Rokee is a chinese Claw Couplings Manufacturer, provide Claw Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Claw Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Claw Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

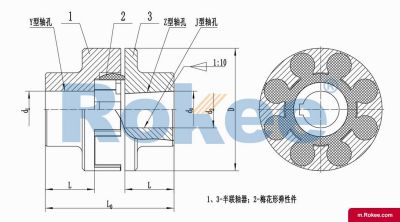

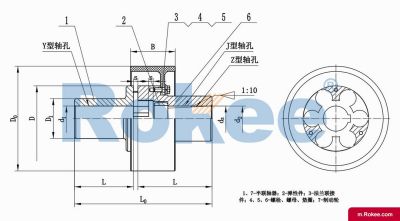

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

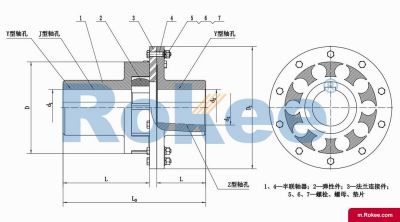

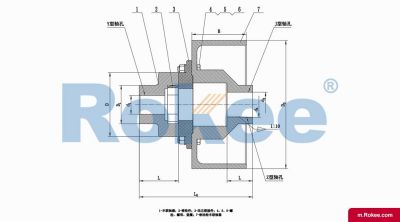

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

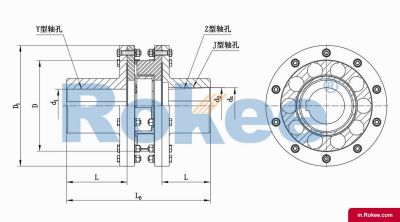

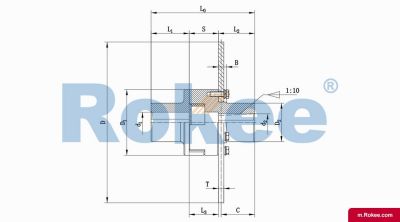

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

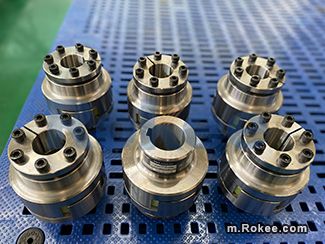

The claw coupling is mainly composed of two metal claw plates and an elastic body. Two metal claw plates are generally made of 45 steel, but in cases where load sensitivity is required, aluminum alloy or stainless steel materials may also be used. Elasticity is usually made of materials such as engineering plastics, rubber, or high-strength wear-resistant polyurethane, which have good elasticity and wear resistance, ensuring the long-term stable operation of the coupling.

The working principle of the claw type coupling is to use a plum blossom shaped elastic element placed between the two halves of the coupling claws to achieve the connection between the two halves of the coupling. When there is a relative offset between the two axes, the elastic element will undergo corresponding elastic deformation, thereby playing an automatic compensation role. This design enables the claw coupling to absorb vibrations, compensate for radial, angular, and axial deviations, while also having good vibration reduction, buffering, and electrical insulation performance.

Characteristics and advantages

Compact structure: Claw coupling has a compact structure, small radial size, light weight, and small moment of inertia, suitable for medium and high-speed applications.

No lubrication required: This coupling does not require lubrication, requires less maintenance, and can operate continuously for a long time.

Strong compensation capability: With significant axial, radial, and angular compensation capabilities, it can adapt to various complex working conditions.

High strength and wear-resistant: High strength polyurethane elastic components are wear-resistant, oil resistant, have high load-bearing capacity, long service life, and safe and reliable.

Easy installation: Claw couplings are easy to install and do not require complex disassembly operations.

Claw couplings are widely used in CNC machine tools, CNC lathes, machining centers, engraving machines, metallurgical machinery, mining machinery, petroleum machinery, chemical machinery, lifting machinery, transportation machinery, light industry machinery, textile machinery, as well as water pumps, fans and other equipment. Especially suitable for working environments with frequent starting, forward and reverse rotation, medium high speed, moderate torque, and high reliability requirements.

When installing a claw type coupling, the first thing to check is whether the two shafts of the prime mover and the working machine are concentric, whether there is packaging paper or collision damage on the surfaces of the two shafts, whether there are debris in the inner holes of the two half couplings of the coupling, and whether there are collision damage on the edges of the inner holes. If necessary, the shaft and half coupling should be cleaned thoroughly, and any scratches should be handled with a fine file. Then tighten and fix according to the prescribed tightening torque. When disassembling, the device should be completely stopped and the locking screws should be loosened in sequence.

In terms of maintenance, claw couplings generally do not require frequent repairs, but the wear of the elastic body should be checked regularly and replaced in a timely manner if necessary. Some models adopt a dual flange split design, supporting radial installation without the need for moving equipment. The elastic body can be quickly replaced, and maintenance does not require dismantling the main shaft sleeve, further reducing maintenance difficulty and cost.

« Claw Couplings » Post Date: 2023/8/30

URL: https://m.rokee.com/tags/claw-couplings.html