GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.

| Model | Rated Torque | Allowable Rotating Speed | Shaft Hole Diameter | Shaft Hole Length L | D | D1 | D2 | C | C1 | H | B | B1 | B2 | Rotational Inertia | Quality | Grease | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y | J1,Z1 | ||||||||||||||||

| kN·m | rpm | d1,d2,dz | mm | kg ·m² | kg | ml | |||||||||||

| GCLD1 | 1.60 | 5600 | 22,24 | 52 | 38 | 127 | 95 | 75 | 27 | 4 | 2 | 66 | 45 | 42 | 0.00875 | 6.2 | 107 |

| 25,28 | 62 | 44 | 0.01025 | 7.2 | |||||||||||||

| 30,32,35,38 | 82 | 60 | 0.011 | 7.8 | |||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 0.01175 | 9.6 | |||||||||||||

| GCLD2 | 2.80 | 5100 | 38 | 82 | 60 | 149 | 116 | 90 | 26.5 | 4 | 2 | 70 | 49 | 42 | 0.02125 | 11.2 | 137 |

| 40,42,45,48,50,55,56 | 112 | 84 | 0.02425 | 14 | |||||||||||||

| 60,63,65 | 142 | 107 | 33 | 0.0215 | 16.4 | ||||||||||||

| GCLD3 | 4.50 | 4600 | 40,42,45,48,50,55,56 | 112 | 84 | 167 | 134 | 105 | 33 | 5 | 2.5 | 80 | 54 | 42 | 0.04 | 17.2 | 201 |

| 60,63,65,70,71,75 | 142 | 107 | 0.0475 | 22.4 | |||||||||||||

| GCLD4 | 6.30 | 4300 | 45,48,50,55,56 | 112 | 84 | 187 | 153 | 125 | 33.5 | 5 | 2.5 | 81 | 55 | 42 | 0.0725 | 25.2 | 238 |

| 60,63,65,70,71,75 | 142 | 107 | 0.0825 | 26.4 | |||||||||||||

| 80,85,90 | 172 | 132 | 38 | 0.095 | 35.6 | ||||||||||||

| GCLD5 | 8.00 | 4000 | 50,55,56 | 112 | 84 | 204 | 170 | 140 | 37.5 | 5 | 2.5 | 89 | 59 | 42 | 0.1125 | 31.6 | 398 |

| 60,63,65,70,71,75 | 142 | 107 | 0.1175 | 38 | |||||||||||||

| 80,85,90,95 | 172 | 132 | 0.1450 | 44.6 | |||||||||||||

| 100,(105) | 212 | 167 | 43.5 | 0.1674 | 53.9 | ||||||||||||

| GCLD6 | 11.2 | 3700 | 55,56 | 112 | 84 | 230 | 186 | 155 | 43.5 | 6 | 3 | 106 | 71 | 47 | 0.1875 | 40.5 | 465 |

| 60,63,65,70,71,75 | 142 | 107 | 0.21 | 49.8 | |||||||||||||

| 80,85,90,95 | 172 | 132 | 0.235 | 56.3 | |||||||||||||

| 100,110,(115) | 212 | 167 | 0.2675 | 67.5 | |||||||||||||

| GCLD7 | 18.0 | 3350 | 60,63,65,70,71,75 | 142 | 107 | 256 | 212 | 180 | 48 | 6 | 3 | 112 | 73 | 47 | 0.13575 | 63.9 | 561 |

| 80,85,90,95 | 172 | 132 | 0.40 | 74.7 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 0.4625 | 88 | |||||||||||||

| 130,(135) | 252 | 202 | 0.5275 | 106.7 | |||||||||||||

| GCLD8 | 25.00 | 3000 | 65,70,71,75 | 142 | 107 | 287 | 239 | 200 | 40.5 | 7 | 3.5 | 118 | 82 | 47 | 0.560 | 81.7 | 734 |

| 80,85,90,95 | 172 | 132 | 0.6275 | 95.5 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 0.72 | 114 | |||||||||||||

| 130,140,150 | 252 | 202 | 48 | 0.8125 | 123 | ||||||||||||

| GCLD9 | 35.5 | 2700 | 70,71,75 | 142 | 107 | 325 | 276 | 235 | 49.5 | 7 | 3.5 | 132 | 85 | 47 | 1.0775 | 112 | 956 |

| 80,85,90,95 | 172 | 132 | 1.2075 | 130 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 1.3825 | 156 | |||||||||||||

| 130,140,150 | 252 | 202 | 1.56 | 181 | |||||||||||||

| 160,170,(175) | 302 | 242 | 58 | 1.77 | 212 | ||||||||||||

| GCLD10 | 56.00 | 2450 | 75 | 142 | 107 | 362 | 313 | 270 | 65 | 8 | 4 | 149 | 95 | 49 | 1.97 | 161 | 1320 |

| 80,85,90,95 | 172 | 132 | 2.0725 | 172 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 2.38 | 206 | |||||||||||||

| 130,140,150 | 252 | 202 | 2.5625 | 239 | |||||||||||||

| 160,170,180 | 302 | 242 | 3.055 | 280 | |||||||||||||

| 190,200,220 | 352 | 282 | 68 | 3.4225 | 319 | ||||||||||||

GCLD drum gear coupling is a type of coupling widely used in mechanical transmission systems. Its unique drum tooth design and reasonable component composition give it various significant advantages.

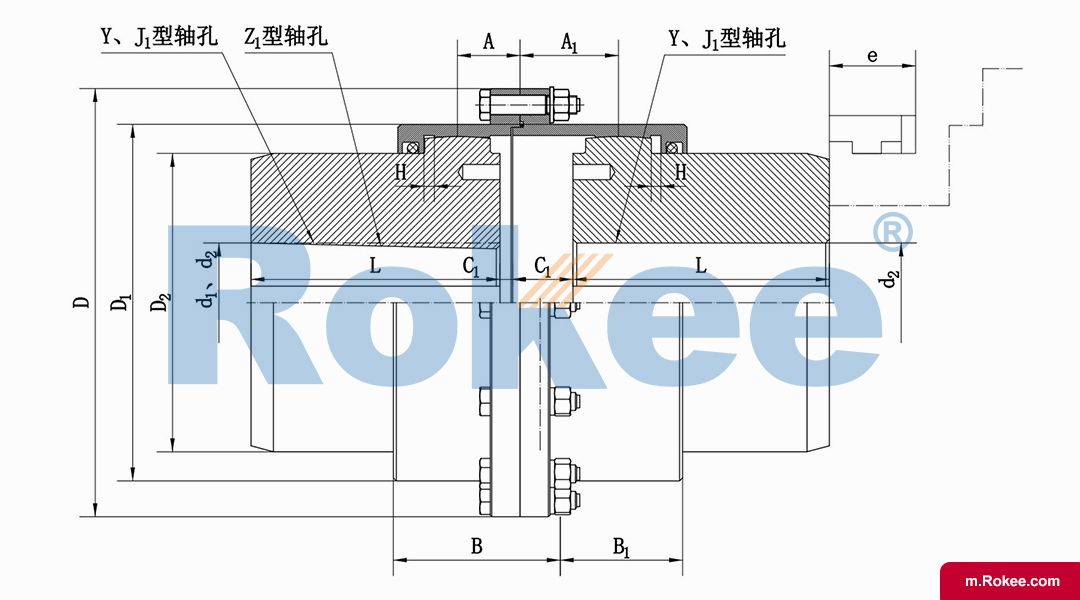

The GCLD drum shaped gear coupling is mainly composed of internal gear ring, external gear shaft sleeve, intermediate shaft, and connecting bolts. Among them, the teeth of the inner ring gear are straight teeth, while the teeth of the outer shaft sleeve are machined into a drum shape. This drum shaped tooth design is a major feature of the coupling, which can effectively compensate for the relative displacement between the two shafts.

During operation, torque is transmitted to the inner gear ring through the drum shaped teeth of the outer gear shaft sleeve, and then transmitted to the shaft connected to it through the inner gear ring. Due to the special shape of the drum teeth, the meshing between the drum teeth and the inner ring gear can still maintain good contact in the presence of relative displacement between the two axes, thereby ensuring effective torque transmission.

Main Features

High displacement compensation capability: The GCLD drum shaped gear coupling can adapt to large axial, radial, and angular displacements, allowing for relative motion between the two shafts within a certain range. This is particularly important for situations where the installation accuracy of the axis is difficult to guarantee in some work environments.

High torque transmission: Due to its reasonable structural design and excellent material selection, the GCLD drum shaped gear coupling can withstand large torque and is suitable for various heavy-duty mechanical equipment.

Strong resistance to impact and vibration: The meshing method of the drum shaped teeth and the elastic characteristics of the intermediate shaft enable the coupling to effectively absorb impact and vibration during torque transmission, protecting the normal operation of the equipment and extending its service life.

High reliability: The connection between the various components of the GCLD drum shaped gear coupling is firm, the structure is compact, and it has undergone strict quality inspection and testing verification, with high reliability and stability.

The technical parameters of GCLD crown gear coupling include nominal torque, allowable speed, shaft hole diameter, and displacement compensation capability. The specific values of these parameters vary depending on the model, but generally speaking, the nominal torque range ranges from several hundred Newton meters to tens of thousands of Newton meters. The allowable speed is related to factors such as the structural dimensions, materials, and working conditions of the coupling. The range of shaft hole diameters is wide and can adapt to the connection requirements of shafts with different diameters. The displacement compensation capability includes axial, radial, and angular displacement compensation capabilities, and the specific values vary depending on the model.

GCLD drum shaped gear coupling is mainly used for horizontal axis connection between motors and mechanical equipment, especially suitable for transmission systems of heavy-duty equipment such as metallurgy and mining. In addition, it can also be used for the connection between the reducer output shaft of the lifting mechanism in lifting equipment and the wire rope drum, as well as other similar mechanical equipment that both transmits torque and bears radial loads. However, it should be noted that GCLD drum toothed couplings cannot be used for transmissions that require axial loads.

The GCLD drum tooth coupling plays an important role in mechanical transmission systems due to its unique drum tooth structure and reasonable component composition. Its significant advantages such as high displacement compensation capability, high torque transmission, strong resistance to impact vibration, and high reliability have made it widely used in various heavy-duty mechanical equipment.

URL: https://m.rokee.com/drum-gear-couplings/gcld-drum-gear-coupling-for-motor.html