Rokee is a chinese Flexible Couplings Manufacturer, provide Flexible Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Flexible Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Flexible Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

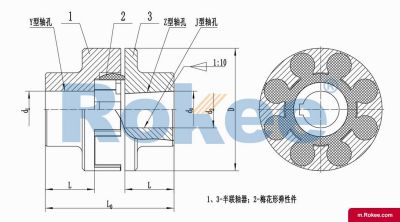

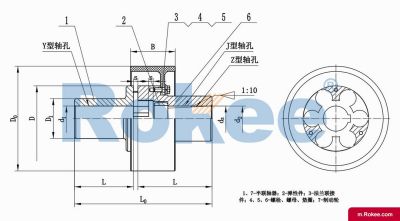

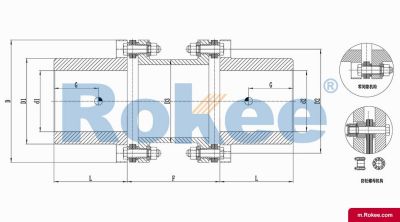

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

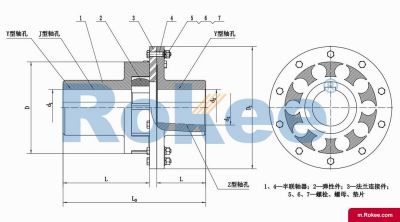

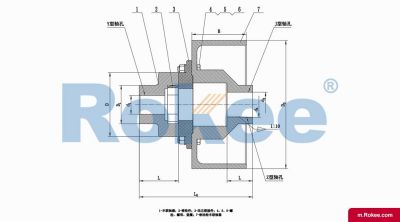

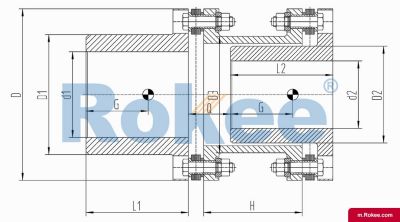

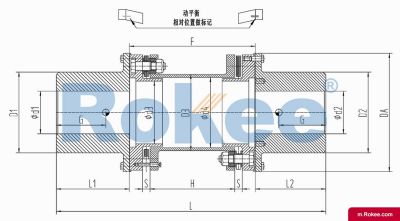

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

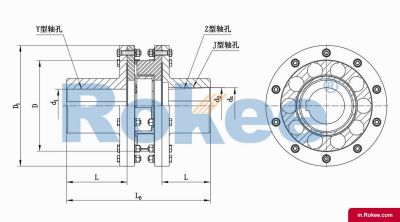

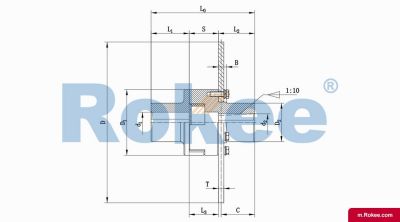

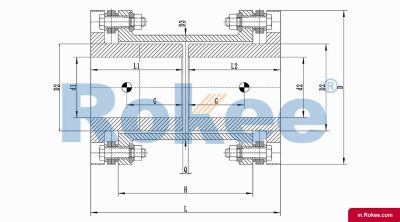

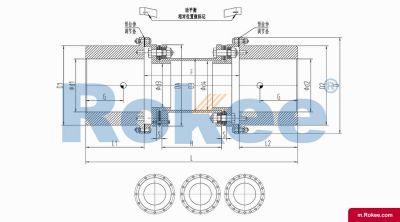

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

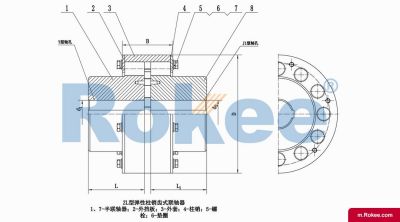

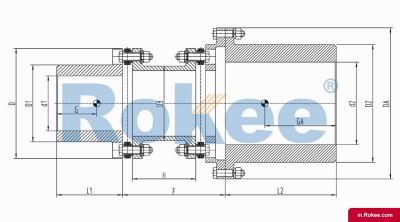

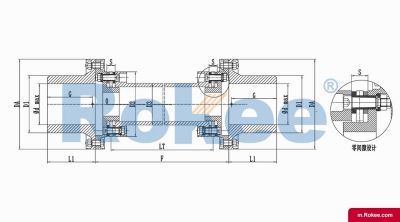

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

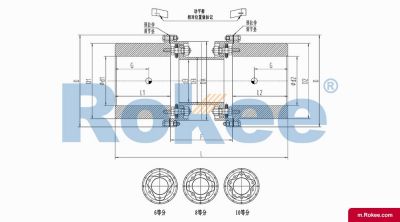

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More -

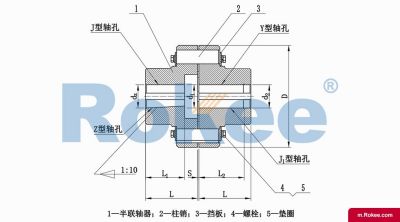

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

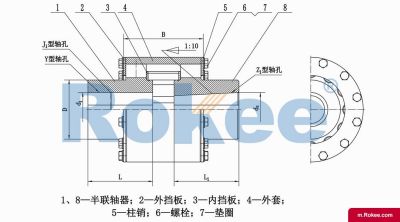

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

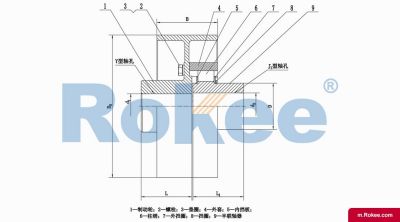

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

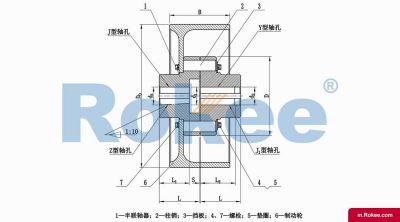

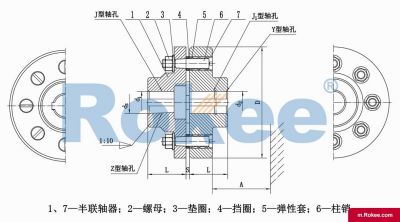

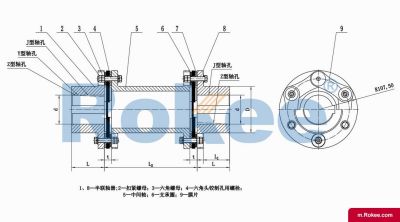

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

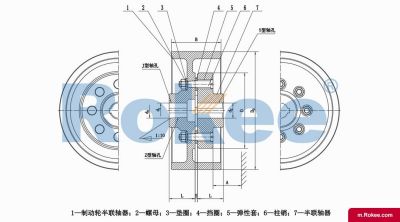

LXZ/HLL Flexible Pin Coupling With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

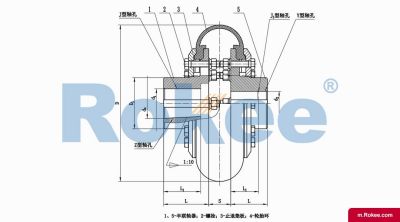

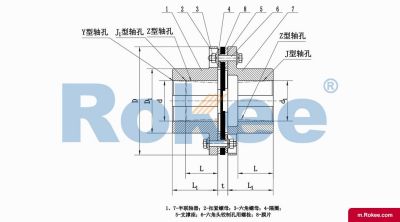

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

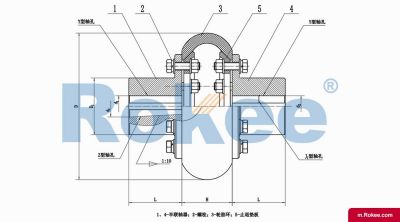

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

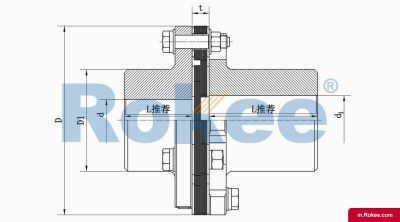

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

LLB Tyre Coupling

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More -

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

A flexible coupling is a device used to connect two shafts and allow for a certain angle and axial displacement while transmitting torque. Flexible couplings can be divided into two categories based on whether they contain elastic elements: non elastic element flexible couplings and elastic element flexible couplings.

Flexible coupling without elastic components: It achieves offset compensation through mechanical structures such as gears, chains, or cross sliders, and does not have buffering and vibration reduction capabilities.

Flexible coupling with elastic elements: relying on elastic elements such as rubber and springs to absorb vibration and adjust displacement, while also having the function of compensating for relative displacement between two axes and buffering vibration reduction.

function and characteristic

Displacement compensation capability: Flexible couplings can compensate for the angle, parallel, and axial displacement between two shafts, ensuring the stability and reliability of the transmission system.

Vibration control: Flexible couplings with elastic elements can reduce the vibration amplitude of the transmission system, especially suitable for working conditions with slight impacts.

Efficient transmission of power: Flexible couplings can efficiently transmit power while compensating for displacement, meeting the needs of various mechanical systems.

Common types and structures

Flexible coupling without elastic components

Cross slider coupling: composed of a cross slider and two connecting plates, with a simple structure and strong compensation ability, suitable for low-speed and heavy-duty applications.

Gear coupling: compensates for complex offsets using gear mesh clearance, suitable for situations requiring high-precision transmission.

Serpentine spring coupling: composed of a serpentine spring and two connecting plates, it has high strength, high precision, and is suitable for high torque transmission.Flexible coupling with elastic elements

Elastic sleeve pin coupling: absorbs impact energy and compensates for the offset between the two shafts through elastic elements (such as rubber sleeves).

Elastic column pin coupling: provides radial compensation through elastic elements (such as nylon column pins).

Application scenarios

Flexible couplings are widely used in various mechanical systems, especially in transmission systems with axial, radial, or angular offsets, where they perform well. For example, in industrial robot joints, the use of serpentine spring couplings can effectively compensate for angle and axial displacement during joint motion, ensuring the accuracy and stability of robot motion. In ship propulsion systems, the use of a cross slider coupling to connect the engine and propeller can compensate for shaft to shaft deviations in complex sea conditions, ensuring the reliability of power transmission.

Design Considerations

Material selection: Choose suitable materials according to the working environment to ensure the durability of the coupling.

Size calculation: Accurately calculate the size of the coupling to ensure its load-bearing capacity and compensation capability.

Installation and maintenance: Strictly follow the specifications for installation and maintenance to extend the service life of the coupling.

Flexible couplings, as an important mechanical transmission device, play a crucial role in mechanical design. By selecting and applying flexible couplings reasonably, the stability and reliability of mechanical systems can be ensured, and transmission efficiency and service life can be improved.

In the complex ecosystem of mechanical power transmission, flexible couplings stand as indispensable components that bridge the gap between power sources and load devices, ensuring the smooth, efficient, and reliable operation of countless industrial systems. Unlike rigid couplings, which require precise alignment between connected shafts and offer little to no tolerance for misalignment, flexible couplings are engineered to accommodate various forms of shaft deviations while transmitting torque effectively. This inherent flexibility not only protects critical machinery components from excessive stress and wear but also contributes to reduced vibration, lower noise levels, and enhanced overall system performance. From the intricate mechanisms of robotics and precision manufacturing to the heavy-duty operations of wind turbines and marine propulsion systems, flexible couplings play a pivotal role in diverse industrial sectors, adapting to varying operational conditions and performance requirements.

At its core, a flexible coupling serves three primary functions: transmitting torque from one rotating shaft to another, compensating for misalignment between the shafts, and dampening vibrations and absorbing shock loads. Torque transmission is the basic requirement, ensuring that the rotational energy generated by a power source (such as an electric motor, internal combustion engine, or turbine) is efficiently transferred to a load (such as a pump, fan, conveyor, or gearbox). The flexibility of these couplings allows them to accommodate three main types of misalignment: angular misalignment, where the shafts are not colinear but intersect at an angle; parallel (radial) misalignment, where the shafts are parallel but offset from each other; and axial misalignment, where the shafts move along their respective axes toward or away from each other. These misalignments can occur due to various factors, including installation errors, thermal expansion and contraction of machinery during operation, foundation settlement, and load-induced deformations. Without effective compensation, such misalignments would generate excessive forces on bearings, seals, and shafts, leading to premature failure and unplanned downtime.

Another critical function of flexible couplings is vibration damping and shock absorption. Mechanical systems inherently generate vibrations due to factors such as unbalanced rotating parts, electromagnetic forces in motors, and intermittent load fluctuations. These vibrations can be transmitted throughout the system, causing noise pollution, reducing the precision of manufacturing processes, and damaging sensitive components. Flexible couplings mitigate these issues by utilizing elastic elements or flexible structures that absorb vibrational energy and reduce the transmission of shocks between connected components. For example, couplings with elastomeric inserts can compress or shear under dynamic loads, dissipating vibration energy as heat, while metallic flexible elements achieve similar effects through controlled flexing. This damping capability not only improves the operational stability of the system but also enhances the working environment by reducing noise levels, making flexible couplings particularly valuable in precision engineering and indoor industrial settings.

Flexible couplings can be broadly categorized into two main types based on their flexibility mechanism: material-flexing couplings and mechanical-flexing couplings. Material-flexing couplings derive their flexibility from the deformation of a resilient material (such as rubber, polyurethane, or metal membranes) or the flexing of thin metallic components. These couplings typically do not require lubrication (with the exception of some grid couplings) and are known for their simplicity, low maintenance requirements, and effective vibration damping. One common type of material-flexing coupling is the jaw coupling, which consists of two intermeshing jaws (one attached to each shaft) and an elastomeric spider insert placed between them. Torque is transmitted through the compression of the elastomeric insert, which also accommodates angular, parallel, and axial misalignments. The elastomeric inserts are available in various materials, such as nitrile butadiene rubber (NBR), polyurethane, and Hytrel, each offering different levels of temperature resistance, chemical compatibility, and durability. Jaw couplings are widely used in general industrial applications, such as pumps, fans, compressors, and conveyors, due to their cost-effectiveness and ease of installation.

Sleeve couplings are another type of material-flexing coupling, utilizing an elastomeric insert with male splines that mate with female splines on the hubs connected to the shafts. Torque is transmitted through shear forces acting on the elastomeric insert, which can be designed as a one-piece or two-piece component. These couplings are suitable for low to medium torque applications and can accommodate moderate misalignments, making them ideal for general-purpose machinery. Tire couplings, named for their rubber or polyurethane tire-like element, are designed for high misalignment capacity and excellent shock absorption. The tire element is connected to two hubs and transmits torque through shear, allowing for easy assembly without moving the connected shafts or equipment. They are commonly used in applications requiring moderate to high-speed operation and are particularly effective in reducing the transmission of shock loads, such as in construction machinery and industrial mixers.

Metallic membrane couplings represent a high-performance subset of material-flexing couplings, utilizing thin, corrugated metal discs or diaphragms (typically made of stainless steel) to transmit torque and accommodate misalignments. Unlike elastomeric couplings, metallic membrane couplings have no backlash, offer high torsional stiffness, and are resistant to high temperatures, oils, and harsh chemical environments. The metal membranes flex to compensate for angular and axial misalignments, while maintaining precise torque transmission. These characteristics make them ideal for high-speed, high-torque, and precision applications, such as aerospace systems, marine propulsion, gas turbines, CNC machines, and servo systems. Metallic membrane couplings are also maintenance-free, as they do not require lubrication and have no wearing parts, ensuring long service life even in demanding operational conditions. Some advanced metallic membrane couplings can operate at temperatures ranging from -50°C to 280°C, with high-temperature alloy variants capable of withstanding temperatures above 600°C, making them suitable for use in extreme environments such as nuclear power plants and industrial furnaces.

Mechanical-flexing couplings, on the other hand, achieve flexibility through the rocking, rolling, or sliding of metal surfaces, rather than the deformation of resilient materials. These couplings can handle high torque and horsepower requirements and are capable of accommodating significant angular misalignments. However, they require regular lubrication to minimize wear between moving parts, with the exception of self-lubricating designs. Gear couplings are a common type of mechanical-flexing coupling, consisting of two hubs with crowned external gear teeth that mesh with internally splined flanged sleeves bolted together. The crowned teeth allow for angular and parallel misalignments (typically up to 4° to 5°) while transmitting high levels of torque. Gear couplings are known for their high torque density, meaning they can transmit large amounts of torque in a compact size, making them suitable for heavy-duty applications such as steel mills, mining equipment, and large industrial compressors. Despite their high performance, gear couplings require periodic lubrication and maintenance to ensure optimal performance and prevent premature wear of the gear teeth.

Universal joint couplings (also known as U-joints) are another type of mechanical-flexing coupling, consisting of two yokes connected by a cross-shaped pivot. They are designed to transmit power at variable angles, making them ideal for applications where the shafts are not fixed in a single plane, such as in automotive drivetrains, agricultural machinery, and industrial conveyors. Universal joints can handle large angular misalignments (up to 45°) and high torque loads, but they suffer from a phenomenon known as angular velocity variation, where the output shaft speed fluctuates slightly as the joint rotates. This issue can be mitigated by using double universal joints (two U-joints connected by an intermediate shaft), which ensure constant velocity transmission when properly aligned. Oldham couplings, a specialized type of mechanical-flexing coupling, utilize a center disc that slides between two hubs with perpendicular slots, allowing for significant parallel misalignment while maintaining constant velocity. They have no backlash and are torsionally rigid, making them suitable for precision applications such as stepper motors, encoders, robotics, and packaging machines. However, they are not suitable for angular or axial misalignments and have limited torque capacity compared to other mechanical-flexing couplings.

The selection of materials for flexible couplings is a critical factor that directly impacts their performance, durability, and suitability for specific applications. For elastomeric elements in material-flexing couplings, common materials include rubber (NBR, EPDM, neoprene), polyurethane, and Hytrel. NBR rubber offers excellent oil resistance and is suitable for general industrial applications, while EPDM rubber provides superior weather and chemical resistance, making it ideal for outdoor or harsh environment use. Polyurethane is harder than rubber and offers higher torque capacity and wear resistance, but it has lower vibration damping capabilities. Hytrel, a thermoplastic elastomer, combines the flexibility of rubber with the strength and durability of plastic, offering excellent temperature resistance and chemical compatibility. For metallic components (hubs, shafts, membranes, gear teeth), materials such as carbon steel, stainless steel, aluminum alloy, and high-temperature alloys are commonly used. Carbon steel is widely used for general-purpose couplings due to its high strength and cost-effectiveness, while stainless steel is preferred for applications requiring corrosion resistance, such as marine environments, chemical processing plants, and food processing equipment. Aluminum alloy is used for lightweight applications, such as aerospace and robotics, where reducing the coupling's rotational inertia is critical for improving system responsiveness. High-temperature alloys, such as Inconel, are used in extreme temperature environments, such as gas turbines and nuclear power plants, where standard materials would fail.

Flexible couplings find applications across a wide range of industrial sectors, each with unique requirements and operational challenges. In the automotive industry, they play a crucial role in transmitting power from the engine to the transmission and drivetrain, compensating for misalignments caused by engine vibration and thermal expansion. Flexible couplings in automotive applications also help dampen vibrations, improving ride comfort and reducing noise levels inside the vehicle. Additionally, they protect critical drivetrain components from shock loads during acceleration, deceleration, and sudden changes in terrain. In the renewable energy sector, particularly in wind turbine systems, flexible couplings are essential for connecting the rotor to the generator. Wind turbines are subject to varying wind loads, which can cause significant misalignments between the rotor and generator shafts. Flexible couplings compensate for these misalignments, ensuring smooth power transmission while minimizing stress on the gearbox and generator. They also provide overload protection, absorbing sudden torque spikes caused by gusts of wind, thereby preventing damage to critical components and reducing maintenance costs.

In the aerospace industry, flexible couplings are used in a variety of applications, including aircraft engines, auxiliary power units (APUs), and flight control systems. These applications require high precision, reliability, and resistance to extreme temperatures and pressures. Metallic membrane couplings are commonly used in aerospace systems due to their high torsional stiffness, zero backlash, and maintenance-free operation. They ensure precise torque transmission and misalignment compensation, contributing to the safe and efficient operation of aircraft. In the pharmaceutical and food processing industries, flexible couplings must meet strict hygiene standards, requiring materials that are easy to clean, corrosion-resistant, and non-toxic. Stainless steel metallic membrane couplings or elastomeric couplings with food-grade rubber inserts are preferred in these applications, as they do not require lubrication (which could contaminate products) and can withstand frequent cleaning and sterilization processes.

The industrial machinery sector, which includes pumps, fans, compressors, conveyors, and machine tools, relies heavily on flexible couplings to ensure reliable operation and reduce downtime. For example, in pump systems, flexible couplings compensate for misalignments between the motor and pump shafts, reducing wear on bearings and seals and extending the service life of the pump. In CNC machine tools, precision metallic membrane couplings are used to connect servo motors to lead screws or spindles, ensuring accurate torque transmission and positioning, which is critical for maintaining machining precision. In the oil and gas industry, flexible couplings are used in drilling rigs, compressors, and pipeline systems, where they must withstand harsh environments, including high temperatures, high pressures, and corrosive fluids. Corrosion-resistant materials, such as stainless steel and high-temperature alloys, are used in these applications to ensure long service life and reliable performance.

Looking toward the future, the development of flexible couplings is expected to be driven by several key trends, including the increasing demand for high-precision, high-speed machinery, the growth of renewable energy sources, and the adoption of smart manufacturing technologies. As industrial systems become more advanced, there will be a greater need for flexible couplings with higher torsional stiffness, lower rotational inertia, and improved misalignment compensation capabilities. This will drive the development of new materials and designs, such as advanced composite materials for elastomeric elements and optimized metallic membrane structures for enhanced performance. The renewable energy sector, particularly offshore wind energy, will also drive innovation in flexible couplings, requiring components that can withstand extreme marine environments, high torque loads, and prolonged operation with minimal maintenance.

The integration of smart technologies into flexible couplings is another emerging trend. Smart couplings equipped with sensors can monitor key performance parameters, such as temperature, vibration, torque, and misalignment, in real time. This data can be transmitted to a central monitoring system, allowing for predictive maintenance and early detection of potential issues. Predictive maintenance can significantly reduce downtime by enabling maintenance personnel to address problems before they lead to component failure, thereby improving overall system reliability and reducing maintenance costs. Additionally, the use of additive manufacturing (3D printing) in the production of flexible couplings is expected to increase, allowing for the creation of complex, customized designs that optimize performance for specific applications. Additive manufacturing also enables the production of lightweight components with reduced material waste, contributing to more sustainable and cost-effective manufacturing processes.

Despite their many advantages, flexible couplings also have certain limitations that must be considered during system design. For example, elastomeric couplings have limited temperature resistance and may degrade over time when exposed to oils, chemicals, or ultraviolet (UV) radiation. Metallic membrane couplings, while durable, are less effective at damping vibrations compared to elastomeric types and require precise initial alignment. Mechanical-flexing couplings, such as gear couplings, require regular lubrication and maintenance, which can increase operational costs. Additionally, all flexible couplings have a maximum torque capacity, and exceeding this limit can result in component failure. To overcome these limitations, ongoing research and development efforts are focused on improving material performance, optimizing design, and integrating advanced technologies to enhance the reliability, durability, and performance of flexible couplings.

In conclusion, flexible couplings are essential components in mechanical power transmission systems, providing torque transmission, misalignment compensation, and vibration damping capabilities that are critical for the reliable and efficient operation of industrial machinery. The wide variety of flexible coupling types, materials, and designs allows them to be tailored to specific applications, from general-purpose industrial machinery to high-precision aerospace systems and harsh-environment oil and gas operations. As industrial systems continue to evolve, the development of flexible couplings will focus on meeting the growing demand for higher performance, greater reliability, and smarter maintenance capabilities. By understanding the principles, types, applications, and future trends of flexible couplings, engineers and system designers can make informed decisions that optimize system performance, reduce downtime, and minimize operational costs, ensuring the continued success of industrial operations across diverse sectors.

« Flexible Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/flexible-couplings.html