The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.

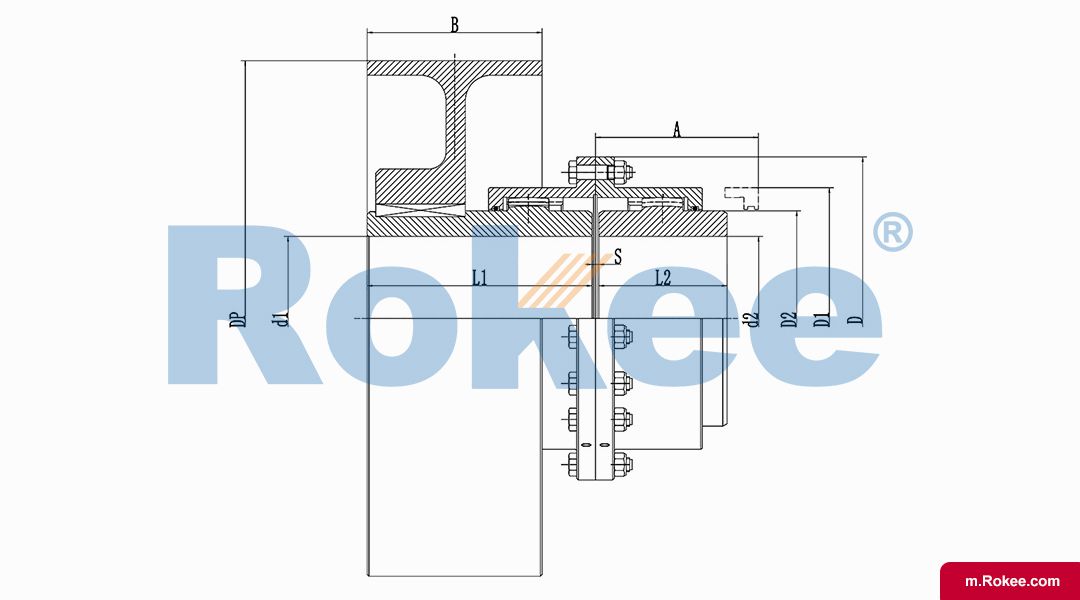

| Model | Rated Torque | Maximum Torque | Maximum Speed | Basic Size | Weight | Rotational Inertia | Grease Usage | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nm | Nm | 1/min | DF | D | D1 | D2 | B | d1-d2 | L1 | L2 | S | A | Kg | J(Kgm²) | Kg | |

| RODU01 | 1900 | 3800 | 3000 | 200 | 110 | 82 | 68 | 75 | 14-50 | 105 | 43 | 3 | 56 | 11.2 | 0.041 | 0.03 |

| RODU02 | 3000 | 5940 | 3000 2500 2000 | 200 250 315 | 140 | 104 | 85 | 75 95 120 | 17-62 | 115 125 140 | 50 | 3 3 3 | 62 | 16.9 21.3 27.7 | 0.059 0.125 0.296 | 0.06 |

| RODU03 | 6200 | 12200 | 2500 2000 1800 1550 | 250 315 350 400 | 170 | 127 | 106 | 95 120 130 155 | 20-80 | 130 145 145 160 | 62 | 3 3 3 3 | 75 | 30.3 38.8 45.0 58.2 | 0.167 0.359 0.552 1.054 | 0.09 |

| RODU04 | 9300 | 18400 | 2000 1800 1550 | 315 350 400 | 210 | 155 | 132 | 120 130 155 | 26-98 | 155 155 170 | 76 | 5 5 5 | 90 | 55.0 60.6 75.5 | 0.460 0.672 1.188 | 0.12 |

| RODU05 | 15400 | 31000 | 2000 1800 1550 1400 | 315 350 400 450 | 235 | 182 | 150 | 120 130 155 175 | 30-112 | 155 155 170 180 | 90 | 5 5 5 5 | 105 | 65.7 71.3 88.3 106.6 | 0.54 0.74 1.26 2.10 | 0.3 |

| RODU06 | 25300 | 49600 | 1550 1400 1300 | 400 450 500 | 270 | 210 | 175 | 155 175 195 | 35-133 | 200 210 220 | 105 | 6 6 6 | 120 | 118.8 137.2 160.5 | 1.59 2.38 3.77 | 0.4 |

| RODU07 | 38600 | 76400 | 1300 1200 1100 | 500 560 630 | 310 | 248 | 206 | 195 200 245 | 70-158 | 220 220 250 | 120 | 6 6 6 | 135 | 177.9 193.4 238.8 | 4.15 4.93 9.15 | 0.6 |

| RODU08 | 48800 | 96500 | 1300 1200 1100 950 | 500 560 630 710 | 338 | 275 | 235 | 195 200 245 270 | 85-174 | 235 235 265 280 | 135 | 8 8 8 8 | 158 | 225.0 230.4 273.3 304.4 | 4.96 5.69 9.86 14.68 | 0.8 |

| RODU09 | 75300 | 147800 | 1200 1100 950 750 | 560 630 710 800 | 378 | 306 | 252 | 200 245 270 320 | 95-192 | 255 265 295 315 | 150 | 8 8 8 8 | 180 | 252.5 303.8 365.5 421.8 | 7.20 11.68 17.35 22.39 | 1.4 |

Drum gear coupling with brake wheels is an important mechanical transmission component that combines the advantages of drum gear coupling with the functions of brake wheels, and is widely used in various industrial equipment.

The crown gear coupling with brake wheels mainly consists of an inner gear ring, a flange half coupling with outer teeth (where the outer teeth are designed as drum shaped teeth), and brake wheels and other components. These components ensure the high performance and reliability of the coupling through precision machining and assembly.

Drum shaped tooth design is one of the core features of this coupling. By shaping the external teeth into a spherical shape and placing the center of the spherical surface on the gear axis, the drum shaped gear coupling can allow for greater angular displacement, thereby improving the contact conditions of the teeth. This design not only improves the ability to transmit torque, but also extends the service life of the coupling. When there is angular displacement, the drum shaped teeth can uniformly contact along the tooth width direction, further enhancing the stability and durability of the coupling.

The braking wheel is used to achieve rapid braking of the equipment. When it is necessary to stop the operation of the equipment, the brake wheel works in conjunction with the brake device to convert the rotational motion into heat energy through friction, thereby achieving a smooth stop of the equipment.

Main advantage

Strong load-bearing capacity: The drum shaped tooth design allows the coupling to increase its load-bearing capacity by an average of 15-20% compared to straight tooth couplings with the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling.

Large angular displacement compensation: The drum shaped gear coupling allows for a larger angular displacement, improving the flexibility and adaptability of the equipment.

Low noise and long maintenance cycle: The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, reduces noise, and extends the maintenance cycle.

Reliable braking performance: The cooperation between the braking wheel and the braking device ensures the fast and smooth parking of the equipment.

Drum tooth couplings with brake wheels are widely used in various industrial equipment that requires the transmission of large torque, the bearing of large angular displacement, and axial and radial displacement. Shaft transmission systems in fields such as metallurgy, mining, lifting and transportation, petroleum, chemical engineering, and general machinery.

Drum teeth couplings with brake wheels come in various models and specifications to meet the needs of different equipment. For example, GICLZ series, NGCLZ series, WGZ series, etc. The different models in these series have different parameters such as size, load-bearing capacity, and rotational speed, and users can choose according to their specific needs.

The crown toothed coupling with brake wheels has become an indispensable and important component in industrial equipment due to its superior performance and wide application fields. When selecting and using, users should choose the model and specifications according to specific needs, and ensure that the installation and commissioning of the coupling comply with relevant standards and requirements.

URL: https://m.rokee.com/drum-gear-couplings/rodu-drum-gear-coupling-with-brake-wheel.html