NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.

| Model | Nominal Torque KN·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1,d2,dz | Shaft Hole Length L | D0 | D | D1 | D2 | D3 | B1 | T | C1 | C | H | B2 | Grease (ml) | Quality kg | Rotational Inertia kg·m² | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| From | To | Y | J、Z | |||||||||||||||||

| NGCLZ1 | 0.63 | 4000 | 20 | 24 | 52 | 38 | 160 | 103 | 71 | 50 | 71 | 42 | 68 | 8 | 22 | 2 | 38 | 31 | 7.3 | 0.071 |

| 25 | 28 | 62 | 44 | 26 | 7.4 | 0.072 | ||||||||||||||

| 30 | 35 | 82 | 60 | 30 | 8.4 | 0.076 | ||||||||||||||

| NGCLZ2 | 1.00 | 4000 | 25 | 28 | 62 | 44 | 160 | 115 | 83 | 60 | 83 | 48 | 68 | 8 | 26 | 2 | 42 | 42 | 9.2 | 0.081 |

| 30 | 38 | 82 | 60 | 30 | 10.3 | 0.084 | ||||||||||||||

| 40 | 45 | 112 | 84 | 36 | 10.5 | 0.088 | ||||||||||||||

| NGCLZ3 | 1.60 | 3800 | 一 | 28 | 62 | 44 | 200 | 127 | 95 | 75 | 95 | 49 | 85 | 8 | 26 | 2 | 42 | 65 | 15.1 | 0.181 |

| 30 | 38 | 82 | 60 | 30 | 16.3 | 0.184 | ||||||||||||||

| 40 | 56 | 112 | 84 | 36 | 18.8 | 0.193 | ||||||||||||||

| NGCLZ4 | 2.80 | 3800 | 一 | 38 | 82 | 60 | 200 | 149 | 116 | 90 | 116 | 53 | 85 | 8 | 30 | 2 | 42 | 82 | 19.8 | 0.225 |

| 40 | 56 | 112 | 84 | 36 | 23.3 | 0.242 | ||||||||||||||

| 60 | 65 | 142 | 107 | 43 | 26.8 | 0.296 | ||||||||||||||

| NGCLZ5 | 4.50 | 3000 | 40 | 56 | 112 | 84 | 250 | 167 | 134 | 105 | 134 | 59 | 105 | 10 | 38 | 2.5 | 42 | 120 | 33.3 | 0.596 |

| 60 | 75 | 142 | 107 | 45 | 39.0 | 0.627 | ||||||||||||||

| NGCLZ6 | 6.30 | 3000 | 45 | 56 | 112 | 84 | 250 | 187 | 153 | 125 | 153 | 60 | 105 | 10 | 38 | 2.5 | 42 | 143 | 40.0 | 0.720 |

| 60 | 75 | 142 | 107 | 45 | 46.4 | 0.776 | ||||||||||||||

| 80 | 90 | 172 | 132 | 50 | 53.2 | 0.837 | ||||||||||||||

| NGCLZ7 | 8.00 | 2400 | 50 | 56 | 112 | 84 | 315 (300) | 204 | 170 | 140 | 170 | 64 | 132 | 10 | 38 | 2.5 | 42 | 179 | 51.8 | 1.178 |

| 60 | 75 | 142 | 107 | 45 | 59.8 | 1.254 | ||||||||||||||

| 80 | 95 | 172 | 132 | 50 | 68.2 | 1.348 | ||||||||||||||

| 100 | 一 | 212 | 167 | 55 | 79.6 | 1.479 | ||||||||||||||

| NGCLZ8 | 11.20 | 1900 | 55 | 56 | 112 | 84 | 400 | 230 | 186 | 155 | 186 | 77 | 168 | 12 | 40 | 3 | 47 | 274 | 84.0 | 3.734 |

| 60 | 75 | 142 | 107 | 47 | 93.1 | 3.860 | ||||||||||||||

| 80 | 95 | 172 | 132 | 52 | 104 | 3.996 | ||||||||||||||

| 100 | 110 | 212 | 167 | 57 | 117 | 4.187 | ||||||||||||||

| NGCLZ9 | 18.00 | 1500 | 60 | 75 | 142 | 107 | 500 | 256 | 212 | 180 | 212 | 80 | 210 | 13 | 48 | 3 | 47 | 337 | 128 | 9.427 |

| 80 | 95 | 172 | 132 | 53 | 138 | 9.605 | ||||||||||||||

| 100 | 125 | 212 | 167 | 58 | 151 | 9.847 | ||||||||||||||

| 130 | 一 | 252 | 202 | 63 | 167 | 10.109 | ||||||||||||||

| NGCLZ10 | 25.00 | 1200 | 65 | 75 | 142 | 107 | 630 (600) | 287 | 239 | 200 | 239 | 90 | 265 | 15 | 50 | 3.5 | 47 | 440 | 184 | 29.32 |

| 80 | 95 | 172 | 132 | 55 | 200 | 29.69 | ||||||||||||||

| 100 | 125 | 212 | 167 | 60 | 222 | 30.21 | ||||||||||||||

| 130 | 150 | 252 | 202 | 65 | 246 | 30.74 | ||||||||||||||

| NGCLZ11 | 35.50 | 1050 | 70 | 75 | 142 | 107 | 710 (700) | 325 | 250 | 235 | 276 | 94 | 298 | 16 | 51 | 3.5 | 47 | 574 | 240 | 44.0 |

| 80 | 95 | 172 | 132 | 56 | 262 | 45.0 | ||||||||||||||

| 100 | 125 | 212 | 167 | 61 | 299 | 45.5 | ||||||||||||||

| 130 | 150 | 252 | 202 | 66 | 326 | 46 | ||||||||||||||

| 160 | 170 | 302 | 242 | 76 | 361 | 47 | ||||||||||||||

| NGCLZ12 | 56.00 | 1050 | 一 | 75 | 142 | 107 | 710 (700) | 362 | 286 | 270 | 313 | 104 | 298 | 17 | 52 | 4 | 49 | 792 | 290 | 48 |

| 80 | 95 | 172 | 132 | 57 | 317 | 49 | ||||||||||||||

| 100 | 125 | 212 | 167 | 62 | 355 | 50 | ||||||||||||||

| 130 | 150 | 252 | 202 | 67 | 382 | 51 | ||||||||||||||

| 160 | 180 | 302 | 242 | 77 | 443 | 52 | ||||||||||||||

| 190 | 200 | 352 | 282 | 87 | 470 | 53 | ||||||||||||||

| NGCLZ13 | 80.00 | 950 | 一 | 150 | 252 | 202 | 800 | 412 | 322 | 300 | 350 | 113 | 335 | 18 | 68 | 4.5 | 49 | 960 | 488 | 82 |

| 160 | 180 | 302 | 242 | 78 | 542 | 85 | ||||||||||||||

| 190 | 220 | 352 | 282 | 88 | 598 | 92 | ||||||||||||||

| NGCLZ14 | 125.00 | 950 | 170 | 180 | 302 | 242 | 800 | 462 | 335 | 335 | 420 | 157 | 335 | 20 | 80 | 5.5 | 63 | 2100 | 638 | 95 |

| 190 | 220 | 352 | 282 | 90 | 698 | 98 | ||||||||||||||

| 240 | 250 | 410 | 330 | 100 | 780 | 102 | ||||||||||||||

The NGCLZ drum gear coupling is an important mechanical engineering component, mainly composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. The outer teeth are divided into two types: straight teeth and drum teeth. Among them, drum teeth are made into spherical surfaces, with the center of the spherical surface on the gear axis. This design results in a larger backlash between the teeth compared to regular gears, allowing for greater angular displacement and improving the contact conditions of the teeth.

Main Features

Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the drum gear coupling is on average 15-20% higher than that of the spur gear coupling.

Large angular displacement compensation: Drum gear couplings allow for larger angular displacements, and when the radial displacement is equal to zero, their allowable angular displacement is much greater than that of spur gear couplings.

Low noise and long maintenance cycle: The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the disadvantages of edge compression and stress concentration at the straight tooth end. At the same time, it improves the friction and wear of the tooth surface, reduces noise, and extends the maintenance cycle.

Easy to assemble and disassemble: The outer gear sleeve has a trumpet shaped tooth end, making it very convenient to assemble and disassemble the inner and outer teeth.

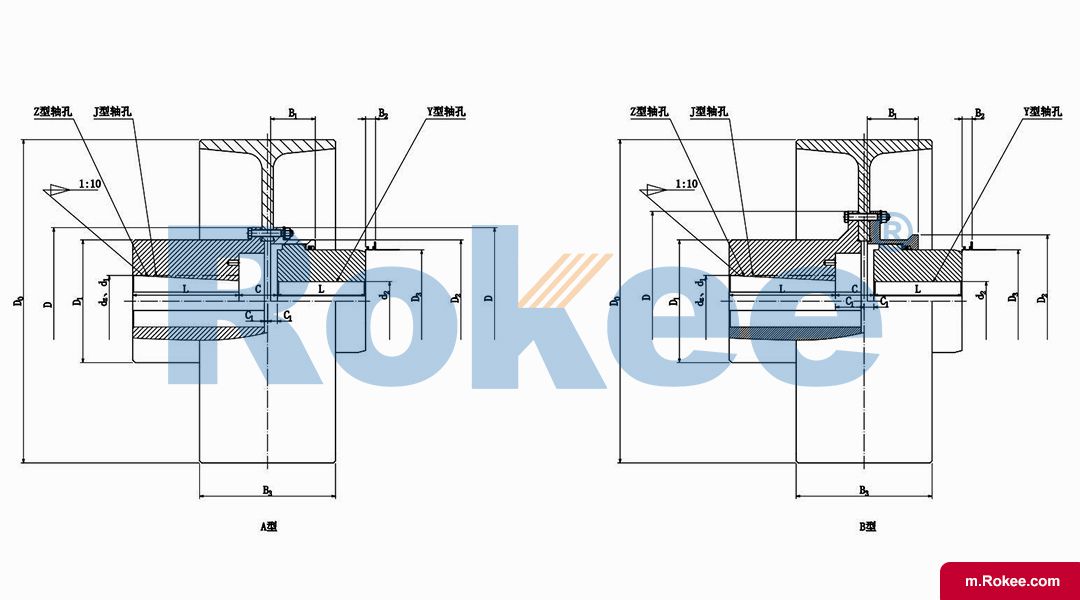

There are two types of NGCLZ drum toothed couplings with brake wheels: Type A and Type B. Type A is suitable for NGCLS1~NGCLS13 types, while Type B is suitable for NGCLS14 types.

The NGCLZ crown gear coupling has the advantages of compact structure, small turning radius, large load-bearing capacity, high transmission efficiency, low noise, and long maintenance cycle, and is therefore widely used in various mechanical engineering fields. Especially in situations where adaptive and self-tuning technology is needed to compensate for load changes, the drum toothed coupling plays a unique role. In addition, with the emergence of new high-voltage power electronic devices and the development of high-voltage and medium voltage drum shaped gear couplings, their application scope is constantly expanding.

Precautions

NGCLZ Drum toothed couplings need to work in a good and sealed condition to ensure their performance and lifespan.

When selecting and using drum gear couplings, appropriate selection should be made based on actual working conditions and requirements, and relevant installation and usage specifications should be followed.

NGCLZ drum tooth coupling plays an important role in the field of mechanical engineering due to its unique structure and excellent performance.

URL: https://m.rokee.com/drum-gear-couplings/ngclz-drum-gear-coupling-with-brake-wheel.html