The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.

| Model | Rated Torque | Maximum Torque | Maximum Speed | Basic Size | Weight | Rotational Inertia | Grease Usage | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

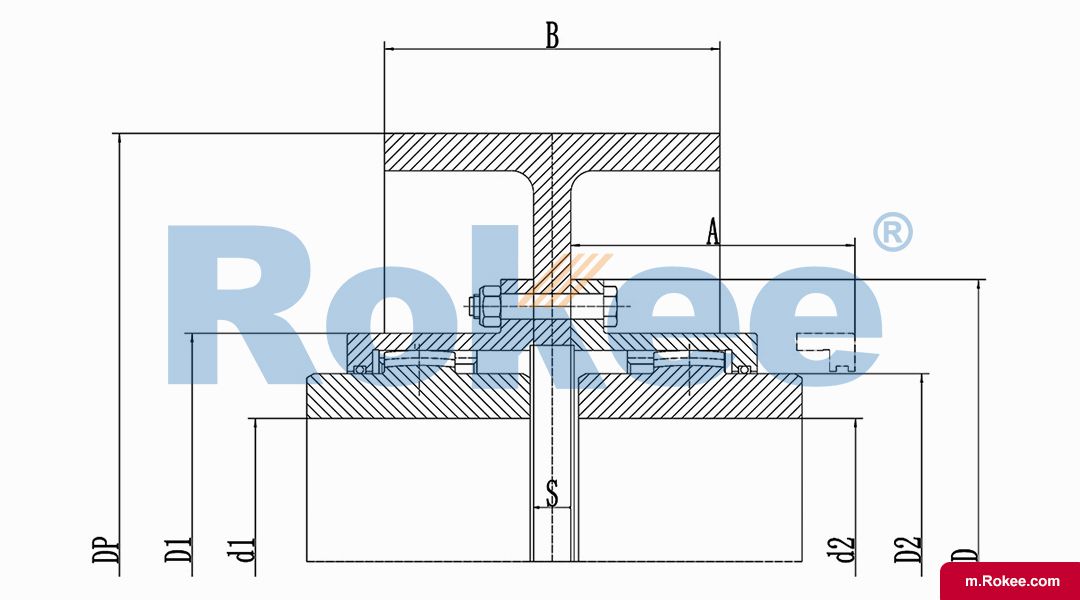

| Nm | Nm | 1/min | DF | D | D1 | D2 | B | d1-d2 | L1-L2 | S | A | Kg | J(Kgm²) | Kg | |

| RODW01 | 1900 | 3800 | 3000 | 200 | 110 | 82 | 68 | 75 | 14-50 | 43 | 12 | 56 | 9.0 | 0.042 | 0.03 |

| RODW02 | 3000 | 5940 | 3000 2500 2000 | 200 250 315 | 140 | 104 | 85 | 75 95 120 | 17-62 | 50 | 12 12 15 | 62 | 12.8 17.5 24.0 | 0.051 0.118 0.322 | 0.06 |

| RODW03 | 6200 | 12200 | 2500 2000 1800 1550 | 250 315 350 400 | 170 | 127 | 106 | 95 120 130 155 | 20-80 | 62 | 12 15 15 18 | 75 | 23.2 30.6 35.0 50.0 | 0.144 0.351 0.419 1.002 | 0.09 |

| RODW04 | 9300 | 18400 | 2000 1800 1550 | 315 350 400 | 210 | 155 | 132 | 120 130 155 | 26-98 | 76 | 16 18 18 | 90 | 43.3 48.0 61.5 | 0.410 0.556 1.129 | 0.12 |

| RODW05 | 15400 | 31000 | 2000 1800 1550 1400 | 315 350 400 450 | 235 | 182 | 150 | 120 130 155 175 | 30-112 | 90 | 16 18 18 18 | 105 | 55.1 59.8 72.0 82.0 | 0.514 0.712 1.249 1.785 | 0.3 |

| RODW06 | 25300 | 49600 | 1550 1400 1300 | 400 450 500 | 270 | 210 | 175 | 155 175 195 | 35-133 | 105 | 20 20 20 | 120 | 87.0 98.5 108.4 | 1.534 2.121 2.924 | 0.4 |

| RODW07 | 38600 | 76400 | 1300 1200 1100 | 500 560 630 | 310 | 248 | 206 | 195 200 245 | 70-158 | 120 | 21 21 23 | 135 | 143.0 152.6 193.0 | 3.422 4.254 9.102 | 0.6 |

| RODW08 | 48800 | 96500 | 1300 1200 1100 950 | 500 560 630 710 | 338 | 275 | 235 | 195 200 245 270 | 85-174 | 135 | 23 23 25 25 | 158 | 170.2 179.9 220.4 262.5 | 3.853 4.795 9.746 15.338 | 0.8 |

| RODW09 | 75300 | 147800 | 1200 1100 950 750 | 560 630 710 800 | 378 | 306 | 252 | 200 245 270 320 | 95-192 | 150 | 23 25 25 29 | 180 | 234.4 293.5 328.8 390.6 | 12.332 17.933 21.694 30.635 | 1.4 |

The brake wheel type drum gear coupling mainly consists of two half couplings, drum gears, brake wheels, and corresponding connecting components. Among them, the two half couplings are respectively connected to the two shaft ends, and the drum shaped teeth are cleverly set between the two half couplings to achieve power transmission through precise meshing. The brake wheel is usually installed on half of the coupling to provide braking function when needed, ensuring the safe shutdown of the transmission system.

The design of drum teeth is the core of the brake wheel type drum tooth coupling. Compared with traditional spur gear couplings, drum teeth have a larger contact area and better meshing performance. This design not only effectively reduces stress concentration between tooth surfaces and extends the service life of the coupling, but also provides smoother power transmission during the transmission process, reducing vibration and noise.

Another highlight of the brake wheel type drum toothed coupling is its integrated braking function. By cooperating with brake wheels and brakes (such as disc brakes or drum brakes), power transmission can be quickly cut off in emergency situations, achieving safe shutdown of the transmission system. This function is particularly important in application scenarios that require frequent start stop or emergency braking, such as cranes, elevators, wind power equipment, etc.

With the continuous advancement of industrial technology, the application of high-performance materials in brake wheel crown gear couplings is becoming increasingly widespread. For example, the coupling body and drum teeth made of high-strength alloy steel not only improve the bearing capacity of the coupling, but also enhance its wear resistance. In addition, advanced heat treatment and surface treatment technologies have further improved the overall performance of the coupling and extended its service life.

URL: https://m.rokee.com/drum-gear-couplings/rodw-drum-gear-coupling-with-brake-wheel.html