Rokee is a chinese Barrel Couplings Manufacturer, provide Barrel Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Barrel Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Barrel Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

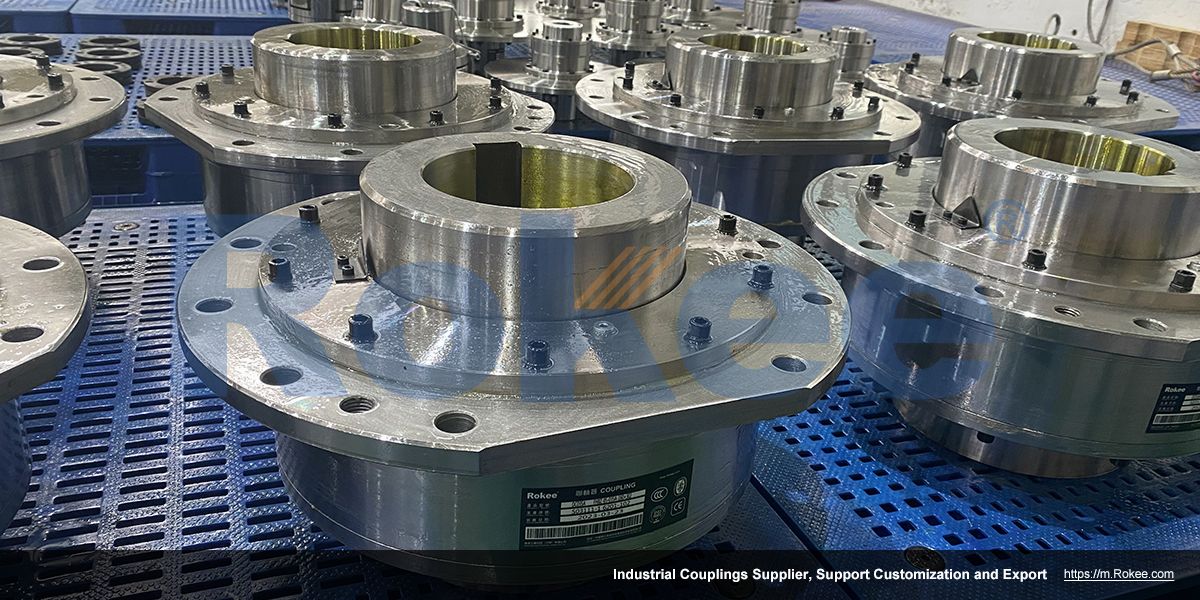

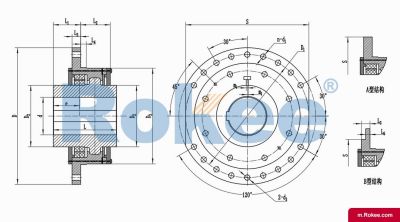

DC Drum Coupling For Crane

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load.View More -

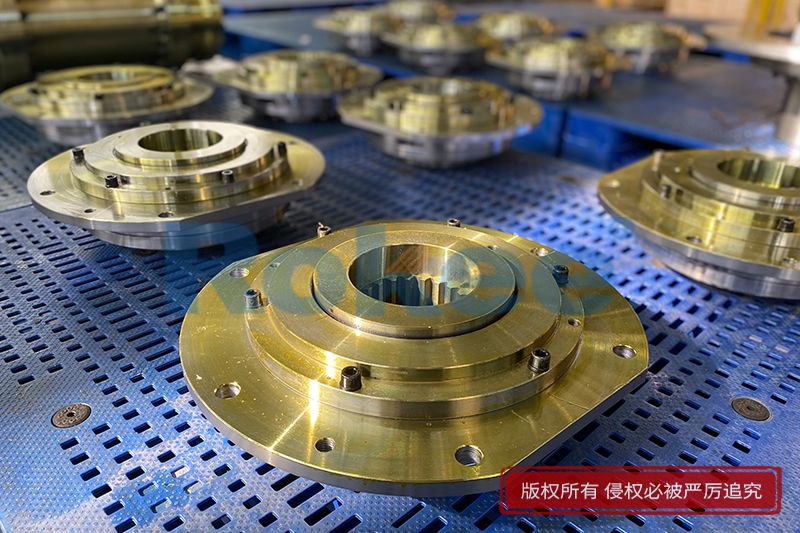

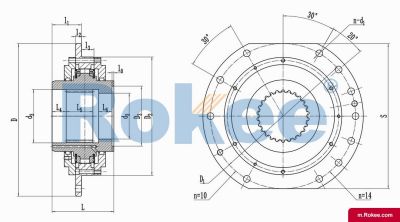

WJ Spherical Roller Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load.View More -

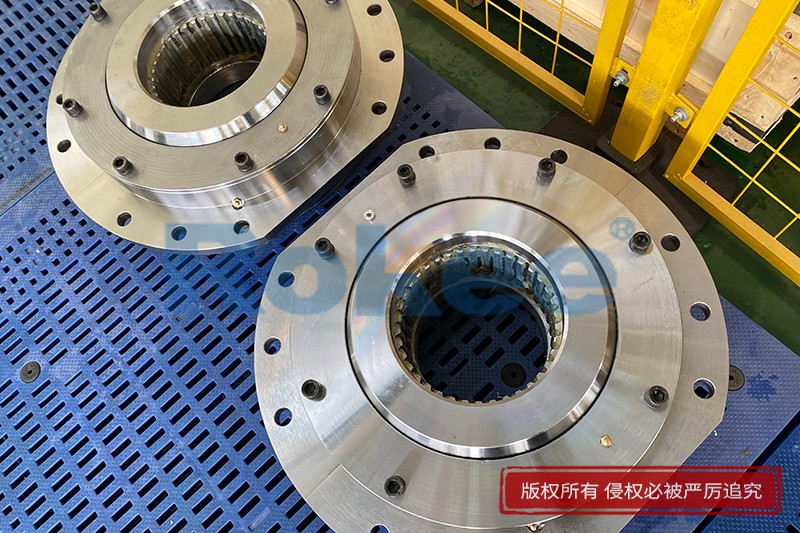

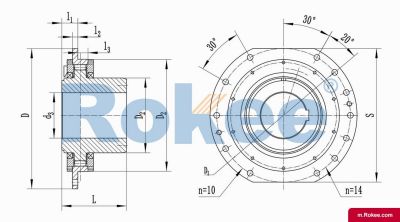

WJA Spherical Roller Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.View More -

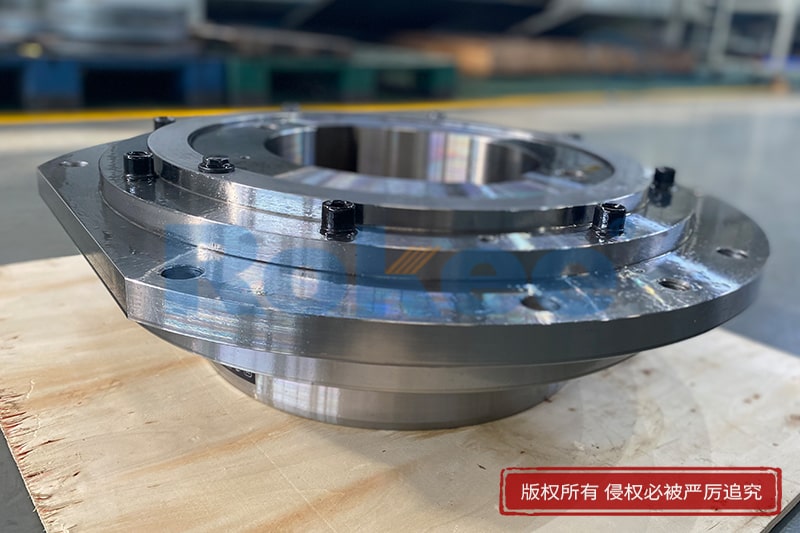

WZL Internal Spline Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure.View More -

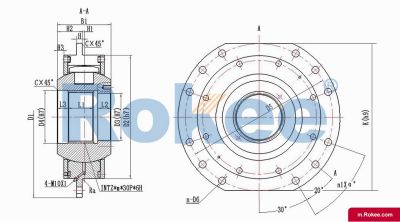

RWC Ball & Drum Gear Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.View More

Barrel couplings are specialized mechanical components designed for torque transmission and shaft alignment in rotational systems. Their unique cylindrical structure and adaptability make them critical in industries requiring precision and durability.

Structural Design

A barrel coupling typically consists of a cylindrical body (or "barrel") roll-formed from a single material unit, featuring integrated cavities and angularly extending lips or wings. Variations include:

Solid Barrel Couplings: Rigid designs for high-torque applications, often incorporating flanges or splines.

Flexible Barrel Couplings: Equipped with elastic elements (e.g., rubber or metal membranes) to accommodate misalignment and dampen vibrations.

Clamping Barrel Couplings: Utilize split sleeves or adjustable collars for easy installation and maintenance.

The cylindrical geometry ensures uniform stress distribution, enhancing load-bearing capacity and fatigue resistance.

Functional Principles

Barrel couplings operate through two core mechanisms:

Torque Transmission: Rotational force is transferred via interlocking teeth, grooves, or friction surfaces within the barrel structure.

Misalignment Compensation: Flexible variants absorb axial, radial, or angular deviations between connected shafts, reducing wear on downstream components.

Advanced designs integrate sealing systems to protect internal components from contaminants, extending service life in harsh environments.

Industrial Applications

Barrel couplings are widely used in:

Oil and Gas: Connect pumps and compressors in pipelines, withstanding high-pressure and corrosive conditions.

Automotive: Transfer power in drivetrains while compensating for engine vibrations.

Aerospace: Enable lightweight, high-strength linkages in aircraft landing gear and control systems.

Manufacturing: Synchronize conveyor belts and robotic arms in automated assembly lines.

Advantages

Compactness: Space-efficient compared to traditional flange couplings.

High Torque Capacity: Robust construction supports heavy-duty operations.

Versatility: Modular designs cater to diverse shaft sizes and alignment needs.

Low Maintenance: Sealed variants minimize lubrication requirements.

Future Trends

Innovations focus on:

Smart Sensors: Embedding strain gauges to monitor torque and alignment in real time.

Lightweight Materials: Using carbon fiber composites to reduce weight without compromising strength.

Conclusion

Barrel couplings exemplify engineering efficiency, combining robust torque transfer with alignment flexibility. Their role in enhancing system reliability and performance ensures continued relevance across industries. For specific applications, consult manufacturers for material and design customization.

In the complex ecosystem of mechanical power transmission, couplings serve as the critical link between rotating components, ensuring the seamless transfer of torque while accommodating inevitable misalignments and mitigating operational stresses. Among the diverse array of coupling designs, the barrel coupling stands out for its unique combination of robustness, torque-bearing capacity, and adaptability to harsh industrial environments. Unlike more common coupling types that rely on gears, chains, or elastomeric elements, barrel couplings utilize a specialized configuration of cylindrical barrels (or rollers) housed within precision-machined troughs to transmit power. This design not only enhances their ability to handle radial loads and misalignments but also extends their service life in high-demand applications such as heavy-duty lifting, steel production, and material handling. As industrial operations continue to evolve toward higher efficiency, greater load capacities, and improved reliability, the role of barrel couplings in maintaining operational continuity has become increasingly prominent. Understanding the fundamental principles, design variations, application scope, and maintenance requirements of barrel couplings is essential for engineers, technicians, and industry professionals tasked with optimizing power transmission systems.

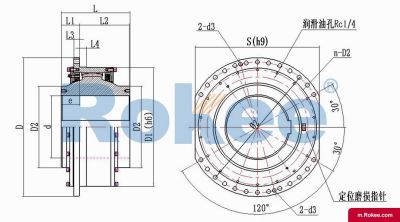

At the core of a barrel coupling’s functionality lies its distinctive structural composition, which is engineered to balance torque transmission efficiency with the ability to compensate for shaft misalignments. A typical barrel coupling consists of three primary components: a sleeve with internal semicircular toothing, a hub with external matching toothing, and a series of cylindrical barrels made from hardened steel. The sleeve and hub are precision machined such that their toothed profiles form complementary troughs when assembled, creating cavities that securely house the cylindrical barrels. These barrels act as the primary torque-transmitting elements, transferring rotational force from the driving shaft (connected to the hub) to the driven shaft (connected to the sleeve) through direct contact with the toothed surfaces. The convex shape of the barrels and the curved profile of the troughs are not arbitrary; this design allows for a large contact surface area between the barrels and the toothing, which distributes loads evenly and reduces localized stress concentrations. This even load distribution is particularly critical in applications where high radial forces are present, as it minimizes wear on both the barrels and the toothed components, thereby extending the coupling’s overall lifespan.

Another key structural feature of barrel couplings is their integrated sealing and lubrication system. To protect the internal components from contamination by dust, debris, or moisture—common hazards in industrial settings—barrel couplings are equipped with internal and external covers fitted with lip seals. These seals create a tight barrier that prevents foreign particles from entering the coupling cavity while retaining the lubricant necessary for smooth operation. Lubrication plays a vital role in reducing friction between the barrels and the toothed surfaces, minimizing wear and heat generation during operation. Without proper lubrication, the metal-to-metal contact would lead to accelerated wear, increased energy loss, and eventual component failure. Additionally, many barrel coupling designs incorporate a wear indicator, typically mounted on the external cover, which provides a visual means of monitoring internal wear without the need for disassembly. This indicator moves relative to marked reference points on the hub as the barrels and toothing wear down, allowing maintenance personnel to assess the coupling’s condition and schedule replacements or repairs before catastrophic failure occurs. This proactive monitoring capability is a significant advantage in industrial settings where unplanned downtime can result in substantial financial losses.

The working principle of barrel couplings revolves around the efficient transmission of torque while accommodating three primary types of shaft misalignment: angular, parallel, and axial. Angular misalignment occurs when the axes of the driving and driven shafts are not collinear but intersect at a point, while parallel misalignment (also known as offset misalignment) happens when the shafts are parallel but offset from one another. Axial misalignment refers to the linear displacement of one shaft relative to the other along the axial direction. The unique design of barrel couplings allows them to compensate for all three types of misalignment to varying degrees, depending on the specific configuration. The convex barrels and curved troughs enable the hub to oscillate relative to the sleeve, accommodating angular misalignments typically up to ±1.5 degrees. For axial misalignment, the barrels are able to slide within the troughs, allowing for axial displacement that can range from a few millimeters to several centimeters, depending on the coupling size and design. Parallel misalignment is compensated for through a combination of the barrel’s curvature and the relative movement between the hub and sleeve, though the capacity for parallel misalignment compensation is generally more limited compared to angular and axial misalignment.

Torque transmission in barrel couplings is achieved through positive engagement between the barrels and the toothed surfaces of the hub and sleeve. When the driving shaft rotates, it imparts rotational force to the hub, which in turn pushes against the cylindrical barrels. The barrels then transfer this force to the sleeve, causing it to rotate and drive the driven shaft. This positive engagement ensures that torque is transmitted efficiently with minimal slippage, making barrel couplings suitable for applications requiring precise torque control. Unlike flexible couplings that use elastomeric elements to absorb vibrations and shocks, barrel couplings are torsionally rigid, meaning they do not deform under torque load. This torsional rigidity is advantageous in applications where precise synchronization between the driving and driven shafts is required, such as in crane hoisting mechanisms where the drum must rotate in perfect harmony with the gearbox output.

Barrel couplings are available in several distinct types, each tailored to specific application requirements based on load capacity, misalignment compensation, and operational environment. One of the most common classifications is based on flexibility, with rigid and flexible barrel couplings being the two primary categories. Rigid barrel couplings are designed for applications where shaft alignment is precise and minimal relative movement is expected. These couplings transmit torque uniformly and ensure accurate shaft synchronization but do not accommodate significant misalignment. They are typically used in applications such as electric motors and generators, where precise alignment can be maintained and high torque transfer is required.

Flexible barrel couplings, by contrast, are engineered to accommodate moderate to significant misalignments between shafts. They incorporate design features such as spherical or hinged elements that allow for greater relative movement between the hub and sleeve. These couplings are particularly useful in applications where shaft misalignment is unavoidable, such as in pump and motor drives, where thermal expansion and contraction or mounting inconsistencies can cause misalignment. Flexible barrel couplings also help absorb vibrations and mitigate the impact of mechanical shocks, reducing wear and tear on other components in the power transmission system. This vibration damping capability is critical in extending the lifespan of expensive equipment such as gearboxes and motors, making flexible barrel couplings a preferred choice in many industrial settings.

Another specialized type of barrel coupling is the elastomeric barrel coupling, which incorporates elastomeric elements (typically made from rubber or polyurethane) into the design. These elements act as a buffer between the hub and sleeve, providing enhanced vibration damping and shock absorption compared to standard flexible couplings. Elastomeric barrel couplings are also capable of accommodating minor misalignments and can help reduce operational noise, making them suitable for applications where smooth and quiet operation is a priority, such as in HVAC systems, marine reduction gears, and industrial fans. The elastomeric elements also provide a degree of torsional flexibility, which can help compensate for slight differences in shaft speeds, further protecting the connected equipment.

Low-friction barrel couplings represent another niche category, designed specifically for applications where minimal rotational resistance is critical. These couplings are typically used in high-precision machinery such as robotic systems, instrumentation devices, and specialized pump systems, where even small increases in friction can lead to performance degradation or inaccurate control. Low-friction barrel couplings achieve their performance through precision machining of components, the use of specialized lubricants, and sometimes the incorporation of self-lubricating materials. By minimizing friction, these couplings ensure efficient torque transmission and maintain the accuracy of the connected equipment, which is essential in applications such as automated manufacturing and scientific instrumentation.

The versatility of barrel couplings is reflected in their wide range of industrial applications, spanning multiple sectors where reliable power transmission and load handling are essential. One of the most prominent applications is in crane and hoisting systems, where barrel couplings play a critical role in connecting the gearbox output shaft to the cable drum. In these systems, the coupling must transmit high torque while accommodating the radial loads generated by the tension of the lifting cable. The ability of barrel couplings to handle these combined loads, along with their integrated wear indicators, makes them ideal for crane applications, where safety and operational reliability are paramount. From gantry cranes in shipping yards to overhead cranes in manufacturing facilities, barrel couplings are a staple component that ensures the smooth and safe lifting of heavy loads.

Steel production is another industry where barrel couplings are extensively used, particularly in equipment such as rolling mills, conveyors, and stackers/reclaimers. These applications involve high torque loads, harsh operating conditions (including high temperatures, dust, and vibration), and frequent misalignments due to the heavy-duty nature of the equipment. Barrel couplings are well-suited to these conditions, thanks to their robust construction, heat resistance, and ability to withstand radial and axial loads. In rolling mills, for example, barrel couplings transmit torque from the drive motors to the rolling stands, ensuring precise control of the rolling process while accommodating the misalignments that occur as the metal is deformed. The durability of barrel couplings in these environments helps minimize downtime and maintain the efficiency of steel production operations.

Winch and conveyor systems, used in industries ranging from mining to agriculture, also rely heavily on barrel couplings. Winches, which are used to pull or lift heavy loads via cables or ropes, require couplings that can transmit high torque and handle the radial loads associated with cable tension. Barrel couplings are often used in winch systems to connect the gearbox to the winch drum, providing reliable torque transmission and misalignment compensation. Conveyor systems, which transport materials across long distances, use barrel couplings to connect the drive motors to the conveyor rollers. In these applications, the coupling must accommodate the misalignments that occur due to the long length of the conveyor and the thermal expansion of components, while also transmitting the torque required to move the conveyor belt and the material load.

The energy sector, including renewable energy sources such as wind power and traditional energy sources such as nuclear and gas turbines, also utilizes barrel couplings in various applications. In wind turbines, for example, barrel couplings may be used in the pitch control systems or in the drive train, where they must transmit torque while accommodating the misalignments caused by wind-induced vibrations and thermal changes. In nuclear and gas turbine systems, barrel couplings are used in auxiliary equipment such as feedwater pumps and cooling systems, where reliability and resistance to harsh environments are critical. The ability of barrel couplings to operate reliably in these demanding applications helps ensure the safe and efficient generation of energy.

Material selection is a critical factor in the performance and durability of barrel couplings, with the choice of materials depending on the application’s operating conditions, load requirements, and environmental factors. The most common material used for the hub, sleeve, and barrels is high-strength steel, which is hardened to enhance its wear resistance and load-bearing capacity. Hardened steel is ideal for applications involving high torque and radial loads, such as crane and steel mill applications, as it can withstand the high stresses without deformation or premature wear. The hardness of the steel also helps reduce friction between the barrels and the toothed surfaces, extending the coupling’s service life.

In applications where corrosion resistance is a concern, such as marine environments or chemical processing plants, stainless steel is often used for barrel coupling components. Stainless steel offers excellent resistance to rust and corrosion, making it suitable for use in wet or corrosive environments. However, stainless steel is generally more expensive than standard carbon steel, so its use is typically reserved for applications where corrosion resistance is essential.

For specialized applications requiring lightweight components or resistance to non-corrosive chemicals, aluminum or plastic materials may be used. Aluminum barrel couplings are lighter than steel counterparts, making them suitable for applications where weight is a critical factor, such as in some aerospace or automotive applications. Plastic barrel couplings, often made from high-performance polymers such as nylon or polypropylene, are used in low-load applications such as small pumps, fans, and laboratory equipment. These materials offer good chemical resistance and are lightweight, but they have lower load-bearing capacities compared to steel or stainless steel.

The selection of lubricants for barrel couplings is equally important, as proper lubrication is essential for minimizing friction, reducing wear, and preventing component failure. The choice of lubricant depends on the operating temperature, load conditions, and environmental factors. For standard operating conditions, mineral-based greases are commonly used, as they provide good lubrication and are cost-effective. In high-temperature applications, synthetic greases are preferred, as they have a higher melting point and can maintain their lubricating properties at elevated temperatures. In applications where contamination is a concern, such as in food processing or pharmaceutical manufacturing, food-grade lubricants may be required to ensure compliance with industry regulations.

Proper maintenance is key to ensuring the long-term performance and reliability of barrel couplings, and a structured maintenance program can help minimize downtime, reduce repair costs, and extend the coupling’s service life. The first step in any maintenance program is regular inspection, which should include checking the coupling for signs of wear, damage, or leakage. The integrated wear indicator, where present, should be checked regularly to assess the condition of the barrels and toothing. If the indicator shows that wear has exceeded the recommended limit, the coupling should be replaced or repaired immediately to prevent catastrophic failure.

Lubrication maintenance is another critical aspect of barrel coupling care. The coupling should be lubricated at regular intervals, as specified by the operating conditions and the manufacturer’s recommendations. Over-lubrication can be just as harmful as under-lubrication, as it can lead to excessive heat buildup and the formation of sludge, which can impede the coupling’s operation. When lubricating the coupling, it is important to use the correct type and amount of lubricant, and to ensure that the lubrication channels are clear of debris.

Alignment checks are also essential, as improper alignment can lead to increased wear, reduced performance, and premature failure of the coupling and other components. Shaft alignment should be checked during installation and at regular intervals thereafter, particularly after any maintenance or equipment modifications. If misalignment is detected, corrective action should be taken immediately to realign the shafts, which may involve adjusting the mounting feet of the motor or gearbox, or replacing worn or damaged mounting components.

In addition to regular inspection and lubrication, periodic disassembly and cleaning may be required for barrel couplings used in harsh environments. During disassembly, the components should be inspected for signs of wear, corrosion, or damage, and any worn or damaged parts should be replaced. The coupling should be thoroughly cleaned before reassembly to remove any debris or old lubricant, and reassembled according to the manufacturer’s specifications to ensure proper operation.

Looking toward the future, the evolution of barrel coupling technology is likely to be driven by the growing demand for higher efficiency, greater load capacities, and improved sustainability in industrial operations. Advances in manufacturing technologies, such as precision machining and additive manufacturing, are expected to enable the production of barrel couplings with more complex geometries, tighter tolerances, and improved performance. Additive manufacturing, in particular, offers the potential to create custom coupling designs tailored to specific application requirements, allowing for optimized performance and reduced material waste.

The development of new materials is also expected to play a role in the future of barrel couplings. The use of advanced composites, which offer high strength-to-weight ratios and excellent corrosion resistance, may lead to the development of lightweight, high-performance couplings suitable for a wider range of applications. Additionally, the integration of smart technologies, such as sensors and IoT (Internet of Things) connectivity, may enable real-time monitoring of coupling performance, providing early warning of potential issues and allowing for predictive maintenance. This real-time monitoring capability would further enhance the reliability of barrel couplings and reduce unplanned downtime in industrial operations.

In conclusion, barrel couplings are a vital component in mechanical power transmission systems, offering a unique combination of robustness, torque-bearing capacity, and misalignment compensation. Their distinctive design, which utilizes cylindrical barrels housed within precision-machined troughs, enables them to perform reliably in a wide range of industrial applications, from crane and hoisting systems to steel production and energy generation. The selection of the appropriate barrel coupling type, material, and lubricant, combined with a structured maintenance program, is essential for ensuring optimal performance and extending the coupling’s service life. As industrial technologies continue to advance, barrel couplings are poised to evolve, incorporating new materials, manufacturing processes, and smart technologies to meet the changing demands of the global industrial landscape. Whether in heavy-duty industrial settings or precision machinery applications, barrel couplings will remain a critical link in ensuring the efficient and reliable transmission of power.

« Barrel Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/barrel-couplings.html