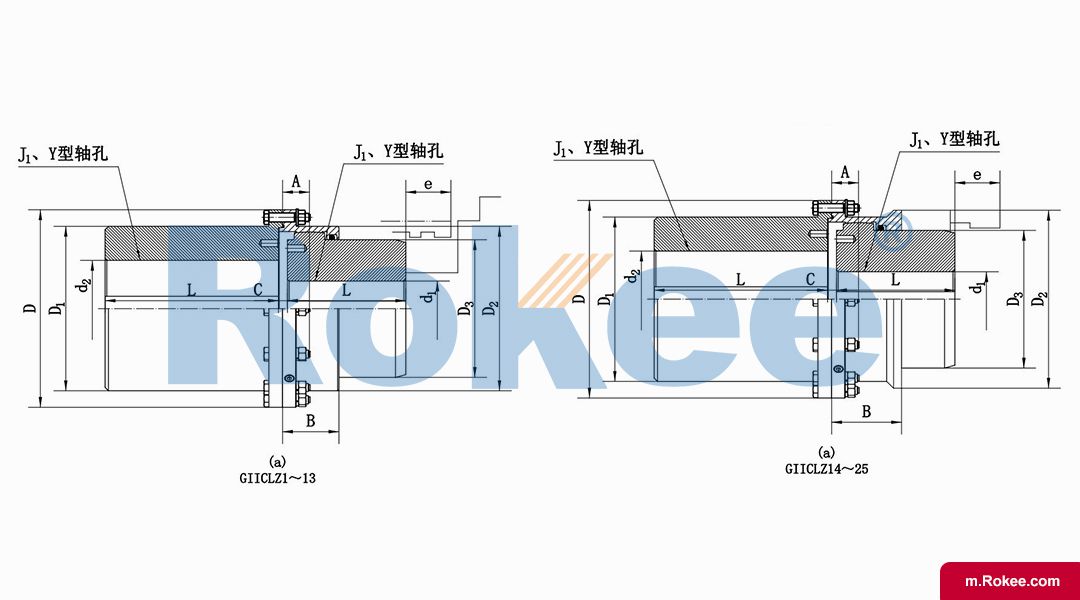

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.

| Model | Rated Torque | Allowable Rotating Speed | Shaft Hole Diameter | Shaft Hole Length L | D | D1 | D2 | D3 | C | H | A | B | e | Rotational Inertia | Quality | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y型 | J1型 | |||||||||||||||

| kN·m | rpm | d1、d2 | mm | kg·m² | kg | |||||||||||

| GIICLZ1 | 0.4 | 4000 | 16,18,19 | 42 | — | 103 | 71 | 71 | 50 | 8 | 2 | 18 | 38 | 38 | 0.004 | 3.5 |

| 20,22,24 | 52 | 38 | 0.00375 | 3.3 | ||||||||||||

| 25,28 | 62 | 44 | 0.004 | 3.5 | ||||||||||||

| 30,32,35,38* | 82 | 60 | 0.005 | 4.1 | ||||||||||||

| 40*,42*,45*,48*,50* | 112 | 84 | 0.007 | 5.7 | ||||||||||||

| GIICLZ2 | 0.71 | 4000 | 20,22,24 | 52 | — | 115 | 83 | 83 | 60 | 8 | 2 | 21 | 44 | 42 | 0.00675 | 5.3 |

| 25,28 | 62 | 44 | 0.00625 | 4.8 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 0.007 | 5.7 | ||||||||||||

| 40,42,45,48*,50*,55*,56* | 112 | 84 | 0.008 | 7.2 | ||||||||||||

| 60* | 142 | 107 | 0.01 | 9.2 | ||||||||||||

| GIICLZ3 | 1.12 | 4000 | 22,24 | 52 | — | 127 | 95 | 95 | 75 | 8 | 2 | 22 | 45 | 42 | 0.009 | 3.8 |

| 25,28 | 62 | 44 | 0.011 | 7.8 | ||||||||||||

| 30,32,35,38 | 82 | 60 | 0.011 | 7.6 | ||||||||||||

| 40,42,45,48,50,55,56 | 112 | 84 | 0.01325 | 9.8 | ||||||||||||

| 60*,63*,65*,70* | 142 | 107 | 0.01675 | 12.5 | ||||||||||||

| GIICLZ4 | 1.8 | 4000 | 38 | 82 | 60 | 149 | 116 | 116 | 90 | 8 | 2 | 24.5 | 49 | 42 | 0.02125 | 10.5 |

| 40,42,45,48,50,55,56 | 112 | 84 | 0.0255 | 13.5 | ||||||||||||

| 60,63,65,70*,71*,75* | 142 | 107 | 0.039 | 16.5 | ||||||||||||

| 80* | 172 | 132 | 0.04875 | 19.4 | ||||||||||||

| GIICLZ5 | 3.15 | 4000 | 40,42,45,48,50,55,56 | 112 | 84 | 167 | 134 | 134 | 105 | 10 | 2.5 | 27.5 | 54 | 42 | 0.044 | 18.1 |

| 60,63,65,70,71,75 | 142 | 107 | 0.05175 | 23.1 | ||||||||||||

| 80*,85*,90* | 172 | 132 | 0.0625 | 28.5 | ||||||||||||

| GIICLZ6 | 5.00 | 4000 | 45,48,50,55,56 | 112 | 84 | 187 | 153 | 153 | 125 | 10 | 2.5 | 28 | 55 | 42 | 0.075 | 23.9 |

| 60,63,65,70,71,75 | 142 | 107 | 0.089 | 29.3 | ||||||||||||

| 80,85,90,95* | 172 | 132 | 0.10425 | 35.4 | ||||||||||||

| 100*,(105)* | 212 | 167 | 0.1065 | 36.2 | ||||||||||||

| GIICLZ7 | 7.1 | 3750 | 50,55,56 | 112 | 84 | 204 | 170 | 170 | 140 | 10 | 2.5 | 30 | 59 | 42 | 0.1145 | 29.6 |

| 60,63,65,70,71,75 | 142 | 107 | 0.1335 | 36.3 | ||||||||||||

| 80,85,90,95 | 172 | 132 | 0.157 | 43.8 | ||||||||||||

| 100,(105),110*,(115)* | 212 | 167 | 0.1898 | 54.3 | ||||||||||||

| GIICLZ8 | 10.0 | 3300 | 55,56 | 112 | 84 | 230 | 186 | 186 | 155 | 12 | 3 | 33.5 | 71 | 47 | 0.184 | 37.8 |

| 60,63,65,70,71,75 | 142 | 107 | 0.215 | 46.1 | ||||||||||||

| 80,85,90,95 | 172 | 132 | 0.249 | 54.9 | ||||||||||||

| 100,110,(115),120*,125* | 212 | 167 | 0.297 | 67.4 | ||||||||||||

| GIICLZ9 | 16.0 | 3000 | 60,63,65,70,71,75 | 142 | 107 | 256 | 212 | 212 | 180 | 12 | 3 | 34.5 | 73 | 47 | 0.358 | 60 |

| 80,85,90,95 | 172 | 132 | 0.415 | 71.8 | ||||||||||||

| 100,110,120,125 | 212 | 167 | 0.499 | 88 | ||||||||||||

| 130,(135),140*,150* | 252 | 202 | 0.575 | 104.4 | ||||||||||||

| GIICLZ10 | 22.4 | 2650 | 65,70,71,75 | 142 | 107 | 287 | 239 | 239 | 200 | 14 | 3.5 | 39 | 82 | 47 | 0.58 | 76.1 |

| 80,85,90,95 | 172 | 132 | 0.6725 | 91.1 | ||||||||||||

| 100,110,120,125 | 212 | 167 | 0.8025 | 111.5 | ||||||||||||

| 130,140,150 | 252 | 202 | 0.935 | 133.5 | ||||||||||||

| GIICLZ11 | 35.5 | 2350 | 110,120,125 | 212 | 167 | 325 | 250 | 276 | 235 | 14 | 3.5 | 40.5 | 85 | 47 | 1.223 | 137 |

| 130,140,150 | 252 | 202 | 1.41 | 162.4 | ||||||||||||

| 160,170,(175) | 302 | 242 | 1.625 | 193 | ||||||||||||

| GIICLZ12 | 50 | 2100 | 130,140,150 | 252 | 202 | 362 | 286 | 313 | 270 | 16 | 4 | 44.5 | 95 | 49 | 2.39 | 212.8 |

| 160,170,180 | 302 | 242 | 2.763 | 268 | ||||||||||||

| 190,200 | 352 | 282 | 3.093 | 290 | ||||||||||||

| GIICLZ13 | 71 | 1850 | 150 | 252 | 202 | 412 | 322 | 350 | 300 | 18 | 4.5 | 49 | 104 | 49 | 3.93 | 272.3 |

| 160,170,180,(185) | 302 | 242 | 4.535 | 320 | ||||||||||||

| 190,200,220,(225) | 352 | 282 | 6.34 | 370 | ||||||||||||

| GIICLZ14 | 112 | 1650 | 170,180,(185) | 302 | 242 | 462 | 420 | 335 | — | 22 | 5.5 | 86 | 148 | 63 | 6.9 | 389 |

| 190,200,220 | 352 | 282 | 7.675 | 438 | ||||||||||||

| 240,250 | 410 | 330 | 8.6 | 509 | ||||||||||||

| GIICLZ15 | 180 | 1500 | 190,200,220 | 352 | 282 | 512 | 470 | 380 | — | 22 | 5.5 | 91 | 158 | 63 | 12.425 | 566 |

| 240,250,260 | 410 | 330 | 13.975 | 650 | ||||||||||||

| 280,(285) | 470 | 380 | 15.575 | 740 | ||||||||||||

| GIICLZ16 | 250 | 1300 | 220 | 352 | 282 | 580 | 522 | 430 | — | 28 | 7 | 104.5 | 177 | 67 | 21.2 | 751 |

| 240,250,260 | 410 | 330 | 23.125 | 857 | ||||||||||||

| 280,300,320 | 470 | 380 | 26.35 | 974 | ||||||||||||

| GIICLZ17 | 355 | 1200 | 250,260 | 410 | 330 | 644 | 582 | 490 | — | 28 | 7 | 99 | 182 | 67 | 38.825 | 1110 |

| 280,(290),300,320 | 470 | 380 | 43.25 | 1255 | ||||||||||||

| 340,360,(365) | 550 | 450 | 49.5 | 1465 | ||||||||||||

| GIICLZ18 | 500 | 1050 | 280,(295),300,320 | 470 | 380 | 726 | 658 | 540 | — | 28 | 8 | 111 | 215 | 75 | 69.5 | 1580 |

| 340,360,380 | 550 | 450 | 78.75 | 1830 | ||||||||||||

| 400 | 650 | 540 | 90.5 | 2160 | ||||||||||||

| GIICLZ19 | 710 | 950 | 300,320 | 470 | 380 | 818 | 748 | 630 | — | 32 | 9 | 116 | 220 | 75 | 122.5 | 2115 |

| 340,(350),360,380,(390) | 550 | 450 | 139.5 | 2457 | ||||||||||||

| 400,420,440,450,460 | 650 | 540 | 161.25 | 2892 | ||||||||||||

| (470) | ||||||||||||||||

| GIICLZ20 | 1000 | 800 | 360,380,(390) | 550 | 450 | 928 | 838 | 720 | — | 32 | 10.5 | 123.5 | 235 | 75 | 240 | 3223 |

| 400,420,440,450,460 | 650 | 540 | 277.25 | 3793 | ||||||||||||

| 480,500 | ||||||||||||||||

| 530,(540) | 800 | 680 | 335 | 4680 | ||||||||||||

| GIICLZ21 | 1400 | 750 | 400,420,440,450,460 | 650 | 540 | 1022 | 928 | 810 | — | 40 | 11.5 | 127.5 | 245 | 75 | 435 | 4780 |

| 480,500 | ||||||||||||||||

| 530,560,600 | 800 | 680 | 527.75 | 5905 | ||||||||||||

| GIICLZ22 | 1800 | 650 | 450,460,480,500 | 650 | 540 | 1134 | 1036 | 915 | — | 40 | 13 | 131 | 255 | 75 | 701.25 | 6069 |

| 530,560,600,630 | 800 | 680 | 852.25 | 7504 | ||||||||||||

| 670,(680) | 900 | 780 | ||||||||||||||

| GIICLZ23 | 2500 | 600 | 530,560,600,630 | 800 | 680 | 1282 | 1178 | 1030 | — | 50 | 14.5 | 149.5 | 290 | 80 | 1415.75 | 9633 |

| 670,(700),710,750,(770) | 900 | 780 | 1638.75 | 11133 | ||||||||||||

| GIICLZ24 | 3550 | 550 | 560,600,630 | 800 | 680 | 1428 | 1322 | 1175 | — | 50 | 16.5 | 158.5 | 305 | 80 | 2330.5 | 12460 |

| 670,710,750 | 900 | 780 | 2682.75 | 14465 | ||||||||||||

| 800,850 | 1000 | 880 | 2976.25 | 16110 | ||||||||||||

| GIICLZ25 | 4500 | 460 | 670,(700),710,750 | 900 | 780 | 1644 | 1538 | 1390 | — | 50 | 19 | 162.5 | 310 | 80 | 5174.25 | 19837 |

| 800,850 | 1000 | 880 | 5836.5 | 22381 | ||||||||||||

| 900,950 | — | 980 | 6413 | 24765 | ||||||||||||

| 1000,(1040) | — | 1100 | 7198.25 | 27797 | ||||||||||||

The GIICLZ drum gear coupling is an efficient mechanical transmission component. The GIICLZ teeth coupling consists of an inner gear ring with the same number of teeth and a flange half coupling with outer teeth. The outer teeth are made into a spherical shape, which allows the coupling to have a larger tooth side clearance, allowing for larger angular displacement, improving tooth contact conditions, enhancing torque transmission ability, and extending service life. This coupling is mainly used to connect horizontal coaxial transmission shaft systems and has the performance of compensating for the relative offset of the two shafts in a certain angular direction.

Main Features

Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the drum shaped gear coupling is on average 15% to 20% higher than that of the spur gear coupling.

Large angular displacement compensation: Due to the drum shaped tooth design of the outer teeth, the coupling can avoid angular contact between the inner and outer teeth during operation, allowing for a certain degree of angular displacement between the two axis lines, thereby improving the flexibility and stability of the transmission.

Compact structure: GIICLZ crown gear coupling has the advantages of small radial size and small turning radius, making its structure more compact and suitable for transmission systems with limited space.

High transmission efficiency: The transmission efficiency of this coupling can reach 0.99, reducing energy loss and improving transmission efficiency.

Low noise: Compared to other types of couplings, GIICLZ drum toothed couplings produce lower noise during transmission, which is beneficial for improving the working environment.

GIICLZ gear type coupling is particularly suitable for shaft transmission under low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. Meanwhile, it can also be used for shaft transmission in various types of machinery such as petroleum, chemical, and general machinery. However, due to its structural characteristics, this coupling is not suitable for high-speed, high-precision shaft transmission, as well as frequent starting and variable forward and reverse working conditions.

GIICLZ drum tooth coupling has a variety of models, such as GIICLZ1, GIICLZ2, GIICLZ3, etc., to meet the needs of different transmission systems. Its main parameters include nominal torque, allowable speed, shaft hole diameter, shaft hole length, etc. Specific parameters can be selected according to the actual requirements of the transmission system.

To ensure the normal operation and prolong the service life of GIICLZ coupling, regular maintenance and upkeep are required. Mainly includes checking the wear, lubrication, and sealing status of the coupling. If serious wear or poor sealing is found, it should be replaced or repaired in a timely manner.

GIICLZ drum toothed gear coupling has a wide range of application prospects in shaft transmission under low-speed and heavy-duty conditions due to its strong load-bearing capacity, large angular displacement compensation, compact structure, high transmission efficiency, and low noise.

URL: https://m.rokee.com/drum-gear-couplings/giiclz-drum-gear-coupling-with-intermediate-shaft.html