The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.

| Model | Nominal Torque N ·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1、d2、dz | Shaft Hole Length L | D | D1 | D2 | D3 | D4 | B | B1 | F | C | C1 | C2 | Quality kg | Moment of Inertia kg ·m² | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y | J1、Z1 | I | Ⅱ | I | Ⅱ | I | Ⅱ | ||||||||||||||

| WG1 | 800 | 7500 | 12,14 | 32 | 一 | 122 | 115 | 98 | 88 | 60 | 116 | 100 | 30 | 30 | 一 | 一 | 5.6 | 4.86 | 0.008 | 0.0063 | |

| 16,18,19 | 42 | 一 | 20 | 14 | 一 | 一 | |||||||||||||||

| 20,22,24 | 52 | 一 | 10 | 4 | 一 | 一 | |||||||||||||||

| 25,28 | 62 | 44 | 3 | 3 | 19 | 18 | |||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 3 | 23 | 12 | |||||||||||||||

| 40,42 | 112 | 84 | 3 | 3 | 29 | 12 | |||||||||||||||

| WG2 | 1400 | 6700 | 22,24 | 52 | 一 | 150 | 145 | 118 | 108 | 77 | 136 | 104 | 30 | 20 | 4 | 一 | 一 | 9.78 | 7.48 | 0.021 | 0.016 |

| 25,28 | 62 | 一 | 10 | 3 | 一 | 一 | |||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 3 | 23 | 16 | |||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 3 | 29 | 16 | |||||||||||||||

| WG3 | 2800 | 6300 | 22,24 | 52 | 一 | 170 | 165 | 140 | 125 | 90 | 160 | 108 | 30 | 33 | 7 | 一 | 一 | 16.7 | 12.2 | 0.047 | 0.033 |

| 25,28 | 62 | 一 | 23 | 3 | 一 | 一 | |||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 3 | 23 | 16 | |||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 3 | 29 | 16 | |||||||||||||||

| 60,63 | 142 | 107 | 3 | 3 | 36 | 16 | |||||||||||||||

| WG4 | 5000 | 5600 | 30,32,35,38 | 82 | 一 | 200 | 195 | 160 | 145 | 112 | 180 | 116 | 30 | 13 | 3 | 一 | 一 | 25.6 | 19.6 | 0.098 | 0.073 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 3 | 29 | 17 | |||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 3 | 3 | 36 | 17 | |||||||||||||||

| 80 | 172 | 132 | 3 | 3 | 41 | 17 | |||||||||||||||

| WG5 | 8000 | 5300 | 30,32,35,38 | 82 | 一 | 225 | 215 | 180 | 168 | 128 | 200 | 126 | 30 | 23 | 3 | 一 | 一 | 35 | 26.1 | 0.175 | 0.126 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 3 | 29 | 19 | |||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 3 | 3 | 36 | 19 | |||||||||||||||

| 80,85,90 | 172 | 132 | 3 | 3 | 41 | 19 | |||||||||||||||

| WG6 | 11200 | 5000 | 32,35,38 | 82 | 一 | 245 | 230 | 200 | 185 | 145 | 224 | 134 | 30 | 35 | 5 | 一 | 一 | 51.6 | 38 | 0.295 | 0.213 |

| 40,42,45,48,50,55,56 | 112 | 一 | 5 | 5 | 一 | 一 | |||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 5 | 5 | 38 | 20 | |||||||||||||||

| 80,85,90,95 | 172 | 132 | 5 | 5 | 43 | 20 | |||||||||||||||

| 100 | 212 | 167 | 5 | 5 | 48 | 20 | |||||||||||||||

| WG7 | 16000 | 4500 | 32,35,38 | 82 | 一 | 272 | 265 | 230 | 210 | 160 | 244 | 148 | 30 | 45 | 5 | 一 | 一 | 68.6 | 45 | 0.53 | 0.35 |

| 40,42,45,48,50,55,56 | 112 | 一 | 15 | 5 | 一 | 一 | |||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 5 | 5 | 38 | 20 | |||||||||||||||

| 80,85,90,95 | 172 | 132 | 5 | 5 | 43 | 20 | |||||||||||||||

| 100,110 | 212 | 167 | 5 | 5 | 48 | 20 | |||||||||||||||

| WG8 | 22400 | 4250 | 55,56 | 112 | 一 | 290 | 272 | 245 | 225 | 176 | 272 | 162 | 30 | 29 | 5 | 一 | 一 | 79.5 | 55.8 | 0.71 | 0.46 |

| 60,63,65,70,71,75 | 142 | 107 | 5 | 5 | 38 | 34 | |||||||||||||||

| 80,85,90,95 | 172 | 132 | 5 | 5 | 43 | 20 | |||||||||||||||

| 100,110,120,125 | 212 | 167 | 5 | 5 | 48 | 20 | |||||||||||||||

| WG9 | 28000 | 4000 | 65,70,71,75 | 142 | 107 | 315 | 305 | 265 | 245 | 190 | 280 | 176 | 30 | 5 | 5 | 38 | 38 | 106.5 | 80.5 | 1.05 | 0.77 |

| 80,85,90,95 | 172 | 132 | 5 | 5 | 43 | 28 | |||||||||||||||

| 100,110,120,125 | 212 | 167 | 5 | 5 | 48 | 28 | |||||||||||||||

| 130,140 | 252 | 202 | 5 | 5 | 53 | 28 | |||||||||||||||

| WG10 | 45000 | 3550 | 75 | 142 | 一 | 355 | 340 | 300 | 280 | 225 | 330 | 196 | 30 | 28 | 5 | 一 | 一 | 158.8 | 121.8 | 1.87 | 1.54 |

| 80,85,90,95 | 172 | 132 | 5 | 5 | 43 | 38 | |||||||||||||||

| 100,110,120,125 | 212 | 167 | 5 | 5 | 48 | 28 | |||||||||||||||

| 130,140,150 | 252 | 202 | 5 | 5 | 53 | 28 | |||||||||||||||

| 160 | 302 | 242 | 5 | 5 | 63 | 28 | |||||||||||||||

| WG11 | 63000 | 3000 | 85,90,95 | 172 | 一 | 412 | 385 | 345 | 325 | 256 | 360 | 224 | 40 | 15 | 8 | 一 | 一 | 214 | 167 | 3.66 | 2.77 |

| 100,110,120,125 | 212 | 167 | 8 | 8 | 51 | 32 | |||||||||||||||

| 130,140,150 | 252 | 202 | 8 | 8 | 56 | 32 | |||||||||||||||

| 160,170,180 | 302 | 242 | 8 | 8 | 66 | 32 | |||||||||||||||

| WG12 | 90000 | 2800 | 120,125 | 212 | 167 | 440 | 435 | 375 | 360 | 288 | 414 | 250 | 40 | 8 | 8 | 51 | 45 | 302 | 242 | 6.39 | 4.75 |

| 130,140,150 | 252 | 202 | 8 | 8 | 56 | 32 | |||||||||||||||

| 160,170,180 | 302 | 242 | 8 | 8 | 66 | 32 | |||||||||||||||

| 190,200 | 352 | 282 | 8 | 8 | 76 | 32 | |||||||||||||||

| WG13 | 125000 | 2500 | 140,150 | 252 | 202 | 490 | 480 | 425 | 400 | 320 | 470 | 272 | 50 | 8 | 8 | 56 | 28 | 390 | 309 | 10.44 | 7.76 |

| 160,170,180 | 302 | 242 | 8 | 8 | 66 | 32 | |||||||||||||||

| 190,200,220 | 352 | 282 | 8 | 8 | 76 | 32 | |||||||||||||||

| WG14 | 180000 | 2300 | 160,170,180 | 302 | 242 | 545 | 540 | 462 | 440 | 362 | 530 | 316 | 50 | 10 | 10 | 68 | 32 | 522 | 423 | 17.46 | 13.52 |

| 190,200,220 | 352 | 282 | 10 | 10 | 78 | 32 | |||||||||||||||

| 240,250,260 | 410 | 330 | 10 | 10 | 一 | 10 | |||||||||||||||

| WG15 | 250000 | 2100 | 160,170,180 | 302 | 242 | 580 | 一 | 488 | 一 | 400 | 560 | 一 | 50 | 10 | 一 | 68 | 43 | 677 | 一 | 24.91 | 一 |

| 190,200,220 | 352 | 282 | 10 | 一 | 78 | 32 | |||||||||||||||

| 240,250,260 | 410 | 330 | 10 | 一 | 一 | 10 | |||||||||||||||

| 270 | 470 | 380 | 10 | 一 | 一 | 10 | |||||||||||||||

| WG16 | 315000 | 1900 | 180 | 302 | 242 | 650 | 一 | 560 | 一 | 440 | 600 | 一 | 50 | 12 | 一 | 70 | 63 | 939 | 一 | 43.22 | 一 |

| 190,200,220 | 352 | 282 | 12 | 一 | 80 | 32 | |||||||||||||||

| 240,250,260 | 410 | 330 | 12 | 一 | 一 | 12 | |||||||||||||||

| 280,300 | 470 | 380 | 12 | 一 | 一 | 12 | |||||||||||||||

| WG17 | 410000 | 1800 | 200,220 | 352 | 282 | 690 | 一 | 600 | 一 | 460 | 650 | 一 | 50 | 12 | 一 | 70 | 48 | 1041 | 一 | 56.27 | 一 |

| 240,250,260 | 410 | 330 | 12 | 一 | 一 | 12 | |||||||||||||||

| 280,300,320 | 470 | 380 | 12 | 一 | 一 | 12 | |||||||||||||||

| WG18 | 500000 | 1700 | 220 | 352 | 282 | 750 | 一 | 650 | 一 | 510 | 700 | 一 | 60 | 12 | 一 | 70 | 73 | 1381 | 一 | 88.17 | 一 |

| 240,250,260 | 410 | 330 | 12 | 一 | 一 | 12 | |||||||||||||||

| 280,300,320 | 470 | 380 | 12 | 一 | 一 | 12 | |||||||||||||||

| 340,360 | 550 | 450 | 12 | 一 | 一 | 12 | |||||||||||||||

| WG19 | 630000 | 1600 | 240,250,260 | 410 | 330 | 775 | 一 | 690 | 一 | 535 | 745 | 一 | 60 | 12 | 一 | 一 | 12 | 1526 | 一 | 108.8 | 一 |

| 280,300,320 | 470 | 380 | 12 | 一 | 一 | 12 | |||||||||||||||

| 340,360,380 | 550 | 450 | 12 | 一 | 一 | 12 | |||||||||||||||

| WG20 | 800000 | 1500 | 260 | 410 | 330 | 825 | 一 | 730 | 一 | 580 | 785 | 一 | 60 | 14 | 一 | 一 | 14 | 2081 | 一 | 164.4 | 一 |

| 280,300,320 | 470 | 380 | 14 | 一 | 一 | 14 | |||||||||||||||

| 340,360,380 | 550 | 450 | 14 | 一 | 一 | 14 | |||||||||||||||

| 400 | 650 | 540 | 14 | 一 | 一 | 14 | |||||||||||||||

| WG21 | 900000 | 1300 | 280,300,320 | 470 | 380 | 925 | 一 | 825 | 一 | 620 | 810 | 一 | 60 | 14 | 一 | 一 | 14 | 2460 | 一 | 242.7 | 一 |

| 340,360,380 | 550 | 450 | 14 | 一 | 一 | 14 | |||||||||||||||

| 400,420,440 | 650 | 540 | 14 | 一 | 一 | 14 | |||||||||||||||

| WG22 | 1000000 | 950 | 320 | 470 | 380 | 950 | 一 | 850 | 一 | 665 | 820 | 一 | 60 | 14 | 一 | 一 | 14 | 2775 | 一 | 297 | 一 |

| 340,360,380 | 550 | 450 | 14 | 一 | 一 | 14 | |||||||||||||||

| 400,420,440,450,460 | 650 | 540 | 14 | 一 | 一 | 14 | |||||||||||||||

| WG23 | 1120000 | 900 | 360,380 | 550 | 450 | 1030 | 一 | 900 | 一 | 710 | 880 | 一 | 60 | 14 | 一 | 一 | 14 | 3148 | 一 | 384.8 | 一 |

| 400,420,440,450,460,480,500 | 650 | 540 | 14 | 一 | 一 | 14 | |||||||||||||||

| WG24 | 1400000 | 850 | 380 | 550 | 450 | 1060 | 一 | 925 | 一 | 730 | 900 | 一 | 70 | 16 | 一 | 一 | 16 | 3766 | 一 | 477.8 | 一 |

| 400,420,440,450,460,480,500 | 650 | 540 | 16 | 一 | 一 | 16 | |||||||||||||||

| 520 | 800 | 680 | 16 | 一 | 一 | 16 | |||||||||||||||

WG drum gear coupling is an important mechanical transmission component widely used in heavy industry fields such as metallurgy, mining, lifting and transportation, petrochemicals, and steel rolling machinery.

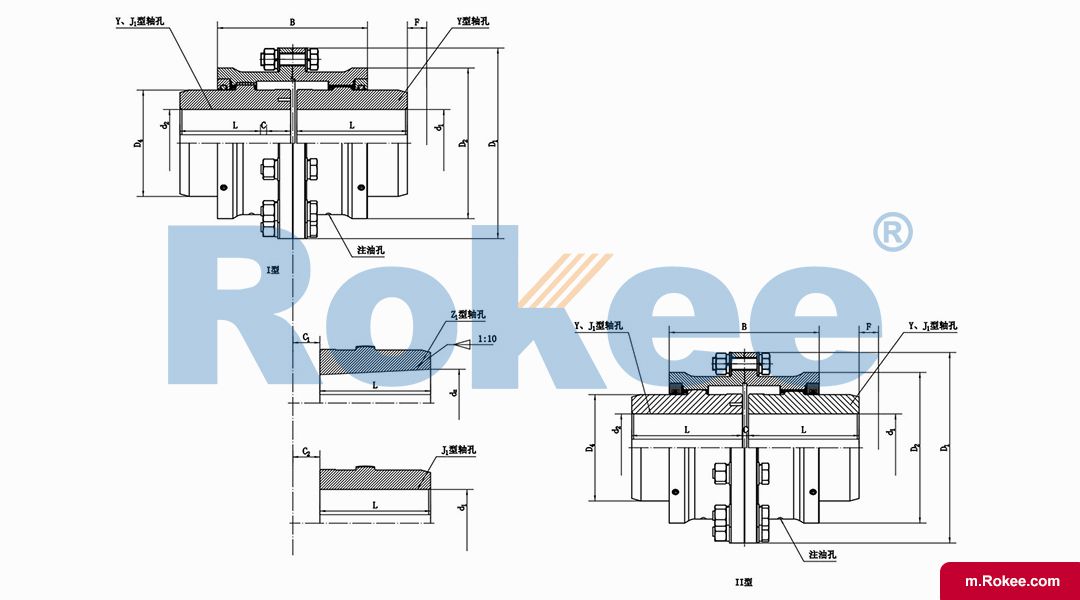

The WG crown gear coupling consists of components such as an inner ring gear with the same number of teeth and a flange half coupling with outer teeth. The core structural feature of the coupling is that the external gear adopts a drum shaped design with spherical tooth tips, which, combined with optimized tooth flank clearance, enables the coupling to have excellent axial deviation compensation capability.

The WG gear coupling series covers various models such as WG1 to WG24, with a nominal torque range from 710N · m to 3150kN · m and a shaft diameter adaptation range of 12-400mm.

FEATURES

Strong load-bearing capacity: The drum shaped tooth design effectively improves the contact conditions of the teeth, enhances the ability to transmit torque, and increases the load-bearing capacity of the WG type drum shaped tooth coupling by 15% to 20% compared to the straight tooth coupling.

Large angular displacement compensation: Drum shaped gear couplings allow for larger angular displacements, with angular compensation capabilities ranging from ± 1.5 ° to ± 2 °. Compared to spur gear couplings, their allowable angular displacement increases by 50%.

High transmission efficiency: With advanced manufacturing technology and precise assembly techniques, the transmission efficiency of WG coupling can reach over 99.7%.

Compact structure and low noise: The overall structure design of the coupling is compact, with a small turning radius, which reduces the noise level during operation and extends the service life.

Long maintenance cycle: The drum shaped tooth surface design avoids stress concentration, improves tooth surface friction and wear, and enables the coupling to have a longer maintenance cycle.

The WG crown gear coupling is particularly suitable for torque transmission tasks under low-speed heavy load conditions, such as metallurgy, mining, lifting and transportation industries. At the same time, it is also applicable to shaft transmission of various types of machinery such as petroleum, chemical, and general machinery.

During use, the wear of the coupling should be checked regularly, and severely worn components should be replaced in a timely manner. At the same time, the coupling should be kept in good lubrication condition to reduce tooth wear and extend its service life. For couplings equipped with forced thin oil lubrication systems or segmented grease lubrication structures, the lubrication system should be regularly inspected and maintained.

The WG drum toothed coupling plays an important role in the field of mechanical transmission due to its excellent performance and wide application scenarios.

URL: https://m.rokee.com/drum-gear-couplings/wg-drum-gear-coupling.html