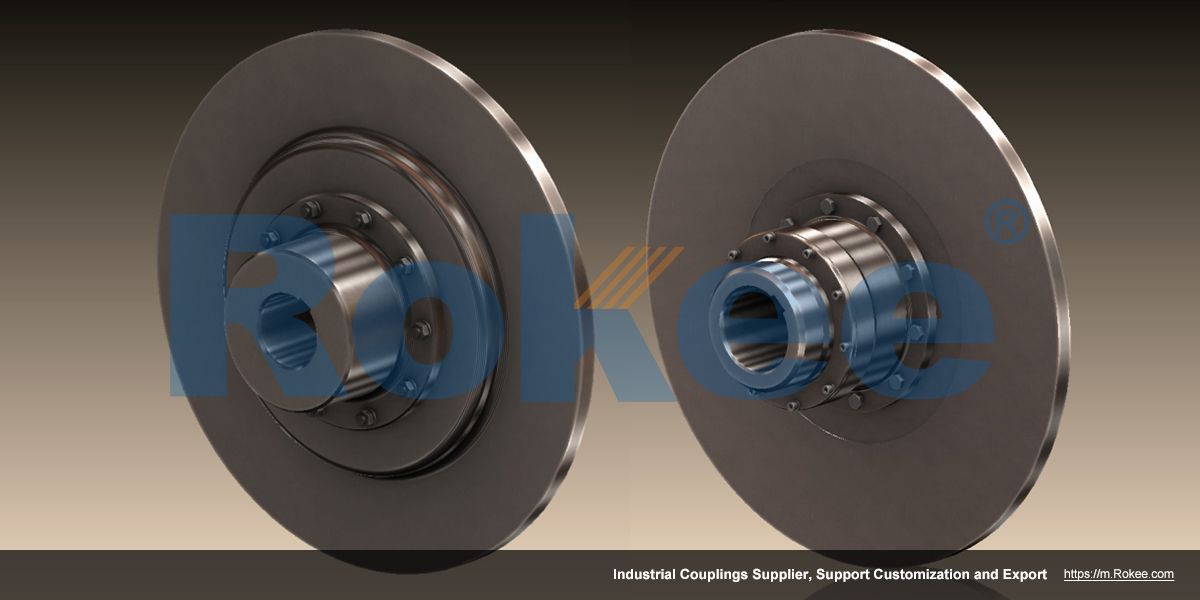

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.

| Model | Nominal Torque KN·m | Allowable Rotating Speed R/min | Shaft Hole Diameter | Shaft Hole Length | D0 | D | D2 | D4 | B | F | N** | R | C* | C1* | C2* | Quality Kg | Rotational Inertia Kg·m2 | Grease Kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1, d2, dz | |||||||||||||||||||

| Y | J1, Z1 | ||||||||||||||||||

| WGP1 | 710 | 4000 | 12,14 | 32 | - | 315 | 122 | 98 | 60 | 58 | 30 | 38 | 2 | 30 | - | - | 5.62 | 0.0078 | 0.11 |

| 16,18,19 | 42 | - | 20 | - | - | ||||||||||||||

| 20,22,24 | 52 | - | 10 | - | - | ||||||||||||||

| 25,28 | 62 | 44 | 3 | 19 | 18 | ||||||||||||||

| 30,32,35,38 | 82 | 60 | 23 | 12 | |||||||||||||||

| 40,42 | 112 | 84 | 29 | 12 | |||||||||||||||

| WGP2 | 1250 | 4000 | 22,24 | 52 | - | 315 | 150 | 118 | 77 | 68 | 30 | 38 | 2.5 | 20 | - | - | 9.62 | 0.022 | 0.12 |

| 25,28 | 62 | - | 10 | - | - | ||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 23 | 16 | ||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 29 | ||||||||||||||||

| WGP3 | 2500 | 3550 | 22,24 | 52 | - | 355 | 170 | 140 | 90 | 80 | 30 | 49 | 3 | 33 | - | - | 16.6 | 0.047 | 0.2 |

| 25,28 | 62 | - | 23 | - | - | ||||||||||||||

| 30,32,35,38 | 82 | 60 | 3 | 23 | 25 | ||||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 29 | 16 | |||||||||||||||

| 60,63 | 142 | 107 | 36 | ||||||||||||||||

| WGP4 | 4500 | 2500 | 30,32,35,38 | 82 | - | 400 450 500 | 200 | 160 | 112 | 90 | 30 | 45 | 3 | 13 | - | - | 25.3 | 0.098 | 0.28 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 29 | 17 | ||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 36 | ||||||||||||||||

| 80 | 172 | 132 | 41 | ||||||||||||||||

| WGP5 | 7100 | 2500 | 30,32,35,38 | 82 | - | 400 450 500 | 225 | 180 | 128 | 100 | 30 | 45 | 4 | 23 | - | - | 34.7 | 0.174 | 0.45 |

| 40,42,45,48,50,55,56 | 112 | 84 | 3 | 29 | 19 | ||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 36 | ||||||||||||||||

| 80,85,90 | 172 | 132 | 41 | ||||||||||||||||

| WGP6 | 10000 | 2000 | 32,35,38 | 82 | - | 400 500 560 630 | 245 | 200 | 145 | 112 | 30 | 44 | 4 | 35 | - | - | 51.3 | 0.293 | 0.65 |

| 40,42,45,48,50,55,56 | 112 | - | 5 | - | - | ||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 38 | 20 | |||||||||||||||

| 80,85,90,95 | 172 | 132 | 43 | ||||||||||||||||

| 100 | 48 | ||||||||||||||||||

| WGP7 | 14000 | 1700 | 32,35,38 | 82 | - | 400 500 560 710 | 272 | 230 | 160 | 122 | 30 | 44 | 4 | 45 | - | - | 68 | 0.53 | 0.8 |

| 40,42,45,48,50,55,56 | 112 | - | 15 | - | - | ||||||||||||||

| 60,63,65,70,71,75 | 142 | 107 | 5 | 38 | 20 | ||||||||||||||

| 80,85,90,95 | 172 | 132 | 43 | ||||||||||||||||

| 100,110 | 212 | 167 | 48 | ||||||||||||||||

| WGP8 | 20000 | 1700 | 55,56 | 112 | - | 400 500 560 710 | 290 | 245 | 170 | 136 | 30 | 44 | 5 | 29 | - | - | 79 | 0.71 | 0.95 |

| 60,63,65,70,71,75 | 142 | 107 | 5 | 38 | 34 | ||||||||||||||

| 80,85,90,95 | 172 | 132 | 43 | 20 | |||||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | ||||||||||||||||

| WGP9 | 25000 | 1600 | 65,70,71,75 | 142 | 107 | 560 630 710 800 | 315 | 265 | 190 | 140 | 30 | 58 | 5 | 5 | 38 | 38 | 106.5 | 1.05 | 1.3 |

| 80,85,90,95 | 172 | 132 | 43 | 28 | |||||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | ||||||||||||||||

| 130,140 | 252 | 202 | 53 | ||||||||||||||||

| WGP10 | 40000 | 1600 | 75 | 142 | - | 630 710 800 | 355 | 300 | 225 | 165 | 30 | 58 | 6 | 28 | - | - | 159 | 1.74 | 1.6 |

| 80,85,90,95 | 172 | 132 | 5 | 43 | 38 | ||||||||||||||

| 100,110,120,125 | 212 | 167 | 48 | 28 | |||||||||||||||

| 130,140,150 | 252 | 202 | 53 | ||||||||||||||||

| 160 | 302 | 242 | 63 | ||||||||||||||||

| WGP11 | 56000 | 1400 | 85,90,95 | 172 | - | 710 800 900 | 412 | 345 | 256 | 180 | 40 | 58 | 6 | 15 | - | - | 215 | 3.67 | 2 |

| 100,110,120,125 | 212 | 167 | 8 | 51 | 32 | ||||||||||||||

| 130,140,150 | 252 | 202 | 56 | ||||||||||||||||

| 160,170,180 | 302 | 242 | 66 | ||||||||||||||||

| WGP12 | 80000 | 1400 | 120,125 | 212 | 167 | 710 800 900 | 440 | 375 | 288 | 207 | 40 | 58 | 7 | 8 | 51 | 45 | 303 | 6.4 | 3.4 |

| 130,140,150 | 252 | 202 | 56 | 32 | |||||||||||||||

| 160,170,180 | 302 | 242 | 66 | ||||||||||||||||

| 190,200 | 352 | 282 | 76 | ||||||||||||||||

| WGP13 | 112000 | 1400 | 140,150 | 252 | 202 | 800 900 | 490 | 425 | 320 | 235 | 50 | 58 | 8 | 8 | 56 | 38 | 291 | 10.45 | 4.4 |

| 160,170,180 | 302 | 242 | 66 | 32 | |||||||||||||||

| 190,200,220 | 352 | 282 | 76 | ||||||||||||||||

| WGP14 | 160000 | 1200 | 160,170,180 | 302 | 242 | 900 1000 | 545 | 462 | 362 | 265 | 50 | 65 | 9 | 10 | 68 | 32 | 523 | 17.48 | 6.6 |

| 190,200,220 | 352 | 282 | 78 | ||||||||||||||||

| 240,250,260 | 410 | 330 | - | 10 | |||||||||||||||

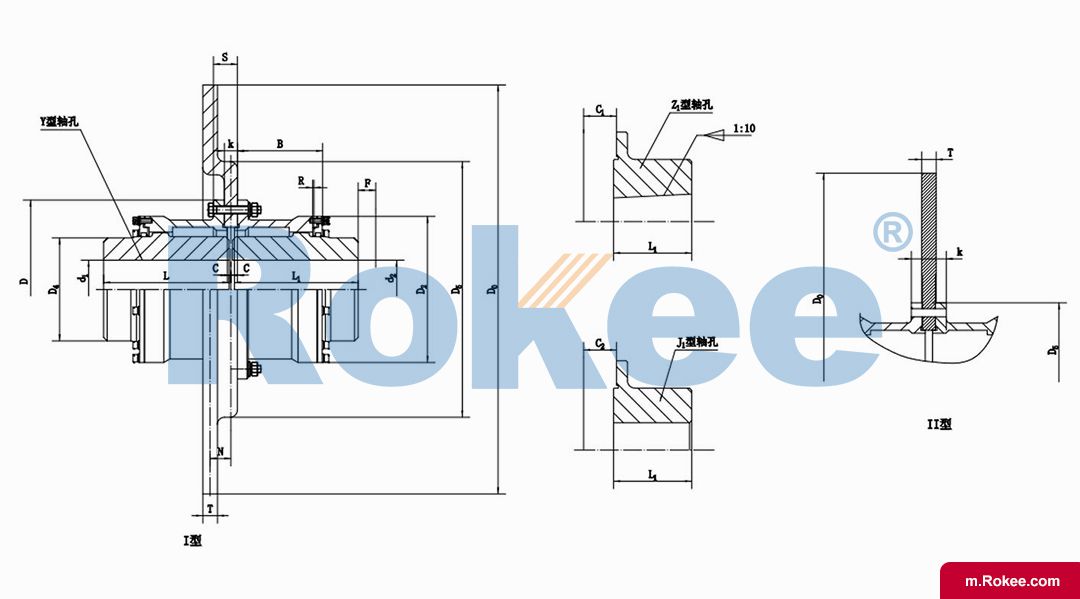

| Diameter of Brake Disc D0 | T | k | S | D5max | Quality Kg | Rotational Inertia Kg.m2 | |||

|---|---|---|---|---|---|---|---|---|---|

| I | II | I | II | I | II | ||||

| 315 | 15 | 10 | 42 | 180 | 155 | 8.5 | 6.7 | 0.116 | 0.110 |

| 355 | 15 | 10 | 54 | 200 | 175 | 11.4 | 9.9 | 0.192 | 0.178 |

| 400 | 15 | 14 | 54 | 255 | 230 | 15.2 | 12.4 | 0.320 | 0.287 |

| 450 | 15 | 16 | 54 | 305 | 280 | 19.7 | 15.6 | 0.550 | 0.462 |

| 500 | 15 | 18 | 54 | 325 | 295 | 25.0 | 20.0 | 0.830 | 0.712 |

| 560 | 15 | 18 | 54 | 350 | 320 | 30.7 | 25.6 | 1.280 | 1.127 |

| 630 | 15 | 20 | 54 | 400 | 360 | 38.8 | 33.0 | 2.060 | 1.826 |

| 710 | 15 | 20 | 54 | 480 | 450 | 46.5 | 39.4 | 3.320 | 2.912 |

| 800 | 15 | 24 | 70 | 540 | 500 | 67.8 | 52.7 | 5.870 | 4.810 |

| 900 | 15 | 24 | 70 | 600 | 560 | 86.6 | 70.3 | 9.300 | 7.852 |

| 1000 | 20 | 30 | 80 | 620 | 560 | 128.8 | 115.1 | 17.400 | 15.650 |

The WGP drum gear coupling consists of two drum shaped gear sleeves and a pair of straight tooth inner rings and other components. Among them, one of the shaft sleeves (such as the left shaft sleeve) is equipped with drum shaped teeth at the end, and the connecting sleeve fitted on the periphery of the shaft sleeve meshes with the drum shaped teeth on the shaft sleeve through its inner teeth. The end of another shaft sleeve (such as the right shaft sleeve) is equipped with a connecting flange, which is fixed to the connecting sleeve by threading bolts. In addition, a brake disc is clamped and fixed between the connecting flange and the connecting sleeve, which makes the brake disc rigidly connected to the right shaft sleeve.

The WGP coupling transmits torque through the meshing of internal and external teeth, and compensates for the relative displacement of the transmission axis by utilizing the axis swing of the drum shaped outer gear sleeve. The crown tooth structure can compensate for a relative offset angle of 1 ° 30 'between the two transmission axes, which makes the WGP drum tooth coupling more stable and reliable during the transmission process.

Product Features

High transmission efficiency: Due to the design of drum shaped teeth, the contact conditions between teeth are improved, making torque transmission more efficient.

Long service life: The contact state of the drum shaped teeth is optimized under angular displacement conditions, reducing noise and wear, thereby extending the service life of the coupling.

Strong ability to compensate for angular displacement: Compared to ordinary gear couplings, WGP drum shaped gear couplings have greater ability to compensate for angular displacement.

Stable braking performance: The rigid connection design between the brake disc and the right shaft sleeve ensures that the braking load and vibration are borne by the right shaft sleeve, without damaging the meshing performance of the drum teeth, while improving the stability of the brake disc.

WGP crown gear couplings are widely used in applications that require high torque transmission and angular displacement compensation, such as metallurgical machinery, mining machinery, heavy machinery, and papermaking industries. Especially in mechanical equipment that requires frequent start stop or precise speed control, the stability and reliability of its braking performance have been fully verified.

URL: https://m.rokee.com/drum-gear-couplings/wgp-drum-gear-coupling-with-brake-discs.html