Rokee is a chinese Pin And Bush Couplings Manufacturer, provide Pin And Bush Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Pin And Bush Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Pin And Bush Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

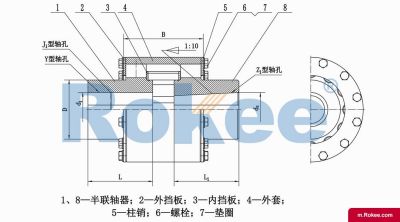

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

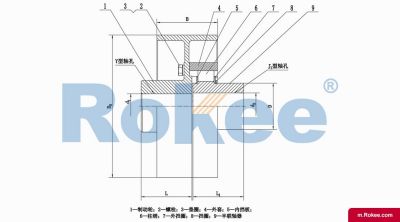

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

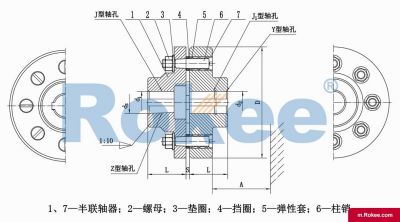

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

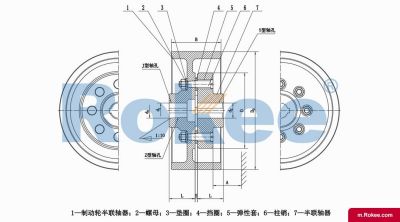

LXZ/HLL Flexible Pin Coupling With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

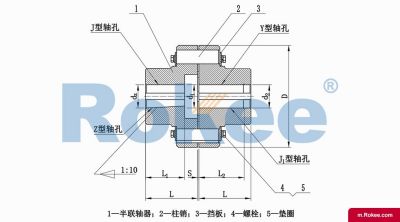

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

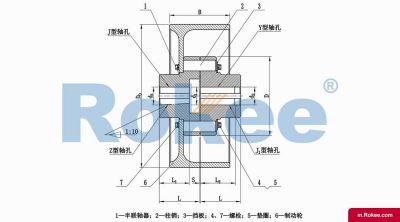

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Pin and bush coupling is a mechanical transmission device that connects two halves of the coupling through elastic elements (such as rubber sleeves, nylon column pins), and has both torque transmission and displacement compensation functions. It is mainly divided into the following two categories:

Elastic sleeve column pin coupling (TL/LT type)

Structure: The column pin is covered with a rubber sleeve, which absorbs vibration through compression deformation and does not require lubrication.

Features: Simple structure but limited compensation capability (radial 0.2-0.6mm, angular 0.5 ° -1.5 °), suitable for small and medium power transmission (such as water pumps and fans).

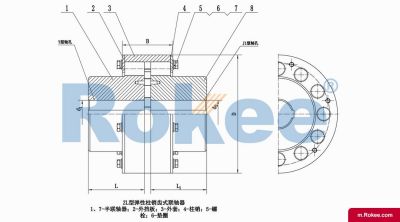

Elastic column pin toothed coupling (ZL type)

Structure: Nylon column pins are embedded in tooth shaped grooves, the baffle prevents detachment, and the drum shaped design enhances compensation capability.

Features: Maintenance free, temperature resistant -20 ℃~80 ℃, can replace some gear couplings, suitable for frequent forward and reverse working conditions.

Core performance advantages

Vibration damping and buffering: Elastic components consume vibration energy through deformation, reducing impact loads by more than 30%.

Displacement compensation: It can adapt to axial, radial, and angular deviations, protecting the alignment error of the shaft system.

Economy: Low manufacturing cost and convenient maintenance.

Selection principle

Load characteristics: ZL type is preferred for impact loads, and TL type should be used with caution in high-frequency start stop scenarios.

Environmental adaptation: For high temperatures (>80 ℃), heat-resistant nylon column pins should be selected, and stainless steel material is recommended for corrosive environments.

Installation specifications

Alignment calibration: The radial deviation should be ≤ 0.1mm, and the angular deviation should be ≤ 0.5 °. Use a laser alignment instrument to improve accuracy.

Maintenance cycle: Check the wear of elastic components every 6 months.

The pin and bush coupling with its modular design and adaptability, continues to play a key role in industrial transmission and will develop towards high-performance materials and digital monitoring in the future.

« Pin And Bush Couplings » Post Date: 2024/5/9

URL: https://m.rokee.com/tags/pin-and-bush-couplings.html