Rokee is a chinese Elastic Sleeve Pin Couplings Manufacturer, provide Elastic Sleeve Pin Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Elastic Sleeve Pin Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Elastic Sleeve Pin Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

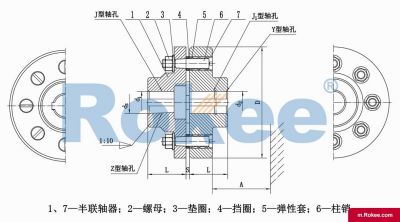

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

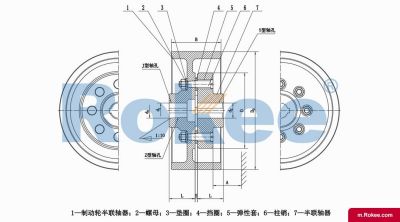

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Elastic Sleeve Pin Coupling is a commonly used mechanical transmission component, which uses a column pin with an elastic sleeve (usually rubber material) on one end, installed in the flange hole of the two half couplings to achieve the connection of the two half couplings. The elastic sleeve pin coupling is composed of fewer parts and has a relatively simple structure, which makes its manufacturing and installation more convenient. Due to its structural advantages, the Elastic Sleeve Pin Coupling does not require complex steps or tools during installation, and the replacement of the elastic sleeve is also easy, without the need to move the two halves of the coupling. Although the deformation of the elastic sleeve is limited, the Elastic Sleeve Pin Coupling still has a certain ability to compensate for the relative offset of the two shafts, which helps reduce vibration and noise in the transmission system. The elastic sleeve can absorb some impact and vibration during operation, thus playing a role in buffering and shock-absorbing.

Elastic Sleeve Pin Couplings are widely used in various small and medium power transmission shaft systems, especially those driven by electric motors, with good base rigidity and high alignment accuracy. It is suitable for transmission systems with low impact loads and low requirements for vibration reduction. There are many types and specifications of elastic sleeve pin couplings for selection to meet the needs of different transmission systems. Common types include LT type (formerly TL type), which may vary in structure, materials, performance, and other aspects. In terms of specifications, the appropriate coupling model and size are mainly determined based on parameters such as torque, speed, and shaft diameter of the transmission system.

The material of the elastic sleeve has a significant impact on the performance of the coupling. Rubber materials are generally chosen because they have good elasticity and wear resistance. However, it should be noted that the performance of different materials may vary in different environments, so suitable materials should be selected according to the actual working environment. Although the elastic sleeve pin coupling has a certain compensation ability, the accuracy during installation still has a significant impact on its performance. It should be ensured that the coaxiality and end face parallelism of the two half couplings are within the allowable range to reduce vibration and noise. Regularly check the wear of the elastic sleeve and replace the severely worn elastic sleeve in a timely manner to ensure the normal operation of the coupling and extend its service life.

« Elastic Sleeve Pin Couplings » Post Date: 2023/8/30

URL: https://m.rokee.com/tags/elastic-sleeve-pin-couplings.html