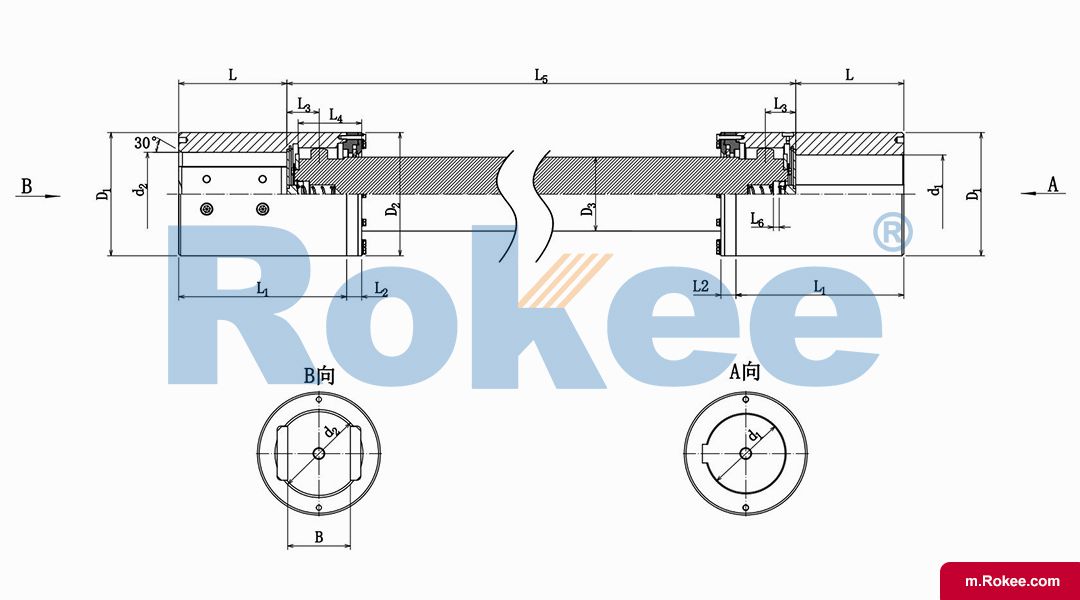

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.

| Model | Nominal Torque Tn/ (KN ·m) | Dimensions of Cylindrical Shaft Holes | Dimensions of Flat Hole Type Shaft Holes | D1 | D2 | D3 | L1 | L2 | L3 | L4 | L5 min | LS | C max | Quality kg | Rotational Inertia kg ·m | Grease mL | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1,d2 | L | d2 max | L max | B max | L5min Quality | Every 1m Increase In Mass | L5min Rotational Inertia | Growth Per Meter Rotational Inertia | |||||||||||||

| J型 | |||||||||||||||||||||

| WGJ1 | 6.3 | 60,63 | 107 | 80 | 132 | 60 | 130 | 85 | 70 | 170 | 30 | 35 | 90 | 500 | 3 | 8 | 46 | 30.2 | 0.05 | 0.018 | 150 |

| 65,70 | |||||||||||||||||||||

| 71,75 | |||||||||||||||||||||

| 80 | 132 | 195 | |||||||||||||||||||

| WGJ2 | 11.2 | 70,71,75 | 107 | 100 | 167 | 75 | 160 | 110 | 90 | 175 | 30 | 40 | 110 | 500 | 3 | 10 | 76 | 49.9 | 0.28 | 0.05 | 250 |

| 80,85 | 132 | 200 | |||||||||||||||||||

| 90,95 | |||||||||||||||||||||

| 100 | 167 | 235 | |||||||||||||||||||

| WGJ3 | 18 | 80,85 | 132 | 110 | 167 | 85 | 180 | 120 | 100 | 210 | 32 | 46 | 120 | 600 | 3 | 11 | 105 | 61.65 | 0.43 | 0.07 | 350 |

| 90,95 | |||||||||||||||||||||

| 100,110 | 167 | 245 | |||||||||||||||||||

| WGJ4 | 25 | 80,85 | 132 | 125 | 167 | 95 | 200 | 140 | 110 | 220 | 32 | 50 | 140 | 600 | 3 | 12 | 140 | 74.6 | 0.73 | 0.158 | 450 |

| 90,95 | |||||||||||||||||||||

| 100,110 | 167 | 253 | |||||||||||||||||||

| 120,125 | |||||||||||||||||||||

| WGJ5 | 31.5 | 90,95 | 132 | 140 | 202 | 105 | 230 | 160 | 130 | 225 | 38 | 54 | 160 | 600 | 5 | 14 | 200 | 104 | 1.43 | 0.22 | 650 |

| 100,110 | 167 | 260 | |||||||||||||||||||

| 120,125 | |||||||||||||||||||||

| 130,140 | 202 | 295 | |||||||||||||||||||

| WGJ6 | 50 | 110,120 | 167 | 160 | 242 | 120 | 260 | 180 | 140 | 287 | 38 | 82 | 180 | 800 | 5 | 16 | 280 | 121 | 2.56 | 0.296 | 900 |

| 130 | 202 | 322 | |||||||||||||||||||

| 140,150 | |||||||||||||||||||||

| 160 | 242 | 362 | |||||||||||||||||||

| WGJ7 | 63 | 140,150 | 202 | 190 | 282 | 140 | 280 | 200 | 160 | 336 | 38 | 85 | 200 | 800 | 5 | 19 | 380 | 158 | 4.26 | 0.501 | 1400 |

| 160 | 242 | 376 | |||||||||||||||||||

| 170,180 | |||||||||||||||||||||

| 190 | 282 | 416 | |||||||||||||||||||

| WGJ8 | 80 | 160,170 | 242 | 200 | 282 | 160 | 300 | 220 | 180 | 392 | 44 | 95 | 220 | 1000 | 5 | 20 | 480 | 200 | 6.02 | 0.81 | 1800 |

| 180 | |||||||||||||||||||||

| 190,200 | 282 | 432 | |||||||||||||||||||

| WGJ9 | 100 | 170,180 | 242 | 220 | 282 | 170 | 330 | 230 | 200 | 392 | 44 | 95 | 230 | 1000 | 5 | 22 | 550 | 247 | 7.95 | 1.24 | 2100 |

| 190,200 | 282 | ||||||||||||||||||||

| 220 | 432 | ||||||||||||||||||||

| WGJ10 | 125 | 190,200 | 282 | 240 | 330 | 180 | 355 | 250 | 220 | 442 | 51 | 98 | 250 | 1000 | 5 | 24 | 720 | 298 | 12.7 | 1.8 | 2500 |

| 220 | |||||||||||||||||||||

| 240 | 330 | 490 | |||||||||||||||||||

| WGJ11 | 200 | 190,200 | 282 | 260 | 330 | 200 | 410 | 290 | 240 | 457 | 51 | 106 | 280 | 1200 | 5 | 26 | 1110 | 355 | 25.95 | 2.56 | 3000 |

| 220 | |||||||||||||||||||||

| 240,250 | 330 | 505 | |||||||||||||||||||

| 260 | |||||||||||||||||||||

| WGJ12 | 315 | 240,250 | 330 | 300 | 380 | 220 | 460 | 320 | 260 | 518 | 57 | 112 | 300 | 1200 | 6 | 30 | 1480 | 417 | 43.43 | 3.52 | 4000 |

| 260 | |||||||||||||||||||||

| 280,300 | 380 | 568 | |||||||||||||||||||

| WGJ13 | 450 | 280,300 | 380 | 340 | 450 | 250 | 510 | 360 | 300 | 596 | 57 | 136 | 340 | 1400 | 6 | 34 | 2020 | 555 | 71.76 | 6.24 | 5200 |

| 320 | |||||||||||||||||||||

| 340 | 450 | 666 | |||||||||||||||||||

| WGJ14 | 560 | 300,320 | 380 | 360 | 450 | 280 | 560 | 400 | 320 | 628 | 64 | 145 | 380 | 1500 | 6 | 36 | 2600 | 631 | 114.4 | 8.1 | 6500 |

| 340,360 | 450 | 698 | |||||||||||||||||||

| WGJ15 | 710 | 340,360 | 450 | 400 | 540 | 300 | 610 | 430 | 350 | 716 | 64 | 160 | 400 | 1500 | 6 | 40 | 3300 | 755 | 178 | 11.6 | 8000 |

| 380 | |||||||||||||||||||||

| 400 | 540 | 806 | |||||||||||||||||||

| WGJ16 | 900 | 360,380 | 540 | 420 | 650 | 320 | 660 | 460 | 380 | 842 | 64 | 172 | 440 | 1600 | 10 | 42 | 4300 | 890 | 272 | 16 | 10000 |

| 400,420 | 680 | 942 | |||||||||||||||||||

| WGJ17 | 1120 | 400,420 | 680 | 460 | 650 | 350 | 710 | 500 | 420 | 964 | 64 | 182 | 480 | 1800 | 10 | 46 | 5500 | 1090 | 392 | 24 | 12000 |

| 440,450 | |||||||||||||||||||||

| 460 | |||||||||||||||||||||

| WGJ18 | 1250 | 420,440 | 680 | 500 | 650 | 380 | 760 | 540 | 460 | 900 | 76 | 195 | 520 | 2000 | 10 | 50 | 6700 | 1310 | 553 | 35 | 15000 |

| 450,460 | |||||||||||||||||||||

| 480,500 | |||||||||||||||||||||

| WGJ19 | 1600 | 440,450 | 680 | 530 | 800 | 400 | 810 | 580 | 500 | 1005 | 76 | 215 | 540 | 2000 | 10 | 53 | 8350 | 1540 | 805 | 48 | 16500 |

| 460,480 | |||||||||||||||||||||

| 500 | |||||||||||||||||||||

| 530 | 780 | 1155 | |||||||||||||||||||

| WGJ20 | 2000 | 450,460 | 680 | 560 | 800 | 420 | 860 | 600 | 530 | 1031 | 76 | 225 | 560 | 2000 | 10 | 56 | 9500 | 1730 | 1024 | 61 | 18500 |

| 480,500 | |||||||||||||||||||||

| 530,560 | 780 | 1181 | |||||||||||||||||||

| WGJ21 | 2240 | 480,500 | 680 | 600 | 800 | 450 | 910 | 650 | 560 | 1056 | 76 | 236 | 600 | 2500 | 10 | 60 | 11500 | 1930 | 1334 | 75.66 | 21000 |

| 530,560 | 780 | 1206 | |||||||||||||||||||

| 600 | |||||||||||||||||||||

| WGJ22 | 2800 | 530,560 | 780 | 630 | 800 | 480 | 965 | 680 | 600 | 1230 | 82 | 246 | 640 | 2500 | 13 | 63 | 12600 | 2220 | 1621 | 99.9 | 24000 |

| 600,630 | |||||||||||||||||||||

| WGJ23 | 3150 | 560,600 | 780 | 670 | 900 | 500 | 1000 | 710 | 630 | 1250 | 82 | 265 | 680 | 2500 | 13 | 67 | 17900 | 2450 | 2579 | 122 | 27000 |

| 630 | |||||||||||||||||||||

| 670 | 880 | 1350 | |||||||||||||||||||

WGJ drum gear coupling is a high-performance mechanical transmission device widely used in various heavy machinery and industrial fields.

The WGJ crown gear coupling is mainly composed of internal gear sleeve, external gear sleeve, intermediate shaft and other components. Its core feature is that the outer gear sleeve adopts a drum shaped tooth design, with a spherical tooth tip and optimized tooth side clearance, making the coupling have better compensation and load-bearing capacity.

Performance and Advantages

Strong bearing capacity: Compared with spur gear couplings, WGJ drum gear couplings have an average increase in bearing capacity of 15% to 20% under the same outer diameter of the inner gear sleeve and maximum outer diameter of the coupling.

Large angular displacement compensation: The drum tooth design allows for greater angular displacement in the coupling. When the radial displacement is equal to zero, the allowable angular displacement of the drum toothed coupling is 50% higher than that of the straight toothed coupling.

High transmission efficiency: The transmission efficiency of WGJ coupling can reach 99.7%, which can effectively reduce energy loss.

Low noise and long maintenance cycle: The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoids the drawbacks of stress concentration and tooth end edge compression, reduces noise, and extends service life.

Easy to assemble and disassemble: The outer gear sleeve has a trumpet shaped tooth end, making the process of assembling and disassembling the inner and outer teeth more convenient.

WGJ gear type couplings are widely used in heavy industry fields such as metallurgy, mining, lifting and transportation, petrochemicals, and steel rolling machinery, mainly responsible for torque transmission tasks under low-speed heavy load conditions. Its high performance and stability have been fully validated and recognized in these fields.

The WGJ drum tooth coupling product series covers multiple models to meet different compensation needs, brake function adaptation, and vertical installation scenarios. Users can choose appropriate models and specifications based on specific application scenarios and needs.

In order to ensure the long-term stable operation of the WGJ drum toothed coupling, regular maintenance and upkeep are required. This includes checking the wear of the coupling, cleaning the tooth surface, lubricating the tooth surface, and checking for loose fasteners. In addition, attention should be paid to avoiding damage to the coupling caused by adverse factors such as overload and impact.

The WGJ gear coupling plays an important role in the field of mechanical transmission due to its excellent performance and wide application scenarios. Users should pay attention to maintenance and upkeep during use to ensure its long-term stable operation.

URL: https://m.rokee.com/drum-gear-couplings/wgj-drum-gear-coupling-with-intermediate-shaft.html