Rokee is a chinese Tooth Couplings Manufacturer, provide Tooth Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Tooth Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Tooth Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

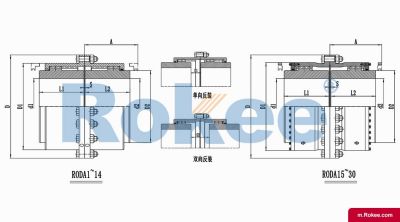

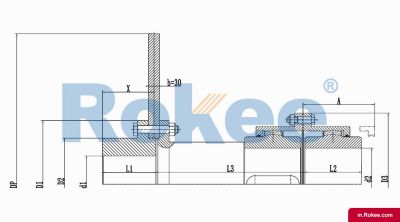

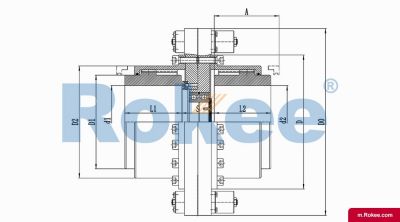

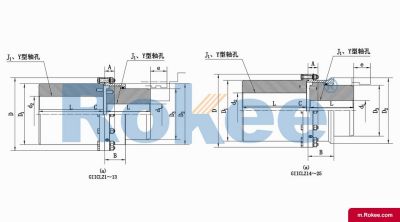

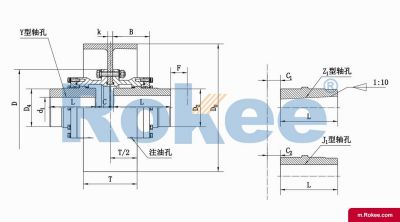

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

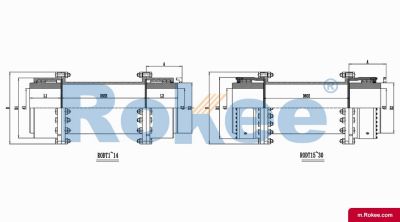

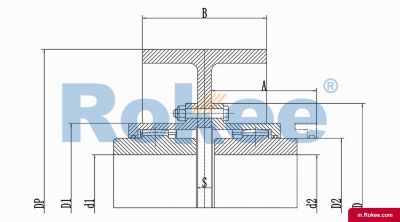

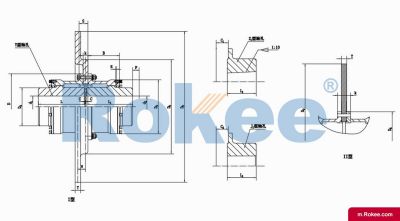

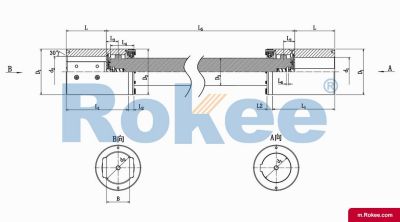

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

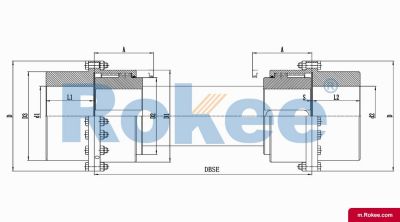

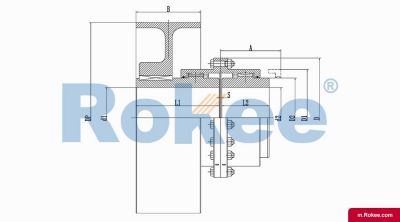

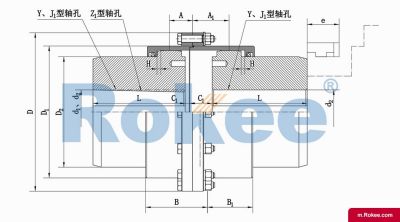

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

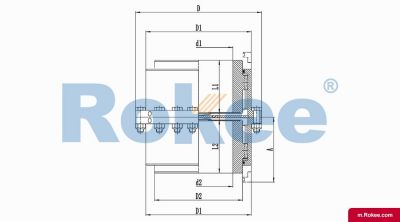

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

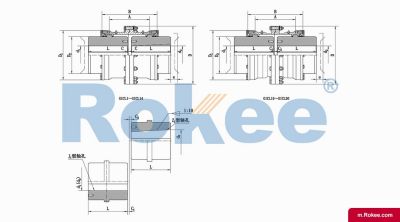

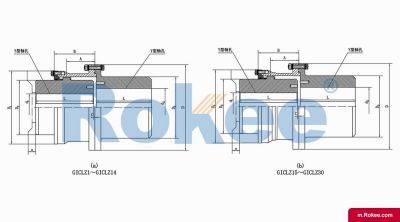

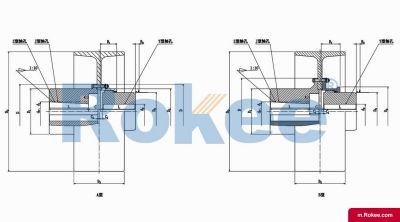

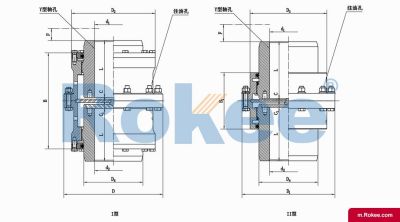

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

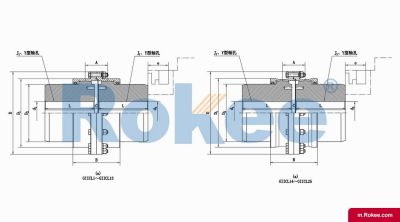

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

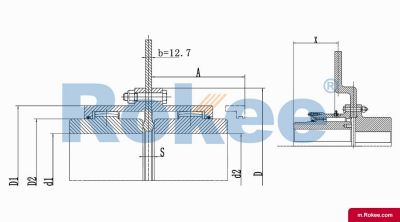

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

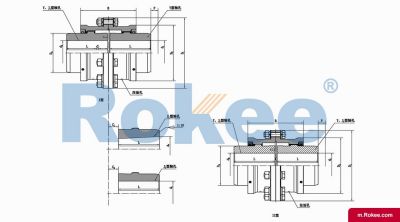

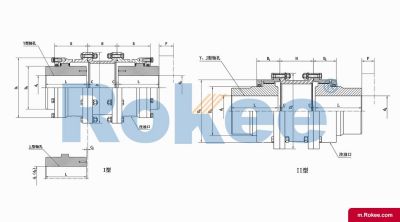

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

A tooth coupling is a movable rigid coupling composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. It utilizes the meshing of internal and external teeth to achieve the transmission of torque and rotational motion between the two halves of the coupling, and has a certain ability to compensate for the relative displacement of the two shafts. The tooth coupling is mainly composed of internal gear rings, gear shaft sleeves (external gear shaft sleeves), end caps, and sealing devices. Among them, small-sized tooth coupling end caps and inner gear rings usually form an integral structure. tooth couplings can be divided into straight tooth couplings, drum tooth couplings, and special drum tooth couplings according to the different axial tooth profiles of their outer gear shaft sleeves. tooth couplings also have advantages such as small radial size and wide range of operating speeds. High precision and dynamically balanced tooth couplings can also be used for high-speed transmission, such as shaft transmission in gas turbines.

When the tooth coupling is in operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear sleeve, which in turn drives the driven shaft to rotate. Due to the meshing of the inner and outer teeth, when there is relative displacement between the two shafts, the tooth surfaces of the inner and outer teeth will periodically slide axially relative to each other. This sliding allows the coupling to adapt to certain angular, radial, and axial displacement compensation, thereby maintaining stable transmission performance. tooth couplings are widely used in metallurgy, mining, lifting and transportation, petroleum, chemical, general machinery, and power industries. Especially under heavy loads, large impacts, or conditions where the shaft system is prone to displacement, the tooth coupling ensures stable operation of the equipment due to its high load-bearing capacity and good displacement compensation capability.

In terms of maintenance, tooth couplings need to maintain good lubrication and sealing conditions to avoid tooth wear and power loss. At the same time, the meshing condition of the coupling teeth should be regularly checked to ensure that its contact area and meshing accuracy meet the specified requirements. If it is necessary to remove the ring gear, special tools must be used and not knocked to avoid damaging the shaft or coupling components.

When selecting a tooth coupling, the selection should be based on the actual working conditions and requirements of the transmission system to ensure that the performance of the coupling meets the usage requirements. Installation should be carried out according to the prescribed installation methods and steps to ensure the installation accuracy and alignment requirements of the coupling. During use, the coupling should be regularly inspected and maintained to promptly identify and address potential problems and malfunctions.

In the intricate network of industrial power transmission systems, tooth couplings stand out as critical components that bridge the gap between driving and driven shafts, ensuring efficient torque transfer while accommodating various forms of misalignment. These mechanical devices, characterized by their gear meshing mechanism, have become indispensable in numerous heavy-duty and precision applications, ranging from metallurgical processing to marine propulsion. Unlike other coupling types that rely on elastic elements or friction, tooth couplings leverage the robust engagement of internal and external gear teeth to transmit high levels of torque, making them particularly suitable for low-speed, high-load operating conditions.

At the core of a tooth coupling lies a simple yet effective structural configuration, primarily consisting of four key components: external gear sleeves, internal gear rings, sealing devices, and connecting fasteners. The external gear sleeves, often referred to as flange half-couplings, feature external teeth machined on their circumference, while the internal gear rings are annular components with matching internal teeth that engage with the external gear sleeves. This meshing relationship forms the basis for torque transmission, as rotational force from the driving shaft is transferred through the external gear teeth to the internal gear ring, which then imparts motion to the driven shaft. Sealing devices, typically in the form of O-rings or gaskets, play a crucial role in preventing lubricant leakage and blocking the ingress of external contaminants such as dust, moisture, and industrial debris, which can significantly degrade coupling performance. Connecting fasteners, including bolts and nuts, secure the coupling components to the shaft ends, ensuring structural integrity during operation. In smaller-sized tooth couplings, the end cover and internal gear ring are often integrated into a single unit to minimize radial dimensions, making them suitable for applications with limited installation space.

Tooth couplings are classified into three primary types based on the axial tooth profile of the external gear sleeve: straight tooth, crowned tooth, and special crowned tooth designs. Straight tooth tooth couplings feature external gear sleeves with axial tooth blanks machined into straight lines or arcs, with both the pitch circle and root circle appearing as straight lines when viewed in cross-section. The meshing form of straight tooth couplings is similar to that of standard involute cylindrical gears, relying on increased tooth backlash to compensate for minor shaft misalignments. However, their misalignment compensation capacity is relatively limited, and they are prone to end load concentration, which can accelerate tooth wear and reduce service life. As a result, straight tooth tooth couplings have gradually been phased out in most modern industrial applications, replaced by more advanced designs. Crowned tooth tooth couplings, by contrast, represent the most widely used type, with the tooth tips of the external gear sleeve machined into an arc shape, giving the tooth blank a spherical profile that forms a drum-like shape in the central plane. This innovative design distributes contact stress more evenly across the tooth surface, eliminating the end load concentration issue associated with straight tooth couplings. Crowned tooth couplings can accommodate angular misalignments of up to 6 degrees, though the recommended operating range is 1.5 to 2.5 degrees to ensure optimal performance and longevity. Additionally, their torque transmission capacity is 15% to 30% higher than that of straight tooth counterparts, making them ideal for heavy-duty applications. Special crowned tooth couplings are modified versions of standard crowned tooth designs, incorporating features such as telescopic functions or enhanced lubrication structures to meet the demands of extreme operating conditions, such as high-temperature environments, corrosive media, or applications requiring frequent axial adjustments.

The performance and durability of tooth couplings are heavily dependent on the selection of appropriate materials and the implementation of rigorous manufacturing and heat treatment processes. The most commonly used materials for tooth coupling components include high-strength alloy steels, high-quality carbon steels, and special alloy steels, each selected based on the specific load requirements and operating conditions of the application. High-strength alloy steels, such as 42CrMo, are preferred for high-performance applications due to their exceptional comprehensive mechanical properties, including high strength, excellent toughness, good hardenability, and no obvious temper brittleness. These steels undergo quenching and tempering followed by surface hardening treatment, resulting in a surface hardness of 50 to 55 HRC, which provides superior wear resistance while maintaining sufficient core toughness to withstand impact loads. High-quality carbon steels, such as forged 45-grade steel, are a cost-effective alternative for medium-load applications. These steels are subjected to quenching and tempering to improve their mechanical properties, achieving a hardness range of 220 to 250 HB. For extreme operating conditions, such as high-temperature environments or applications involving corrosive media, special alloy steels like 34Cr2Ni2Mo are utilized. These steels undergo carburizing and quenching treatment, resulting in a surface hardness of 58 to 62 HRC and a core hardness of 30 to 35 HRC, balancing exceptional wear resistance with core toughness. The manufacturing process of tooth couplings involves precision machining operations, including hobbing, shaping, and grinding, to ensure accurate tooth profiles and tight dimensional tolerances. The tooth surfaces are often subjected to additional treatments such as grinding or polishing to reduce friction and improve meshing efficiency.

The working principle of tooth couplings revolves around two core functions: torque transmission and misalignment compensation. Torque transmission occurs through the meshing of internal and external gear teeth. When the driving shaft rotates, torque is transmitted to the external gear sleeve via a key connection. The external gear teeth then engage with the internal gear ring, transferring the torque to the internal gear ring, which in turn drives the driven shaft. This meshing mechanism ensures efficient power transfer with minimal energy loss, with transmission efficiency typically ranging from 98% to 99%. Misalignment compensation is achieved through a combination of tooth backlash, tooth profile design, and the loose fit between the hub and sleeve. Backlash, the clearance between the gear teeth, provides space for lubricant and allows for relative movement between the teeth, enabling the coupling to accommodate minor radial, axial, and angular misalignments. In crowned tooth couplings, the spherical drum-shaped tooth profile further enhances misalignment compensation by broadening the contact area between the teeth during operation, reducing contact stress and preventing tooth binding. When relative displacement occurs between the two shafts, the tooth surfaces of the internal and external gears slide axially relative to each other periodically, a motion that allows the coupling to adapt to shaft misalignments without generating excessive additional loads or vibrations. This ability to compensate for misalignments is particularly critical in industrial applications, as misalignments can arise from a variety of factors, including temperature variations, bearing wear, foundation settlement, and installation errors.

Tooth couplings are widely employed across a diverse range of industrial sectors, owing to their high load-bearing capacity, excellent misalignment compensation, compact structure, and reliable performance. In the metallurgical industry, they are used in the main drive systems of rolling mills, continuous casting equipment, and heating furnace conveyor rollers, where they must withstand large impact loads and accommodate the thermal expansion and contraction of shafts. Crowned tooth couplings are the preferred choice in these applications due to their superior torque transmission and misalignment compensation capabilities. The mining and construction machinery sector relies on tooth couplings for power transmission in equipment such as crushers, ball mills, and belt conveyors, which operate in harsh environments characterized by high levels of dust and vibration. In these applications, tooth couplings are equipped with enhanced sealing devices to prevent contamination and ensure reliable operation. The lifting and transportation industry, including bridge cranes and port machinery, utilizes tooth couplings in hoisting mechanisms to connect reducer output shafts with reels, requiring high reliability and periodic lubrication to maintain performance. In the petrochemical industry, tooth couplings are used in compressors, centrifugal pumps, and reaction kettles, where they must compensate for shaft displacements caused by pipeline thermal deformation and resist corrosion from chemical media. Special alloy steels or stainless steel materials are often used in these applications to enhance corrosion resistance. The marine and power generation industries also rely on tooth couplings for high-speed shaft connections, such as in gas turbine generator sets and diesel engine propulsion systems. These applications require precise dynamic balancing to minimize vibrations and ensure smooth operation at high rotational speeds, with transmission efficiency reaching up to 99.7% and low noise levels.

Proper installation and alignment are critical to the performance and service life of tooth couplings. Before installation, it is essential to disconnect the system from all power sources to ensure safety. The coupling components and shaft ends should be thoroughly cleaned to remove any protective coatings, lubricants, or contaminants that could affect the fit or performance. The finish bore of the coupling hub must be machined within strict dimensional limits, typically adhering to tolerance classes such as H7 or JS9, to ensure a proper fit with the shaft. Face run-out and concentricity must also be maintained within specified limits, with maximum allowable values of 0.04 mm for outside diameters between 10 and 180 mm, 0.08 mm for diameters between 180 and 400 mm, and 0.1 mm for diameters between 400 and 630 mm. During installation, the hubs should be mounted on their respective shafts with the correct gap maintained between them, as specified by the coupling design. Laser alignment tools are recommended for achieving precise coaxiality and horizontal alignment, as excessive misalignment beyond the coupling's compensation range can lead to local tooth contact, additional bending moments, and axial forces, which may result in tooth breakage or axial displacement of the gear ring. Once installed, the connecting bolts should be tightened to the specified torque to ensure a secure connection, with spring washers used to prevent loosening during operation.

Regular maintenance and proper lubrication are essential to extend the service life of tooth couplings and ensure reliable operation. Lubrication plays a critical role in reducing friction between the meshing teeth, minimizing wear, and dissipating heat generated during operation. The selection of an appropriate lubricant is dependent on the operating conditions, with high-viscosity lubricants recommended for high-load applications and high-temperature-resistant lubricants for elevated temperature environments. Insufficient lubrication or the use of inferior lubricants can lead to dry friction between the teeth, resulting in accelerated wear, gluing, or pitting of the tooth surfaces. The lubricant should be replaced periodically, with the frequency determined by the operating conditions and the manufacturer's recommendations. Sealing devices should be inspected regularly to ensure they are intact and functioning properly, as damaged seals can lead to lubricant leakage and contamination. Periodic inspections should also include checking for tooth wear, bolt tightness, and any signs of abnormal vibration or noise. Tooth wear, if not addressed promptly, can increase the meshing gap, leading to increased transmission impact and potential coupling failure. Bolt preload failure, such as loose or broken bolts, can also result in catastrophic coupling failure, so regular torque checks are essential. In the event of excessive wear or damage to coupling components, they should be replaced promptly to avoid further damage to the transmission system.

Despite their numerous advantages, tooth couplings are not without limitations. Unlike some modern coupling types such as diaphragm couplings, tooth couplings require regular lubrication and maintenance, which can increase operational costs and downtime. The sliding friction between the meshing teeth can also generate noise and wear over time, particularly in applications with high rotational speeds or frequent start-stop cycles. Additionally, tooth couplings are generally heavier than other coupling types, which can be a disadvantage in applications where weight is a critical factor. However, their high torque transmission capacity, excellent misalignment compensation, and reliability in heavy-duty applications make them irreplaceable in many industrial scenarios. When compared to diaphragm couplings, which offer zero-backlash transmission and require no lubrication, tooth couplings are more suitable for applications requiring ultra-high torque transmission, while diaphragm couplings are preferred for high-speed, precision, or maintenance-free applications. The selection between the two depends on the specific requirements of the application, including load capacity, speed, misalignment, and maintenance availability.

In conclusion, tooth couplings are essential components in modern industrial power transmission systems, offering a unique combination of high torque transmission capacity, excellent misalignment compensation, and structural compactness. Their design, which leverages the meshing of internal and external gear teeth, enables them to withstand the rigorous demands of heavy-duty applications across a wide range of industries, from metallurgy and mining to marine and power generation. The selection of appropriate materials and heat treatment processes ensures their durability and performance in various operating conditions, while proper installation, alignment, and maintenance practices are critical to maximizing their service life and reliability. Although they require regular maintenance and are not suitable for all applications, tooth couplings remain a preferred choice for low-speed, high-load applications where reliability and torque transmission efficiency are paramount. As industrial machinery continues to evolve, advancements in material science and manufacturing technology are likely to further improve the performance and durability of tooth couplings, ensuring their continued relevance in the global industrial landscape.

« Tooth Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/tooth-couplings.html