Rokee is a chinese Elastic Couplings Manufacturer, provide Elastic Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Elastic Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Elastic Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

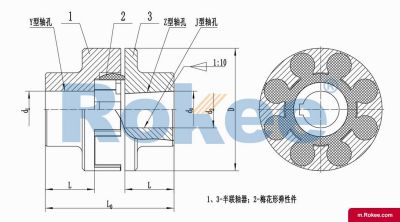

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

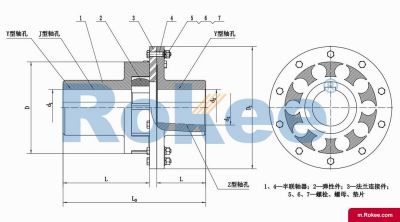

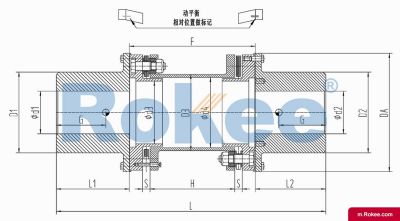

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

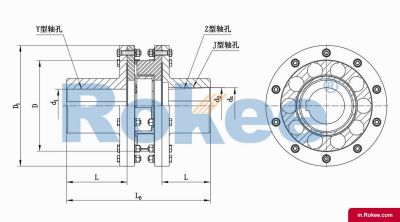

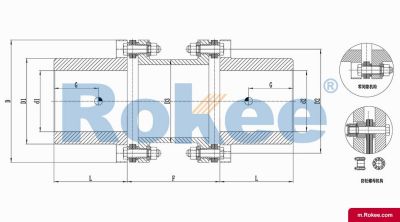

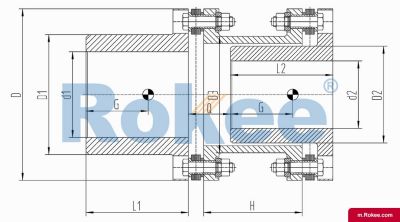

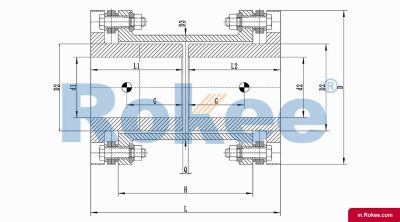

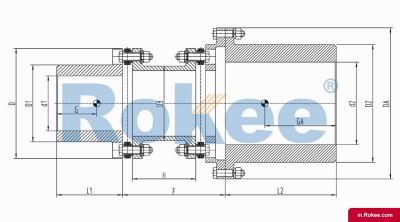

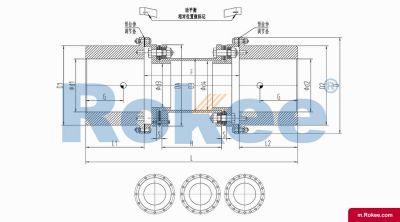

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

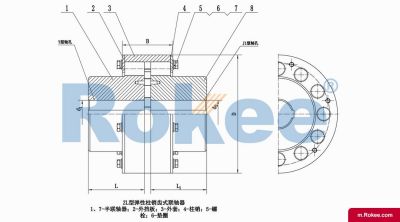

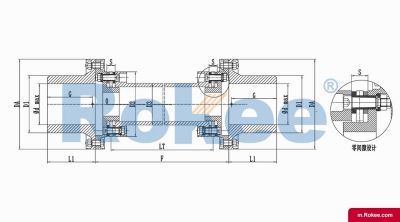

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

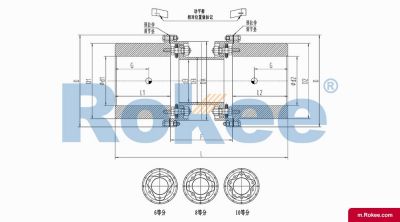

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

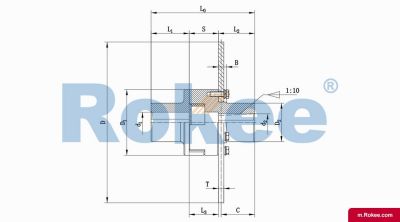

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More -

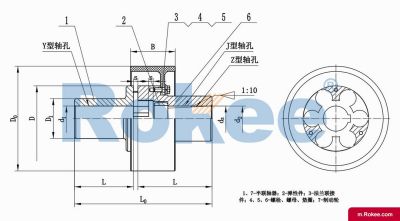

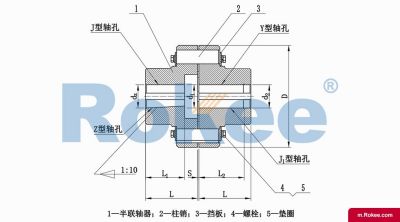

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

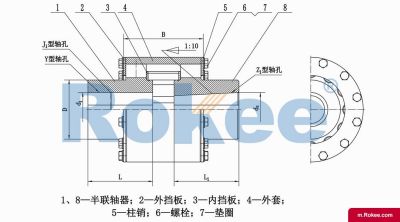

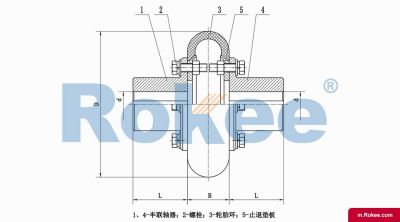

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

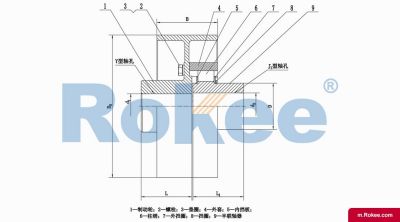

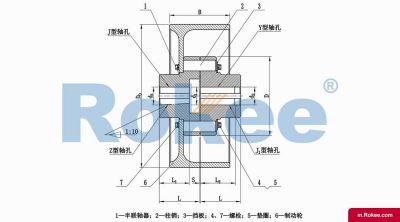

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

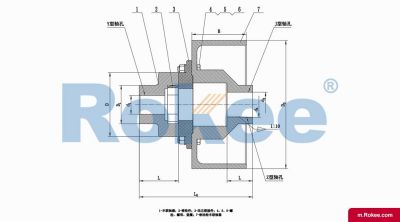

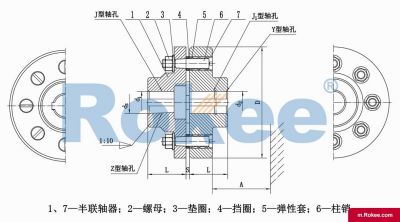

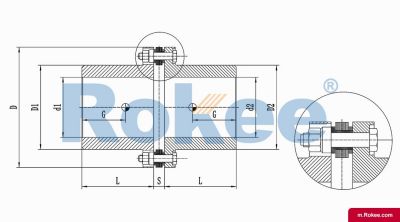

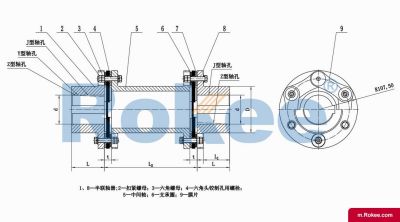

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

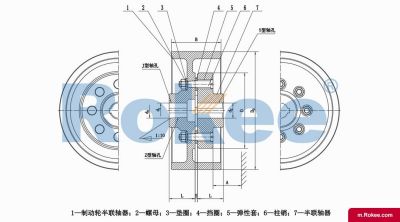

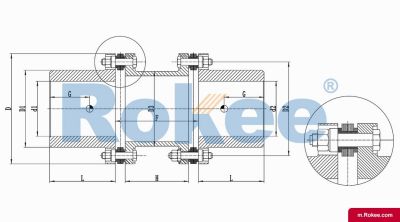

LXZ/HLL Flexible Pin Coupling With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

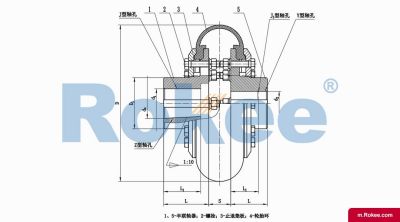

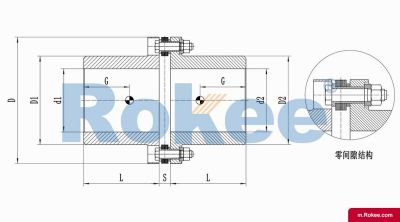

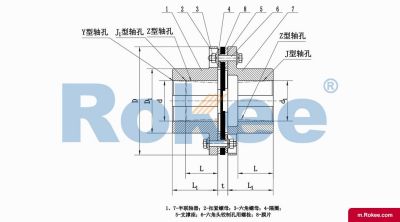

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

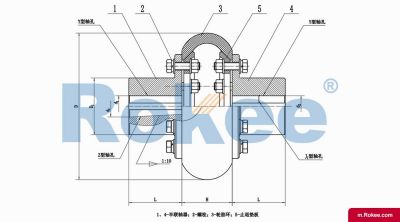

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

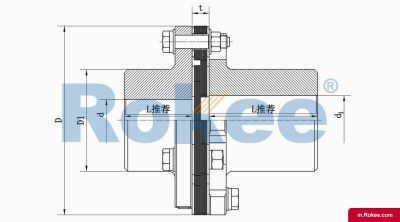

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

LLB Tyre Coupling

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More -

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Elastic coupling is a component used in mechanical transmission shaft systems to connect two shafts or shafts with rotating parts. It is usually cut from a metal round bar wire and contains an elastic compound of pre pressed rubber, which provides additional strength and extends its service life. Elastic couplings can accommodate various types of deviations and achieve precise torque transmission. There are two basic series of elastic couplings: spiral groove type and parallel groove type. In addition, according to the different stress conditions and structural applications, elastic couplings can be further subdivided. For example, it can be divided into compression type and shear type according to the force situation; According to their structural applications, compression type couplings include rubber sleeve pin couplings, rubber plate couplings, plum blossom elastic couplings, universal elastic couplings, and air spring couplings, while shear type couplings include rubber metal ring couplings, tire type couplings, U-shaped rubber couplings, etc.

Characteristics and advantages

Integrated metal elastomer: This design allows the elastic coupling to have zero rotational clearance and achieve synchronous operation.

Elastic compensation capability: Elastic couplings can compensate for radial, angular, and axial deviations, ensuring smooth transmission.

High torque rigidity and sensitivity: This makes the elastic coupling have excellent performance in transmitting torque.

Maintenance free, oil resistant, and corrosion-resistant: These characteristics increase the service life and reliability of elastic couplings.

Easy installation: Due to the rubber part being a segmented insert, the elastic coupling can be inserted and installed after the shaft is aligned, greatly simplifying the installation process.

Elastic couplings are widely used in various mechanical equipment, such as ships, metallurgical equipment, chemical equipment, power equipment, and engineering machinery. Especially in situations where high-precision compensation, buffering, and vibration absorption are required, elastic couplings play an irreplaceable role. For example, in the field of shipbuilding, high elasticity couplings can be applied in power systems, capable of transmitting power and torque, compensating for radial, axial, and angular displacements, adjusting the system's natural frequency, and possessing strong compensation, absorption, and frequency modulation capabilities.

Elastic couplings stand as indispensable components in modern mechanical power transmission systems, serving as the critical link between driving and driven shafts while fulfilling multiple essential functions that ensure the smooth, efficient, and reliable operation of machinery. At their core, these couplings utilize elastic elements to transmit torque, absorb vibrations, compensate for shaft misalignments, and mitigate shock loads, thereby protecting downstream components such as motors, gearboxes, and bearings from premature wear or failure. Unlike rigid couplings that require precise alignment and offer no flexibility, elastic couplings introduce a degree of compliance that makes them adaptable to the dynamic conditions commonly encountered in industrial, automotive, aerospace, and renewable energy applications. The versatility of elastic couplings stems from their diverse designs, materials, and performance characteristics, which allow engineers to tailor their selection to specific operational requirements, whether it be high torque transmission in heavy machinery, precision motion control in robotics, or vibration damping in high-speed rotating equipment.

The fundamental structure of an elastic coupling typically consists of three main components: two hubs (or sleeves) that connect to the driving and driven shafts, and an elastic element that interfaces between these hubs to transmit power. The hubs are commonly fabricated from high-strength materials such as alloy steel, stainless steel, or aluminum alloy, selected for their ability to withstand the mechanical stresses imposed by torque transmission and their compatibility with different shaft attachment methods. These attachment methods include interference fits, keyway connections, or bolted flanges, each designed to ensure a secure and slip-free connection that maximizes torque transfer efficiency. The elastic element, meanwhile, is the defining feature of the coupling, as its material properties and geometric design directly dictate the coupling’s performance in terms of vibration damping, misalignment compensation, and service life. Elastic elements can take various forms, including blocks, pads, sleeves, discs, or laminated plates, with each configuration optimized for specific types of misalignment or load conditions. For instance, block-type elastic elements are often used in applications requiring high angular misalignment compensation, while laminated disc elements excel in high-speed scenarios where low inertia and precise torque transmission are critical.

Material selection for the elastic element is a key determinant of the coupling’s performance and applicability to different operating environments. The most commonly used materials include rubber, polyurethane, and metal alloys, each offering distinct advantages and limitations. Rubber, including natural rubber and synthetic variants such as neoprene (chloroprene rubber) and silicone rubber, is valued for its excellent elasticity, superior vibration damping capabilities, and cost-effectiveness. Natural rubber, with its high resilience and low modulus of elasticity, is ideal for low to medium speed applications with light to moderate loads, such as in conveyor systems and small pumps. However, it exhibits poor resistance to oil, ozone, and high temperatures, limiting its use in harsh environments. Neoprene rubber addresses these shortcomings by providing enhanced resistance to oil, chemicals, ozone, and weathering, making it suitable for outdoor applications, marine environments, and industrial settings where exposure to lubricants or corrosive substances is common. Silicone rubber, meanwhile, offers exceptional high-temperature resistance, with operating temperatures ranging from -40°C to 200°C, making it suitable for applications such as automotive engine compartments and industrial ovens.

Polyurethane has emerged as a popular alternative to rubber in many applications due to its superior mechanical properties, including higher tensile strength, better wear resistance, and improved load-carrying capacity. Polyurethane elastic elements can withstand higher torques and exhibit less creep than rubber, making them suitable for heavy-duty and high-speed applications such as in mining equipment, robotics, and machine tools. Additionally, polyurethane offers good resistance to oil and chemicals, though it is less effective than neoprene in extreme chemical environments. Metal elastic elements, typically made from spring steel or stainless steel, are used in applications requiring high precision, high temperature resistance, and long service life without significant material degradation. These elements, often in the form of laminated springs or coil springs, provide excellent torsional stiffness and can transmit very high torques, making them suitable for use in gas turbines, steam turbines, and large industrial compressors. Unlike rubber and polyurethane, metal elastic elements do not age or degrade over time, ensuring consistent performance throughout the coupling’s service life, though they offer lower vibration damping capabilities compared to elastomeric materials.

The working principle of elastic couplings revolves around the elastic deformation of the coupling element, which enables torque transmission while accommodating misalignments and absorbing vibrations. When torque is applied to the driving shaft, the hub connected to this shaft transfers the force to the elastic element, causing it to deform elastically. This deformation then transmits the torque to the driven hub and ultimately to the driven shaft. During this process, the elastic element acts as a buffer, absorbing and dissipating vibrational energy generated by the driving machinery or by irregularities in the load. This vibration damping effect is crucial for reducing noise levels, minimizing fatigue damage to components, and improving the overall stability of the transmission system. Elastic couplings are capable of compensating for three main types of misalignment: radial misalignment (where the shafts are offset parallel to each other), angular misalignment (where the shafts are inclined at an angle to each other), and axial misalignment (where the shafts are displaced along their axial direction). The degree of misalignment compensation varies depending on the design and material of the elastic element; for example, rubber elements can typically compensate for angular misalignments of up to 3-5 degrees, while metal elements offer more limited compensation but higher precision.

One of the primary advantages of elastic couplings is their ability to protect connected machinery from shock loads and torsional vibrations. In industrial applications such as mining, construction, and manufacturing, machinery often experiences sudden load fluctuations or impact loads, which can cause significant stress on shafts, bearings, and gearboxes. Elastic couplings absorb these shock loads by deforming elastically, reducing the magnitude of the force transmitted to downstream components and preventing catastrophic failures. Torsional vibrations, which occur due to the cyclic nature of torque generation in engines and motors, can also be mitigated by elastic couplings. By adjusting the torsional stiffness of the elastic element, engineers can tune the coupling to avoid resonance, a phenomenon where the natural frequency of the system matches the frequency of the vibrational input, leading to excessive vibrations and potential component failure. This resonance avoidance is particularly important in high-speed applications such as centrifugal pumps, fans, and turbines, where even small vibrations can lead to significant damage over time.

The versatility of elastic couplings is reflected in their wide range of applications across various industries. In the industrial sector, they are extensively used in conveyor systems, crushers, mixers, and compressors, where they handle high torques and compensate for misalignments caused by thermal expansion, foundation settlement, or manufacturing tolerances. In the renewable energy industry, elastic couplings play a critical role in wind turbines, connecting the rotor to the gearbox and the gearbox to the generator. In this application, they must withstand variable wind loads, compensate for misalignments caused by tower deflection, and dampen vibrations to protect the sensitive electrical components of the generator. The automotive industry utilizes elastic couplings in engine-transmission connections, drivelines, and suspension systems, where they contribute to improved ride comfort by reducing vibration transmission to the vehicle cabin and accommodating misalignments between moving components. In precision engineering and robotics, elastic couplings are used in servo motor systems, where they provide precise torque transmission with minimal backlash, compensate for minor misalignments, and dampen high-frequency vibrations that could affect the accuracy of robotic movements.

The selection of an appropriate elastic coupling for a specific application requires careful consideration of several key factors, including torque requirements, operating speed, misalignment type and magnitude, environmental conditions, and maintenance constraints. Torque capacity is one of the most critical parameters, as the coupling must be capable of transmitting the maximum operating torque of the system without permanent deformation or failure. Engineers typically select a coupling with a torque rating that exceeds the maximum operating torque by a safety factor of 1.5 to 2.5 to account for transient load peaks and ensure long service life. Operating speed is another important consideration, as high-speed applications require couplings with low rotational inertia to minimize energy loss and prevent resonance. The type and magnitude of misalignment present in the system will dictate the choice of elastic element material and design; for example, applications with significant angular misalignment will benefit from a coupling with flexible rubber elements, while those with minor radial misalignment may use a polyurethane or metal element coupling.

Environmental conditions such as temperature, humidity, exposure to chemicals, and presence of dust or debris also influence coupling selection. High-temperature environments require elastic elements made from heat-resistant materials such as silicone rubber or metal alloys, while corrosive environments may necessitate the use of stainless steel hubs and neoprene or polyurethane elastic elements. Outdoor applications must consider resistance to weathering, ozone, and UV radiation, which can degrade rubber elements over time. Maintenance requirements are another factor, as some couplings require regular inspection and replacement of elastic elements, while others are designed for long-term, maintenance-free operation. For example, metal elastic couplings typically have longer service lives and require less maintenance than rubber or polyurethane couplings, which may need periodic replacement due to material aging, wear, or degradation.

Recent advancements in materials science and engineering design have driven significant innovations in elastic coupling technology, leading to improved performance, durability, and functionality. One notable trend is the development of composite elastic materials, such as carbon fiber-reinforced polyurethane and rubber-metal composites, which offer enhanced mechanical properties compared to traditional materials. These composites provide higher strength, stiffness, and wear resistance, while maintaining excellent vibration damping capabilities, making them suitable for high-performance applications such as aerospace and racing vehicles. Another trend is the integration of smart technologies into elastic couplings, including embedded sensors for real-time monitoring of vibration, temperature, and torque. These sensors enable predictive maintenance, allowing engineers to detect potential issues such as elastic element degradation, misalignment, or overload before they lead to coupling failure and system downtime. This integration of smart technologies aligns with the broader trend of Industry 4.0, where data-driven maintenance and optimization are becoming increasingly important in industrial operations.

Bionic design has also emerged as a promising area of innovation in elastic coupling development, drawing inspiration from natural systems to improve performance. For example, couplings designed to mimic the flexible transmission mechanism of octopus tentacles utilize adaptive elastic elements that can dynamically adjust to changes in misalignment and load, providing superior compensation capabilities and system stability. Additionally, advancements in computational modeling and simulation tools have enabled engineers to optimize coupling designs more effectively, using finite element analysis (FEA) to predict stress distribution, vibration characteristics, and fatigue life under various operating conditions. This allows for the development of more efficient, lightweight, and cost-effective couplings that are tailored to specific application requirements.

Despite their many advantages, elastic couplings are not without limitations. Elastomeric elements (rubber and polyurethane) are susceptible to aging, creep, and degradation over time, particularly in harsh environments, which can reduce their performance and require periodic replacement. Metal elastic couplings, while more durable, offer lower vibration damping capabilities and are typically more expensive to manufacture. Additionally, elastic couplings generally have lower torque density compared to rigid couplings, meaning they may require a larger physical size to transmit the same amount of torque. However, these limitations are often outweighed by the benefits of vibration damping, misalignment compensation, and component protection that elastic couplings provide, making them the preferred choice in most dynamic power transmission systems.

In conclusion, elastic couplings are essential components in modern mechanical systems, providing a flexible and reliable means of power transmission while protecting machinery from vibration, shock, and misalignment. Their diverse designs, materials, and performance characteristics make them adaptable to a wide range of applications across industries, from heavy industrial machinery to precision robotics and renewable energy systems. The selection of an appropriate elastic coupling requires careful consideration of torque requirements, operating speed, misalignment, environmental conditions, and maintenance needs. Ongoing advancements in materials science, smart technology integration, and computational design are continually improving the performance and functionality of elastic couplings, enabling them to meet the evolving demands of modern engineering applications. As machinery becomes more complex, efficient, and automated, the role of elastic couplings in ensuring system reliability, performance, and longevity will only grow in importance.

« Elastic Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/elastic-couplings.html