WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.

| Model | Nominal Torque N ·m | Shaft Hole Diameter | Shaft Hole Length L | D | D1 | D2 | D3 | D4 | B | B1 | F | H min | C | C2 | Weight Without Intermediate Section kg | Rotational Inertia kg · m2 | Grease kg | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1、d2 | Y | J1 | I | Ⅱ | I | Ⅱ | I | Ⅱ | I | Ⅱ | ||||||||||||

| WGT1 | 800 | 12,14 | 32 | 一 | 122 | 115 | 98 | 88 | 60 | 58 | 50 | 30 | 75 | 30 | 一 | 一 | 5.66 | 4.86 | 0.008 | 0.0063 | 0.085 | 0.04 |

| 16,18,19 | 42 | 一 | 20 | 14 | 一 | |||||||||||||||||

| 20,22,24 | 52 | 一 | 10 | 4 | 一 | |||||||||||||||||

| 25,28 | 62 | 44 | 3 | 3 | 18 | |||||||||||||||||

| 30,32,35,38 | 82 | 60 | 12 | |||||||||||||||||||

| 40,42 | 112 | 84 | 12 | |||||||||||||||||||

| WGT2 | 1400 | 22,24 | 52 | 一 | 150 | 145 | 118 | 108 | 77 | 68 | 52 | 30 | 80 | 20 | 4 | 一 | 9.78 | 7.48 | 0.021 | 0.016 | 0.09 | 0.06 |

| 25,28 | 62 | 一 | 10 | 3 | 一 | |||||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 16 | ||||||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | ||||||||||||||||||||

| WGT3 | 2800 | 22,24 | 52 | 一 | 170 | 165 | 140 | 125 | 90 | 80 | 54 | 30 | 80 | 33 | 7 | 一 | 16.7 | 12.2 | 0.047 | 0.033 | 0.17 | 0.10 |

| 25,28 | 62 | 一 | 23 | 3 | 一 | |||||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 25 | ||||||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 16 | |||||||||||||||||||

| 60,63 | 142 | 107 | ||||||||||||||||||||

| WGT4 | 5000 | 30,32,35,38 | 82 | — | 200 | 195 | 160 | 145 | 112 | 90 | 58 | 30 | 100 | 13 | 3 | 一 | 25.6 | 19.6 | 0.098 | 0.073 | 0.25 | 0.15 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 17 | ||||||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | ||||||||||||||||||||

| 80 | 172 | 132 | ||||||||||||||||||||

| WGT5 | 8000 | 30,32,35,38 | 82 | 一 | 225 | 215 | 180 | 168 | 128 | 100 | 63 | 30 | 100 | 23 | 3 | 一 | 35.0 | 26.1 | 0.175 | 0.126 | 0.35 | 0.22 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 19 | ||||||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | ||||||||||||||||||||

| 80,85,90 | 172 | 132 | ||||||||||||||||||||

| WGT6 | 11200 | 32,35,38 | 82 | 一 | 245 | 230 | 200 | 185 | 145 | 112 | 67 | 30 | 100 | 35 | 5 | 一 | 51.6 | 38.0 | 0.295 | 0.213 | 0.40 | 0.29 |

| 40,42,45,48,50,55,56 | 112 | 一 | 5 | 一 | ||||||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 20 | |||||||||||||||||||

| 80,85,90,95 | 172 | 132 | ||||||||||||||||||||

| 100 | 212 | 167 | ||||||||||||||||||||

| WGT7 | 16000 | 32,35,38 | 82 | 一 | 272 | 265 | 230 | 210 | 160 | 122 | 74 | 30 | 120 | 45 | 5 | 一 | 68.6 | 45.0 | 0.53 | 0.35 | 0.60 | 0.44 |

| 40,42,45,48,50,55,56 | 112 | 一 | 15 | 一 | ||||||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 5 | 20 | ||||||||||||||||||

| 80,85,90,95 | 172 | 132 | ||||||||||||||||||||

| 100,110 | 212 | 167 | ||||||||||||||||||||

| WGT8 | 22400 | 55,56 | 112 | 一 | 290 | 272 | 245 | 225 | 176 | 136 | 81 | 30 | 120 | 29 | 5 | 一 | 79.5 | 55.8 | 0.71 | 0.46 | 0.75 | 0.55 |

| 60,63,65,70,71,75 | 142 | 107 | 5 | 34 | ||||||||||||||||||

| 80.85,90,95 | 172 | 132 | 20 | |||||||||||||||||||

| 100,110,120,125 | 212 | 167 | ||||||||||||||||||||

| WGT9 | 28000 | 65,70,71,75 | 142 | 107 | 315 | 305 | 265 | 245 | 190 | 140 | 88 | 30 | 155 | 5 | 5 | 38 | 106.5 | 80.5 | 1.05 | 0.77 | 1.0 | 0.79 |

| 80,85,90,95 | 172 | 132 | 28 | |||||||||||||||||||

| 100,110,120,125 | 212 | 167 | ||||||||||||||||||||

| 130,140 | 252 | 202 | ||||||||||||||||||||

| WGT10 | 45000 | 75 | 142 | 一 | 355 | 340 | 300 | 280 | 225 | 165 | 98 | 30 | 155 | 28 | 5 | 一 | 158.8 | 121.8 | 1.87 | 1.54 | 1.3 | 0.9 |

| 80,85,90,95 | 172 | 132 | 5 | 38 | ||||||||||||||||||

| 100,110,120,125 | 212 | 167 | 28 | |||||||||||||||||||

| 130,140,150 | 252 | 202 | ||||||||||||||||||||

| 160 | 302 | 242 | ||||||||||||||||||||

| WGT11 | 63000 | 85,90,95 | 172 | 一 | 412 | 385 | 345 | 325 | 256 | 180 | 112 | 40 | 175 | 15 | 8 | 一 | 216.6 | 169.6 | 3.71 | 2.82 | 1.6 | 1.23 |

| 100,110,120,125 | 212 | 167 | 8 | 32 | ||||||||||||||||||

| 130,140,150 | 252 | 202 | ||||||||||||||||||||

| 160,170,180 | 302 | 242 | ||||||||||||||||||||

| WGT12 | 90000 | 120,125 | 212 | 167 | 440 | 435 | 375 | 360 | 288 | 210 | 125 | 40 | 205 | 8 | 8 | 45 | 305.3 | 245.3 | 6.48 | 4.84 | 2.6 | 1.90 |

| 130,140,150 | 252 | 202 | 32 | |||||||||||||||||||

| 160,170,180 | 302 | 242 | ||||||||||||||||||||

| 190,200 | 352 | 282 | ||||||||||||||||||||

| WGT13 | 125000 | 140,150 | 252 | 202 | 490 | 480 | 425 | 400 | 320 | 235 | 136 | 50 | 205 | 8 | 8 | 38 | 394.5 | 313.5 | 10.58 | 7.9 | 3.3 | 2.4 |

| 160,170,180 | 302 | 242 | 32 | |||||||||||||||||||

| 190,200,220 | 352 | 282 | ||||||||||||||||||||

| WGT14 | 180000 | 160,170,180 | 302 | 242 | 545 | 540 | 462 | 440 | 362 | 265 | 158 | 50 | 240 | 10 | 10 | 32 | 529.5 | 430.5 | 17.72 | 13.78 | 4.8 | 3.7 |

| 190,200,220 | 352 | 282 | ||||||||||||||||||||

| 240,250,260 | 410 | 330 | 10 | |||||||||||||||||||

| WGT15 | 250000 | 160,170,180 | 302 | 242 | 580 | 一 | 488 | 一 | 385 | 280 | 一 | 50 | 240 | 10 | 一 | 43 32 10 | 684.5 | 一 | 25.25 | 一 | 5 | 一 |

| 190,200,220 | 352 | 282 | ||||||||||||||||||||

| 240,250,260 | 410 | 330 | ||||||||||||||||||||

| 280 | 470 | 380 | ||||||||||||||||||||

| WGT16 | 315000 | 180 | 302 | 242 | 650 | 一 | 560 | 一 | 440 | 300 | 一 | 50 | 240 | 12 | 一 | 63 32 12 | 948.2 | 一 | 43.7 | 一 | 7 | 一 |

| 190,200,220 | 352 | 282 | ||||||||||||||||||||

| 240.250.260 | 410 | 330 | ||||||||||||||||||||

| 280,300 | 470 | 380 | ||||||||||||||||||||

| WGT17 | 400000 | 200,220 | 352 | 282 | 690 | 一 | 600 | 一 | 460 | 325 | 一 | 50 | 280 | 12 | 一 | 48 | 1059 | 一 | 57.37 | 一 | 8 | 一 |

| 240,250,260 | 410 | 330 | 12 | |||||||||||||||||||

| 280,300,320 | 470 | 380 | ||||||||||||||||||||

| WGT18 | 500000 | 220 | 352 | 282 | 750 | 一 | 650 | 一 | 510 | 350 | 一 | 60 | 280 | 12 | 一 | 73 | 1399 | 一 | 59.37 | 一 | 10 | 一 |

| 240,250,260 | 410 | 330 | 12 | |||||||||||||||||||

| 280,300,320 | 470 | 380 | ||||||||||||||||||||

| 340,360 | 550 | 450 | ||||||||||||||||||||

| WGT19 | 630000 | 240,250,260 | 410 | 330 | 775 | 一 | 690 | 一 | 535 | 372 | 一 | 60 | 350 | 12 | 一 | 12 | 1544 | 一 | 110.2 | 一 | 11 | 一 |

| 280,300,320 | 470 | 380 | ||||||||||||||||||||

| 340,360,380 | 550 | 450 | ||||||||||||||||||||

| WGT20 | 800000 | 260 | 410 | 330 | 825 | 一 | 730 | 一 | 580 | 392.5 | 一 | 60 | 350 | 14 | 一 | 14 | 2099 | 一 | 166.1 | 一 | 13 | 一 |

| 280,300,320 | 470 | 380 | ||||||||||||||||||||

| 340,360,380 | 550 | 450 | ||||||||||||||||||||

| 400 | 650 | 540 | ||||||||||||||||||||

| WGT21 | 900000 | 280,300,320 | 470 | 380 | 925 | 一 | 825 | 一 | 620 | 405 | 一 | 60 | 350 | 14 | 一 | 14 | 2482 | 一 | 242.7 | 一 | 20 | 一 |

| 340,360,380 | 550 | 450 | ||||||||||||||||||||

| 400,420,440 | 650 | 540 | ||||||||||||||||||||

| WGT22 | 1000000 | 320 | 470 | 380 | 950 | 一 | 850 | 一 | 665 | 410 | 一 | 60 | 400 | 14 | 一 | 14 | 2797 | 一 | 299.2 | 一 | 26 | 一 |

| 340,360,380 | 550 | 450 | ||||||||||||||||||||

| 400,420,440,450,460 | 650 | 540 | ||||||||||||||||||||

| WGT23 | 1120000 | 360,380 | 550 | 450 | 1030 | 一 | 900 | 一 | 710 | 440 | 一 | 60 | 400 | 14 | 一 | 14 | 3183 | 一 | 388.8 | 一 | 29 | 一 |

| 400,420,440,450,460,480,500 | 650 | 540 | ||||||||||||||||||||

| WGT24 | 1400000 | 380 | 550 | 450 | 1060 | 一 | 925 | 一 | 730 | 450 | 一 | 70 | 400 | 16 | 一 | 16 | 3801 | 一 | 482 | 一 | 32 | 一 |

| 400,420,440,450,460,480,500 | 650 | 540 | ||||||||||||||||||||

| 520 | 800 | 680 | ||||||||||||||||||||

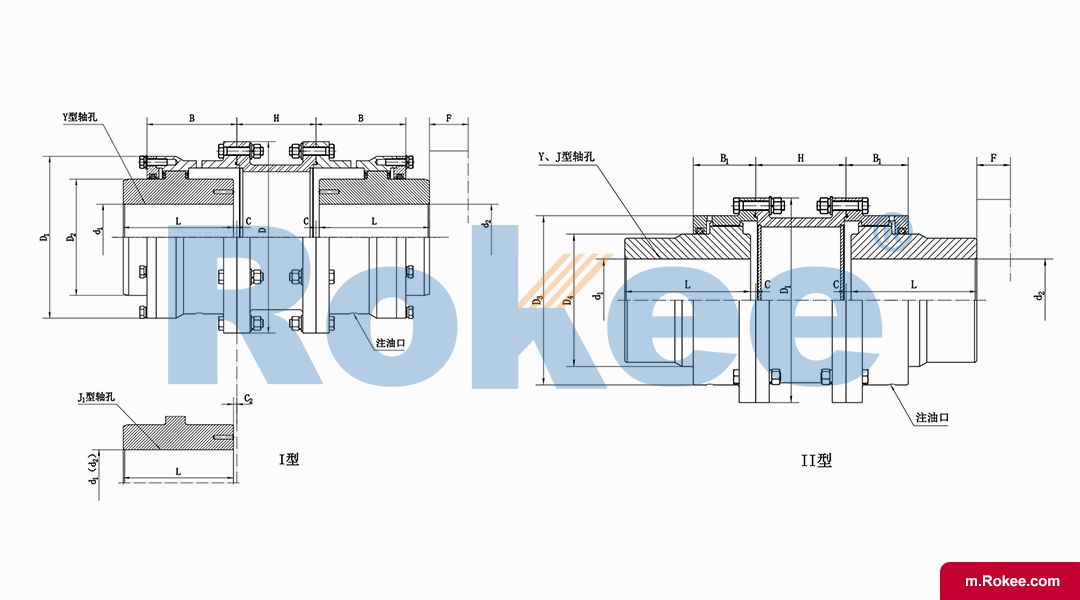

The WGT drum gear coupling is mainly composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Among them, the outer teeth are made into drum shaped teeth, which are spherical in shape, with the center of the spherical surface located on the gear axis. This design results in a larger backlash between the teeth compared to regular gears, allowing the coupling to withstand greater angular displacement.

During operation, the two axes generate relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide axially relative to each other. The design of drum shaped teeth can improve the contact conditions of teeth, enhance the ability to transmit torque, and extend the service life. At the same time, the WGT drum shaped gear coupling has the ability to compensate for radial, axial, and angular axis deviations, and can adapt to large deflection angles between two axes.

Characteristics and Advantages

Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the drum shaped gear coupling is on average 15-20% higher than that of the spur gear coupling.

Large angular displacement compensation: Drum shaped gear couplings allow for larger angular displacements, which is particularly important for transmission devices with shaft installation errors.

High transmission efficiency: The transmission efficiency of the drum shaped gear coupling can reach 99.7%, reducing energy loss.

Low noise: Due to the improvement of tooth contact conditions, the drum shaped gear coupling produces lower noise during operation.

Long maintenance cycle: The design of the drum shaped teeth reduces the risk of component wear, extends the service life and maintenance cycle of the equipment.

WGT crown gear coupling is particularly suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. At the same time, it is also suitable for shaft transmission of various types of machinery such as petroleum, chemical, and general machinery.

Although WGT couplings have many advantages, the following points should still be noted when using them:

Couplings need to work in a good and sealed condition to prevent dust and impurities from entering and affecting performance.

- For transmission systems that require buffering and vibration reduction, WGT drum toothed couplings may not be the best choice due to their high rigidity and lack of elasticity.

Careful selection is also necessary to ensure the stability and reliability of the equipment under frequent start-up and variable forward and reverse operating conditions.

The WGT drum tooth coupling plays an important role in the field of mechanical transmission due to its compact structure, high load-bearing capacity, high transmission efficiency, low noise, and long maintenance cycle. However, when selecting and using, it is necessary to consider comprehensively based on specific working conditions and requirements.

URL: https://m.rokee.com/drum-gear-couplings/wgt-drum-gear-coupling-with-indirect-tube.html