Rokee is a chinese Diaphragm Couplings Manufacturer, provide Diaphragm Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Diaphragm Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Diaphragm Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

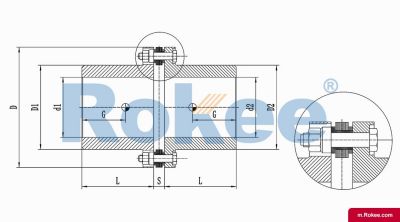

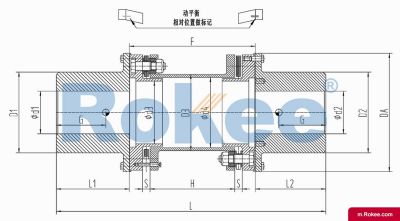

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

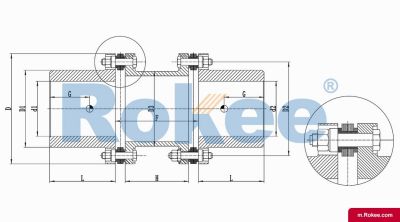

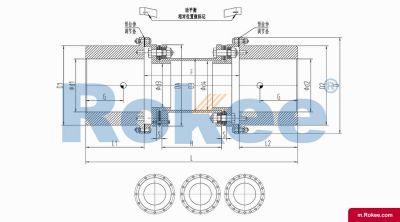

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

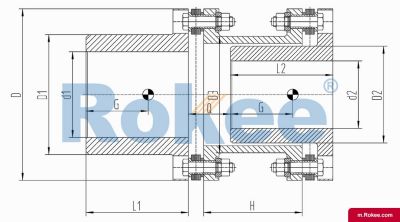

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

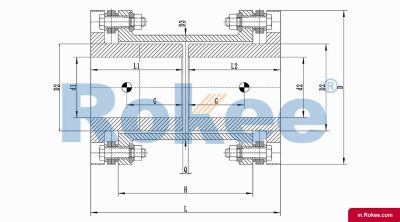

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

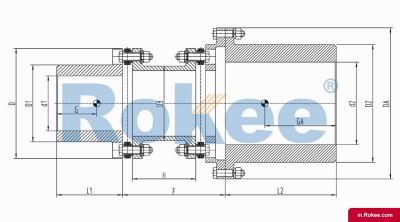

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

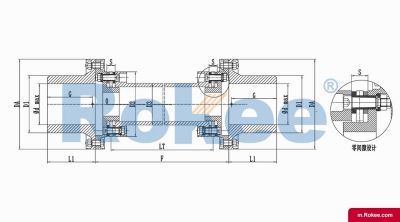

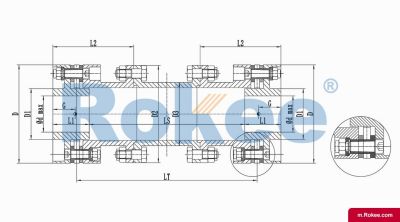

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

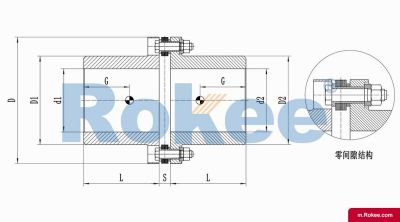

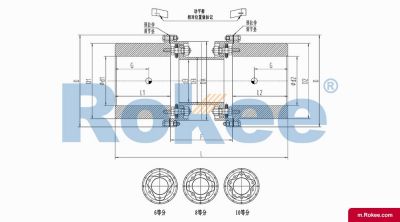

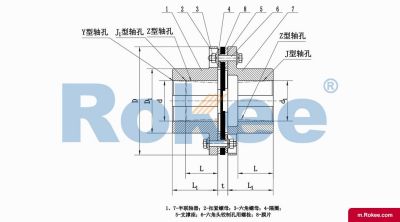

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

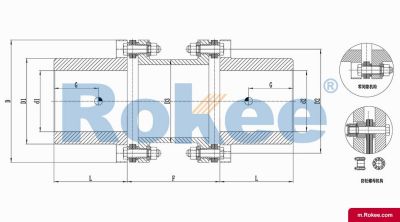

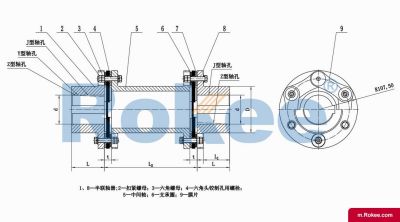

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

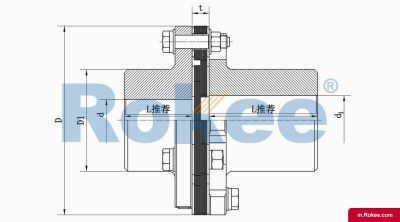

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

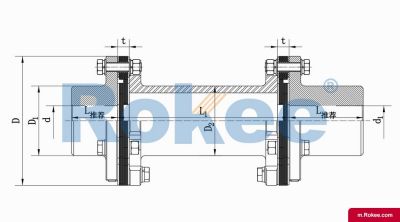

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Diaphragm Coupling is a high-performance metal strong element flexible coupling that uses metal elastic diaphragms as flexible elements to transmit torque. The Diaphragm Coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is made of stainless steel sheet and is fastened to the shaft sleeve with a pin, which generally does not loosen or cause backlash between the diaphragm and the shaft sleeve. Some membrane couplings consist of two membranes, while others consist of three membranes with one or two rigid elements in between, connected to the shaft sleeve on both sides. The Diaphragm Coupling compensates for the relative displacement of the two shafts connected by the elastic deformation of the diaphragm, such as axial, radial, and angular offsets. This elastic deformation ability enables the Diaphragm Coupling to adapt to various misalignment situations, ensuring smooth and efficient transmission.

The Diaphragm Coupling has strong ability to compensate for misalignment of two axes. Compared with the gear coupling, its angular displacement can be twice as large, and the reaction force is small and the flexibility is large when it undergoes radial displacement. It has obvious shock absorption effect, no noise, no wear, and is suitable for occasions with strict requirements for vibration and noise. Suitable for working in high temperatures and harsh environments, able to operate safely under conditions of impact and vibration. At the same time, the Diaphragm Coupling also has the characteristics of acid resistance, alkali resistance, and corrosion resistance. High transmission efficiency, especially suitable for medium and high-speed high-power transmission. Simple structure, light weight, small size, easy to assemble and disassemble, no need to move the machine, no lubrication required. It can accurately transmit speed, operate without slip, and can be used for transmission of precision machinery.

Diaphragm Couplings are widely used in shaft transmission of various mechanical devices, such as water pumps, fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation, high-speed power transmission systems for ships, steam turbines, piston power mechanical transmission systems, tracked vehicles, as well as high-speed and high-power mechanical transmission systems for generator sets.

When installing the Diaphragm Coupling, it should be ensured that the axis deviation is within the allowable range to avoid deformation or damage to the coupling. At the same time, before installation, the end faces of both shafts should be cleaned and the fit of the end face key slots should be checked. After installation, all screws should be checked for looseness and repeatedly tightened to ensure they do not loosen. In addition, to prevent micro motion wear of the diaphragm during high-speed operation, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the diaphragm surface can be treated with anti wear coatings.

In the complex landscape of industrial power transmission, the role of couplings as critical connecting components cannot be overstated. Among the diverse range of coupling technologies available, diaphragm couplings have emerged as a preferred solution for high-performance applications, thanks to their unique combination of reliability, precision, and adaptability to harsh operating conditions. Unlike traditional coupling designs that rely on mechanical contact or elastomeric elements, diaphragm couplings utilize the elastic deformation of thin, flexible diaphragms to transmit torque while accommodating for shaft misalignments. This innovative design eliminates the need for lubrication, reduces maintenance requirements, and ensures consistent performance even in extreme temperatures and corrosive environments. As industries continue to pursue higher speeds, greater torque capacities, and improved operational efficiency, the importance of understanding the working principles, material characteristics, and application considerations of diaphragm couplings becomes increasingly vital.

At the core of a diaphragm coupling's functionality lies its structural composition, which is engineered to balance torque transmission efficiency with the ability to compensate for axial, angular, and parallel misalignments between connected shafts. A typical diaphragm coupling consists of four primary components: two hubs, a set of diaphragms, connecting fasteners, and optional auxiliary positioning elements. The hubs serve as the interface between the coupling and the shafts of the driving and driven machinery, featuring precision-machined bores that match the shaft dimensions. These bores may be cylindrical, conical, or equipped with keyways to ensure a secure fit, preventing relative slippage during operation. The design of the hubs is critical to maintaining transmission accuracy, with strict tolerances applied to the flatness of the flange surfaces and the positional accuracy of the bolt holes that connect to the diaphragms.

The diaphragms themselves are the most essential component of the coupling, acting as both the torque transmitter and the flexible element that accommodates misalignments. Typically constructed from thin metal sheets stacked in groups, the diaphragms are designed with a series of corrugations or precision-cut patterns that enable controlled elastic deformation. This stacked configuration is not merely a matter of increasing thickness but serves to distribute stress evenly across the entire diaphragm assembly, enhancing both load capacity and fatigue resistance. The number of diaphragm sheets and their thickness can be adjusted according to the specific torque requirements and misalignment compensation needs of the application—thicker or more numerous diaphragms provide higher torsional stiffness and torque-carrying capacity, while thinner designs offer greater flexibility for misalignment compensation. Three common diaphragm configurations are widely used: continuous polygonal annular diaphragms, which are simple to manufacture and suitable for medium-low speed applications; split link-type diaphragms, which feature a staggered arrangement for space-saving and high impact resistance; and corrugated diaphragms, which offer enhanced axial flexibility and are ideal for high-precision servo systems.

Connecting fasteners, including high-strength bolts and nuts, play a crucial role in maintaining the integrity of the coupling assembly. These fasteners are typically arranged in a circular pattern around the flange of the hubs, securing the diaphragms in place with uniform tension. To prevent direct friction between the bolts and the diaphragm holes—which can lead to stress concentration and premature failure—buffer sleeves are often installed between the bolts and the diaphragms. These sleeves not only reduce wear but also provide a degree of elastic support, mitigating the impact of transient loads during operation. The installation of these fasteners requires careful attention to torque specifications, with a diagonal tightening sequence recommended to ensure even distribution of clamping force. In high-vibration environments, additional anti-loosening measures such as thread-locking adhesives or lock washers may be employed to prevent fastener loosening over time.

The working principle of a diaphragm coupling revolves around the elastic deformation of the diaphragm assembly to achieve two primary objectives: efficient torque transmission and compensation for shaft misalignments. When torque is applied by the driving shaft, the hubs transfer this torque to the diaphragms through the connecting fasteners. The diaphragms transmit the torque via pure tensile and shear deformation, with no mechanical friction involved—this frictionless operation is one of the key advantages of diaphragm couplings, contributing to their high transmission efficiency (typically exceeding 99.8%) and long service life. When misalignment occurs between the driving and driven shafts, the diaphragms undergo controlled elastic bending deformation to absorb the deviation, rather than transferring excessive forces and moments to the connected machinery components. This ability to compensate for misalignments is critical for protecting bearings, seals, and other shaft-associated components from premature wear and failure. It is important to note that single diaphragm assemblies are primarily effective for angular and axial misalignment compensation, while radial misalignment compensation typically requires a dual-diaphragm configuration with an intermediate shaft, which allows for greater flexibility in absorbing radial deviations.

The selection of materials for diaphragm couplings is a critical factor that directly impacts their performance, durability, and suitability for specific applications. The choice of material is primarily driven by the operating conditions, including temperature, torque requirements, environmental corrosiveness, and weight constraints. Metal materials are the most commonly used for diaphragms, with stainless steel being a preferred option for many industrial applications. Stainless steel, particularly grades such as 304 and 316, offers an excellent balance of strength, toughness, and corrosion resistance, making it suitable for use in humid, acidic, or alkaline environments. These grades can withstand operating temperatures ranging from -30°C to 280°C, covering the needs of most industrial applications. For high-temperature or high-stress applications, such as gas turbines or aerospace propulsion systems, more advanced materials such as Inconel or titanium may be used, as these alloys offer superior high-temperature strength and resistance to thermal fatigue.

In applications where weight reduction is a priority—such as aerospace or high-speed railway systems—high-strength aluminum alloys are often selected for the hubs and other non-diaphragm components. Aluminum alloys offer the advantages of low density, good thermal conductivity, and ease of machining, while still providing sufficient strength for many medium-torque applications. Non-metallic materials, although less common, are used in specialized applications where electrical insulation or extreme chemical resistance is required. Polytetrafluoroethylene (PTFE) is one such material, offering a low friction coefficient, excellent chemical inertness, and good insulation properties, making it suitable for use in electronic equipment and chemical processing applications. High-performance engineering plastics such as polyetheretherketone (PEEK) may also be used, providing a balance of light weight, high strength, and thermal stability.

The installation and maintenance of diaphragm couplings are relatively straightforward compared to other coupling types, but proper procedures are essential to ensure optimal performance and longevity. Prior to installation, the end faces of the connected shafts should be thoroughly cleaned to remove any dirt, rust, or debris that could affect alignment accuracy. The fit of keyways and other mating surfaces should also be inspected to ensure a proper mechanical connection. During installation, the choice of assembly method depends on the type of fit between the hubs and the shafts—common methods include dynamic pressing, static pressing, and thermal expansion. Thermal expansion, which involves heating the hub to expand its bore or cooling the shaft to contract its diameter, is often preferred for interference fits, as it minimizes damage to the mating surfaces compared to pressing methods. Care must be taken to control the heating temperature, however, as excessive heat can alter the material properties of the hub—for steel components, the heating temperature should generally not exceed 400°C to avoid structural changes.

After installation, a post-operational inspection is recommended following the first shift of operation to check for fastener loosening. This inspection should be repeated for several consecutive shifts to ensure that the coupling remains securely fastened. During regular operation, periodic inspections should be conducted to check for signs of diaphragm wear, such as cracks around the bolt holes or excessive deformation. To prevent micro-motion wear between the diaphragm sheets during high-speed operation, a solid lubricant such as molybdenum disulfide can be applied between the sheets, or the diaphragm surfaces can be treated with an anti-wear coating. In addition, safety precautions such as installing protective guards are essential to prevent injury from rotating components and to protect the coupling from contamination by external debris.

Diaphragm couplings find application across a wide range of industries and operating conditions, owing to their versatility, reliability, and performance advantages. In the power generation industry, they are commonly used in gas turbine-generator sets, where they must transmit high torque at high speeds while accommodating minor misalignments and operating in high-temperature environments. Their ability to operate without lubrication is particularly beneficial in this context, as it eliminates the risk of oil contamination that could damage sensitive turbine components. In the chemical and petrochemical industries, diaphragm couplings are preferred for use with pumps, compressors, and reaction vessels, where their corrosion resistance ensures reliable operation in the presence of harsh chemicals and humid environments.

The aerospace and marine industries also rely heavily on diaphragm couplings for high-performance power transmission systems. In aircraft engines and helicopter drive systems, the lightweight and high-strength characteristics of diaphragm couplings make them ideal for applications where weight reduction and reliability are critical. Similarly, in marine propulsion systems, they can withstand the corrosive effects of saltwater while transmitting high torque efficiently. In the manufacturing sector, diaphragm couplings are widely used in machine tools, printing machinery, and textile equipment, where their high precision and zero backlash ensure accurate torque transmission and positioning. High-speed servo systems, in particular, benefit from the low inertia and high torsional stiffness of diaphragm couplings, which enable rapid acceleration and deceleration with minimal positional error.

When compared to other types of couplings, diaphragm couplings offer several distinct advantages that make them a preferred choice for many high-performance applications. Unlike gear couplings, which rely on interlocking teeth for torque transmission, diaphragm couplings have no sliding components and do not require lubrication. This eliminates the maintenance costs associated with lubricant replacement and reduces the risk of environmental contamination. Gear couplings also tend to generate higher reaction forces and moments when misaligned, whereas diaphragm couplings produce lower, more predictable reaction loads, reducing stress on connected equipment. Compared to elastomeric couplings, which use rubber or plastic elements for flexibility, diaphragm couplings offer superior temperature resistance, higher torque capacity, and longer service life, as they are not susceptible to the aging, hardening, or degradation that affects elastomeric materials over time.

Despite their numerous advantages, diaphragm couplings are not without limitations. They generally have a higher initial cost compared to some other coupling types, such as elastomeric couplings, which can be a consideration for cost-sensitive applications. Additionally, their flexibility is limited compared to elastomeric couplings, making them less suitable for applications requiring significant vibration damping. Stress concentration at the edges of the diaphragm corrugations or bolt holes can also lead to fatigue failure if the coupling is operated beyond its design limits or subjected to excessive shock loads. Proper selection, installation, and maintenance are therefore essential to mitigate these risks and ensure optimal performance.

In conclusion, diaphragm couplings represent a sophisticated and reliable solution for power transmission in a wide range of industrial applications. Their unique design, which leverages the elastic deformation of precision-engineered diaphragms, enables efficient torque transmission, effective misalignment compensation, and operation without lubrication. The careful selection of materials, based on operating conditions and performance requirements, ensures that diaphragm couplings can withstand extreme temperatures, corrosive environments, and high torque loads. Proper installation and maintenance procedures further enhance their reliability and longevity, making them a cost-effective choice in the long term despite their higher initial investment. As industries continue to advance toward higher speeds, greater precision, and more demanding operating conditions, the role of diaphragm couplings in ensuring efficient and reliable power transmission is set to become even more prominent. Their ability to balance performance, durability, and low maintenance requirements makes them an indispensable component in modern industrial machinery and equipment.

« Diaphragm Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/diaphragm-couplings.html