Rokee is a chinese Teeth Couplings Manufacturer, provide Teeth Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Teeth Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Teeth Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

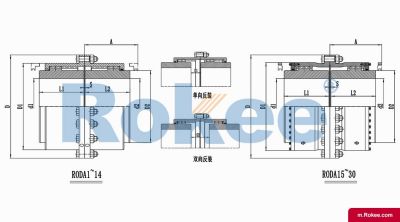

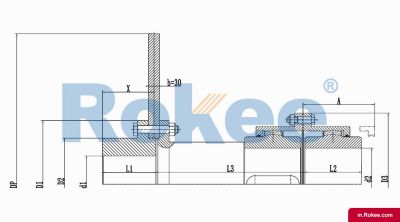

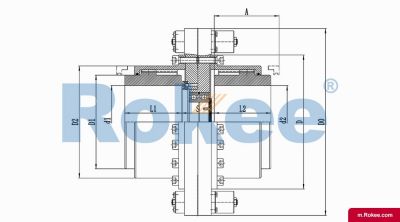

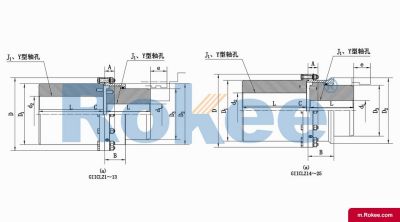

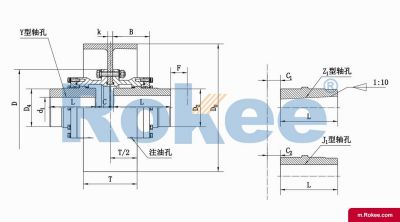

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

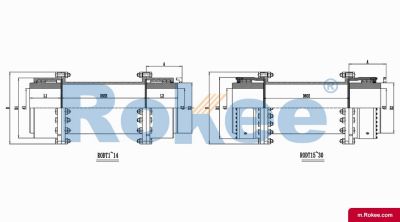

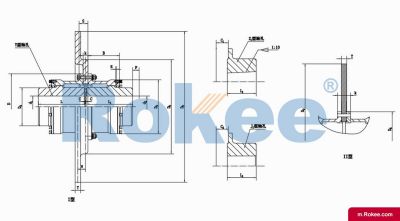

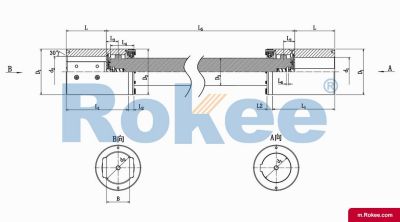

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

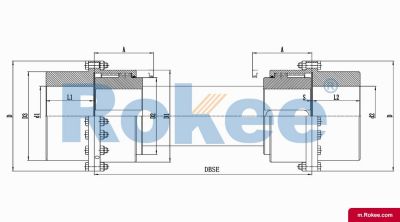

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

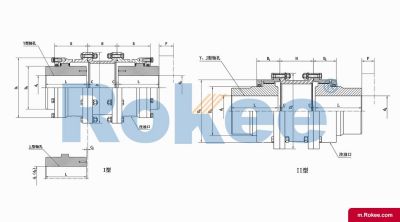

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

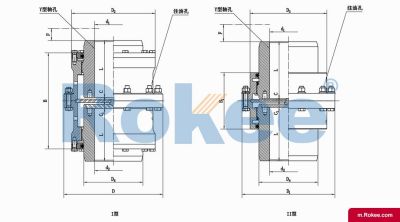

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

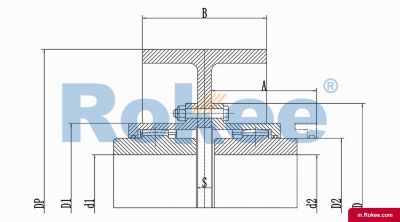

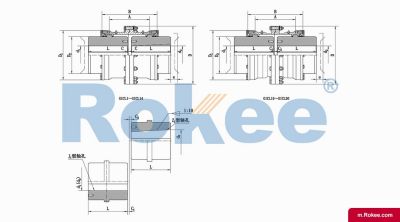

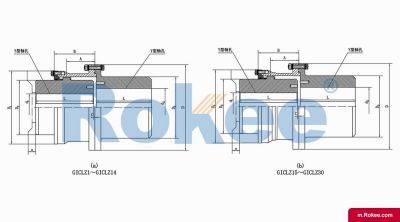

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

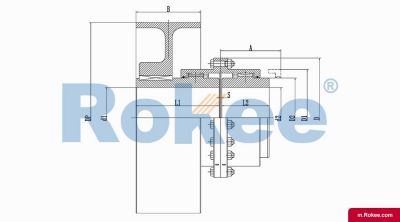

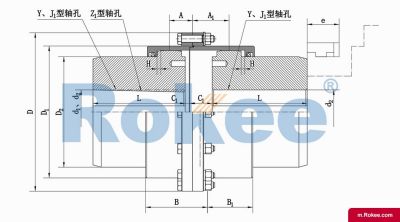

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

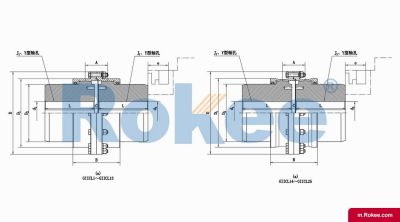

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

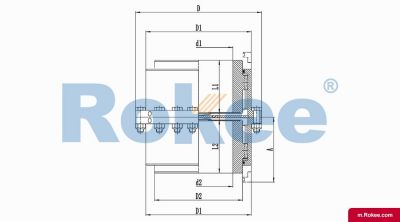

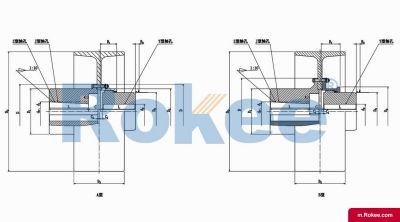

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

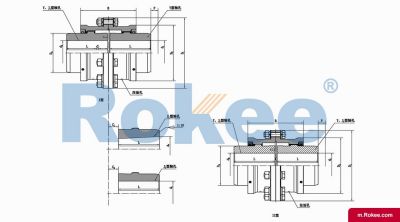

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

A teeth coupling is a movable rigid coupling composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. It utilizes the meshing of internal and external teeth to achieve the transmission of torque and rotational motion between the two halves of the coupling, and has a certain ability to compensate for the relative displacement of the two shafts. The teeth coupling is mainly composed of internal gear rings, gear shaft sleeves (external gear shaft sleeves), end caps, and sealing devices. Among them, small-sized teeth coupling end caps and inner gear rings usually form an integral structure. teeth couplings can be divided into straight tooth couplings, drum tooth couplings, and special drum tooth couplings according to the different axial tooth profiles of their outer gear shaft sleeves. teeth couplings also have advantages such as small radial size and wide range of operating speeds. High precision and dynamically balanced teeth couplings can also be used for high-speed transmission, such as shaft transmission in gas turbines.

When the teeth coupling is in operation, the torque of the driving shaft is transmitted to the inner gear ring through the outer gear sleeve, which in turn drives the driven shaft to rotate. Due to the meshing of the inner and outer teeth, when there is relative displacement between the two shafts, the tooth surfaces of the inner and outer teeth will periodically slide axially relative to each other. This sliding allows the coupling to adapt to certain angular, radial, and axial displacement compensation, thereby maintaining stable transmission performance. teeth couplings are widely used in metallurgy, mining, lifting and transportation, petroleum, chemical, general machinery, and power industries. Especially under heavy loads, large impacts, or conditions where the shaft system is prone to displacement, the teeth coupling ensures stable operation of the equipment due to its high load-bearing capacity and good displacement compensation capability.

In terms of maintenance, teeth couplings need to maintain good lubrication and sealing conditions to avoid tooth wear and power loss. At the same time, the meshing condition of the coupling teeth should be regularly checked to ensure that its contact area and meshing accuracy meet the specified requirements. If it is necessary to remove the ring gear, special tools must be used and not knocked to avoid damaging the shaft or coupling components.

When selecting a teeth coupling, the selection should be based on the actual working conditions and requirements of the transmission system to ensure that the performance of the coupling meets the usage requirements. Installation should be carried out according to the prescribed installation methods and steps to ensure the installation accuracy and alignment requirements of the coupling. During use, the coupling should be regularly inspected and maintained to promptly identify and address potential problems and malfunctions.

In the intricate network of industrial power transmission systems, teeth couplings stand out as indispensable components that bridge rotating shafts, ensuring efficient torque transfer while accommodating inevitable misalignments. These mechanical devices, characterized by their interlocking gear teeth design, have become the backbone of heavy-duty and precision-driven industries, enabling the seamless operation of machinery ranging from steel mill rolling stands to marine propulsion systems. Unlike other coupling types that prioritize flexibility or simplicity, teeth couplings are engineered to balance high load-bearing capacity with exceptional adaptability, making them suitable for some of the most demanding operational environments.

At the heart of a teeth coupling lies a relatively straightforward yet highly effective design principle: torque transmission through the meshing of internal and external gear teeth. A typical teeth coupling consists of four primary components: two flanged half-couplings with external gear teeth, two internal gear rings that mate with the external teeth, sealing devices, and connecting bolts. The external gear teeth are machined on the circumference of the half-couplings, which are then attached to the ends of the shafts requiring connection. The internal gear rings, often referred to as sleeves, enclose the external teeth and are joined together by bolts, creating a unified assembly that transfers rotational force from the driving shaft to the driven shaft. What distinguishes teeth couplings from rigid couplings is their ability to accommodate misalignments between the connected shafts, a feature made possible by three key design elements: backlash between the gear teeth, crowning of the tooth surfaces, and a precise major diameter fit.

Backlash, the slight clearance between the meshing teeth, is not merely a manufacturing tolerance but a functional necessity. It provides the necessary space for lubricant retention, reducing friction and wear during operation, while also allowing the sleeves to shift slightly relative to the half-couplings without binding. Crowning, or the curvature of the external tooth surfaces, further enhances misalignment capability by broadening the contact area between the teeth as the shafts deviate from perfect coaxiality. This curvature can take various forms, including tip crowns, flank crowns, or chamfers on the tooth edges, all of which prevent the sharp edges of the teeth from digging into the mating surfaces and causing premature failure. Variable crowning, a more advanced design, adjusts the curvature radius along the tooth flank to maintain a larger contact area during misalignment, thereby distributing torque more evenly and reducing stress concentrations. The major diameter fit, where the tip diameter of the external teeth closely matches the root diameter of the internal gear ring, ensures stable torque transmission while still permitting the slight movements needed to compensate for misalignments. Together, these design features enable teeth couplings to accommodate radial displacements of up to 4.5mm, axial displacements of up to 11mm, and angular deviations ranging from 0°30' for standard straight-tooth designs to 6° for advanced drum-shaped tooth configurations.

The performance of a teeth coupling is inherently tied to the materials used in its construction, as these materials must withstand high levels of torque, stress, friction, and in many cases, harsh environmental conditions. The most commonly used material for standard teeth coupling components is high-strength alloy steel, with 42CrMo being a prevalent choice. This alloy offers an exceptional combination of high strength, toughness, and hardenability, with no significant temper brittleness. After quenching and tempering, followed by surface hardening, 42CrMo achieves a surface hardness of 50-55 HRC, providing excellent wear resistance while maintaining a tough core that can withstand impact loads. For medium-load applications where cost is a consideration, high-quality carbon steel such as 45-grade forged steel is often used. This material, when subjected to proper heat treatment, achieves a hardness of 220-250 HB, offering sufficient strength for less demanding operational environments.

In extreme operating conditions, specialized materials are required to ensure reliability and longevity. For high-temperature or corrosive environments, such as those found in the petrochemical industry, alloy steels like 34Cr2Ni2Mo are utilized. These steels undergo carburizing and quenching processes, resulting in a tooth surface hardness of 58-62 HRC—ideal for wear resistance—while retaining a core hardness of 30-35 HRC to maintain toughness. Stainless steel is another material option for corrosive environments, as it provides inherent resistance to chemical attack and oxidation. The selection of materials is not limited to the gear components; sealing devices, for example, may be made from nitrile rubber, fluororubber, or other elastomers depending on the temperature and chemical exposure of the application. Each material choice represents a balance between performance requirements, operational conditions, and cost considerations, highlighting the importance of material selection in optimizing the lifespan and efficiency of teeth couplings.

The versatility of teeth couplings is reflected in their wide range of applications across numerous industries, each leveraging specific performance characteristics to meet unique operational demands. In the metallurgical industry, where heavy loads, high impact forces, and significant misalignments are common, teeth couplings are the preferred choice for connecting the main drive shafts of rolling mills, continuous casting equipment, and heating furnace conveyor rollers. The high torque-bearing capacity and robust construction of these couplings enable them to withstand the dynamic loads associated with metal forming processes, while their misalignment compensation capability accommodates the thermal expansion and contraction of shafts during operation. Similarly, in the mining and construction sectors, teeth couplings are used in crushers, ball mills, and belt conveyors, where they must operate reliably in dusty, high-vibration environments. For these applications, enhanced sealing designs are often incorporated to prevent the ingress of dust and debris, which can accelerate tooth wear and reduce coupling lifespan.

The lifting and transportation industry also relies heavily on teeth couplings, particularly in crane hoisting mechanisms where they connect the reducer output shaft to the drum. In these applications, the couplings must not only transmit high torque but also withstand radial loads while maintaining precise positioning. The marine industry utilizes teeth couplings for connecting diesel engines to propellers, a application that demands high dynamic balance precision to minimize vibration in ship hulls. These marine-grade couplings are subjected to rigorous balancing processes to ensure smooth operation at varying speeds, even in the face of the dynamic forces encountered at sea. The power generation sector, including gas turbine and steam turbine systems, employs high-precision teeth couplings that offer transmission efficiencies of up to 99.7% and low noise levels. These couplings are critical for transferring the high rotational speeds and large torques generated by turbines to electrical generators, requiring exceptional manufacturing precision to avoid vibration and ensure long-term reliability.

Even in general mechanical manufacturing, teeth couplings find widespread use in standard equipment such as fans and water pumps. For these applications, nylon inner gear ring variants are often employed to reduce maintenance requirements and operational noise, leveraging the self-lubricating properties of nylon to minimize the need for frequent lubrication. The adaptability of teeth couplings to such a diverse range of industries underscores their fundamental role in modern industrial infrastructure, where reliable power transmission is essential for productivity and safety.

While teeth couplings are renowned for their durability and performance, their long-term reliability is heavily dependent on proper maintenance practices. The most critical maintenance task is ensuring adequate lubrication, as the meshing gear teeth operate under high contact pressures that can lead to rapid wear if not properly lubricated. Lubricants serve multiple purposes: they reduce friction between the tooth surfaces, dissipate heat generated during operation, prevent corrosion, and flush away any contaminants that may have entered the coupling. The choice of lubricant depends on the operating conditions—high-temperature applications may require synthetic lubricants with excellent thermal stability, while heavy-load applications benefit from grease with high viscosity and load-carrying capacity. Regular lubrication intervals are essential, with the frequency determined by factors such as operating speed, load, and environmental conditions. In dusty or wet environments, more frequent lubrication may be necessary to compensate for lubricant degradation or contamination.

Sealing maintenance is another crucial aspect of ensuring teeth coupling longevity. Seals prevent the leakage of lubricant and the ingress of external contaminants such as dust, water, and chemicals. Damaged or worn seals can lead to lubricant loss, resulting in increased friction and wear, as well as corrosion of the gear teeth. Regular inspections of seal integrity, including checking for signs of leakage or damage, are therefore essential. If seals are found to be compromised, they should be replaced promptly to avoid further damage to the coupling. Additionally, periodic inspections of the gear teeth for signs of wear, pitting, or cracking are necessary. Wear patterns can indicate misalignment issues or inadequate lubrication, allowing for corrective action to be taken before catastrophic failure occurs. In high-speed applications, regular dynamic balance checks may also be required to ensure that the coupling remains balanced, as unbalanced couplings can generate excessive vibration, leading to premature wear of bearings and other components.

To understand the unique value proposition of teeth couplings, it is useful to compare them with other common coupling types, such as diaphragm couplings, rubber sleeve couplings, and chain couplings. Diaphragm couplings, which use flexible metal diaphragms to transmit torque and compensate for misalignments, offer the advantage of being maintenance-free, as they require no lubrication and have no sliding components. They also provide higher transmission efficiency (up to 99.86%) and are suitable for high-speed, precision applications. However, diaphragm couplings have lower load-bearing capacity compared to teeth couplings and are more susceptible to damage from excessive misalignment or shock loads. Rubber sleeve couplings, on the other hand, are low-cost and offer good vibration damping, but they have limited torque capacity and are not suitable for high-temperature or high-speed applications. Chain couplings, which use a roller chain to connect two sprockets, are simple and easy to maintain, but they have lower transmission efficiency and are prone to wear and noise.

Teeth couplings occupy a unique niche between these coupling types, offering a combination of high torque capacity, excellent misalignment compensation, and wide speed adaptability that is unmatched by many other designs. While they require more maintenance than diaphragm or rubber sleeve couplings, their robustness and versatility make them the preferred choice for heavy-duty applications where reliability and performance are paramount. For example, in a steel mill rolling stand, where torque loads are extremely high and misalignments are inevitable due to thermal expansion, a teeth coupling is the only viable option, as diaphragm or rubber sleeve couplings would not be able to withstand the operational stresses. Conversely, in a precision servo motor application, where maintenance-free operation and high precision are critical, a diaphragm coupling would be more appropriate than a teeth coupling.

Advancements in manufacturing technology have further enhanced the performance and versatility of teeth couplings in recent years. Computer numerical control (CNC) machining has enabled the production of gear teeth with tighter tolerances, improving meshing precision and reducing vibration. Finite element analysis (FEA) has been used to optimize tooth profiles and material selection, resulting in couplings that are lighter, stronger, and more efficient. Additionally, the development of advanced surface treatment technologies, such as plasma nitriding and physical vapor deposition (PVD), has improved the wear resistance and corrosion resistance of gear teeth, extending coupling lifespan in harsh environments. These technological advancements have expanded the range of applications for teeth couplings, allowing them to meet the evolving demands of modern industry, from renewable energy systems like wind turbines to advanced manufacturing processes like additive manufacturing.

Despite their many advantages, teeth couplings are not without limitations. Their reliance on lubrication means that they are not suitable for applications where lubricant contamination could pose a risk, such as in food processing or pharmaceutical manufacturing. They also tend to be heavier and more bulky than some other coupling types, making them less suitable for applications where space is at a premium. Additionally, the initial cost of teeth couplings is often higher than that of rubber sleeve or chain couplings, although their longer lifespan and lower maintenance costs over time often offset this initial investment. It is important for engineers and maintenance professionals to carefully evaluate the specific requirements of each application when selecting a coupling, weighing the advantages and limitations of teeth couplings against other available options.

In conclusion, teeth couplings represent a critical component in modern industrial power transmission systems, offering a unique combination of high torque capacity, excellent misalignment compensation, and wide application versatility. Their design, which leverages the meshing of internal and external gear teeth, is both simple and effective, enabling reliable operation in some of the most demanding industrial environments. The selection of appropriate materials, based on operational conditions, is essential for ensuring coupling performance and longevity, while proper maintenance practices, particularly lubrication and seal inspection, are critical for maximizing lifespan. Advancements in manufacturing and materials technology continue to enhance the performance of teeth couplings, expanding their range of applications and ensuring that they remain a vital part of industrial infrastructure for years to come. Whether in a steel mill, a mining operation, a marine vessel, or a power plant, teeth couplings play a crucial role in keeping industrial machinery running smoothly, efficiently, and reliably.

« Teeth Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/teeth-couplings.html