Rokee is a chinese Universal Shaft Manufacturer, provide Universal Shaft processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Universal Shaft selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Universal Shaft is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

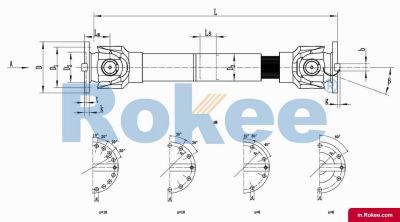

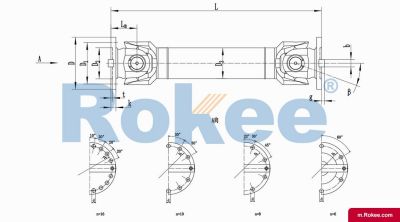

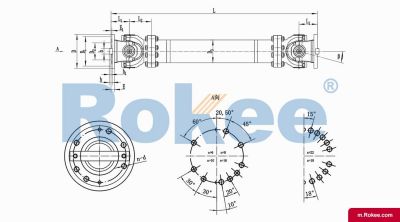

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

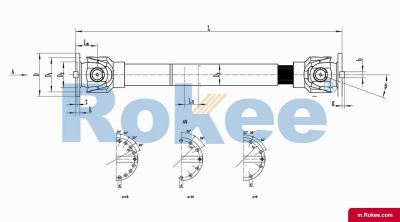

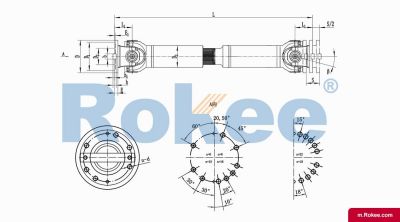

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

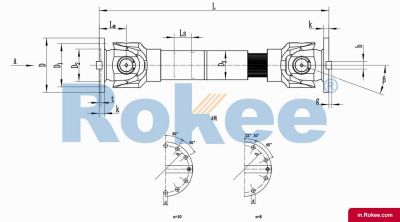

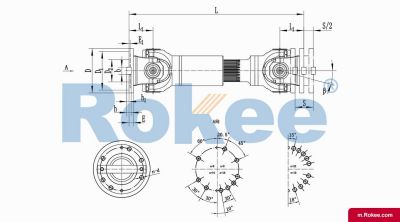

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

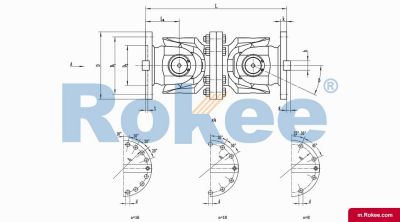

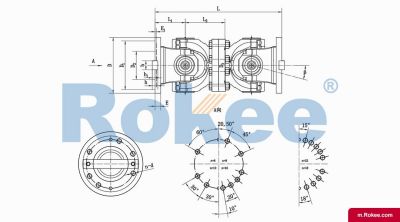

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

Universal Shaft is a mechanism that utilizes the characteristics of its mechanism to enable continuous rotation of the two shafts connected without being on the same axis and with an angle between the axes, and to reliably transmit torque and motion. It has a large angular compensation capability, compact structure, and high transmission efficiency. There are various structural types of Universal Shafts, such as cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type. The core component of the cross axis Universal Shaft is the cross axis, which allows the two shafts to rotate continuously at equal angular velocities within a large range of angles. The ball cage Universal Shaft achieves two axis transmission through components such as the outer ring of the ball cage, the inner ring of the star shape, the cage, and the transmission steel ball. It is suitable for working conditions with large inclination angles and limited radial dimensions.

According to the magnitude of the transmitted torque, Universal Shafts can be classified as heavy, medium, light, and small. Different models of Universal Shafts are suitable for different mechanical transmission systems. Universal Shafts are widely used in metallurgy, heavy machinery, petrochemicals, engineering machinery, rail transportation, agricultural machinery, industrial machinery and other fields. For example, in steel rolling machinery, Universal Shafts are used to connect rollers and transmission systems, achieving reliable torque transmission; In heavy transportation equipment, it is used to connect the wheels and transmission shaft, ensuring that the vehicle can travel smoothly in various road conditions.

Universal Shafts have significant angular compensation capabilities and can adapt to changes in the angle between two shafts. Compact structure, small footprint, easy to install and maintain. The transmission efficiency of Universal Shafts is high, which can reduce energy loss and improve the overall performance of mechanical transmission systems. Using high-quality materials and advanced manufacturing processes, the Universal Shaft has high reliability and durability.

When selecting a Universal Shaft, factors such as the magnitude of the transmitted torque, the speed of the shaft, and the magnitude and direction of the relative displacement between the two shafts need to be considered. At the same time, it is necessary to refer to the characteristics of various types of couplings and choose a suitable type of coupling. For the Universal Shafts that have already been selected, regular maintenance and upkeep are required. For example, regular lubrication can extend its service life; When disassembling and reinstalling, it is necessary to pay attention to adjusting the position of the cross axis to balance wear and tear; In addition, it is necessary to regularly check the wear of the coupling and replace damaged components in a timely manner.

In the intricate network of mechanical transmission systems, the universal shaft stands as a fundamental component that enables power transfer between non-coaxial shafts, accommodating angular misalignments and ensuring operational continuity across a vast array of industrial and mechanical applications. Often referred to as a cardan shaft, this mechanical device has evolved from simple early designs to sophisticated engineering solutions capable of handling extreme torques, high rotational speeds, and harsh environmental conditions. Its ability to transmit rotational motion and torque while compensating for axial, angular, and radial deviations makes it indispensable in scenarios where perfect alignment between driving and driven shafts is impractical or impossible. From the powertrains of automobiles to the heavy-duty machinery in steel mills, from marine propulsion systems to precision industrial equipment, the universal shaft plays a quiet yet critical role in keeping modern mechanical systems running efficiently and reliably.

The basic structure of a universal shaft is defined by its core components, which work in harmony to achieve flexible power transmission. A typical assembly consists of two universal joints (also known as cardan joints) connected by a central shaft, with additional components such as yokes, cross shafts, needle roller bearings, and seals enhancing functionality and durability. The universal joints serve as the flexible linkages, allowing the central shaft to rotate freely while accommodating angular deviations between the connected shafts. Each universal joint comprises two yokes—one attached to the driving shaft and the other to the central shaft or driven shaft—and a cross-shaped bearing (often called a spider) that connects these yokes. Needle roller bearings are fitted between the cross shaft and the yoke bores, reducing friction and enabling smooth rotation even under high torque loads. Seals are integrated to prevent the ingress of contaminants such as dust, dirt, and moisture, which can degrade bearing performance and shorten the service life of the assembly. Depending on the application requirements, variations in design exist, including ball cage-type universal joints that use steel balls in grooved races to achieve constant velocity transmission, a critical feature for high-speed applications where speed uniformity is essential.

The working principle of a universal shaft revolves around its ability to transmit torque and rotational motion between shafts that are not aligned on the same axis. When the driving shaft rotates, it imparts motion to the first universal joint, which then transfers this motion to the central shaft. The second universal joint at the opposite end of the central shaft converts the rotational motion back to the driven shaft, even as the angle between the two shafts changes during operation. A key characteristic of single universal joints is that they introduce a certain degree of velocity fluctuation when operating at an angle—a phenomenon where the driven shaft speed varies cyclically relative to the driving shaft speed. This fluctuation becomes more pronounced as the angle between the shafts increases, potentially causing vibration and noise. To mitigate this issue, engineers often employ double universal joint configurations, where two universal joints are arranged such that the driving and driven shafts form equal angles with the central shaft, and the yoke axes on the central shaft lie in the same plane. This arrangement cancels out the velocity fluctuations, ensuring uniform speed transmission between the driving and driven shafts, making it suitable for applications requiring smooth operation at varying angles.

Material selection is a critical aspect of universal shaft design, as it directly impacts the component's strength, durability, load-carrying capacity, and resistance to wear and environmental factors. The choice of materials is primarily determined by the application's requirements, including torque levels, rotational speed, operating temperature, and environmental conditions such as exposure to moisture, chemicals, or abrasive particles. Carbon steel and alloy steel are the most commonly used materials for universal shaft components due to their excellent strength, toughness, and wear resistance. For example, medium-carbon steels like 45# steel (translated as 45 steel) are widely used for central shafts and yokes, as they can be heat-treated to achieve a balance of hardness and ductility, with tensile strength exceeding 800 MPa and yield strength over 600 MPa. Alloy steels such as 20CrMnTi and 40CrMo are preferred for high-performance applications, as the addition of alloying elements enhances their wear resistance, corrosion resistance, and fatigue strength, making them suitable for heavy-duty machinery and high-speed rotating systems.

In recent years, advancements in material science have led to the adoption of alternative materials for specific applications. Lightweight materials such as aluminum are used in scenarios where weight reduction is a priority, such as in automotive and aerospace applications, as they offer good corrosion resistance and lower mass without compromising sufficient strength. Composite materials, including glass fiber-reinforced plastic (GFRP) and carbon fiber-reinforced plastic (CFRP), are emerging as viable options for high-speed and precision applications, as they provide an excellent balance of strength, flexibility, and lightweight properties, while also offering superior corrosion resistance compared to traditional metals. For applications in harsh environments, such as marine or chemical processing industries, stainless steel is often used to prevent rust and corrosion, ensuring long-term reliability. The selection of materials also considers processing feasibility and cost-effectiveness; for example, powder metallurgy materials are used for certain components to achieve high precision and material utilization, reducing production waste and costs.

Heat treatment plays a crucial role in enhancing the mechanical properties of universal shaft components, ensuring they can withstand the stresses and loads encountered during operation. Common heat treatment processes include annealing, normalizing, quenching, tempering, and carburizing. Annealing is used to eliminate internal stresses in raw materials, improving their machinability and reducing hardness, making it easier to form and process components. Normalizing is employed to refine the grain structure of steel, enhancing its strength and hardness for components that do not require high precision. Quenching involves heating the steel to a high temperature and then rapidly cooling it, which significantly increases its hardness and wear resistance, but can also make the material brittle. To address this brittleness, tempering is performed after quenching, where the material is reheated to a lower temperature and then cooled slowly, balancing hardness with toughness. For components subject to high surface loads, such as cross shafts and needle roller bearings, carburizing is used to create a hard surface layer while maintaining a ductile core, improving wear resistance and fatigue life. The precise parameters of heat treatment, including heating temperature, holding time, and cooling rate, are tailored to the specific material and application requirements, ensuring optimal performance.

The versatility of universal shafts is reflected in their wide range of applications across various industries, each with unique requirements that drive design modifications and material selections. In the automotive industry, universal shafts are a key component of drivetrain systems, transmitting power from the engine to the wheels. In rear-wheel-drive vehicles, a single or double universal joint shaft (propeller shaft) connects the transmission to the differential, accommodating the angular changes caused by suspension movement and road irregularities. Ball cage-type universal joints are commonly used in front-wheel-drive vehicles to ensure constant velocity transmission, which is essential for maintaining smooth handling and reducing vibration at high speeds. In commercial vehicles such as trucks and buses, heavy-duty universal shafts made of alloy steel are used to handle the high torques required for hauling heavy loads.

The metallurgical industry relies heavily on universal shafts for heavy-duty applications such as rolling mills, piercing machines, and straightening machines. These applications require the transmission of extremely high torques—often exceeding 10,000 kNm—and the ability to accommodate significant angular misalignments caused by thermal expansion and contraction of machinery components. Universal shafts used in steel mills are typically large in size, with diameters up to 1.3 meters and weights exceeding 50 tons, constructed from high-strength alloy steels that can withstand the harsh operating conditions, including high temperatures and exposure to abrasive dust. Similarly, in the mining industry, universal shafts are used in excavators, loaders, and conveyor systems, where they must endure heavy loads, shock impacts, and dusty environments, requiring robust construction and regular maintenance.

Marine applications utilize universal shafts in propulsion systems, connecting the engine to the propeller. These shafts must accommodate the dynamic misalignments caused by the movement of the vessel in water, as well as resist corrosion from saltwater. Stainless steel and corrosion-resistant alloys are commonly used for marine universal shafts, with seals and lubrication systems designed to prevent water ingress and ensure smooth operation. In the paper industry, universal shafts are used in paper machines and presses, where they transmit power between non-aligned components, ensuring smooth and continuous operation at high speeds. The precision required in paper manufacturing demands universal shafts with tight tolerances and low vibration, often utilizing ball cage designs for constant velocity transmission.

Other industries that benefit from universal shaft technology include agriculture, where they are used in tractors and farm machinery to transmit power to various attachments; aerospace, where lightweight and high-precision universal shafts are used in aircraft control systems and engine components; and renewable energy, where they play a role in wind turbine drivetrains, accommodating misalignments between the rotor and generator. The adaptability of universal shafts to different operating conditions and load requirements makes them a fundamental component in modern industrial machinery, enabling the efficient and reliable operation of complex systems.

Proper installation, operation, and maintenance are essential to ensure the longevity and optimal performance of universal shafts. During installation, accurate alignment of the connected shafts is critical, as excessive initial misalignment can lead to increased vibration, premature wear, and reduced service life. While universal shafts are designed to accommodate misalignments, operating within the recommended angular limits—typically between 5° and 45° depending on the design—ensures efficient power transmission and minimizes stress on components. Proper lubrication is another key maintenance requirement, as the needle roller bearings and cross shafts rely on lubricants to reduce friction and prevent wear. The type of lubricant used depends on the operating conditions, including temperature, speed, and environmental factors; grease lubrication is common for most applications, while oil lubrication may be used for high-speed or high-temperature scenarios. Regular inspection of lubricant levels and condition is necessary to prevent dry operation, which can cause severe damage to components.

Routine maintenance also includes checking for signs of wear, such as excessive play in the universal joints, unusual noise or vibration during operation, and leakage of lubricants. Worn components such as bearings, seals, and cross shafts should be replaced promptly to avoid further damage to the universal shaft assembly and the connected machinery. In high-speed applications, dynamic balancing of the universal shaft is essential to reduce vibration and prevent fatigue failure. Dynamic balancing involves adjusting the mass distribution of the shaft to ensure smooth rotation at operating speeds, minimizing stress on bearings and other components. Additionally, protecting the universal shaft from contaminants such as dust, dirt, and moisture through proper sealing and shielding extends its service life, particularly in harsh environments.

Despite their robustness and versatility, universal shafts have certain limitations that engineers must consider during the design and selection process. As previously mentioned, single universal joints introduce velocity fluctuations at large angles, which can cause vibration and noise, making them unsuitable for high-speed applications requiring smooth operation. This limitation is addressed through the use of double universal joint configurations or ball cage-type constant velocity joints, although these solutions may increase complexity and cost. Another limitation is the need for regular maintenance, particularly lubrication, which can be a challenge in hard-to-reach locations or remote applications. Additionally, universal shafts are subject to fatigue failure over time, especially when operating under cyclic loads or excessive torques, requiring careful design and material selection to ensure sufficient fatigue strength.

Advancements in engineering technology continue to address these limitations, driving innovations in universal shaft design and performance. Finite element analysis (FEA) is now widely used during the design phase to simulate the performance of universal shafts under various load conditions, optimizing their structure for strength, weight, and durability. This computer-aided engineering approach allows engineers to identify potential stress points and modify the design to improve performance, reducing the need for physical prototypes and accelerating the development process. The use of advanced materials such as composites and high-strength alloys further enhances the performance of universal shafts, enabling higher torque capacity, lighter weight, and improved corrosion resistance. Additionally, the development of self-lubricating bearings and seals reduces maintenance requirements, making universal shafts more reliable in remote or inaccessible applications.

Looking to the future, the role of universal shafts in modern machinery is likely to expand as industrial processes become more automated and demanding. The growing trend toward electrification in automotive and industrial applications will require universal shafts that are lightweight, efficient, and compatible with electric drivetrains. In the renewable energy sector, the increasing size and power output of wind turbines will demand larger and more robust universal shafts capable of handling higher torques and misalignments. Advances in additive manufacturing (3D printing) may also impact universal shaft production, allowing for the creation of complex geometries that optimize performance and reduce weight, while enabling customization for specific applications. These innovations will continue to enhance the versatility and reliability of universal shafts, ensuring they remain a critical component in mechanical transmission systems for years to come.

In conclusion, the universal shaft is a vital mechanical component that enables the efficient transmission of power between non-coaxial shafts, supporting a wide range of industrial and mechanical applications. Its design, material selection, and performance characteristics are tailored to meet the specific requirements of each application, from lightweight automotive drivetrains to heavy-duty steel mill machinery. Proper installation, operation, and maintenance are essential to ensure its longevity and optimal performance, while ongoing technological advancements continue to address its limitations and expand its capabilities. As modern industry evolves, the universal shaft will remain a cornerstone of mechanical transmission systems, playing an indispensable role in powering the machinery that drives our economy and daily lives.

« Universal Shaft » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/universal-shaft.html