Rokee is a chinese Spherical Gear Coupling Manufacturer, provide Spherical Gear Coupling processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Spherical Gear Coupling selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Spherical Gear Coupling is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

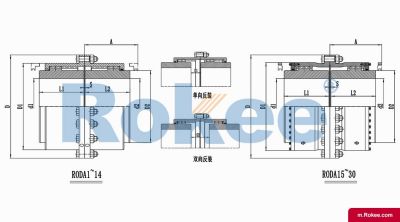

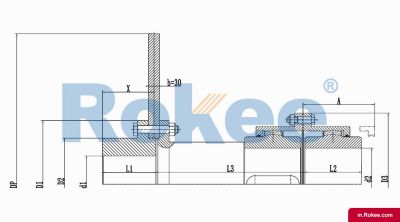

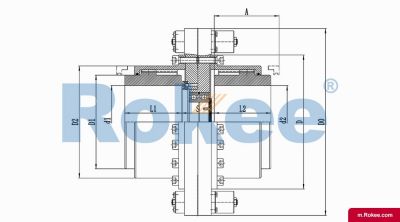

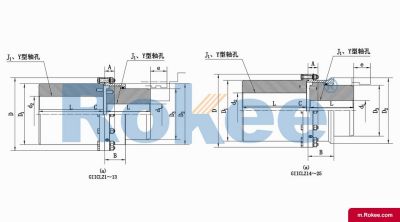

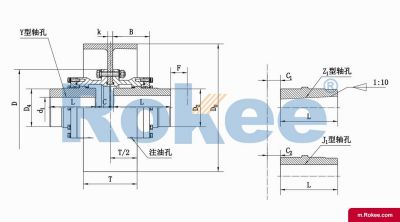

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

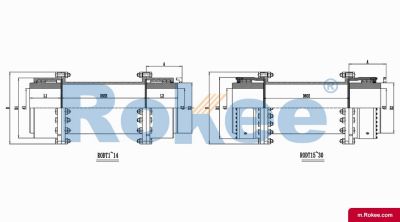

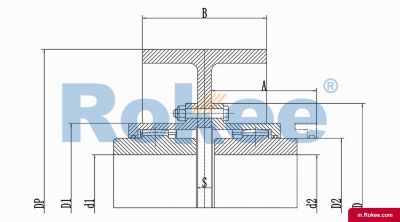

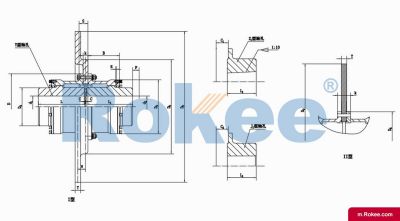

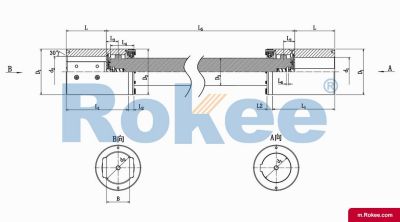

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

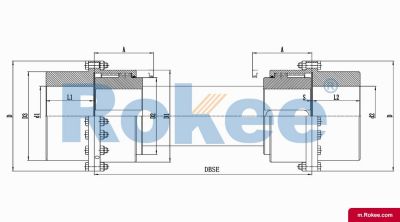

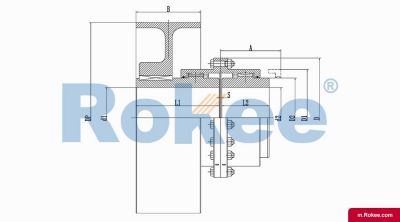

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

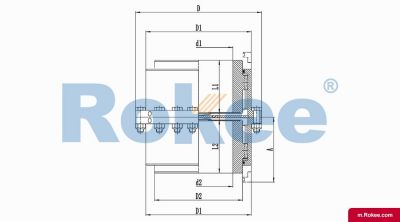

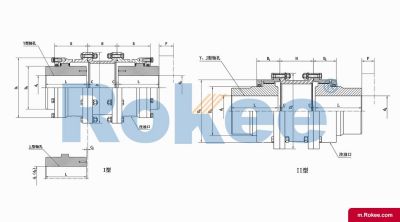

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

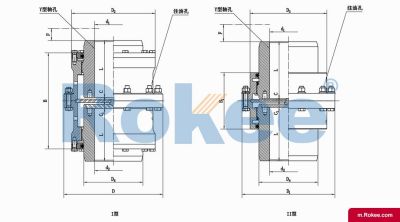

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

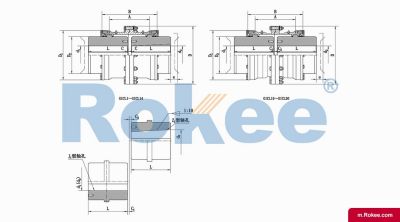

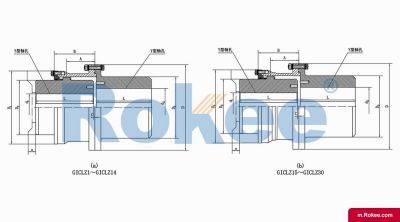

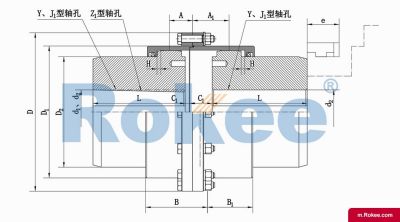

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

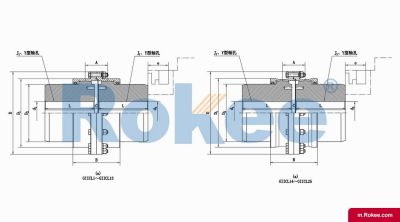

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

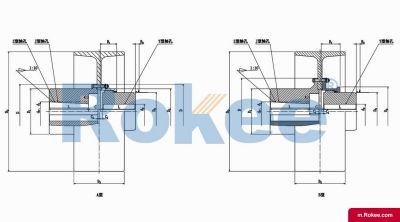

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

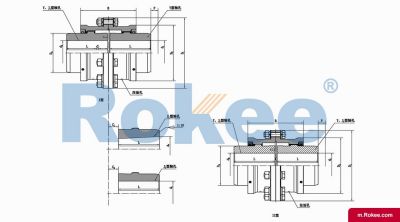

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

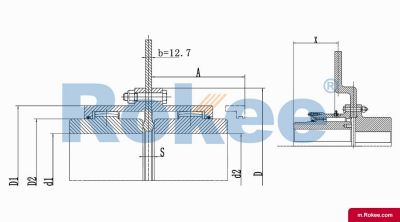

The spherical gear coupling consists of two key components: a flange half coupling with spherical outer teeth and an inner ring gear. Its core feature is that the outer teeth are machined into a spherical profile, with the center of the sphere located on the gear axis. This design creates unique kinematic characteristics:

Three dimensional compensation capability: The spherical tooth profile enables the coupling to simultaneously compensate for radial, axial, and angular deviations. When there is angular displacement, the contact point of the tooth surface will naturally slide along the spherical surface, avoiding the common edge squeezing phenomenon of spur gear couplings. The typical compensation capability reaches 1 ° 30 ', which is 50% higher than traditional spur gear couplings.

Optimize contact stress distribution: The spherical tooth profile ensures that the contact area of the tooth surface is always in the optimal state when there is deviation. By optimizing the meshing contact through a drum shaped curve, the distribution of contact stress is more uniform, the peak stress is reduced by 30-40%, and the service life is significantly extended.

Self centering feature: Spherical geometry design endows the coupling with automatic centering ability, which can dynamically adapt to changes in the position of the shaft system during operation, especially suitable for large equipment with foundation settlement or thermal deformation.

Face gear couplings exhibit multiple performance advantages in industrial applications:

Excellent carrying capacity:

At the same size, spherical design increases the load-bearing capacity by 15-20% compared to spur gear couplings

The transmission efficiency is as high as 99.7%, and the power loss is extremely low

The nominal torque range is wide, ranging from 0.4kN · m to 4500kN · m

Environmental adaptability:

Working temperature range: -30 ℃ to+150 ℃ (depending on lubricant selection)

The protection level can reach IP65, suitable for harsh environments such as humidity and dust

The corrosion-resistant version is made of stainless steel material and is suitable for corrosive environments such as chemical and marine environments

Dynamic performance:

Allowable speed range 460-4000r/min

Models that have undergone precise dynamic balancing can be used for high-speed transmission, such as steam turbine units

The vibration amplitude is reduced by 40-50% compared to a spur gear coupling

Maintenance features:

Adopting advanced grease sealing system, with a maintenance cycle of up to 8000-10000 hours

Modular design enables the replacement of vulnerable parts without the need to move the device body

Tooth surface hardness HRC58-62, excellent wear resistance

Spherical gear couplings have been widely used in multiple industrial fields due to their unique advantages

In the field of heavy industry:

Metallurgical rolling mill: compensating for frequent adjustment and thermal deformation of rolling rolls

Mining Machinery: Resistant to Impact Load and Misalignment of Shaft System

Large cranes: adaptable to structural deformation and dynamic loads

Energy equipment:

Steam turbine generator set: meets the requirements of high speed and high precision

Wind Turbine: Adapt to Tower Swing and Transmission Chain Deformation

Oil drilling equipment: responding to dynamic offset of wellhead devices

Special equipment:

Ship propulsion system: compensating for shaft installation errors and hull deformation

Shield tunneling machine: adapted to the installation deviation of large-diameter main bearings

Rocket launch pad: meets reliability requirements under extreme working conditions

Proper selection and installation are crucial for maximizing the performance of spherical gear couplings

Selection considerations:

Calculate the maximum torque of the system (including starting and braking conditions)

Assess the possible types and quantities of deviations in the shaft system

Consider external conditions such as environmental temperature and corrosiveness

Determine the lubrication method (grease lubrication or oil lubrication)

Installation technical requirements:

Using laser alignment instrument to ensure initial installation accuracy

The angular deviation should be controlled within 0.5 °, and the radial deviation should not exceed 0.2mm

During hot installation, the heating temperature should not exceed 120 ℃

Tighten the bolts three times in diagonal order to the specified torque

Maintenance suggestion:

Check the wear of the tooth surface every 2000 hours of operation

Regularly replenish specified types of lubricating grease

When there is abnormal vibration, the machine should be stopped immediately to check the alignment status

When storing spare parts, it is necessary to apply anti rust oil and rotate them regularly

Spherical gear couplings represent the advanced level of modern industrial transmission technology, and their innovative spherical tooth design solves the technical bottleneck of traditional couplings under heavy loads, high speeds, and complex working conditions. With the advancement of materials science and manufacturing processes, these types of couplings are developing towards higher torque density, longer service life, and greater intelligence, providing more reliable transmission solutions for industrial equipment.

« Spherical Gear Coupling » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/spherical-gear-coupling.html