplings as a critical component in transmission systems is expected to remain vital, with continuous innovations ensuring they meet the evolving needs of the industry.

« Tooth Gear Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/tooth-gear-couplings.html