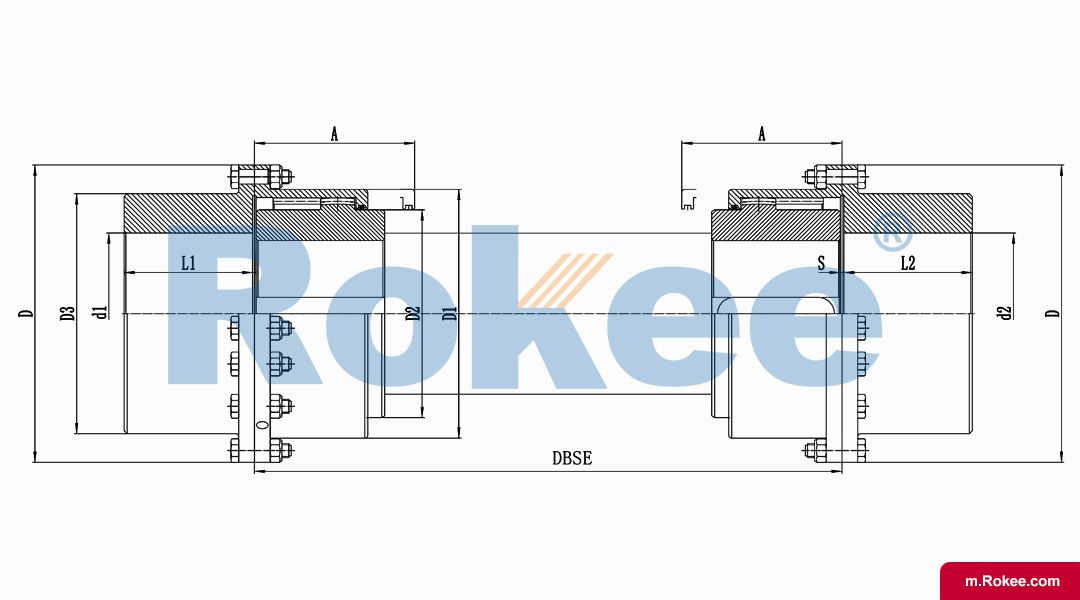

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.

| Model | Rated Torque | Maximum Torque | Maximum Speed | Basic Size | Weight | Weight of The Connecting Shaft (/100mm) | Rotational Inertia | Rotational Inertia of The Connecting Shaft (/100mm) | Grease Usage | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nm | Nm | 1/min | D | D1 | D2 | D3 | d1-d2 | L1-L2 | S | A | Kg | Kg | J(Kgm²) | J(Kgm²) | Kg | |

| RODX01 | 1900 | 3800 | 6000 | 110 | 82 | 68 | 82 | 14-56 | 43 | 3 | 53 | 24 | 2.2 | 0.018 | 0.0009 | 0.03 |

| RODX02 | 3000 | 5940 | 4700 | 140 | 104 | 85 | 105 | 17-70 | 50 | 3 | 65 | 38 | 2.8 | 0.047 | 0.0019 | 0.06 |

| RODX03 | 6200 | 12200 | 4400 | 170 | 127 | 106 | 130 | 20-90 | 62 | 3 | 80 | 62 | 4.5 | 0.117 | 0.0038 | 0.09 |

| RODX04 | 9300 | 18400 | 4000 | 210 | 155 | 132 | 155 | 26-105 | 76 | 5 | 95 | 104 | 6.5 | 0.29 | 0.009 | 0.12 |

| RODX05 | 15400 | 31000 | 3920 | 235 | 182 | 150 | 178 | 30-120 | 90 | 5 | 110 | 138 | 8.6 | 0.55 | 0.012 | 0.3 |

| RODX06 | 25300 | 49600 | 3850 | 270 | 210 | 175 | 210 | 35-142 | 105 | 6 | 125 | 202 | 13.5 | 1.13 | 0.025 | 0.4 |

| RODX07 | 38600 | 76400 | 3300 | 310 | 248 | 206 | 248 | 70-168 | 120 | 6 | 140 | 289 | 16.6 | 2.22 | 0.056 | 0.6 |

| RODX08 | 48800 | 96500 | 2900 | 338 | 275 | 235 | 275 | 85-190 | 135 | 8 | 155 | 370 | 22.3 | 3.42 | 0.084 | 0.8 |

| RODX09 | 75300 | 147800 | 2650 | 378 | 306 | 252 | 308 | 95-216 | 150 | 8 | 180 | 480 | 26.2 | 6.1 | 0.122 | 1.4 |

| RODX10 | 93000 | 181400 | 2300 | 400 | 330 | 274 | 335 | 105-230 | 175 | 8 | 205 | 592 | 32 | 8.94 | 0.172 | 2.5 |

| RODX11 | 166100 | 327200 | 2100 | 445 | 365 | 305 | 360 | 120-252 | 190 | 8 | 218 | 730 | 36.8 | 12.25 | 0.278 | 3.0 |

| RODX12 | 226000 | 447000 | 1800 | 508 | 425 | 355 | 415 | 130-290 | 220 | 10 | 252 | 1048 | 54 | 25.04 | 0.522 | 4.5 |

| RODX13 | 242000 | 480000 | 1550 | 540 | 465 | 368 | 430 | 140-292 | 250 | 16 | 300 | 1985 | 62 | 33.05 | 0.622 | 3.0 |

| RODX14 | 275000 | 543000 | 1420 | 580 | 500 | 405 | 465 | 160-350 | 270 | 16 | 320 | 2460 | 68.5 | 50.5 | 0.902 | 3.6 |

| RODX15 | 352000 | 696000 | 1300 | 648 | 546 | 450 | 510 | 170-380 | 290 | 16 | 340 | 3070 | 85 | 78.2 | 1.335 | 4.8 |

| RODX16 | 440000 | 880000 | 1200 | 685 | 582 | 486 | 550 | 200-410 | 325 | 20 | 370 | 3700 | 95.2 | 107.5 | 1.711 | 5.0 |

| RODX17 | 561000 | 1122000 | 1100 | 760 | 642 | 520 | 600 | 220-450 | 245 | 20 | 400 | 4255 | 105.8 | 150.2 | 2.159 | 9.0 |

| RODX18 | 726000 | 1452000 | 1050 | 800 | 684 | 555 | 640 | 245-480 | 265 | 20 | 420 | 5003 | 125.3 | 201 | 3.03 | 9.8 |

| RODX19 | 858000 | 1716000 | 990 | 840 | 720 | 590 | 690 | 275-520 | 400 | 20 | 450 | 5998 | 152.5 | 291.2 | 4.162 | 11.5 |

| RODX20 | 1100000 | 2200000 | 930 | 920 | 760 | 640 | 742 | 300-560 | 410 | 25 | 490 | 7078 | 173.6 | 414.8 | 5.813 | 11.5 |

| RODX21 | 1320000 | 2640000 | 870 | 990 | 844 | 704 | 800 | 325-600 | 430 | 25 | 520 | 8600 | 203.9 | 588.8 | 8.335 | 14.5 |

| RODX22 | 1760000 | 3520000 | 820 | 1040 | 895 | 744 | 865 | 350-650 | 470 | 25 | 550 | 10003 | 241.5 | 809.4 | 11.345 | 23.0 |

| RODX23 | 1980000 | 3960000 | 770 | 1142 | 970 | 810 | 905 | 375-680 | 500 | 30 | 600 | 11942 | 264.5 | 1091.5 | 13.61 | 23.0 |

| RODX24 | 2090000 | 4180000 | 730 | 1185 | 1015 | 835 | 950 | 400-710 | 520 | 30 | 630 | 13162 | 284.8 | 1327 | 16.22 | 30.0 |

| RODX25 | 2310000 | 4620000 | 680 | 1230 | 1060 | 870 | 1035 | 425-770 | 540 | 30 | 650 | 15720 | 322.6 | 1768.3 | 19.92 | 36.0 |

| RODX26 | 2860000 | 5720000 | 650 | 1280 | 1130 | 928 | 1080 | 450-810 | 570 | 30 | 680 | 17220 | 376.5 | 2252.5 | 28.02 | 38.0 |

| RODX27 | 4180000 | 8360000 | 580 | 1390 | 1240 | 1020 | 1200 | 475-900 | 600 | 30 | 725 | 20960 | 435 | 3315.6 | 36.55 | 46.0 |

| RODX28 | 5962000 | 11924000 | 540 | 1550 | 1375 | 1130 | 1355 | 500-900 | 670 | 35 | 800 | 28990 | 562.2 | 5988.4 | 60.42 | 57.0 |

| RODX29 | 7975000 | 15950000 | 480 | 1700 | 1560 | 1280 | 1500 | 525-1000 | 740 | 35 | 890 | 33506 | 695.6 | 7586.6 | 95.88 | 75.0 |

| RODX30 | 9515000 | 19030000 | 400 | 1860 | 1685 | 1430 | 1650 | 575-1200 | 800 | 35 | 980 | 36460 | 832.5 | 9981.3 | 132.5 | 115.0 |

The drum gear coupling with an intermediate shaft belongs to a type of rigid flexible coupling, which connects two horizontal coaxial transmission shafts through the intermediate shaft and has the performance of compensating for the relative offset of the two shafts. According to specific models and structural characteristics, drum toothed couplings with intermediate shafts can be further subdivided into various types, such as GIICL type, GIICLZ type, etc.

Working principle:

The drum tooth coupling with an intermediate shaft allows for certain radial, axial, and angular displacements between the two shafts through its special gear structure, thereby achieving effective compensation for shaft transmission.

When the two axes are relatively offset, the drum shaped tooth surface can maintain good contact, avoid stress concentration and tooth surface wear, thereby improving transmission efficiency and extending service life.

Characteristics:

Compact structure: The drum toothed coupling with an intermediate shaft adopts a drum toothed design, making the structure more compact and occupying less space.

High load-bearing capacity: Due to its special tooth structure, the drum shaped gear coupling has a large load-bearing capacity and is suitable for heavy load conditions.

High transmission efficiency: The drum shaped tooth surface can maintain good lubrication and contact state, reduce friction and wear, thereby improving transmission efficiency.

Low noise: Due to the optimization of the tooth structure and the improvement of lubrication effect, the drum shaped gear coupling with an intermediate shaft produces lower noise during operation.

Long maintenance cycle: Due to its excellent structural design and material selection, the drum shaped gear coupling has high durability and reliability, and a long maintenance cycle.

Drum teeth couplings with intermediate shafts are widely used in shaft transmission of various machinery such as metallurgy, mining, lifting and transportation, petroleum, chemical, and general machinery. Especially under low-speed and heavy-duty conditions, its superior performance has been fully utilized.

Selection:

When selecting, it is necessary to choose the appropriate coupling model and specifications based on the specific requirements and working conditions of the transmission system.

Factors to consider include transmission torque, shaft diameter, rotational speed, installation space, and working environment temperature.

Installation:

The installation of crown gear couplings with intermediate shafts needs to follow certain specifications and steps.

During the installation process, it is necessary to ensure that the axis alignment of the two shafts is within the specified range to avoid additional dynamic loads and vibrations caused by installation errors.

At the same time, attention should be paid to the lubrication and sealing of the coupling to ensure its long-term stable operation.

In order to ensure the long-term stable operation of drum gear couplings with intermediate shafts, regular maintenance and upkeep are required. Specific measures include:

Regularly check the wear of the coupling teeth and replace severely worn components in a timely manner.

Keep the coupling clean and lubricated to prevent dust and impurities from entering the tooth surface and exacerbating wear.

Regularly check whether the fasteners of the coupling are loose or damaged, and tighten or replace them in a timely manner.

Drum gear coupling with intermediate shaft is a mechanical transmission component with superior performance, compact structure, and high load-bearing capacity. In terms of selection, installation, maintenance, and upkeep, certain standards and steps need to be followed to ensure long-term stable operation and optimal performance.

URL: https://m.rokee.com/drum-gear-couplings/rodx-drum-gear-coupling-with-intermediate-shaft.html