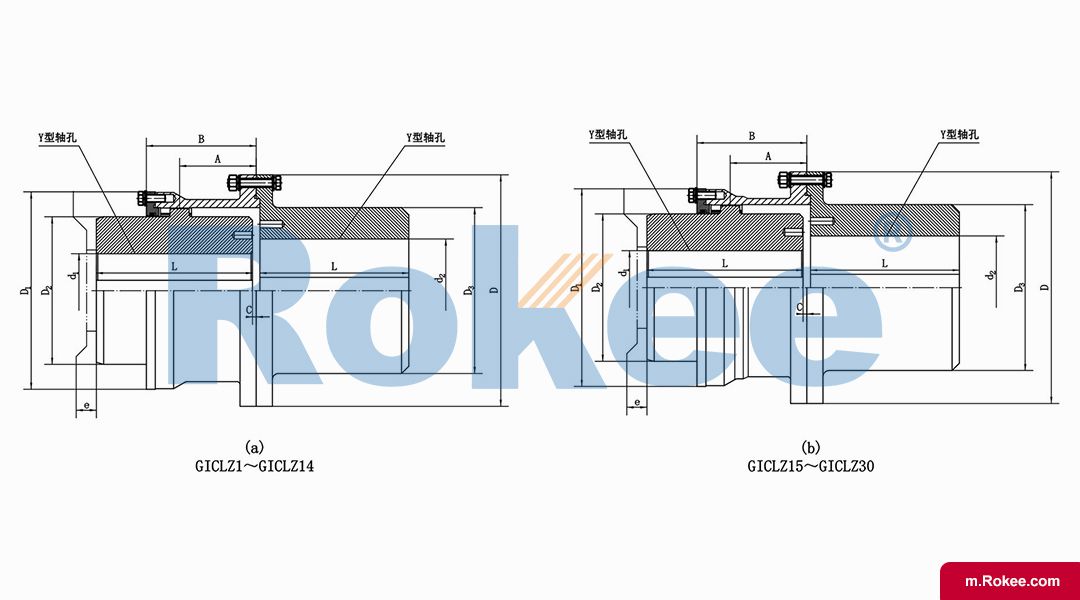

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.

| Model | Rated Torque kN·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1、d2 | Shaft Hole Length L | D | D1 | D2 | D3 | B1 | C | C1 | Rotational Inertia kg·m² | Quality kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y | |||||||||||||

| L | |||||||||||||

| mm | |||||||||||||

| GICLZ1 | 0.800 | 7100 | 16,18,19 | 42 | 125 | 95 | 60 | 80 | 57 | 24 | 一 | 0.0084 | 5.4 |

| 20,22,24 | 52 | 14 | |||||||||||

| 25,28 | 62 | 6.5 | |||||||||||

| 30,32,35,38 | 82 | 19 | |||||||||||

| 40*,42*,45*,48*,50* | 112 | ||||||||||||

| GICLZ2 | 1.400 | 6300 | 25,28 | 62 | 145 | 120 | 75 | 95 | 67 | 16 | — | 0.018 | 9.2 |

| 30,32.35,38 | 82 | 8 | 18 | ||||||||||

| 40,42,45,48,50*,55*,56* | 112 | 19 | |||||||||||

| 60* | 142 | ||||||||||||

| GICLZ3 | 2.800 | 5900 | 30,32,35,38 | 82 | 170 | 140 | 95 | 115 | 77 | 7 | 29 | 0.0427 | 16.4 |

| 40,42,45,48,50,55,56 | 112 | 22 | |||||||||||

| 60,63*,65*,70* | 142 | ||||||||||||

| GICLZ4 | 5.000 | 5400 | 32,35,38 | 82 | 195 | 165 | 115 | 130 | 89 | 8.5 | 42 | 0.076 | 22.7 |

| 40,42,45,48,50,55,56 | 112 | 19 | 22 | ||||||||||

| 60,63,65,70,71*,75* | 142 | ||||||||||||

| 80* | 172 | ||||||||||||

| GICLZ5 | 8.000 | 5000 | 40,42,45,48,50,55,56 | 112 | 225 | 183 | 130 | 150 | 99 | 9.5 | 31 | 0.0149 | 36.2 |

| 60,63,65,70,71,75 | 142 | 26 | |||||||||||

| 80,85*,90* | 172 | 28 | |||||||||||

| GICLZ6 | 11.200 | 4800 | 48,50,55,56 | 112 | 240 | 200 | 145 | 170 | 109 | 11.5 | 41 | 0.24 | 46.2 |

| 60,63,65,70,71,75 | 142 | 9.5 | 26 | ||||||||||

| 80,85,90,95* | 172 | 28 | |||||||||||

| 100* | 212 | ||||||||||||

| GICLZ7 | 15.0 | 4500 | 60,63,65,70,71,75 | 142 | 260 | 230 | 160 | 195 | 122 | 10.5 | 31 | 0.43 | 68.4 |

| 80,85,90,95 | 172 | 28 | |||||||||||

| 100,110*,120* | 212 | ||||||||||||

| GICLZ8 | 21.2 | 4000 | 65,70,71,75 | 142 | 280 | 245 | 175 | 210 | 132 | 12 | 41 | 0.61 | 81.1 |

| 80,85,90,95 | 172 | 28 | |||||||||||

| 100,110,120* | 212 | ||||||||||||

| 130* | 252 | ||||||||||||

| GICLZ9 | 26.5 | 3500 | 70,71,75 | 142 | 315 | 270 | 200 | 225 | 142 | 18 | 53 | 0.94 | 100.1 |

| 80,85,90,95 | 172 | 13 | 30 | ||||||||||

| 100,110,120,125 | 212 | ||||||||||||

| 130*,140* | 252 | ||||||||||||

| GICLZ10 | 42.5 | 3200 | 80,85,90,95 | 172 | 345 | 300 | 220 | 250 | 165 | 14 | 51 | 1.67 | 147.1 |

| 100,110,120,125 | 212 | 30 | |||||||||||

| 130,140,150* | 252 | 37 | |||||||||||

| 160* | 302 | ||||||||||||

| GICLZ11 | 60.0 | 3000 | 100,110,120 | 212 | 380 | 330 | 260 | 285 | 180 | 14 | 37 | 2.98 | 206.3 |

| 130,140,150 | 252 | ||||||||||||

| 160,170*,180* | 302 | ||||||||||||

| GICLZ12 | 80.0 | 2600 | 120 | 212 | 440 | 380 | 290 | 325 | 208 | 14 | 65 | 5.31 | 284.5 |

| 130,140,150 | 252 | 37 | |||||||||||

| 160,170,180 | 302 | ||||||||||||

| 190*,200* | 352 | ||||||||||||

| GICLZ13 | 112 | 2300 | 140,150 | 252 | 480 | 420 | 320 | 360 | 238 | 15 | 62 | 9.26 | 402.0 |

| 160,170,180 | 302 | 40 | |||||||||||

| 190,200,220* | 352 | ||||||||||||

| GICLZ14 | 160 | 2100 | 160,170,180 | 302 | 520 | 465 | 360 | 410 | 266 | 16 | 50 | 15.92 | 582.2 |

| 190,200,220 | 352 | 40 | |||||||||||

| 240*,250* | 410 | ||||||||||||

| GICLZ15 | 224 | 1900 | 190,200,220 | 352 | 580 | 510 | 400 | 450 | 278 | 17 | 41 | 25.78 | 778.2 |

| 240,250,260* | 410 | 45 | |||||||||||

| 280* | 470 | ||||||||||||

| GICLZ16 | 355 | 1600 | 200,220 | 352 | 680 | 595 | 465 | 500 | 320 | 16.5 | 65 | 16.89 | 1071.0 |

| 240,250,260 | 410 | 15.5 | 45 | ||||||||||

| 280,300*,320* | 470 | ||||||||||||

| GICLZ17 | 400 | 1500 | 220 | 352 | 720 | 645 | 495 | 530 | 336 | 17 | 81 | 60.59 | 1210.0 |

| 240,250,260 | 410 | 46 | |||||||||||

| 280,300,320 | 470 | ||||||||||||

| GICLZ18 | 500 | 1400 | 240,250,260 | 410 | 775 | 675 | 520 | 540 | 351 | 16.5 | 53 | 81.75 | 1475.0 |

| 280,300,320 | 470 | 48 | |||||||||||

| 340* | 550 | ||||||||||||

| GICLZ19 | 630 | 1300 | 260 | 410 | 815 | 715 | 560 | 580 | 372 | 17 | 74 | 101.57 | 1603.0 |

| 280,300,320 | 470 | 48 | |||||||||||

| 340,360* | 550 | ||||||||||||

| GICLZ20 | 710 | 1200 | 280,300,320 | 470 | 855 | 755 | 585 | 600 | 393 | 20 | 51 | 140.03 | 2033.0 |

| 340,360,380* | 550 | ||||||||||||

| GICLZ21 | 900 | 1100 | 300,320 | 470 | 915 | 795 | 620 | 640 | 404 | 20 | 51 | 183.49 | 2385.0 |

| 340,360,380 | 550 | ||||||||||||

| 400* | 650 | ||||||||||||

| GICLZ22 | 950 | 950 | 340,360,380 | 550 | 960 | 840 | 665 | 680 | 415 | 20 | 51 | 235.04 | 2452.0 |

| 400,420* | 650 | ||||||||||||

| GICLZ23 | 1120 | 900 | 360,380 | 550 | 1010 | 890 | 710 | 720 | 435 | 20 | 51 | 323.16 | 3332.0 |

| 400,420,450* | 650 | 55 | |||||||||||

| GICLZ24 | 1250 | 875 | 380 | 550 | 1050 | 925 | 730 | 760 | 445 | 22 | 53 | 387.97 | 3639.0 |

| 400,420,450,480* | 650 | 57 | |||||||||||

| GICLZ25 | 1400 | 850 | 400,420,450,480,500* | 650 | 1120 | 970 | 770 | 800 | 465 | 22 | 58 | 485.96 | 4073.0 |

| GICLZ26 | 1600 | 825 | 420,450,480,500 | 650 | 1160 | 990 | 800 | 850 | 475 | 22 | 58 | 573.64 | 4527.0 |

| 530* | 800 | ||||||||||||

| GICLZ27 | 1800 | 800 | 450,480,500 | 650 | 1210 | 1060 | 850 | 900 | 479 | 22 | 58 | 789.74 | 5485.0 |

| 530,560* | 800 | ||||||||||||

| GICLZ28 | 2000 | 770 | 480,500 | 650 | 1250 | 1080 | 890 | 960 | 517 | 28 | 63 | 960.26 | 6050.0 |

| 530,560,600* | 800 | ||||||||||||

| GICLZ29 | 2800 | 725 | 500 | 650 | 1340 | 1200 | 960 | 1010 | 517 | 28 | 65 | 1268.98 | 7090.0 |

| 530,560,600,630* | 800 | 63 | |||||||||||

| GICLZ30 | 3500 | 700 | 530,560,600,630* | 800 | 1390 | 1240 | 1005 | 1070 | 525 | 28 | 63 | 1822.02 | 9264.0 |

| 670* | 900 | ||||||||||||

GICLZ drum gear coupling is an efficient mechanical transmission component widely used in various industrial fields.

The GICLZ gear coupling is mainly composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. The outer teeth adopt a drum shaped tooth design, which means that the outer teeth are made into spherical surfaces, with the center of the spherical surface on the gear axis. This design results in a larger backlash between the teeth compared to regular gears, allowing for greater angular displacement and improving the contact conditions of the teeth.

During operation, the two shafts of the GICLZ drum shaped gear coupling experience relative angular displacement, and the tooth surfaces of the inner and outer teeth periodically slide axially relative to each other. This sliding will cause tooth surface wear and power consumption, therefore, the drum shaped gear coupling needs to work in a good and sealed state.

Performance characteristics

Large bearing capacity: The GICLZ crown gear coupling has a small radial size but a large bearing capacity, making it particularly suitable for shaft transmission under low-speed and heavy-duty conditions.

Strong angular displacement compensation capability: Due to the use of drum tooth design, the GICLZ drum tooth coupling allows for larger angular displacement, thus better adapting to small offsets in the transmission shaft system.

Long service life: The design of drum shaped teeth improves the contact conditions of the teeth, enhances the ability to transmit torque, and thus extends the service life of the coupling.

Easy to assemble and disassemble: Some GICLZ couplings have a trumpet shaped outer sleeve tooth end, making it easier to assemble and disassemble the inner and outer teeth.

GICLZ drum tooth couplings are widely used in industries such as metallurgy, mining, lifting and transportation under low-speed and heavy load conditions. Meanwhile, high-precision and dynamically balanced gear couplings can also be used for high-speed transmission, such as shaft transmission in gas turbines.

GICLZ drum gear coupling has a variety of models and parameters to meet the needs of different transmission shafting. For example, different models of GICLZ drum tooth couplings have different parameters such as nominal torque, allowable speed, shaft hole diameter, and shaft hole length. When choosing, users should match and select according to their actual transmission needs.

When using the GICLZ drum toothed coupling, it should be ensured that it operates in a good and sealed state to reduce tooth wear and power consumption. Regularly inspect and maintain the coupling, promptly identify and address potential issues, and ensure its long-term stable operation.

The GICLZ gear coupling has many advantages and has a wide range of application prospects in industrial production. When selecting and using, users should fully understand its performance characteristics and precautions to ensure the stability and reliability of the transmission system.

URL: https://m.rokee.com/drum-gear-couplings/giclz-drum-gear-coupling-with-intermediate-shaft.html