Rokee is a chinese Cardan Shaft Manufacturer, provide Cardan Shaft processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Cardan Shaft selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Cardan Shaft is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

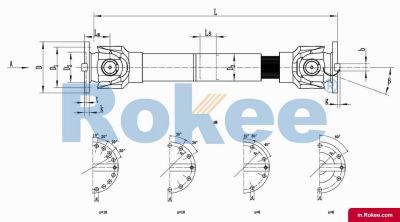

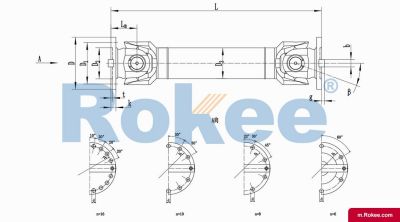

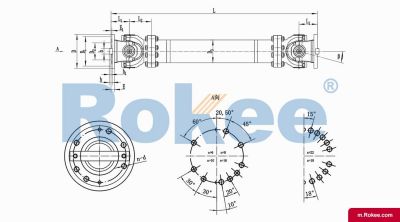

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

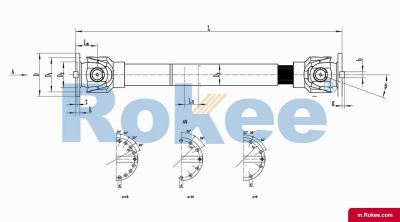

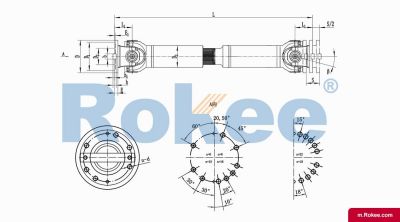

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

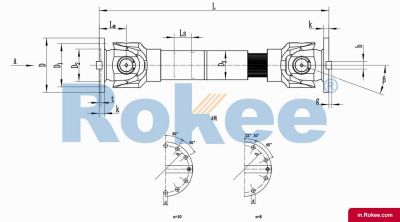

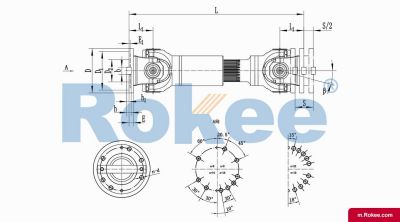

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

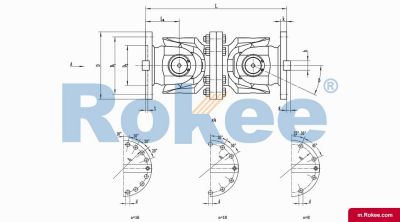

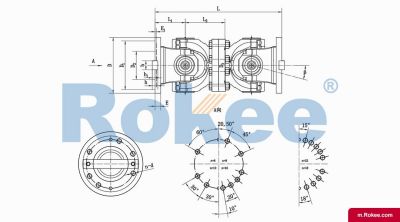

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

The Cardan Shaft is mainly composed of two parts: fork head and cross shaft. The fork head has an inner hole that can be fitted onto the input shaft, while the cross shaft is connected to the output shaft through bearings. In the inner hole of the Cardan Shaft, there is a ball and socket shaped connection point, which is connected between the input shaft and the output shaft through the cooperation of steel balls and plastic retainers. At the same time, the outer surface of the Cardan Shaft has a planar connection point, which is connected between the output shaft and mechanical components through the cooperation of bolts and nuts.

Its working principle is based on the contact between the ball socket and the steel ball. When there is relative displacement between the input shaft and the output shaft, the ball socket can freely swing around the steel ball, thereby eliminating centering deviation and ensuring the stability and accuracy of power transmission. In addition, the elastic support of the plastic cage can absorb impact and vibration, reducing damage to mechanical components.

There are various structural types of Cardan Shafts, such as cross shaft type, ball cage type, ball fork type, etc. Among them, the cross axis Cardan Shaft is the most commonly used type. In practical applications, Cardan Shafts can be classified into different categories such as heavy, medium, light, and small according to the magnitude of the transmitted torque.

Cardan Shafts are widely used in various industrial fields, including but not limited to the following aspects:

In the automotive field, Cardan Shafts play a crucial role in the transmission system of automobiles, connecting components such as engines, transmissions, and drive shafts to ensure the stability and efficiency of power transmission.

In the aviation field, Cardan Shafts are used to connect rotating components such as engines and propellers in aircraft, achieving reliable power transmission.

In the field of petrochemicals, Cardan Shafts are used to connect various rotating machinery such as pumps, compressors, etc. in petrochemical equipment to ensure the normal operation of the equipment.

Mining Machinery: In mining machinery, Cardan Shafts are used to connect heavy equipment and transmission systems, withstanding significant impacts and vibrations.

Advantages and characteristics of Cardan Shaft

High precision power transmission: Universal shafts can ensure high-precision power transmission and are suitable for various high-precision mechanical equipment.

Strong centering adaptability: Universal shafts have a large range of axial, radial, and angular swing, and can adapt to various centering deviations.

Good buffering and vibration reduction performance: Universal shafts can absorb impacts and vibrations, reducing damage to mechanical components.

Flexible layout: Universal shafts are suitable for various flexible layouts of mechanical equipment and can meet the needs of different occasions.

Long service life: Due to the use of high-strength materials and high-precision manufacturing processes, the Cardan Shaft has a long service life.

In the realm of mechanical transmission systems, the cardan shaft stands as a fundamental component that enables the transfer of rotational motion and torque between shafts that are not aligned coaxially. This versatile mechanical device has evolved over centuries to adapt to a wide range of industrial, automotive, agricultural, and aerospace applications, playing a crucial role in ensuring the smooth and efficient operation of countless machines. From the propulsion systems of heavy-duty trucks to the articulating joints of industrial robots, the cardan shaft’s ability to accommodate angular misalignment while maintaining reliable power transmission makes it indispensable in modern engineering.

At the core of a cardan shaft assembly lies the universal joint, a mechanism that allows rotational motion to be transmitted between two shafts intersecting at an angle. The basic structure of a typical cardan shaft consists of two universal joints (also known as cardan joints) connected by a central shaft tube. Each universal joint comprises a cross-shaped component, referred to as the cross or spider, which is fitted with bearing cups at each of its four ends. These bearing cups, often equipped with needle bearings, facilitate smooth rotation and reduce friction between the cross and the yokes—flanged components that attach the universal joint to the input and output shafts. The yokes are designed to pivot around the cross, enabling the cardan shaft to adapt to changes in the angle between the connected shafts during operation. In some configurations, especially those requiring longer transmission distances, an intermediate support bearing may be incorporated to stabilize the central shaft tube, preventing excessive vibration and ensuring structural integrity at high rotational speeds.

The working principle of the cardan shaft is rooted in the kinematic properties of the universal joint. When rotational motion is applied to the input shaft, the corresponding yoke drives the cross of the universal joint, which in turn imparts motion to the output yoke and shaft. A key characteristic of a single universal joint is that it does not transmit motion at a constant angular velocity when the input and output shafts are misaligned. Instead, the output shaft’s angular velocity fluctuates cyclically, creating a phenomenon known as non-uniform rotation. This fluctuation can lead to vibration, noise, and additional stress on the transmission system components. To mitigate this issue, most practical applications employ a double universal joint configuration, where two universal joints are mounted in series with the central shaft tube. When properly aligned—with the yokes of the two universal joints positioned in the same plane—the non-uniform rotation effects of each joint cancel each other out, resulting in uniform angular velocity transmission between the input and output shafts. This configuration is particularly critical in high-speed applications, such as automotive drivetrains, where smooth power delivery is essential for vehicle performance and passenger comfort.

The performance and durability of a cardan shaft are heavily dependent on the selection of appropriate materials, which must balance strength, toughness, fatigue resistance, and weight considerations. For most standard applications, the central shaft tube and universal joint components are fabricated from high-strength alloy steels, such as 42CrMo or 40Cr. These alloys exhibit excellent tensile strength (exceeding 800 MPa), good ductility, and superior fatigue resistance, making them capable of withstanding the high torques and cyclic stresses encountered during operation. In applications where weight reduction is a priority, such as in aerospace or high-performance automotive systems, lightweight materials like aluminum alloys or carbon fiber composites may be used. Aluminum alloys offer a favorable strength-to-weight ratio, while carbon fiber composites provide exceptional strength and rigidity with minimal weight, though their higher cost limits their use to specialized applications. The bearing components within the universal joints typically utilize hardened steel or ceramic materials, which offer high wear resistance and low friction coefficients to ensure long service life.

The manufacturing process of a cardan shaft involves a series of precision operations to ensure dimensional accuracy, structural integrity, and optimal performance. The process begins with material selection and inspection, where the raw materials are tested for chemical composition and mechanical properties to meet specific requirements. The central shaft tube is typically produced through seamless tube extrusion or rolling processes, followed by precision machining to achieve the required outer and inner diameters, wall thickness, and surface finish. The universal joint components—cross, yokes, and bearing cups—undergo forging or casting to form their basic shapes, followed by machining operations such as turning, milling, and drilling to achieve precise dimensions and tolerances. Heat treatment processes, such as quenching and tempering, are applied to enhance the hardness, strength, and fatigue resistance of critical components. For example, the cross and yokes may be heat-treated to achieve a hardness range of HRC 58-62, ensuring they can withstand high torques without deformation. After machining and heat treatment, the components undergo surface treatment processes such as phosphating, galvanizing, or epoxy coating to improve corrosion resistance and extend service life. The final assembly involves fitting the bearings into the yokes and cross, connecting the universal joints to the central shaft tube, and performing dynamic balance testing. Dynamic balancing is a critical step, as any imbalance in the cardan shaft at high rotational speeds can cause severe vibration, noise, and premature component failure. The imbalance tolerance is typically controlled to less than 10 g·cm for most applications.

The cardan shaft’s versatility makes it indispensable across a wide range of industries and applications. In the automotive industry, it is a key component in the drivetrains of rear-wheel-drive, four-wheel-drive, and all-wheel-drive vehicles. In these applications, the cardan shaft transmits power from the transmission to the differential, allowing for angular misalignment between the transmission output shaft and the differential input shaft as the vehicle travels over uneven terrain and the suspension system compresses and extends. Heavy-duty trucks and commercial vehicles often utilize multiple cardan shafts in series to transmit power across long distances and accommodate the large angular misalignments associated with their complex drivetrain configurations. In the agricultural industry, cardan shafts are widely used in tractors and farm machinery to transmit power from the tractor’s engine to various implements, such as plows, harvesters, and mowers. These applications require the cardan shaft to withstand harsh operating conditions, including dust, dirt, and varying load conditions, while maintaining reliable power transmission. In the construction and mining industries, cardan shafts are used in excavators, cranes, loaders, and other heavy machinery to transmit power between hydraulic motors, gearboxes, and working components. They are designed to handle high torques and withstand the shock loads associated with these demanding applications. The aerospace industry also utilizes cardan shafts in aircraft landing gear systems, engine mounts, and auxiliary power units, where they must operate reliably under extreme conditions of temperature, pressure, and vibration. Additionally, in robotics and industrial automation, cardan shafts are used in robotic arms and conveyor systems to enable precise motion transmission between moving components with varying angular positions.

Proper maintenance is essential to ensure the reliable operation and extend the service life of a cardan shaft. Regular maintenance practices include inspection, lubrication, and replacement of worn components. Routine inspections should check for signs of wear, damage, or looseness in the universal joints, central shaft tube, and mounting hardware. Common signs of wear include excessive play in the universal joints, unusual noise during operation (such as clunking or buzzing sounds), vibration, and oil leaks from the bearing seals. Lubrication is critical to reduce friction and wear in the universal joint bearings. The type of lubricant used depends on the operating temperature and conditions; lithium-based greases are commonly used for general applications, with different grades selected for summer (higher viscosity) and winter (lower viscosity) use. The lubrication intervals vary depending on the application and operating conditions, but typically range from every 5,000 to 20,000 operating hours. It is also important to ensure that the cardan shaft remains properly aligned and balanced. If the shaft becomes misaligned due to worn or damaged mounts, it can cause increased stress on the universal joints and bearings, leading to premature failure. If dynamic imbalance is detected, the shaft may need to be rebalanced or repaired.

Despite proper maintenance, cardan shafts may experience various during their service life. The most common include universal joint wear, central shaft tube bending or cracking, bearing failure, and imbalance. Universal joint wear typically occurs due to insufficient lubrication, contamination by dust and debris, or normal wear and tear. This can result in excessive play in the joint, leading to vibration and noise. Bearing failure may occur due to lubrication failure, contamination, or overloading, resulting in increased friction, heat generation, and eventually seizure of the bearing. Central shaft tube bending or cracking is often caused by overloading, impact loads, or improper installation. This can lead to severe vibration and, in extreme cases, shaft failure. Imbalance can occur due to the loss of balance weights, wear of components, or damage to the shaft tube. Symptoms of imbalance include vibration that increases with rotational speed, noise, and premature wear of bearings and other components. The repair of cardan shaft typically involves replacing worn or damaged components, such as universal joints, bearings, or the central shaft tube. In some cases, the shaft may be straightened and rebalanced if it is bent but not cracked. Traditional repair methods include welding, bushing installation, and machining, but modern techniques such as polymer composite repairs are becoming increasingly popular due to their ability to provide quick, cost-effective repairs with minimal downtime. Polymer composites offer excellent strength and wear resistance, and can be applied on-site, eliminating the need for expensive machining or replacement of entire components.

The future development of cardan shafts is focused on improving performance, reducing weight, enhancing durability, and integrating advanced technologies. One of the key trends is the use of lightweight materials, such as carbon fiber composites and advanced aluminum alloys, to reduce the overall weight of the cardan shaft. This not only improves fuel efficiency in automotive and aerospace applications but also reduces inertial forces, leading to smoother operation and reduced wear on other components. Another trend is the integration of smart sensors and monitoring systems to enable real-time condition monitoring of the cardan shaft. These sensors can detect vibration, temperature, and wear, providing early warning of potential and allowing for predictive maintenance. This helps to reduce downtime, lower maintenance costs, and extend the service life of the cardan shaft. Advances in manufacturing technologies, such as additive manufacturing (3D printing), are also enabling the production of complex, lightweight universal joint components with optimized geometries for improved performance and efficiency. Additive manufacturing allows for the creation of internal channels for lubrication, lightweight lattice structures, and customized designs tailored to specific applications. Additionally, improvements in bearing technology, such as the use of self-lubricating bearings and ceramic bearings, are helping to reduce maintenance requirements and extend the service life of cardan shafts in harsh operating conditions.

In conclusion, the cardan shaft is a critical component in mechanical transmission systems, enabling the reliable transfer of rotational motion and torque between non-coaxial shafts across a wide range of applications. Its structural design, based on universal joints and a central shaft tube, allows it to accommodate angular misalignment while maintaining efficient power transmission. The selection of appropriate materials and precision manufacturing processes are essential to ensure its performance, durability, and reliability. Proper maintenance practices, including regular inspection, lubrication, and balancing, are crucial to extend its service life and prevent premature failure. As technology advances, the cardan shaft continues to evolve, with trends focusing on lightweight materials, smart monitoring systems, and advanced manufacturing techniques driving improvements in performance and efficiency. Whether in automotive, agricultural, construction, aerospace, or robotic applications, the cardan shaft remains an indispensable component, playing a vital role in the smooth and efficient operation of modern machinery. Its continued development will ensure that it meets the evolving needs of industries worldwide, adapting to new challenges and enabling the creation of more efficient, reliable, and sustainable mechanical systems.

« Cardan Shaft » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/cardan-shaft.html