Rokee is a chinese Drum Gear Couplings Manufacturer, provide Drum Gear Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Drum Gear Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Drum Gear Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

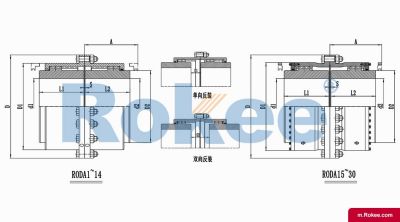

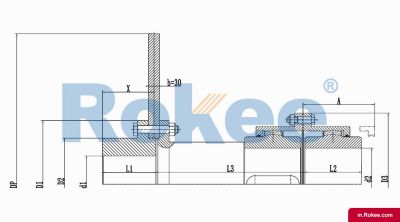

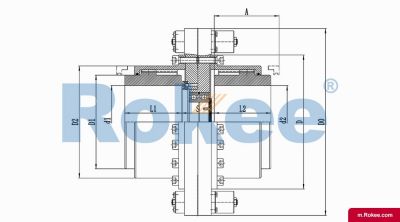

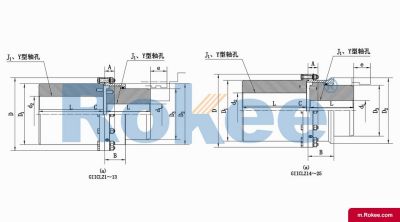

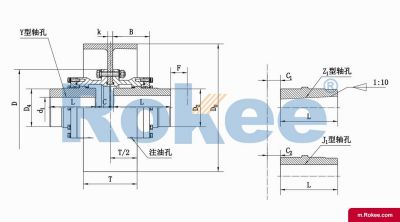

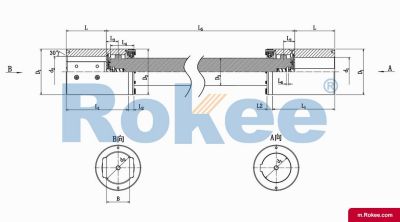

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

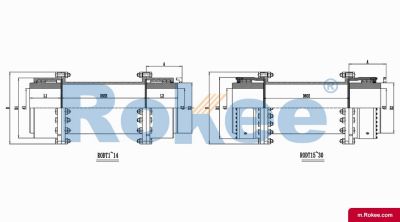

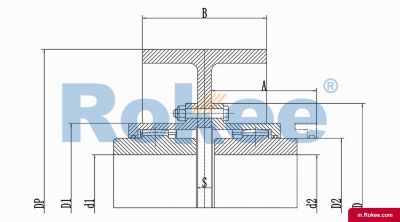

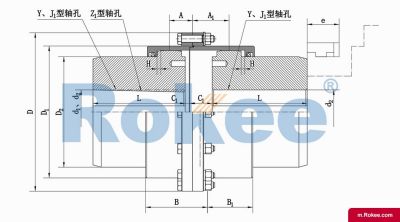

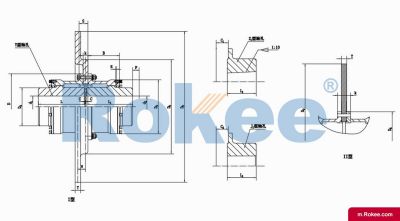

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

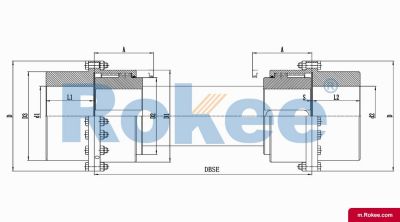

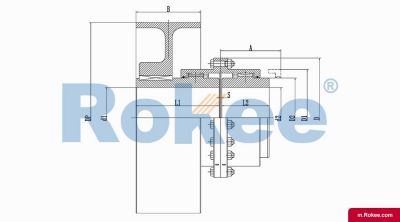

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

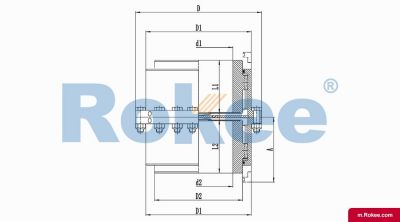

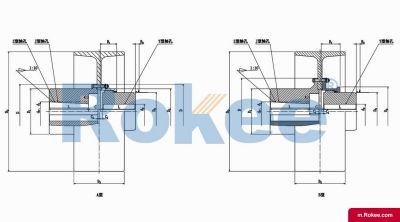

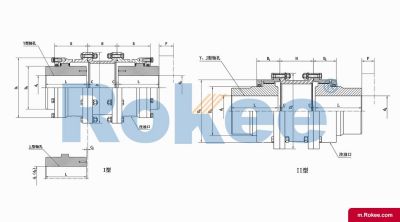

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

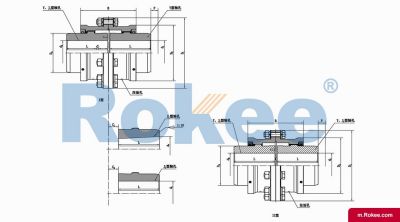

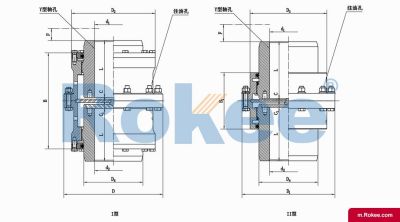

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

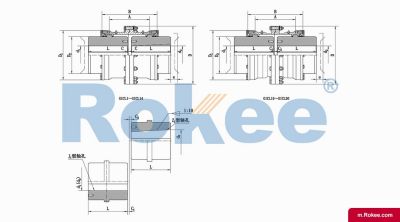

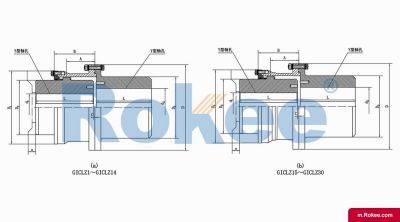

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

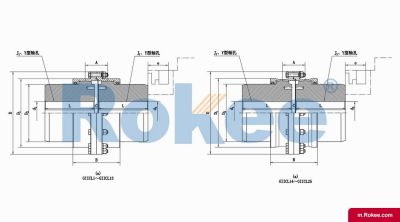

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

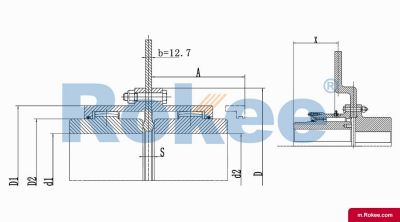

Drum Gear Coupling is an important mechanical basic component, belonging to rigid flexible coupling, and has a wide range of applications in the field of engineering technology. Drum Gear Coupling is composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Its core structure consists of an inner gear sleeve and an outer gear sleeve, and the outer gear adopts a drum shaped design with a spherical tooth tip. This design not only has a compact structure, but also has the characteristic of a small turning radius.

Advantages and Characteristics

Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the Drum Gear Coupling is on average 15-20% higher than that of the spur gear coupling. This enables the drum toothed coupling to withstand greater loads and is suitable for various heavy-duty conditions.

Large angular displacement compensation: The Drum Gear Coupling has a large angular displacement compensation capability. When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1 °, while the allowable angular displacement of the drum gear coupling is 1 ° 30 ', an increase of 50%. This enables the Drum Gear Coupling to better adapt to axis deviations and ensure smooth transmission.

High transmission efficiency: The Drum Gear Coupling has a transmission efficiency of up to 99.7%, which can efficiently transmit power from the driving shaft to the driven shaft.

Low noise and long maintenance cycle: The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the drawbacks of edge compression and stress concentration at the straight tooth end under angular displacement conditions. At the same time, this design also improves the friction and wear of the tooth surface, reduces noise, and extends the maintenance cycle.

Easy to assemble and disassemble: The outer tooth sleeve of the Drum Gear Coupling has a trumpet shaped tooth end, making the assembly and disassembly of the inner and outer teeth very convenient and improving maintenance efficiency.

Drum Gear Couplings are particularly suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. At the same time, it is also suitable for shaft transmission of various types of machinery such as petroleum, chemical, and general machinery. Due to its many advantages, drum toothed couplings have been widely used in these fields.

Drum Gear Couplings come in various models and specifications, such as GICL, GIICL, WG, and more than ten other models. These models can meet the needs of different compensation requirements, brake function adaptation, and vertical installation scenarios. At the same time, different models of Drum Gear Couplings also have different load-bearing capacity, angular displacement compensation capacity, etc. Users can choose according to their actual needs.

« Drum Gear Couplings » Post Date: 2024/5/5

URL: https://m.rokee.com/tags/drum-gear-couplings.html