Rokee is a chinese Gear Couplings Manufacturer, provide Gear Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Gear Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Gear Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

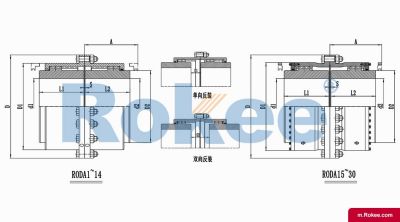

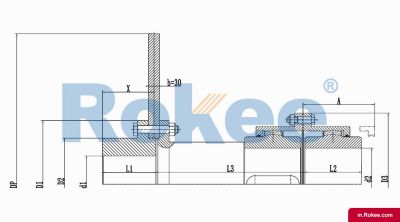

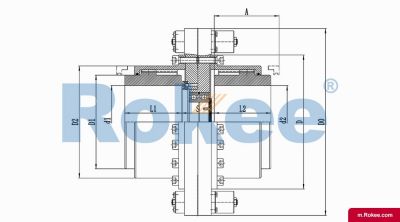

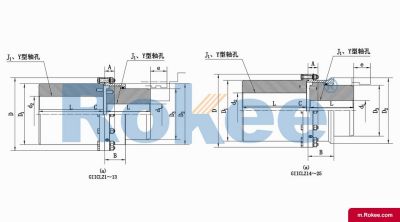

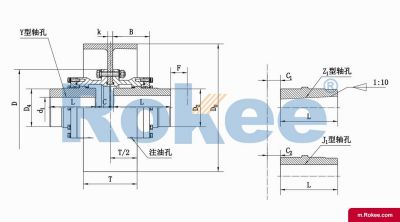

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

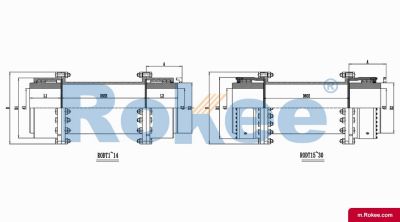

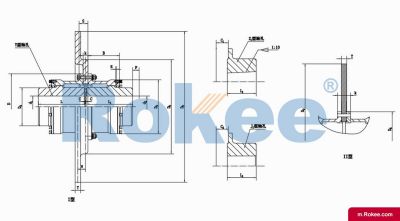

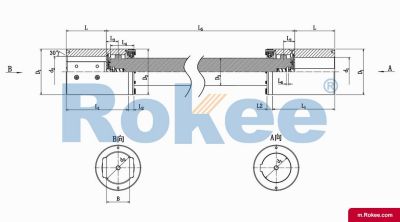

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

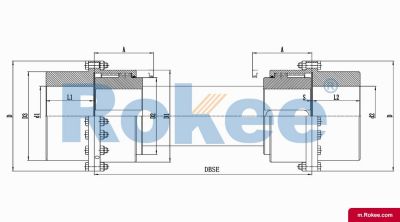

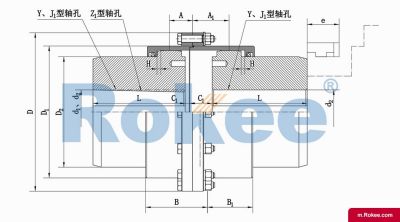

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

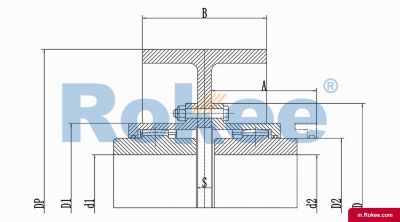

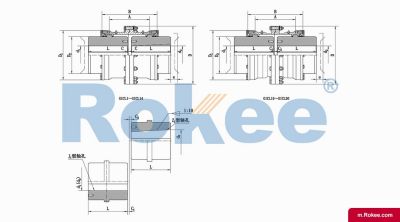

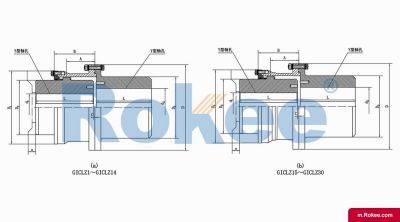

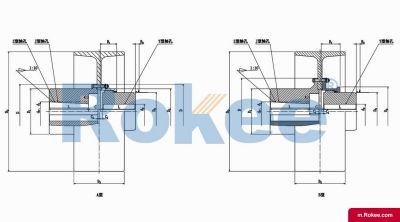

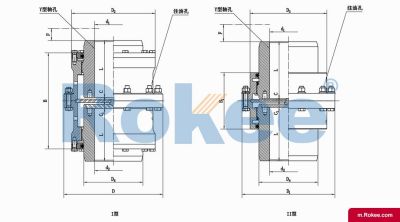

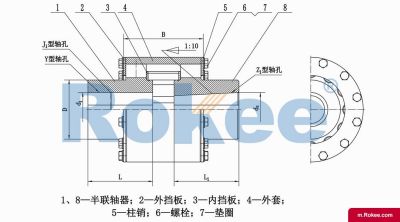

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

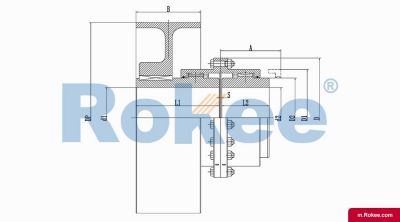

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

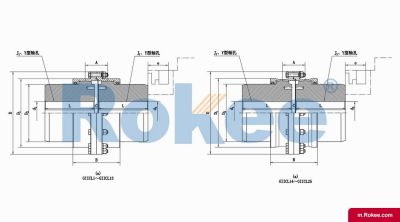

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

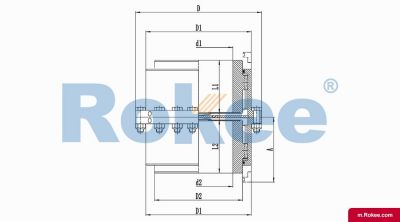

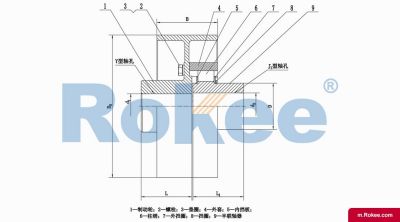

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

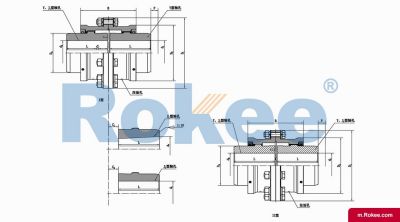

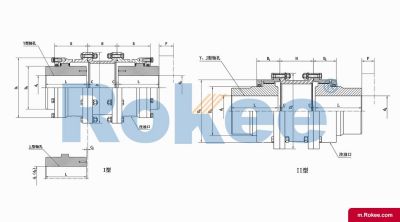

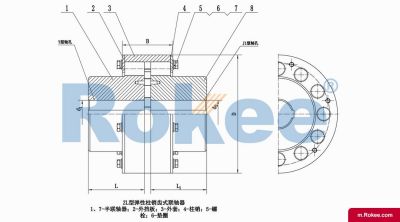

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More -

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

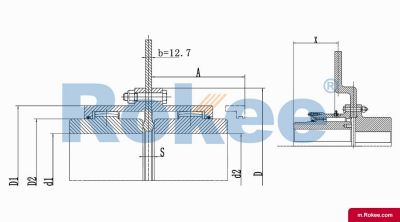

The gear coupling is mainly composed of internal gear ring, flange half coupling with external teeth (external gear shaft sleeve), end cover and other main components. According to the different axial tooth shapes of the external gear shaft sleeve, gear couplings can be divided into spur gear couplings, drum gear couplings, and special drum gear couplings. Among them, the outer gear sleeve tooth top of the drum shaped gear coupling is processed into a circular arc shape, that is, the gear blank is processed into a spherical surface, which is the key feature that distinguishes it from other gear couplings. In addition, some gear couplings are equipped with sealed lubrication systems to support regular lubrication or continuous oil circulation modes, reducing tooth wear rates.

When the gear coupling is in operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear sleeve, which in turn drives the driven shaft to rotate. Due to the meshing of the inner and outer teeth, the tooth surfaces will periodically slide axially relative to each other when the two shafts undergo relative displacement. This kind of sliding not only transmits torque, but also causes certain tooth wear and power loss. Therefore, gear couplings usually need to work in a well lubricated and sealed state to ensure their long-term stable operation.

Gear couplings are widely used in various industrial fields, including but not limited to:

Metallurgical industry: In large equipment such as rolling mills and blast furnaces, gear couplings are used to connect motors and reducers, reducers and working machines, etc., to meet their heavy-duty and high impact working conditions.

Mining machinery, such as crushers, ball mills, and other equipment, work in harsh environments and are prone to shaft displacement. Gear couplings, with their excellent displacement compensation capabilities and high reliability, ensure the stable operation of the equipment.

Petrochemical industry: In equipment such as pumps and compressors, gear couplings are used to transmit power. Their corrosion resistance and stable transmission performance ensure the continuity and safety of chemical production.

Power industry: In equipment such as steam turbine generators and fans, gear couplings are key transmission components that provide reliable power transmission for power production.

When selecting a gear coupling, users need to choose the corresponding model based on parameters such as shaft diameter, speed, torque, and deviation compensation. Meanwhile, the following points should also be noted:

Check the meshing condition of the coupling teeth: Ensure that the contact area is not less than 50% along the tooth height and not less than 70% along the tooth width, and that there is no severe pitting, wear, or cracks on the tooth surface.

Pay attention to installation accuracy: Although the gear coupling has relatively loose requirements for the alignment of the two shafts, it is still necessary to ensure installation accuracy to avoid additional loads and vibrations caused by excessive misalignment.

Regular lubrication and inspection: To ensure the long-term stable operation of the gear coupling, it is necessary to regularly lubricate and inspect it, promptly identify and address potential issues.

In the complex landscape of industrial power transmission systems, gear couplings stand out as indispensable components that ensure the seamless transfer of torque and motion between rotating shafts. These mechanical devices are engineered to address the inherent challenges of shaft misalignment, which can arise from factors such as thermal expansion, manufacturing tolerances, or structural deflection during operation. Unlike rigid couplings that demand precise alignment, gear couplings offer a unique combination of high torque capacity and flexibility, making them suitable for a wide range of heavy-duty and precision applications across various industries. Their ability to accommodate angular, radial, and axial misalignments while maintaining efficient power transmission has solidified their position as a preferred choice in systems where reliability and durability are paramount.

At the core of a gear coupling's functionality lies its distinctive structural design, which typically consists of two key components: hubs with external gear teeth and a sleeve (or two sleeves) with internal gear teeth that mesh with the external teeth of the hubs. The hubs are securely mounted on the respective drive and driven shafts, usually via keyway connections, to ensure a tight fit that prevents slippage during torque transmission. The meshing of the external and internal gear teeth forms the primary torque-transfer mechanism, allowing rotational energy to flow from the input shaft to the output shaft with minimal power loss. To enhance performance and longevity, gear couplings are also equipped with sealing devices that prevent the ingress of contaminants such as dust, dirt, and moisture, while simultaneously retaining lubricants that reduce friction and wear between the meshing gear surfaces. In some designs, the sealing system may include O-rings or lip seals integrated into the sleeve or hub components, creating a closed environment that protects the gear teeth from harsh operating conditions.

The working principle of a gear coupling revolves around the synchronized interaction between its gear components, which not only transmits torque but also accommodates misalignments through controlled relative movement. When the drive shaft rotates, it imparts rotational force to the attached external gear hub, which in turn engages with the internal gear sleeve. The meshing teeth transfer this torque to the second external gear hub, driving the driven shaft into rotation. A critical aspect of this design is the clearance between the gear teeth and the specific tooth profile, which enable the coupling to compensate for misalignments. For instance, when there is an angular misalignment between the two shafts, the spherical or drum-shaped design of the external gear teeth allows for slight tilting of the hubs relative to the sleeve without causing excessive stress or wear on the gear surfaces. Similarly, radial misalignment is accommodated by the radial clearance between the gear teeth, while axial misalignment is handled by the axial movement of the hubs within the sleeve. This flexibility ensures that the coupling maintains a consistent meshing pattern even when the shafts are not perfectly aligned, reducing the risk of premature failure in the transmission system.

Gear couplings are available in several distinct types, each tailored to specific application requirements based on factors such as misalignment tolerance, torque capacity, and spatial constraints. One of the most common types is the spur gear coupling, which features straight external gear teeth that mesh with the internal teeth of the sleeve. Spur gear couplings are valued for their simplicity, high torque capacity, and compact design, making them suitable for applications with moderate misalignment requirements, such as pumps and compressors. Another widely used type is the helical gear coupling, which incorporates helical gear teeth that engage at an angle, resulting in smoother meshing and reduced noise and vibration compared to spur gear couplings. The helical design also allows for higher misalignment tolerance, making these couplings ideal for heavy-duty applications in steel mills, mining equipment, and marine propulsion systems.

Bevel gear couplings represent another specialized type, utilizing bevel gears to transmit torque between shafts that intersect at an angle. These couplings are particularly useful in applications with limited space and high misalignment demands, such as automotive drivetrains and industrial mixers. Floating shaft gear couplings, on the other hand, are designed for long-span applications where the distance between the drive and driven shafts is too great for a standard coupling. These couplings incorporate an intermediate floating shaft connected to two gear coupling assemblies, bridging the gap while maintaining the ability to compensate for misalignments. Additionally, there are half gear couplings, which combine a gear hub with a rigid hub, suitable for applications where only one side of the coupling requires flexibility. Each type of gear coupling is engineered to balance torque transmission efficiency with misalignment compensation, ensuring optimal performance in its intended application.

Material selection and manufacturing processes play a crucial role in determining the performance, durability, and reliability of gear couplings. Traditional gear couplings are primarily constructed from high-strength alloy steels, such as 42CrMo and 20CrMnTi, which offer excellent tensile strength, wear resistance, and toughness. These materials are well-suited for heavy-duty applications that involve high torque and harsh operating conditions. The manufacturing process typically begins with forging, which enhances the material's mechanical properties by refining the grain structure. This is followed by precision machining to achieve the required gear tooth profile, dimensional accuracy, and surface finish. The gear teeth are then subjected to heat treatment processes, such as carburizing and quenching, which harden the tooth surface to a hardness range of HRC 58-62, significantly improving wear resistance while maintaining the toughness of the core material.

In recent years, advancements in materials and manufacturing technologies have expanded the range of options for gear coupling construction. For example, plastic gear couplings, utilizing materials such as MC nylon or nylon 66, have emerged as viable alternatives to traditional metal couplings in certain applications. These plastic couplings offer advantages such as self-lubrication, vibration damping, and corrosion resistance, making them suitable for light to medium-duty applications in industries such as food processing, pharmaceuticals, and chemical processing. Additionally, additive manufacturing technologies, such as fused deposition modeling (FDM), have enabled the production of custom gear couplings in small batch quantities, providing a cost-effective solution for specialized applications where traditional molding methods are economically unfeasible. However, the use of plastic and 3D-printed components is limited to applications with lower torque requirements, as their mechanical properties are not yet comparable to those of high-strength alloy steels.

The performance advantages of gear couplings are numerous, making them indispensable in many industrial applications. One of their most notable benefits is their high torque transmission capacity, which allows them to handle the heavy loads encountered in mining, steel production, and marine propulsion. Unlike other types of couplings, such as jaw or tire couplings, gear couplings can transmit large amounts of torque without sacrificing compactness, making them ideal for applications where space is limited. Another key advantage is their superior misalignment compensation capability, which enables them to accommodate angular, radial, and axial misalignments simultaneously. This flexibility reduces the stress on other components in the transmission system, such as bearings and shafts, extending the overall service life of the equipment.

Gear couplings also exhibit high reliability and durability when properly maintained, with a long service life even in harsh operating environments. Their robust construction and use of high-strength materials make them resistant to wear, impact, and temperature fluctuations, ensuring consistent performance in conditions such as high temperatures, dust, and moisture. Additionally, gear couplings operate with high transmission efficiency, minimizing power loss during torque transfer. This efficiency is particularly important in energy-intensive industries, where reducing power consumption can lead to significant cost savings. Despite these advantages, gear couplings do have some limitations, including the need for regular lubrication to prevent gear tooth wear and the potential for noise generation at high speeds. However, these limitations can be mitigated through proper maintenance and design optimization.

The applications of gear couplings span a wide range of industries, reflecting their versatility and adaptability to diverse operating conditions. In the steel industry, gear couplings are used in rolling mills, where they transmit high torque between the drive motors and the rolling stands, while accommodating the misalignments caused by thermal expansion of the rolls. In the mining industry, they are employed in crushers, conveyors, and excavators, handling the heavy loads and harsh environmental conditions typical of mining operations. The marine industry relies on gear couplings for propulsion systems, connecting the ship's engine to the propeller shaft and accommodating the misalignments resulting from hull flexure during navigation.

Power generation facilities, including thermal, hydroelectric, and wind power plants, use gear couplings in turbines and generators to ensure efficient torque transmission between rotating components. In the oil and gas industry, they are utilized in pumps, compressors, and drilling equipment, operating under high pressures and corrosive conditions. Additionally, gear couplings find applications in general industrial machinery such as fans, blowers, and machine tools, where they provide reliable power transmission and misalignment compensation. The widespread use of gear couplings across these industries is a testament to their ability to meet the demanding requirements of modern industrial power transmission systems.

Proper installation and maintenance are essential to ensuring the optimal performance and longevity of gear couplings. During installation, it is critical to ensure that the shafts are aligned within the coupling's specified tolerance limits. Excessive misalignment beyond the coupling's capacity can lead to premature wear, increased noise, and reduced service life. The use of precision alignment tools, such as laser alignment systems, can help achieve the required alignment accuracy. Additionally, the hubs must be securely mounted on the shafts, with proper keyway fitting and bolt tightening to prevent slippage. The sealing devices should be inspected to ensure they are intact and functioning properly, as any leakage can lead to lubricant loss and contamination of the gear teeth.

Lubrication is a critical aspect of gear coupling maintenance, as it reduces friction between the meshing gear teeth, prevents wear, and dissipates heat. The type of lubricant used depends on the operating conditions, such as temperature, speed, and load. For high-speed or heavy-duty applications, high-performance lubricants with excellent thermal stability and wear resistance are recommended. Lubrication intervals should be strictly followed, with regular inspections to check for lubricant degradation or contamination. In addition to lubrication, regular inspections of the gear teeth for signs of wear, pitting, or cracking are essential. Any damage to the gear teeth should be addressed promptly to prevent further deterioration of the coupling. The connecting bolts should also be inspected periodically to ensure they are tight, as loose bolts can cause excessive vibration and lead to coupling failure.

Troubleshooting common issues with gear couplings requires a systematic approach to identify the root cause and implement appropriate solutions. One of the most common problems is excessive gear tooth wear, which is often caused by inadequate lubrication, improper alignment, or contamination. To address this issue, the lubricant should be replaced with the correct type, the shafts should be realigned, and the sealing devices should be repaired or replaced to prevent further contamination. Another common issue is axial displacement of the inner gear ring, which is typically caused by excessive angular or radial misalignment. This can be resolved by re-aligning the shafts to within the specified tolerance limits. In cases of gear tooth cracking or breakage, the coupling should be replaced immediately to avoid catastrophic failure of the transmission system. Regular maintenance and inspections can help detect these issues early, minimizing downtime and repair costs.

Looking to the future, the evolution of gear couplings is likely to be driven by advancements in materials science, manufacturing technologies, and the growing demand for more efficient and sustainable power transmission systems. The development of new high-strength, lightweight materials may lead to the design of gear couplings with even higher torque capacity and reduced weight, making them suitable for emerging applications such as electric vehicles and renewable energy systems. Additive manufacturing technologies are expected to become more prevalent, enabling the production of complex, customized gear coupling designs that optimize performance and reduce material waste. Additionally, the integration of condition monitoring sensors into gear couplings may become more common, allowing for real-time monitoring of wear, temperature, and vibration, and enabling predictive maintenance strategies that further enhance reliability and reduce downtime.

In conclusion, gear couplings are vital components in industrial power transmission systems, offering a unique combination of high torque capacity, misalignment compensation, and reliability. Their diverse designs, materials, and applications reflect their adaptability to the varying needs of modern industry. Proper installation, maintenance, and troubleshooting are essential to maximizing their performance and service life. As technology continues to advance, gear couplings are poised to evolve further, incorporating new materials and technologies to meet the growing demands for efficiency, sustainability, and performance in industrial power transmission. Whether in heavy-duty applications such as steel mills and mining operations or precision applications such as machine tools and renewable energy systems, gear couplings will continue to play a critical role in ensuring the seamless and reliable transfer of power.

« Gear Couplings » Update Date: 2026/1/10