Rokee is a chinese Spring Couplings Manufacturer, provide Spring Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Spring Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Spring Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

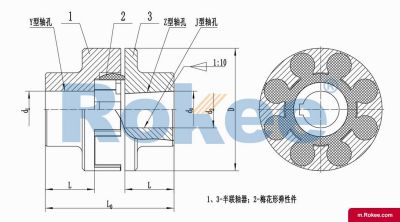

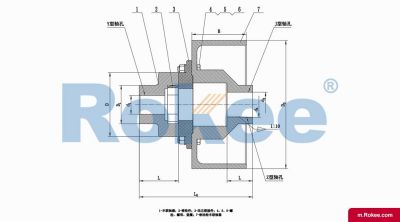

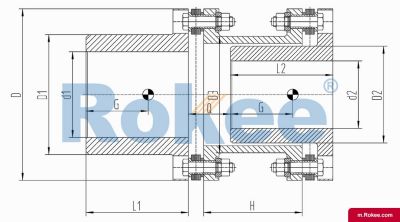

LM/ML Flexible Plum Jaw Coupling

LM Plum-shaped Flexible Coupling is the basic form of this series of couplings.View More -

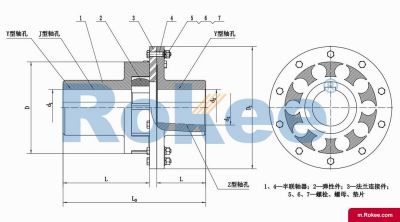

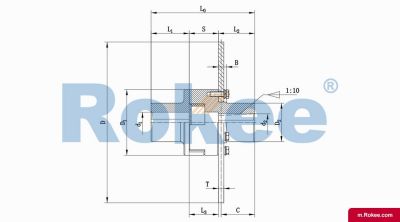

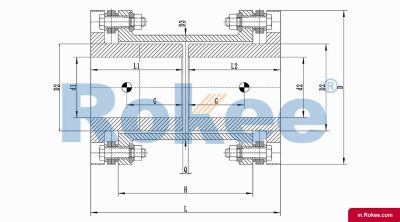

LMD/MLZ Flexible Plum Jaw Coupling With Single Flange

LMD Plum-shaped Flexible Coupling is added with transition connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

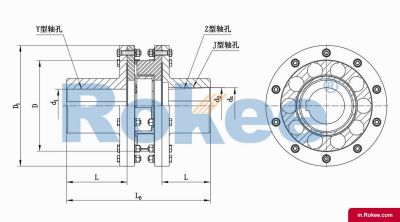

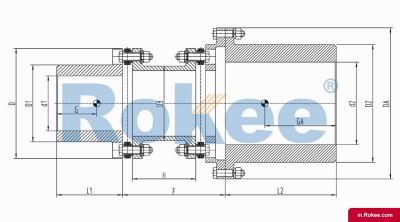

LMS/MLS Flexible Plum Jaw Coupling With Double Flange

LMS Plum-shaped Flexible Coupling adopts double transition flange connection, which eliminates the need of axially moving the semi-coupling when replacing the elastomer.View More -

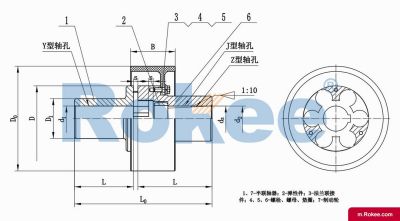

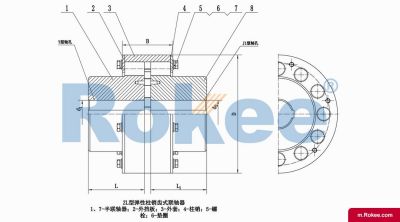

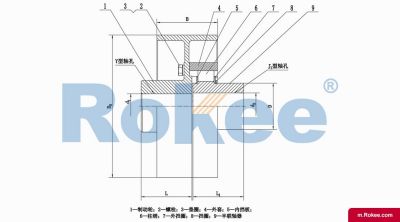

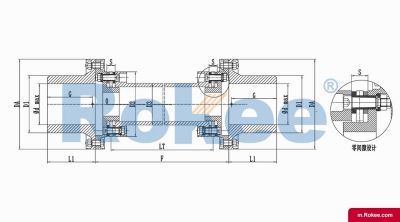

LMZ-I/MLL-I Flexible Plum Jaw Coupling With Split Brake Wheel

LMZ-I Plum-shaped Flexible Coupling adopts split brake wheel design, suitable for situations where braking is required.View More -

LMZ-II/MLL-II Flexible Plum Jaw Coupling With Integral Brake Wheel

LMZ- II Plum-shaped Flexible Coupling adopts integral brake wheel design, suitable for situations where braking is required.View More -

LMPK/MLPK Flexible Plum Jaw Coupling With Split Brake Disc

LMPK Plum-shaped Flexible Coupling adopts split brake disc design, suitable for situations where braking is required and eliminating the need of axially moving the semi-coupling when replacing the elastomer.View More -

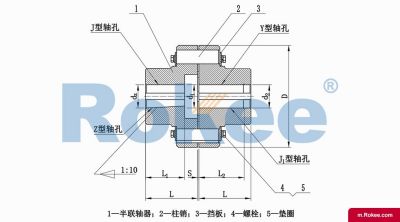

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

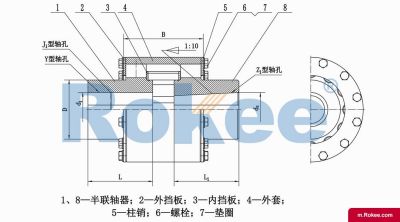

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

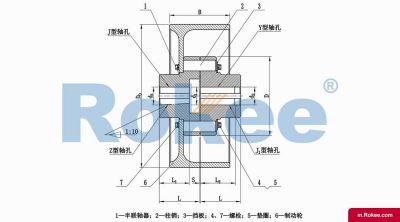

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

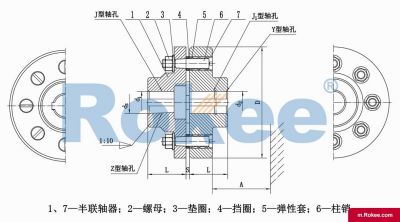

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

LXZ/HLL Flexible Pin Coupling With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

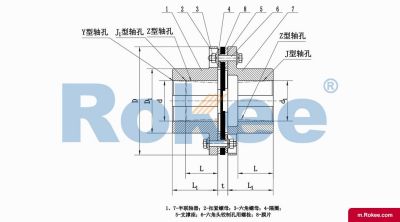

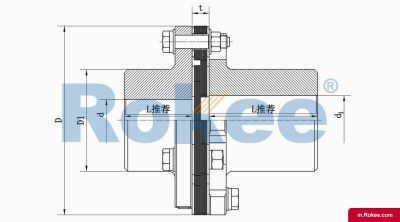

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

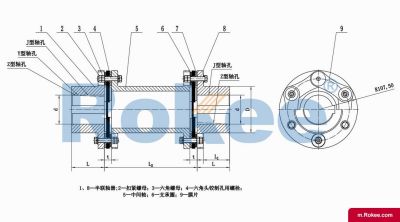

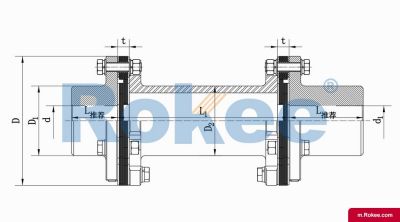

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

LLA Tyre Coupling

The LLA Tyre Coupling uses two semi-couplings to connect both sides of the elastic tyre body through internal pressing plates and bolts, making it easy to replace the elastic tyre body. The LLA Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance.The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

LLB Tyre Coupling

The LLB Tyre Coupling is a kind of high elastic coupling, with good damping buffer and superior offset compensation performance. The working temperature of 20~80 degrees Celsius, transmitting torque 10~20000NM, suitable for damp, dust, shock, vibration, reversing the changeable and frequent starting working conditions, and convenient assembly and disassembly, no lubrication, durable and reliable. Non standard couplings are made in accordance with special needs. In overloading work and half coupling, there will be no malignant accidents.View More -

UL Tyre Coupling

UL Tyre Coupling adopts the structure of vulcanizing and bonding the tyre body with the metal connecting plate with threaded holes, which is then directly connected to the two semi-couplings by bolts for torque transmission and other displacement compensation.UL Tyre Couplings are flexible shaft coupling. UL type tire has good buffering performance. Operating temperature: -20~+80℃. Torque range: 10~25000N.M.UL Tyre Coupling mainly used in damp, dusty, vibration working environment. Because the elastic part is the whole tire, so, easy to disassemble and assemble. No lubrication is required.View More -

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

A spring coupling is a mechanical device that transmits motion and power through spring elements. Spring couplings mainly utilize the elastic deformation of springs to compensate for the relative displacement between two shafts and transmit torque. According to the form and layout of springs, spring couplings can be divided into various types, such as spiral spring couplings, serpentine spring couplings (coupling springs), and reed spring couplings.

Spring couplings, as key components in mechanical transmission systems, play a crucial role in modern industrial equipment. It can not only effectively transmit torque and rotational motion, but also compensate for various installation deviations, absorb vibration impacts, and reduce noise.

spring coupling is a mechanical device that connects two shafts through elastic elements and is an important branch of flexible coupling. Unlike rigid couplings, spring couplings compensate for various deviations between shaft systems through built-in elastic elements (metal or non-metal), while providing cushioning and vibration reduction functions to protect the transmission system from impact loads and vibrations.

The basic structure of an spring coupling usually consists of three parts: two half couplings that connect the driving shaft and the driven shaft respectively, and an elastic element located between the two. This structural design enables the coupling to adapt to a certain degree of radial, axial, and angular deviations while maintaining effective torque transmission. According to different application requirements, the elastic components of spring couplings can be made of metal (such as aluminum alloy, stainless steel) or non-metal materials (such as rubber, polyurethane, nylon, etc.), and various materials exhibit different performance characteristics in terms of stiffness, damping characteristics, temperature resistance, and corrosion resistance.

In industrial applications, spring couplings are widely popular due to their maintenance free, oil resistant, and corrosion-resistant advantages. They are particularly suitable for situations where precise torque transmission is required while there are various deviations, such as servo systems, stepper motor drive systems, and various precision mechanical transmission devices. The integrated design enables many modern spring couplings to achieve zero rotational clearance, further improving transmission accuracy.

The core function of an spring coupling is to compensate for the deviation between shaft systems and absorb vibration energy through the deformation of elastic elements. When there is radial, axial, or angular deviation between the two axes, the elastic element will undergo corresponding elastic deformation, thereby avoiding stress concentration and component damage that may occur due to rigid connections. This compensation capability eliminates the need for extremely high alignment accuracy during installation, reducing installation difficulty and maintenance costs.

In terms of torque transmission, spring couplings achieve power transmission through the shear or compression action of elastic elements. Taking the spiral groove type spring coupling as an example, the continuous multi turn long grooves on its metal elastic body will produce slight twisting deformation under torque, which ensures effective torque transmission and provides necessary flexibility. For rubber spring couplings, torque is transmitted through compression or shear deformation of rubber materials, while utilizing the high damping characteristics of rubber to attenuate vibration.

Another important function of an spring coupling is to adjust the system stiffness and change the natural frequency of the transmission system. By selecting the appropriate stiffness of elastic elements, the transmission system can avoid the resonance speed zone and prevent dangerous resonance phenomena during operation. This is particularly important for power units such as diesel engines that experience periodic torque fluctuations, which can effectively reduce the impact of variable torque on the gear surface and extend the service life of the gears.

In addition, the spring coupling also has overload protection function. When the torque borne by the system exceeds the design value, the elastic elements in some types of spring couplings will undergo destructive deformation or fracture, thereby interrupting torque transmission and protecting expensive mechanical equipment from damage. This safety protection function is particularly important in heavy-duty situations such as mining machinery and engineering machinery.

The reason why spring couplings are widely used in the field of industrial transmission is due to their excellent performance characteristics. These characteristics enable them to solve technical problems that traditional rigid couplings cannot cope with, providing more reliable and efficient transmission solutions for modern mechanical equipment.

« Spring Couplings » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/spring-couplings.html