Rokee is a chinese Stainless Steel Jaw Couplings Manufacturer, provide Stainless Steel Jaw Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Stainless Steel Jaw Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Stainless Steel Jaw Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

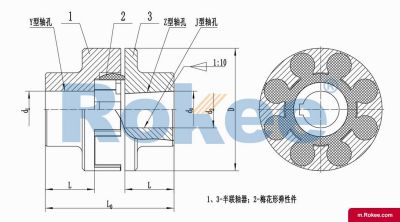

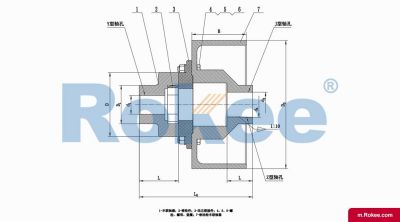

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

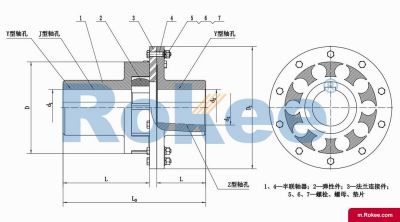

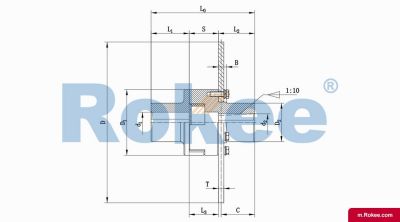

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

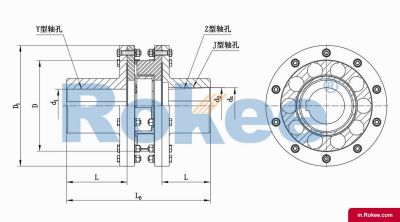

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

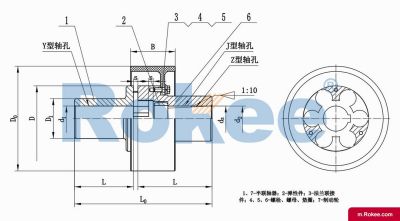

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More

Stainless steel jaw couplings as a special material flexible coupling, occupy an important position in the field of mechanical transmission.

Claw coupling (also known as plum blossom coupling) mainly consists of three parts: two metal half coupling discs with protruding claws and an elastic element. The standard model usually uses 45 steel as the claw plate material, while in corrosive environments or special load requirements, stainless steel material is used.

Stainless steel claw discs have three significant advantages:

Excellent corrosion resistance: can resist harsh environmental erosion such as moisture, acid and alkali, and extend the service life of equipment

Higher strength characteristics: Compared to ordinary steel, stainless steel provides better mechanical strength while maintaining toughness

Health and safety standards: meet the hygiene requirements of industries such as food and medicine, and avoid pollution risks

The intermediate elastomer is usually made of polyurethane or engineering rubber, providing vibration absorption and deviation compensation functions. The elastomer is designed in the shape of plum petals (commonly 4-8 petals) and achieves flexible transmission through compression deformation. Its lifespan can usually reach 10 years.

Application Fields

Food and pharmaceuticals: filling equipment, packaging machinery

Marine engineering: ship pumps, deck machinery

Chemical industry: pumping system for corrosive media

Precision manufacturing: CNC machine tools, semiconductor equipment

Stainless steel jaw couplings demonstrate irreplaceable value under special working conditions through their unique material advantages and structural design. Proper selection and use can significantly improve system reliability and reduce full lifecycle costs, making it an important component of modern industrial transmission systems.

« Stainless Steel Jaw Couplings » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/stainless-steel-jaw-couplings.html