LZ Pin Gear Coupling is the basic form of this series of couplings.

| Model | Nominal Torque N ·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1、d2 | Shaft Hole Length L Y型 | D mm | D1 mm | B mm | S mm | Rotational Inertia Kg ·m² | Weight kg | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | |||||||||||

| Long Series | Short Series | ||||||||||

| LZ1 | 112 | 5000 | 12,14 | 32 | 27 | 78 | 40 | 42 | 2.5 | 0.001 | 1.53 |

| 16,18,19 | 42 | 30 | 1.60 | ||||||||

| 20,22,24 | 52 | 38 | 1.67 | ||||||||

| LZ2 | 250 | 5000 | 16,18,19 | 42 | 30 | 90 | 50 | 50 | 2.5 | 0.002 | 2.70 |

| 20,22,24 | 52 | 38 | 2.76 | ||||||||

| 25,28 | 62 | 44 | 0.003 | 2.79 | |||||||

| 30,32 | 82 | 60 | 3.00 | ||||||||

| LZ3 | 630 | 4500 | 25,28 | 62 | 44 | 118 | 65 | 70 | 3 | 0.011 | 6.49 |

| 30,32,35,38 | 82 | 60 | 7.05 | ||||||||

| 40,42 | 112 | 84 | 0.012 | 7.31 | |||||||

| LZ4 | 1800 | 4200 | 40,42,45,48,50,55 | 112 | 84 | 158 | 90 | 90 | 4 | 0.044 | 16.20 |

| 60 | 142 | 107 | 0.045 | 15.25 | |||||||

| LZ5 | 4500 | 4000 | 50,55 | 112 | 84 | 192 | 120 | 90 | 4 | 0.100 | 24.82 |

| 60,63,65,70,75 | 142 | 107 | 0.107 | 27.02 | |||||||

| 80 | 172 | 132 | 0.108 | 25.44 | |||||||

| LZ6 | 8000 | 3300 | 60,63,65,70,75 | 142 | 107 | 230 | 130 | 112 | 5 | 0.238 | 40.89 |

| 80,85,90,95 | 172 | 132 | 0.242 | 40.15 | |||||||

| LZ7 | 11200 | 2900 | 70,75 | 142 | 107 | 260 | 160 | 112 | 5 | 0.406 | 54.93 |

| 80,85,90,95 | 172 | 132 | 0.428 | 59.14 | |||||||

| 100,110 | 212 | 167 | 0.443 | 59.60 | |||||||

| LZ8 | 18000 | 2500 | 80,85,90,95 | 172 | 132 | 300 | 190 | 128 | 6 | 0.860 | 89.35 |

| 100,110,120,125 | 212 | 167 | 0.911 | 94.67 | |||||||

| 130 | 252 | 202 | 0.908 | 87.43 | |||||||

| LZ9 | 25000 | 2300 | 90,95 | 172 | 132 | 335 | 220 | 150 | 7 | 1.559 | 113.9 |

| 100,110,120,125 | 212 | 167 | 1.678 | 138.1 | |||||||

| 130,140,150 | 252 | 202 | 1.733 | 136.6 | |||||||

| LZ10 | 31500 | 2100 | 100,110,120,125 | 212 | 167 | 355 | 245 | 152 | 8 | 2.236 | 165.5 |

| 130,140,150 | 252 | 202 | 2.362 | 169.3 | |||||||

| 160,170 | 302 | 242 | 2.422 | 164.0 | |||||||

| LZ11 | 40000 | 2000 | 110,120,125 | 212 | 167 | 380 | 260 | 172 | 8 | 3.054 | 190.9 |

| 130,140,150 | 252 | 202 | 3.249 | 203.1 | |||||||

| 160,170,180 | 302 | 242 | 3.369 | 202.1 | |||||||

| LZ12 | 63000 | 1700 | 130,140,150 | 252 | 202 | 445 | 290 | 182 | 8 | 6.146 | 288.5 |

| 160,170,180 | 302 | 242 | 6.432 | 296.6 | |||||||

| 190,200 | 352 | 282 | 6.524 | 288.0 | |||||||

| LZ13 | 100000 | 1500 | 150 | 252 | 202 | 515 | 345 | 218 | 8 | 12.76 | 413.6 |

| 160,170,180 | 302 | 242 | 13.62 | 469.2 | |||||||

| 190,200,220 | 352 | 282 | 14.19 | 480.0 | |||||||

| 240 | 410 | 330 | 13.98 | 436.1 | |||||||

| LZ14 | 125000 | 1400 | 170,180 | 302 | 242 | 560 | 390 | 218 | 8 | 19.90 | 581.5 |

| 190,200,220 | 352 | 282 | 21.17 | 621.7 | |||||||

| 240,250,260 | 410 | 330 | 21.67 | 599.4 | |||||||

| LZ15 | 160000 | 1300 | 190,200,220 | 352 | 282 | 590 | 420 | 240 | 10 | 28.08 | 736.9 |

| 240,250,260 | 410 | 330 | 29.18 | 730.5 | |||||||

| 280,300 | 470 | 380 | 29.52 | 702.1 | |||||||

| LZ16 | 250000 | 1000 | 220 | 352 | 282 | 695 | 490 | 265 | 10 | 56.21 | 1045 |

| 240,250,260 | 410 | 330 | 60.05 | 1129 | |||||||

| 280,300,320 | 470 | 380 | 60.56 | 1144 | |||||||

| 340 | 550 | 450 | 62.47 | 1064 | |||||||

| LZ17 | 355000 | 950 | 240,250,260 | 410 | 330 | 770 | 550 | 285 | 10 | 105.5 | 1500 |

| 280,300,320 | 470 | 380 | 102.3 | 1557 | |||||||

| 340,360,380 | 550 | 450 | 106.0 | 1535 | |||||||

| LZ18 | 450000 | 850 | 250,260 | 410 | 330 | 860 | 605 | 300 | 13 | 152.3 | 1902 |

| 280,300,320 | 470 | 380 | 161.5 | 2025 | |||||||

| 340,360,380 | 550 | 450 | 169.9 | 2062 | |||||||

| 400,420 | 650 | 540 | 175.4 | 2029 | |||||||

| LZ19 | 630000 | 750 | 280,300,320 | 470 | 380 | 970 | 695 | 322 | 14 | 283.7 | 2818 |

| 340,360,380 | 550 | 450 | 303.4 | 2963 | |||||||

| 400,420,440,450 | 650 | 540 | 323.2 | 3068 | |||||||

| LZ20 | 1120000 | 650 | 320 | 470 | 380 | 1160 | 800 | 355 | 15 | 581.2 | 4010 |

| 340,360,380 | 550 | 450 | 624.5 | 4426 | |||||||

| 400,420,440,450,460,480,500 | 650 | 540 | 669.4 | 4715 | |||||||

| LZ21 | 1800000 | 530 | 380 | 550 | 450 | 1440 | 1020 | 360 | 18 | 1565 | 7293 |

| 400,420,440,450,460,480,500 | 650 | 540 | 1715 | 8228 | |||||||

| 530,560,600,630 | 800 | 680 | 1880 | 8699 | |||||||

| LZ22 | 2240000 | 500 | 420,440,450,460,480,500 | 650 | 540 | 1520 | 1100 | 405 | 19 | 2338 | 9736 |

| 530,560,600,630 | 800 | 680 | 2596 | 10631 | |||||||

| 670,710,750 | — | 780 | 2522 | 9473 | |||||||

| LZ23 | 2800000 | 460 | 480,500 | 650 | 540 | 1640 | 1240 | 440 | 20 | 3490 | 11946 |

| 530,560,600,630 | 800 | 680 | 3972 | 13822 | |||||||

| 670,710,750 | — | 780 | 3949 | 12826 | |||||||

| 800,850 | — | 880 | 3982 | 12095 | |||||||

LZ Elastic Pin Gear Coupling is a mechanical device that uses several non-metallic materials to make column pins, which are placed in the mating holes between the two halves of the coupling and the inner surface of the outer ring, and transmit torque through the column pins to connect the two halves of the coupling.

Structural characteristics

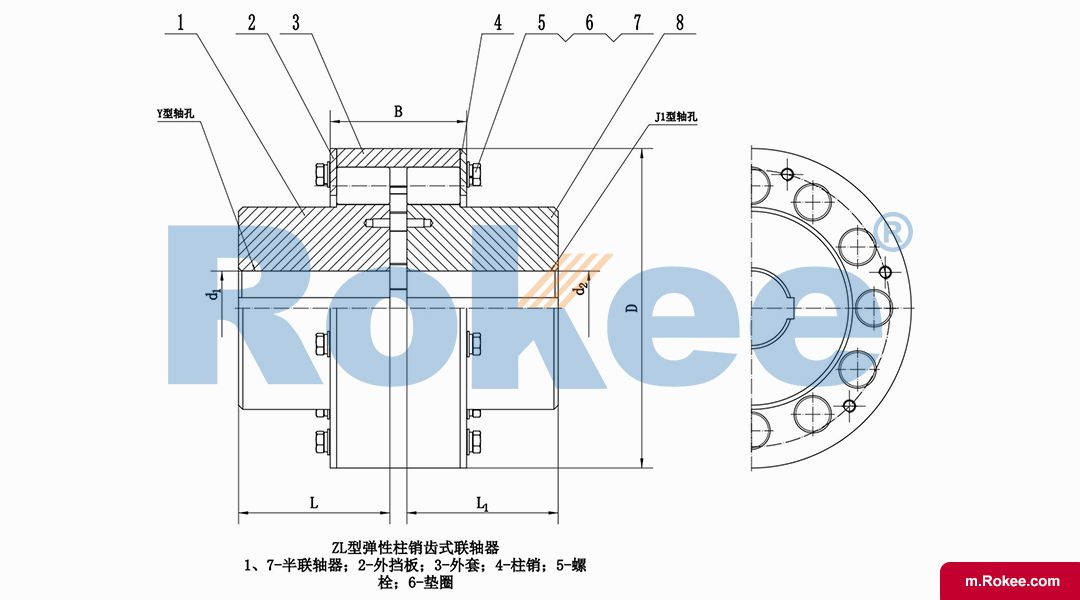

- The LZ Elastic Pin Gear Coupling consists of two half couplings, an outer ring, and column pins. The outer edge of the flange of the two halves of the coupling and the inner edge of the outer sleeve are made into semi-circular grooves with the same radius to form a column pin hole, which is embedded with an elastic column pin.

The driving shaft half coupling drives the outer sleeve through the column pin, and the outer sleeve then drives the driven shaft half coupling to rotate through the column pin, thereby transmitting torque.

Main advantage

High transmission torque: At the same torque, the rotation diameter of LZ elastic pin toothed coupling is usually smaller than that of toothed coupling, so it has a small volume and light weight, and can partially replace toothed coupling.

Simple structure: Compared with gear couplings, ZL elastic pin gear couplings have a simpler structure, fewer components, and are easier to manufacture without the need for gear machining machines.

Easy maintenance: The LZ Elastic Pin Gear Coupling has a long service life, and the nylon column pin can be replaced by removing the baffle, resulting in low maintenance costs.

Self lubricating material: Nylon column pins are self-lubricating materials that do not require lubrication, saving lubricating oil and helping to purify the working environment.

Application

- The ZL elastic column pin tooth coupling has a certain compensation performance for the relative offset of the two shafts, and is suitable for medium and high power transmission.

Due to its relatively poor damping kinetic energy and high noise, it is not suitable for working areas that require certain requirements for damping and strict noise control.

The assembly steps of LZ type intermediate shaft Elastic Pin Gear Coupling are as follows:

Insert the outer ring onto the half coupling and install a suitable baffle onto the flange of the half coupling. Secure the outer ring and half coupling with screws.

Fill the nylon rod into the hole between the outer ring and the half coupling.

Install the other half coupling into the outer ring.

Insert another nylon rod into the hole of the outer ring and half coupling.

Finally, use screws to secure the other baffle to the outer ring of the coupling.

The LZ Elastic Pin Gear Coupling plays an important role in mechanical transmission systems due to its unique structure and advantages. When selecting and using, reasonable selection should be made based on specific working conditions and transmission requirements.

URL: https://m.rokee.com/pin-and-bush-couplings/lz-or-zl-elastic-pin-gear-coupling.html