WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.

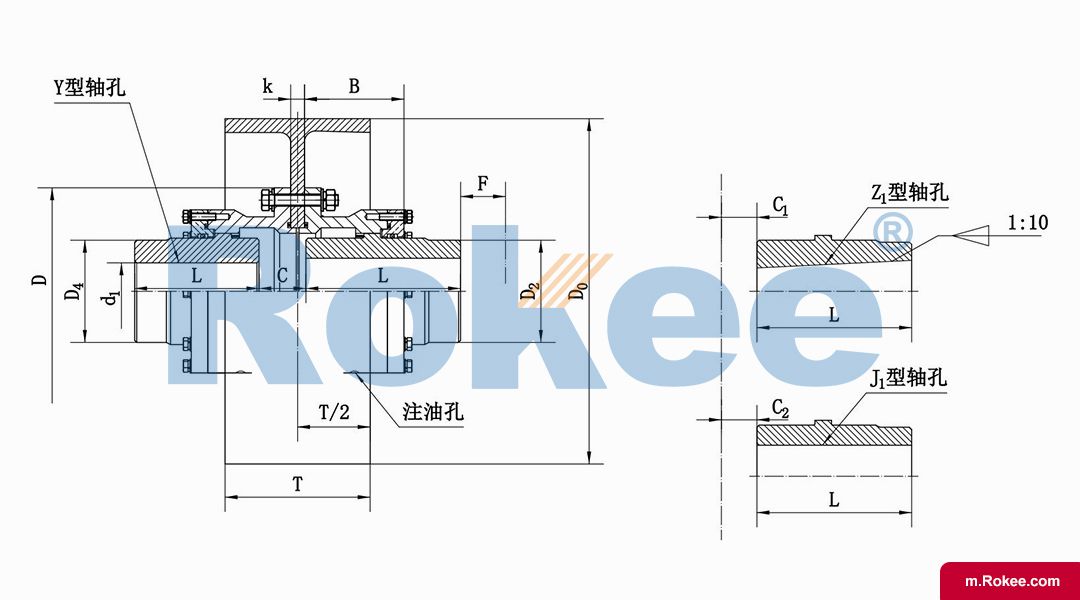

| Model | Nominal Torque N ·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1、d2、dZ | Shaft Hole Length L | D0 | D | D2 | D4 | B | F | C | C1 | C2 | C3 | Mass Without Brake Wheels kg | Rotational Inertia kg ·m² | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y | J1、Z1 | ||||||||||||||||

| WGZ1 | 800 | 4000 | 12,14 | 32 | 一 | 160 200 250 | 122 | 98 | 60 | 58 | 30 | 30 | 一 | 一 | 1 | 5.62 | 0.0078 |

| 16,18,19 | 42 | 一 | 20 | 一 | 一 | ||||||||||||

| 20,22,24 | 52 | 一 | 10 | 一 | 一 | ||||||||||||

| 25,28 | 62 | 44 | 3 | 19 | 18 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 23 | 12 | |||||||||||||

| 40,42 | 112 | 84 | 29 | 12 | |||||||||||||

| WGZ2 | 1400 | 4000 | 22,24 | 52 | 一 | 200 250 315 | 150 | 118 | 77 | 68 | 30 | 20 | 一 | 一 | 2 | 9.65 | 0.022 |

| 25,28 | 62 | 一 | 10 | 一 | |||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 23 | 16 | ||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 29 | 16 | |||||||||||||

| WGZ3 | 2800 | 4000 | 22,24 | 52 | 一 | 200 250 315 | 170 | 140 | 90 | 80 | 30 | 33 | 一 | 一 | 2 | 16.5 | 0.047 |

| 25,28 | 62 | 一 | 23 | 一 | 一 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 23 | 25 | ||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 29 | 16 | |||||||||||||

| 60,63 | 142 | 107 | 36 | ||||||||||||||

| WGZ4 | 5000 | 3000 | 30,32,35,38 | 82 | 一 | 250 315 400 | 200 | 160 | 112 | 90 | 30 | 13 | 一 | 一 | 2 | 25.3 | 0.098 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 29 | 17 | ||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 36 | ||||||||||||||

| 80 | 172 | 132 | 41 | ||||||||||||||

| WGZ5 | 8000 | 3000 | 30,32,35,38 | 82 | 一 | 315 400 | 225 | 180 | 128 | 100 | 30 | 23 | 一 | 一 | 2 | 34.7 | 0.174 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 29 36 41 | 19 | ||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | |||||||||||||||

| 80,85,90 | 172 | 132 | |||||||||||||||

| WGZ6 | 11200 | 3000 | 32,35,38 | 82 | 一 | 315 400 | 245 | 200 | 145 | 112 | 30 | 35 | 一 | 一 | 2 | 51.3 | 0.29 |

| 40,42,45,48,50,55,56 | 112 | 一 | 5 | 一 | 一 | ||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 38 43 | 20 | |||||||||||||

| 80,85,90,95 | 172 | 132 | |||||||||||||||

| 100 | 212 | 167 | 48 | ||||||||||||||

| WGZ7 | 16000 | 2500 | 32,35,38 | 82 | 一 | 400 500 | 272 | 230 | 160 | 122 | 30 | 45 | 一 | 一 | 3 | 68 | 0.53 |

| 40,42,45,48,50,55,56 | 112 | 一 | 15 | 一 | 一 | ||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 5 | 38 | 20 | ||||||||||||

| 80,859,095 | 172 | 132 | 43 | ||||||||||||||

| 100,110 | 202 | 167 | 48 | ||||||||||||||

| WGZ8 | 22400 | 2500 | 55,56 | 112 | 一 | 400 450 | 290 | 245 | 176 | 136 | 30 | 29 | 一 | 一 | 3 | 79 | 0.71 |

| 60,63,65,70,71,75 | 142 | 107 | 5 | 38 | 34 | ||||||||||||

| 80,85,90,95 | 172 | 132 | 43 | 20 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | 20 | |||||||||||||

| WGZ9 | 28000 | 2000 | 65,70,71,75 | 142 | 107 | 400 500 630 | 315 | 265 | 190 | 140 | 30 | 5 | 38 | 38 | 3 | 106.5 | 1.05 |

| 80,85,90,95 | 172 | 132 | 43 | 28 | |||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | ||||||||||||||

| 130,140 | 252 | 202 | 53 | ||||||||||||||

| WGZ10 | 45000 | 2000 | 75 | 142 | 一 | 400 500 630 | 355 | 300 | 225 | 165 | 30 | 28 | 一 | 一 | 3 | 159 | 1.74 |

| 80,85,90,95 | 172 | 132 | 5 | 43 | 38 | ||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | 28 | |||||||||||||

| 130,140,150 | 252 | 202 | 53 | ||||||||||||||

| 160 | 302 | 242 | 63 | ||||||||||||||

| WGZ11 | 63000 | 1700 | 85,90,95 | 172 | 一 | 500 630 710 | 412 | 345 | 256 | 180 | 40 | 15 | 一 | 一 | 4 | 215 | 3.67 |

| 100,110,120,125 | 212 | 162 | 8 | 51 | 32 | ||||||||||||

| 130,140,150 | 252 | 202 | 56 | ||||||||||||||

| 160,170,180 | 302 | 242 | 66 | ||||||||||||||

| WGZ12 | 90000 | 1700 | 120,125 | 212 | 162 | 500 630 710 | 440 | 375 | 288 | 207 | 40 | 8 | 51 | 45 | 4 | 303 | 6.4 |

| 130,140,150 | 252 | 202 | 56 66 76 | 32 | |||||||||||||

| 160,170,180 | 302 | 242 | |||||||||||||||

| 190,200 | 352 | 282 | |||||||||||||||

| WGZ13 | 125000 | 1700 | 140,150 | 252 | 202 | 630 710 | 490 | 425 | 320 | 235 | 50 | 8 | 56 | 38 | 4 | 391 | 10.45 |

| 160,170,180 | 302 | 242 | 66 | 32 | |||||||||||||

| 190,200,220 | 352 | 282 | 76 | ||||||||||||||

| WGZ14 | 180000 | 1500 | 160,170,180 | 302 | 242 | 710 800 | 545 | 462 | 362 | 265 | 50 | 10 | 68 | 32 | 4 | 523 | 17.48 |

| 190,200,220 | 352 | 282 | 78 | ||||||||||||||

| 240,250,260 | 410 | 330 | 一 | 10 | |||||||||||||

The WGZ drum gear coupling is mainly composed of internal gear rings and flange half couplings with external teeth. The outer teeth are divided into two forms: straight teeth and drum teeth. The design of drum teeth optimizes the contact state of the tooth surface by increasing the angular displacement tolerance. Drum shaped teeth are formed by shaping the outer teeth into a spherical surface, with the center of the spherical surface on the gear axis and a larger tooth flank clearance than typical gears.

When the WGZ coupling is in operation, the two shafts produce relative angular displacement, and the tooth surfaces of the inner and outer teeth will periodically slide axially relative to each other. Due to the design of the drum shaped teeth, this coupling can allow for large angular displacement and compensate for angular errors, axial and radial installation errors caused by the misalignment of the two connecting shafts, adapting to large angular deviations between the two axes.

Characteristics and Advantages

Strong compensation capability: It has the ability to compensate for axis deviations such as radial, axial, and angular directions.

Compact structure: small turning radius and high load-bearing capacity. Under the same outer diameter of the inner gear sleeve and the larger outer diameter of the coupling, the average load-bearing capacity is 15-20% higher than that of a spur gear coupling.

High transmission efficiency: up to 99.7%, with low noise and long maintenance cycle.

Braking function: The WGZ type coupling is equipped with brake wheels and is suitable for matching with tile brakes. It uses the combination of brake wheels and tile brakes to achieve braking and is commonly used in low-speed heavy-duty equipment that requires reliable braking.

WGZ crown gear couplings are widely used in industrial fields that require low-speed heavy-duty transmission, such as metallurgy, mining, lifting and transportation industries. Meanwhile, due to its braking function design, it is particularly suitable for working environments that require rapid braking.

The WGZ drum gear toothed coupling includes various models such as WGZ1 to WGZ14, and is manufactured strictly in accordance with the JBT 7003-2007 technical standard.

URL: https://m.rokee.com/drum-gear-couplings/wgz-drum-gear-coupling-with-brake-wheel.html