Rokee is a chinese Crown Gear Couplings Manufacturer, provide Crown Gear Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Crown Gear Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Crown Gear Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

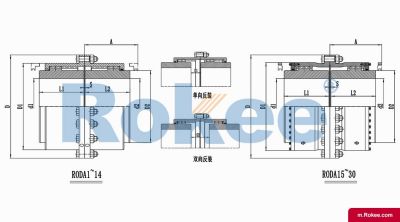

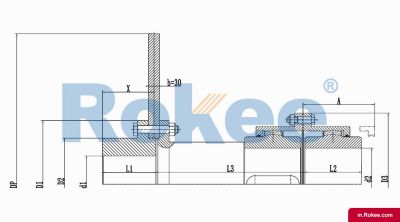

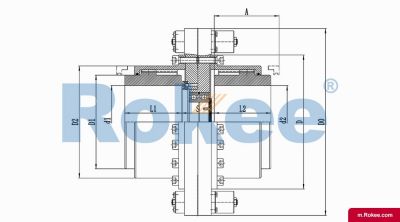

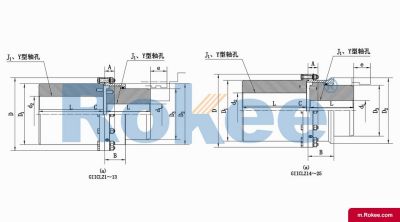

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

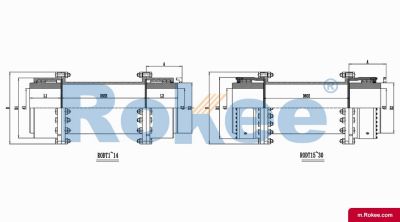

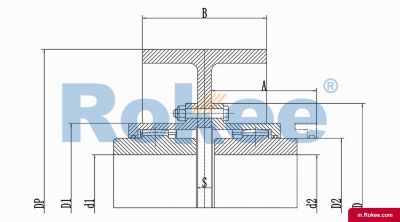

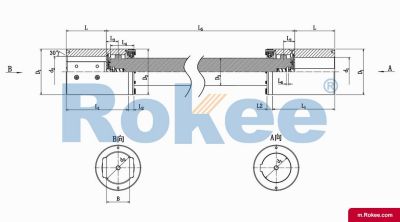

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

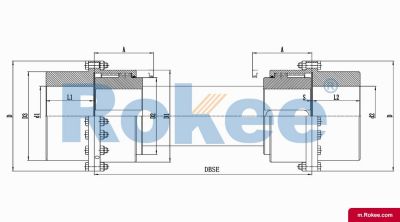

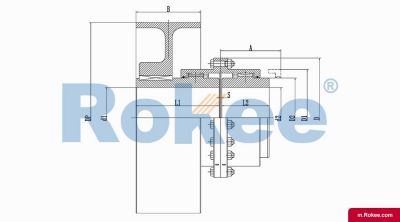

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

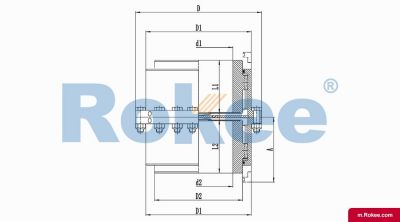

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

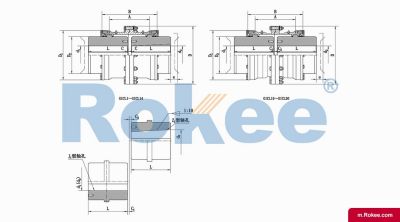

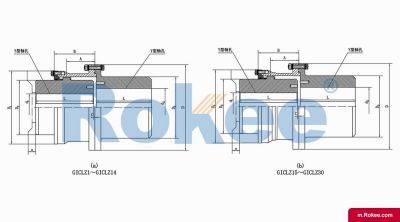

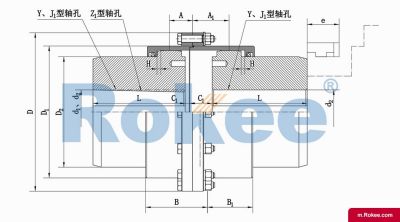

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

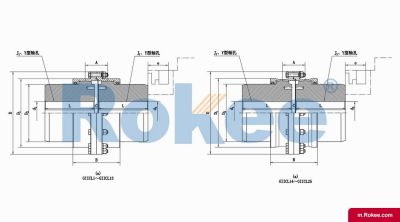

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

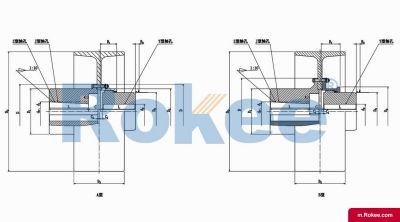

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

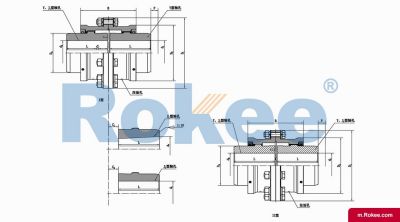

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

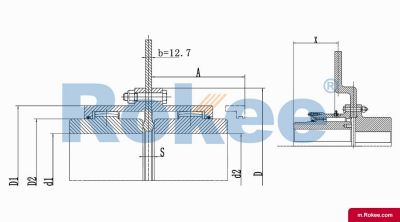

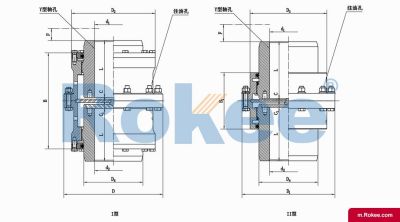

Crown Gear Coupling is an important mechanical basic component, belonging to rigid flexible coupling, and has a wide range of applications in the field of engineering technology. Crown Gear Coupling is composed of internal gear rings with the same number of teeth and flange half couplings with external teeth. Its core structure consists of an inner gear sleeve and an outer gear sleeve, and the outer gear adopts a drum shaped design with a spherical tooth tip. This design not only has a compact structure, but also has the characteristic of a small turning radius.

Advantages and Characteristics

Strong load-bearing capacity: Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-bearing capacity of the Crown Gear Coupling is on average 15-20% higher than that of the spur gear coupling. This enables the drum toothed coupling to withstand greater loads and is suitable for various heavy-duty conditions.

Large angular displacement compensation: The Crown Gear Coupling has a large angular displacement compensation capability. When the radial displacement is equal to zero, the allowable angular displacement of the spur gear coupling is 1 °, while the allowable angular displacement of the drum gear coupling is 1 ° 30 ', an increase of 50%. This enables the Crown Gear Coupling to better adapt to axis deviations and ensure smooth transmission.

High transmission efficiency: The Crown Gear Coupling has a transmission efficiency of up to 99.7%, which can efficiently transmit power from the driving shaft to the driven shaft.

Low noise and long maintenance cycle: The drum shaped tooth surface improves the contact conditions between the inner and outer teeth, avoiding the drawbacks of edge compression and stress concentration at the straight tooth end under angular displacement conditions. At the same time, this design also improves the friction and wear of the tooth surface, reduces noise, and extends the maintenance cycle.

Easy to assemble and disassemble: The outer tooth sleeve of the Crown Gear Coupling has a trumpet shaped tooth end, making the assembly and disassembly of the inner and outer teeth very convenient and improving maintenance efficiency.

Crown Gear Couplings are particularly suitable for low-speed and heavy-duty working conditions, such as metallurgy, mining, lifting and transportation industries. At the same time, it is also suitable for shaft transmission of various types of machinery such as petroleum, chemical, and general machinery. Due to its many advantages, drum toothed couplings have been widely used in these fields.

Crown Gear Couplings come in various models and specifications, such as GICL, GIICL, WG, and more than ten other models. These models can meet the needs of different compensation requirements, brake function adaptation, and vertical installation scenarios. At the same time, different models of Crown Gear Couplings also have different load-bearing capacity, angular displacement compensation capacity, etc. Users can choose according to their actual needs.

In the complex landscape of mechanical power transmission, crown gear couplings stand out as a critical component designed to address the challenges of torque transfer between misaligned shafts. These couplings are engineered with precision to balance high torsional stiffness, excellent misalignment compensation, and long service life, making them indispensable in a wide range of industrial environments. Unlike conventional gear couplings, the unique crowned tooth profile of these components enables them to adapt to various forms of shaft displacement while maintaining stable and efficient power transmission.

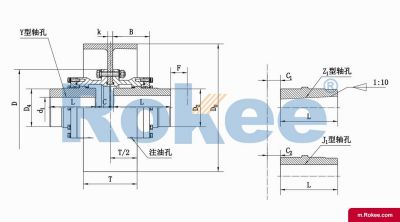

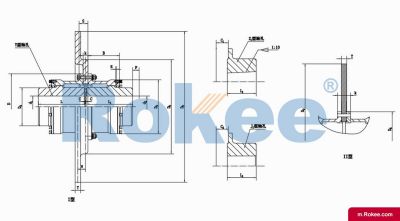

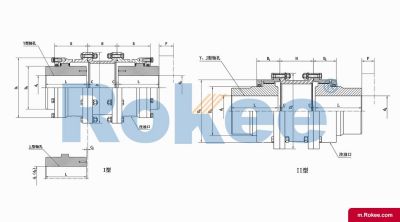

The fundamental structure of a crown gear coupling is composed of several key components that work in harmony to achieve reliable power transmission and displacement compensation. Typically, the coupling consists of two crowned tooth geared hubs, two internal straight-tooth flanges, end caps, and sealing devices. The crowned tooth hubs are the core elements, with their tooth tips shaped into a spherical or drum-like curvature; the center of this spherical curvature is aligned with the gear axis, a design feature that distinguishes crown gear couplings from other types of gear couplings. The internal flanges feature straight teeth that mesh precisely with the crowned teeth of the hubs, creating a robust connection for torque transfer. End caps are installed to secure and protect the internal components, while sealing devices—often O-rings or metal seals—prevent the ingress of dust, moisture, and other contaminants, ensuring the integrity of the coupling's internal environment. In some specialized designs, additional components such as grease nipples are integrated to facilitate lubrication, and high-strength bolts are used to fasten the flanges, enhancing the overall structural rigidity.

The working principle of a crown gear coupling is both elegant and efficient, centered on the interaction between the crowned teeth and the internal straight teeth. When in operation, torque from the driving shaft is transmitted to the crowned tooth hub, which then engages with the internal gear flange. The meshing of the crowned teeth with the straight teeth of the flange transfers this torque to the driven shaft, causing it to rotate in synchronization with the driving shaft. The key advantage of the crowned tooth profile lies in its ability to compensate for shaft misalignments. When angular, radial, or axial displacement occurs between the driving and driven shafts, the spherical curvature of the crowned teeth allows the contact points between the meshing teeth to shift dynamically. This dynamic adjustment ensures that the coupling maintains a consistent level of torque transmission without excessive stress or wear on the tooth surfaces. Unlike rigid couplings that require precise shaft alignment, crown gear couplings can accommodate a certain degree of misalignment, which is common in industrial equipment due to factors such as thermal expansion, vibration, and installation errors. This misalignment compensation capability not only improves the operational stability of the equipment but also reduces the mechanical stress on other components in the transmission system.

Crown gear couplings possess a set of performance characteristics that make them suitable for demanding industrial applications. One of their most notable advantages is high torsional stiffness, which enables them to transmit large torques without significant angular deflection. This is particularly important in heavy-duty applications where precise torque transfer is essential for the efficient operation of equipment. Additionally, these couplings have a high torque density, meaning they can transmit large amounts of torque relative to their size, allowing for more compact mechanical designs. The crowned tooth profile also results in an optimized contact area between the meshing teeth, reducing surface pressure and minimizing wear. Compared to conventional gear couplings, crown gear couplings typically have a longer service life due to this reduced wear and tear. Another key performance feature is their ability to operate over a wide range of temperatures, with standard designs capable of functioning reliably between -10°C and +80°C. This temperature tolerance makes them suitable for use in both indoor and outdoor environments, as well as in applications where temperature fluctuations are common, such as in the petrochemical and power generation industries. Furthermore, crown gear couplings exhibit low mass moment of inertia, which is beneficial in high-speed applications as it reduces the inertial load on the driving motor, improving energy efficiency and reducing wear on the motor and other transmission components.

The versatility of crown gear couplings makes them indispensable in a wide range of industrial sectors, each with its own unique requirements and operating conditions. In the metallurgical industry, these couplings are widely used in large-scale equipment such as rolling mills and blast furnaces. These applications involve heavy-duty operation, high impact loads, and frequent shaft misalignments due to the high temperatures and mechanical stresses involved. Crown gear couplings excel in these environments, providing reliable torque transmission and misalignment compensation to ensure the continuous operation of the equipment. The mining industry is another major user of crown gear couplings, where they are employed in equipment such as crushers and ball mills. These machines operate in harsh environments characterized by dust, vibration, and heavy loads, and require couplings that can withstand these conditions while maintaining performance. The robust construction and excellent misalignment compensation of crown gear couplings make them ideal for these applications, ensuring the stable operation of mining equipment even in the most challenging conditions.

In the petrochemical industry, crown gear couplings are used in pumps, compressors, and other equipment that plays a critical role in the production and transportation of chemicals and petroleum products. These applications require couplings that are corrosion-resistant, reliable, and capable of maintaining stable performance in the presence of hazardous substances. The sealing devices in crown gear couplings prevent the ingress of corrosive fluids and gases, protecting the internal components and ensuring long-term reliability. The power generation industry also relies heavily on crown gear couplings, particularly in steam turbine generators and fans. These applications involve high-speed operation and require precise torque transfer to ensure efficient power generation. The low mass moment of inertia and high torsional stiffness of crown gear couplings make them well-suited for these high-speed applications, contributing to the overall efficiency and reliability of power generation systems.

Beyond these traditional industries, crown gear couplings are also finding applications in more specialized fields. For example, in the manufacturing industry, they are used in ultra-precision tool holders for lathes. The high precision and misalignment compensation capability of these couplings enable ultra-precise positioning of the tool holder, improving the accuracy of machining operations. They are also used in dividing ultra-flat tables with direct differential dividing, where their precise torque transmission and angular displacement capabilities are essential for achieving the required level of precision. In addition, crown gear couplings are used in folding mechanisms, where their ability to accommodate large angular displacements is leveraged to enable the folding and unfolding of mechanical components. This application is particularly relevant in modern machinery that requires compact designs for transportation and storage, such as in the aerospace and automotive industries.

The proper installation of crown gear couplings is crucial for ensuring their optimal performance and long service life. Before installation, it is essential to thoroughly clean all components to remove any dirt, debris, or residual cleaning fluids that could cause corrosion or interfere with the meshing of the teeth. The mating surfaces of the hubs and flanges should be inspected for any signs of damage or wear, and any damaged components should be replaced before installation. Shaft alignment is a critical step in the installation process, as improper alignment can lead to increased wear, vibration, and reduced service life of the coupling. Professional measuring tools such as dial indicators, level gauges, and rulers should be used to ensure that the axial and radial errors between the driving and driven shafts are within acceptable limits. Typically, the axial error should be less than 0.04 mm, and the radial error should be less than 0.08 mm. These tight tolerances ensure that the coupling operates smoothly and efficiently, minimizing stress on the teeth and other components.

During installation, the hubs are usually mounted on the shafts using either a press fit or a shrink fit. In the case of a shrink fit, the hubs are heated to a specific temperature to expand their inner diameter, allowing them to be easily slipped onto the shafts. Once cooled, the hubs contract, creating a tight interference fit with the shafts. It is important to follow the correct heating temperature to avoid damaging the hubs or altering their material properties. After mounting the hubs, the flanges are attached using high-strength bolts, which should be tightened to the specified torque to ensure a secure connection. The distance between the hubs should be checked and adjusted to meet the design requirements, as this affects the coupling's ability to compensate for axial displacement. Finally, the sealing devices should be installed correctly to ensure that they provide an effective barrier against contaminants.

Proper maintenance is essential for maximizing the service life and performance of crown gear couplings. Lubrication is one of the most critical maintenance tasks, as it reduces friction between the meshing teeth, minimizes wear, and helps to dissipate heat. The type of lubricant used depends on the application and operating conditions, with lubricating grease being commonly used for small to medium-sized equipment and lubricating oil for high-speed or heavy-duty applications. In high-speed applications, some couplings are equipped with oil collecting groove holes that use centrifugal force generated by the rotating coupling to spray oil into the meshing area, ensuring continuous and sufficient lubrication. It is important to regularly inspect the lubricant level and condition, and to refill or replace the lubricant at specified intervals. For standard applications, lubricating grease should be refilled every 1000 working hours and replaced every 5000 working hours. In addition to lubrication, regular inspections of the coupling components are necessary to detect any signs of wear, damage, or misalignment. The teeth should be inspected for signs of pitting, scuffing, or excessive wear, and the sealing devices should be checked for leaks. Any damaged or worn components should be replaced promptly to avoid further damage to the coupling or other parts of the transmission system.

In conclusion, crown gear couplings are a vital component in modern mechanical power transmission systems, offering a unique combination of high torsional stiffness, excellent misalignment compensation, and long service life. Their robust construction, optimized tooth profile, and versatile performance make them suitable for a wide range of industrial applications, from heavy-duty metallurgical and mining equipment to high-precision manufacturing and power generation systems. Proper installation and maintenance are essential for ensuring the optimal performance of these couplings, with particular attention to shaft alignment, lubrication, and regular inspections. As industrial equipment continues to evolve towards higher efficiency, higher speed, and more compact designs, the demand for crown gear couplings is expected to grow, driven by their ability to meet the increasingly demanding requirements of modern mechanical systems. By understanding the structural characteristics, working principles, and performance advantages of crown gear couplings, engineers and maintenance professionals can make informed decisions about their selection, installation, and maintenance, ensuring the reliable and efficient operation of industrial equipment for years to come.

« Crown Gear Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/crown-gear-couplings.html