Rokee is a chinese Pin Bush Couplings Manufacturer, provide Pin Bush Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Pin Bush Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Pin Bush Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

LZ/ZL Elastic Pin Gear Coupling

LZ Pin Gear Coupling is the basic form of this series of couplings.View More -

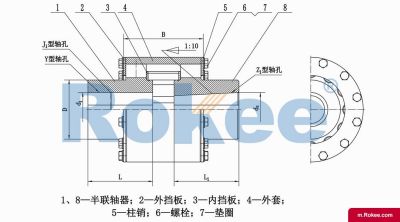

LZD/ZLD Elastic Pin Gear Coupling With Conical Shaft Hole

One end of the LZD Pin Gear Coupling is designed with a conical shaft hole, and the clearance between the semi-couplings is increased to facilitate the fixing space at the shaft end.View More -

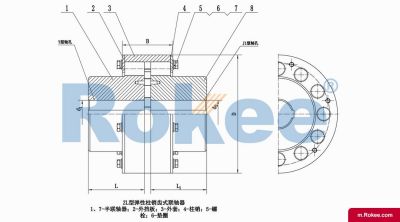

LZZ/ZLL Elastic Pin Gear Coupling With Brake Wheel

LZZ Pin Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

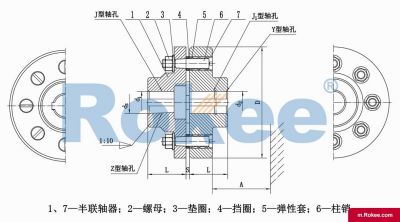

LX/HL Flexible Pin Coupling

LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.View More -

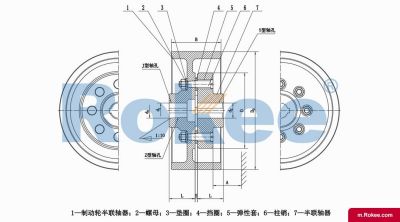

LXZ/HLL Flexible Pin Coupling With Brake Wheel

LXZ(HLL) Flexible Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

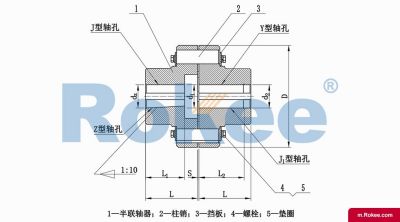

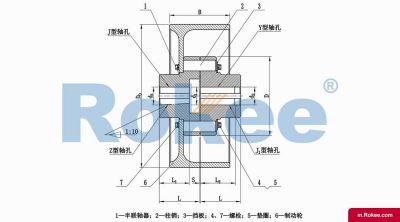

LT/TL Elastic Sleeve Pin Coupling

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.View More -

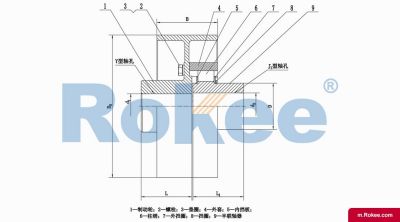

LTZ/TLL Elastic Sleeve Pin Coupling With Brake Wheel

LTZ Elastic Sleeve Pin Coupling is designed with a brake wheel, suitable for situations where braking is required.View More

Pin bush coupling is a flexible coupling that achieves power transmission through the combination of elastic bushing and pin shaft. Its typical structure includes:

Metal wheel hub: usually made of aluminum alloy or steel flange, connected to the driving/driven shaft at both ends through keyway or taper sleeve.

Elastic lining: mostly made of polyurethane or rubber material, embedded with metal lining to enhance wear resistance, absorb vibration and compensate for axial/radial deviation.

Pin shaft component: a cylindrical pin made of stainless steel or alloy steel that runs through the bushing and wheel hub, allowing for slight deformation when transmitting torque.

Working principle: When the active shaft rotates, the torque is compressed by the pin shaft to produce deformation of the elastic bushing, thereby buffering the impact load and compensating for installation deviation.

Elastic bushings can convert 30% -50% of torsional vibration energy into thermal energy, making them particularly suitable for scenarios such as motor pump units that are prone to harmonic vibration.

Deviation compensation characteristics

Axial deviation: ± 1.5mm

Radial deviation: ± 0.8mm

Angular deviation: ± 1.5 °

Polyurethane lining is resistant to oil stains and aging, with a working temperature range of -30 ℃ to+80 ℃ (short-term peak 120 ℃), no need for lubrication, and a lifespan of up to 50000 hours.

Application scenarios

Construction machinery: excavator slewing mechanism, loader transmission shaft, using the anti impact characteristics of lining to protect hydraulic motors.

Automation equipment: The joint connection of the robotic arm and the flexibility of the bushing can reduce the positioning error of the servo motor.

Energy equipment: The yaw system of the wind turbine, with multiple sets of bushings connected in series, can withstand megawatt level dynamic loads.

The pin bush coupling with its characteristics of "rigid transmission and flexible buffering", is gradually replacing traditional gear couplings and becoming the preferred solution for modern industrial transmission.

« Pin Bush Couplings » Post Date: 2024/5/9

URL: https://m.rokee.com/tags/pin-bush-couplings.html