Rokee is a chinese Elastic Pin Gear Couplings Manufacturer, provide Elastic Pin Gear Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Elastic Pin Gear Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Elastic Pin Gear Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

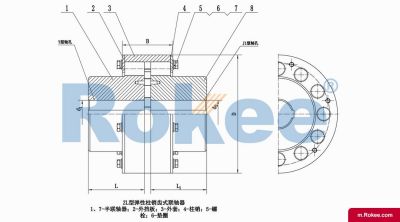

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

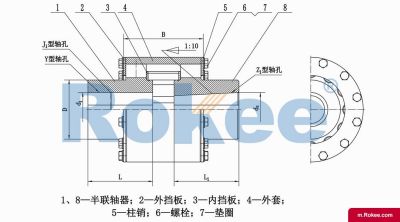

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

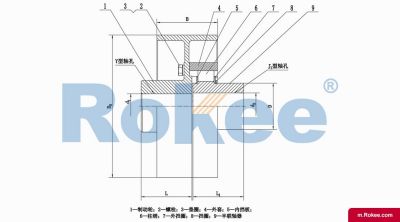

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Elastic Pin Gear Coupling is a mechanical transmission device that uses several non-metallic material column pins placed in the mating holes between the two halves of the coupling and the inner surface of the outer ring, and transmits torque through the column pins to achieve the connection between the two halves of the coupling.

Structural characteristics

Two semi-circular grooves with the same radius are made on the outer edge of the semi coupling flange and the inner edge of the outer sleeve to form a column pin hole, which is embedded with an elastic column pin. The driving shaft half coupling drives the outer sleeve through the column pin, and the outer sleeve then drives the driven shaft half coupling to rotate through the column pin, thereby transmitting torque.

The Elastic Pin Gear Coupling has a certain compensation performance for the relative offset of the two shafts, including axial, radial, and angular offsets.

Main advantage

High transmission torque: At the same torque, its rotational diameter is mostly smaller than that of a gear coupling, so it has a small volume and light weight, and can partially replace a gear coupling.

Simple structure: Compared with gear couplings, it has fewer components, is easier to manufacture, and does not require gear machining machines.

Easy maintenance: Long lifespan, the nylon pillar pin can be replaced by removing the baffle.

Self lubrication: Nylon column pins are made of self-lubricating material and do not require lubrication, which not only saves lubricating oil but also purifies the working environment.

Strong universality: can be derived into various structural forms, with a wide range of applications.

Main Disadvantages

Vibration reduction kinetic energy difference: Compared to some other types of couplings, its vibration reduction effect is relatively poor.

High noise: Due to insufficient damping energy, significant noise may be generated during operation.

The Elastic Pin Gear Coupling is suitable for medium and high power transmission systems, especially for situations where it is difficult to install the axis alignment or where auxiliary work hours need to be minimized as much as possible. However, it is not suitable for working areas that have certain requirements for vibration reduction and strict noise control.

Elastic Pin Gear Couplings can be divided into various types based on their structure and usage, such as LZ type, LZZ type with brake wheel Elastic Pin Gear Couplings, LZD type tapered shaft hole Elastic Pin Gear Couplings, LZJ type intermediate shaft Elastic Pin Gear Couplings, etc.

Installation and maintenance

During installation, it is necessary to ensure that the axis of the two halves of the coupling is aligned to avoid excessive displacement that may cause damage to the coupling.

During maintenance, the wear of the column pins should be regularly checked, and severely worn column pins should be replaced in a timely manner to ensure the normal operation of the coupling.

« Elastic Pin Gear Couplings » Post Date: 2023/8/30

URL: https://m.rokee.com/tags/elastic-pin-gear-couplings.html