The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.

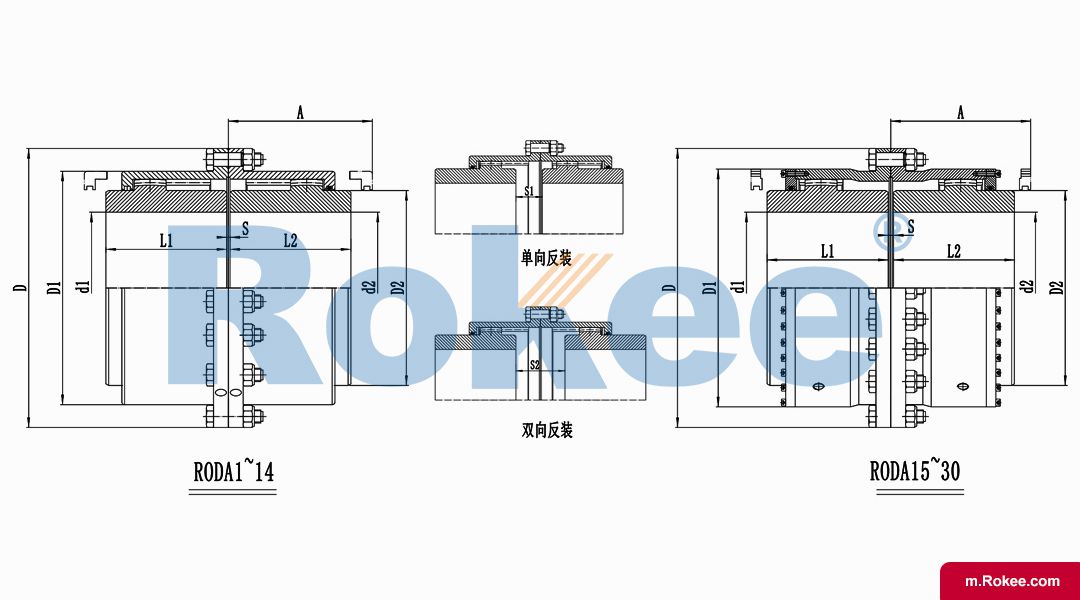

| Model | Rated Torque | Maximum Torque | Maximum Rotating Speed | Basic Size | Weight | Rotational Inertia(4) | Torsional Stiffness(4) | Grease | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nm | Nm | 1/min | D | D1 | D2 | d1-d2 (2) | L1-L2 | S | S1 | S2 | A | Kg | J(Kgm²) | MNm/rad | Kg | |

| RODA01 | 1900 | 3800 | 8800 | 110 | 82 | 68 | 14-50 | 43 | 3 | 5 | 7 | 56 | 4 | 0.005 | 2.51 | 0.03 |

| RODA02 | 3000 | 5940 | 7200 | 140 | 104 | 85 | 17-62 | 50 | 3 | 8 | 13 | 62 | 8 | 0.016 | 5.79 | 0.06 |

| RODA03 | 6200 | 12200 | 6200 | 170 | 127 | 106 | 20-80 | 62 | 3 | 14 | 25 | 75 | 14 | 0.040 | 8.76 | 0.09 |

| RODA04 | 9300 | 18400 | 5300 | 210 | 155 | 132 | 26-98 | 76 | 5 | 12 | 19 | 90 | 26 | 0.11 | 16.46 | 0.12 |

| RODA05 | 15400 | 31000 | 5000 | 235 | 182 | 150 | 30-112 | 90 | 5 | 24 | 43 | 105 | 39 | 0.20 | 21.86 | 0.3 |

| RODA06 | 25300 | 49600 | 4800 | 270 | 210 | 175 | 35-133 | 105 | 6 | 27 | 48 | 120 | 58 | 0.45 | 34.87 | 0.4 |

| RODA07 | 38600 | 76400 | 4100 | 310 | 248 | 206 | 70-158 | 120 | 6 | 32 | 58 | 135 | 91 | 0.88 | 60.06 | 0.6 |

| RODA08 | 48800 | 96500 | 3800 | 338 | 275 | 235 | 85-174 | 135 | 8 | 37 | 66 | 158 | 115 | 1.33 | 69.56 | 0.8 |

| RODA09 | 75300 | 147800 | 3400 | 378 | 306 | 252 | 95-192 | 150 | 8 | 50 | 92 | 180 | 165 | 2.48 | 113 | 1.4 |

| RODA10 | 93000 | 181400 | 3200 | 400 | 330 | 274 | 105-210 | 175 | 8 | 52 | 96 | 200 | 211 | 3.59 | 119 | 2.5 |

| RODA11 | 166100 | 327200 | 2900 | 445 | 365 | 305 | 120-232 | 190 | 8 | 58 | 108 | 214 | 260 | 5.00 | 140 | 3.0 |

| RODA12 | 226000 | 447000 | 2500 | 508 | 425 | 355 | 130-276 | 220 | 10 | 72 | 134 | 245 | 411 | 10.39 | 216 | 4.5 |

| RODA13 | 242000 | 480000 | 2300 | 540 | 465 | 368 | 140-282 | 250 | 16 | 96 | 176 | 295 | 527 | 14.94 | 118 | 3.0 |

| RODA14 | 275000 | 543000 | 2100 | 580 | 500 | 405 | 160-312 | 270 | 16 | 106 | 196 | 315 | 676 | 22.93 | 274 | 3.6 |

| RODA15 | 352000 | 696000 | 1900 | 648 | 546 | 450 | 170-345 | 290 | 16 | 126 | 236 | 335 | 884 | 36.84 | 387 | 4.8 |

| RODA16 | 440000 | 880000 | 1800 | 685 | 582 | 486 | 190-372 | 325 | 20 | 150 | 280 | 365 | 1105 | 53.16 | 434 | 5.0 |

| RODA17 | 561000 | 1122000 | 1700 | 760 | 642 | 520 | 220-390 | 245 | 20 | 149 | 278 | 395 | 1379 | 79.63 | 637 | 9.0 |

| RODA18 | 726000 | 1452000 | 1500 | 800 | 684 | 555 | 245-425 | 265 | 20 | 166 | 312 | 415 | 1667 | 110 | 817 | 9.8 |

| RODA19 | 858000 | 1716000 | 1400 | 840 | 720 | 590 | 275-465 | 400 | 20 | 180 | 340 | 445 | 2043 | 153 | 966 | 11.5 |

| RODA20 | 1100000 | 2200000 | 1300 | 920 | 760 | 640 | 300-505 | 410 | 25 | 176 | 327 | 485 | 2452 | 217 | 1.180 | 11.5 |

| RODA21 | 1320000 | 2640000 | 1100 | 990 | 844 | 704 | 325-555 | 430 | 25 | 185 | 345 | 515 | 3035 | 313 | 1.533 | 14.5 |

| RODA22 | 1760000 | 3520000 | 950 | 1040 | 895 | 744 | 350-595 | 470 | 25 | 215 | 405 | 545 | 3720 | 434 | 1.827 | 23.0 |

| RODA23 | 1980000 | 3960000 | 900 | 1142 | 970 | 810 | 375-625 | 500 | 30 | 228 | 425 | 595 | 4648 | 633 | 2.117 | 23.0 |

| RODA24 | 2090000 | 4180000 | 850 | 1185 | 1015 | 835 | 400-660 | 520 | 30 | 226 | 422 | 620 | 5152 | 765 | 2.383 | 30.0 |

| RODA25 | 2310000 | 4620000 | 800 | 1230 | 1060 | 870 | 425-690 | 540 | 30 | 238 | 446 | 640 | 5954 | 990 | 2.991 | 36.0 |

| RODA26 | 2860000 | 5720000 | 750 | 1280 | 1130 | 928 | 450-735 | 570 | 30 | 260 | 490 | 670 | 6956 | 1.277 | 3.361 | 38.0 |

| RODA27 | 4180000 | 8360000 | 700 | 1390 | 1240 | 1020 | 475-800 | 600 | 30 | 250 | 470 | 715 | 9036 | 1.980 | 4.557 | 46.0 |

| RODA28 | 5962000 | 11924000 | 660 | 1550 | 1375 | 1130 | 500-900 | 670 | 35 | 275 | 515 | 790 | 13330 | 3.663 | 7.743 | 57.0 |

| RODA29 | 7975000 | 15950000 | 600 | 1700 | 1560 | 1280 | 525-1000 | 740 | 35 | 275 | 515 | 880 | 17975 | 5.766 | 9.391 | 75.0 |

| RODA30 | 9515000 | 19030000 | 560 | 1860 | 1685 | 1430 | 550-1100 | 800 | 35 | 300 | 565 | 970 | 23150 | 8.683 | 10.967 | 115.0 |

The Basic Drum Gear Coupling is mainly composed of an inner gear ring, an outer gear shaft sleeve, an end cover, and a sealing device. Its key feature is that the tooth tip of the outer gear shaft sleeve is made into a drum shape, and the tooth surface is in a circular arc shape. This special design makes its meshing with the inner gear ring smoother and has good compensation ability.

During operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear shaft sleeve, which in turn drives the driven shaft to rotate. Due to the presence of drum shaped teeth, when there is relative displacement between the two shafts, the contact point between the tooth surface of the drum shaped teeth and the tooth surface of the inner ring gear will change, allowing the coupling to compensate for angular, radial, and axial displacement within a certain range. This displacement compensation capability enables the drum shaped gear coupling to maintain stable transmission performance under complex working conditions.

Performance advantages

High torque transmission capability: The tooth profile design of the drum shaped gear coupling is reasonable, with a large contact area on the tooth surface, which can withstand large torque and is particularly suitable for heavy-duty transmission applications.

Good displacement compensation capability: Its structural characteristics enable it to effectively compensate for angular displacement, radial displacement, and axial displacement between two shafts, reduce additional loads caused by misalignment of the shaft system, and improve the reliability and service life of the equipment.

Smooth operation and low noise: The meshing process of the drum shaped teeth is smooth, and compared to other couplings, the noise generated during operation is lower, making it suitable for work environments with strict noise requirements.

Easy installation and maintenance: Its structure is relatively simple, and there is no strict requirement for the alignment of the two shafts during installation. The sealing device is easy to replace, and the maintenance of internal components is also relatively convenient.

Basic Drum Gear Couplings are widely used in multiple industrial fields due to their excellent performance, including but not limited to:

Metallurgical industry: used in large equipment such as rolling mills and blast furnaces to connect motors and reducers, reducers and working machines, etc., to meet their heavy-duty and high impact working conditions.

Mining machinery, such as crushers, ball mills, and other equipment, work in harsh environments and are prone to shaft displacement. Drum shaped gear couplings, with their excellent displacement compensation capabilities and high reliability, ensure the stable operation of the equipment.

Petrochemical industry: Used in equipment such as pumps and compressors to transmit power, its corrosion resistance and stable transmission performance ensure the continuity and safety of chemical production.

Power industry: widely used in equipment such as steam turbine generators and fans, providing reliable power transmission for power production.

URL: https://m.rokee.com/drum-gear-couplings/roda-basic-drum-gear-coupling.html