Rokee is a chinese Cardan Couplings Manufacturer, provide Cardan Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Cardan Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Cardan Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

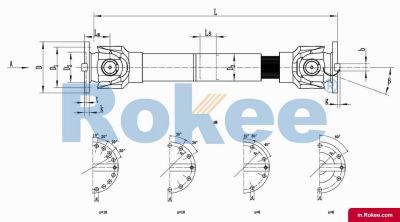

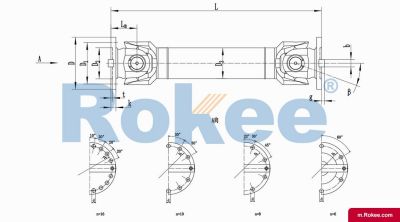

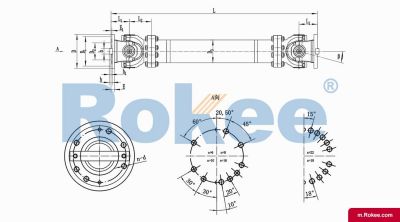

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

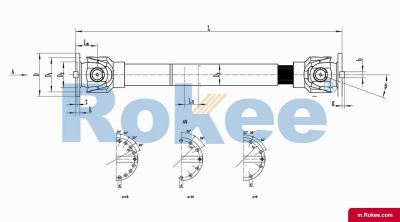

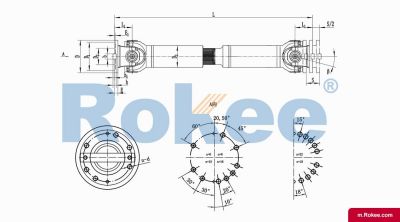

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

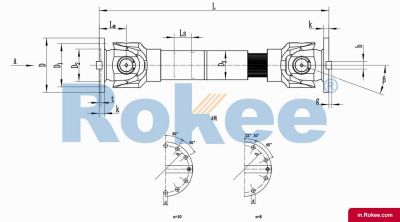

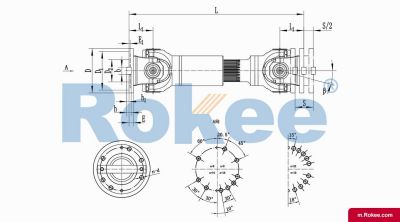

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

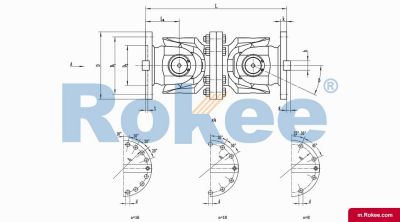

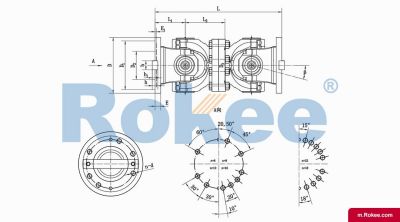

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

The Cardan Coupling utilizes its structural characteristics to enable the two shafts to rotate continuously and reliably transmit torque and motion when they are not on the same axis and there is an angle between the axes. The biggest feature of Cardan Coupling is its large angular compensation ability, compact structure, and high transmission efficiency. The angle between the two axes of Cardan Couplings of different structural types is not the same, generally between 5 ° -45 °.

There are various structural types of Cardan Couplings, such as cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type.

Cross axis Cardan Coupling is a type with a large usage, and its bearings are vulnerable parts. The main difference between several large cross axis Cardan Couplings lies in the variation of the bearing seat and cross fork head, forming different structural forms. The cross head components of the cross shaft Cardan Coupling have the following forms: SWC type integral fork head cross shaft Cardan Coupling, SWP type partial bearing seat cross shaft Cardan Coupling, SWZ type integral bearing seat cross shaft Cardan Coupling, WS type small double cross shaft Cardan Coupling, WSD type small single cross shaft Cardan Coupling, etc.

Cardan Couplings are widely used in various industrial equipment, especially in situations where torque and rotational motion need to be transmitted. For example, Cardan Couplings play an important role in metallurgy, heavy machinery, petrochemicals, engineering machinery, rail transit and other fields. In addition, specialized Cardan Couplings are often seen in sports machinery products such as agricultural and industrial machinery.

The assembly of Cardan Couplings requires adherence to certain technical specifications and steps. During assembly, it is necessary to ensure the cleanliness and accuracy of each component, especially the centerline of the two welded fork bearing holes in the middle should be on the same plane, and the allowable difference should not exceed a certain range. At the same time, the spline part should slide freely and the joint should rotate flexibly.

The daily maintenance of Cardan Couplings mainly includes lubrication and inspection. Regular lubrication is the key to maintaining good operation of the coupling, and it is recommended to develop a reasonable lubrication cycle based on the usage environment and working conditions. At the same time, it is necessary to regularly check the operation of the coupling, including whether there are any abnormal noises, whether there is axial movement of the cross package, and whether there is bearing heating phenomenon.

Precautions

In principle, both ends of the Cardan Coupling can be used as active or passive, and installation should comply with the design regulations of the transmission system, and the spline pair should be kept away from vibration or impact sources as much as possible.

For Cardan Couplings with expandable spline pairs, the arrow marks on the spline shaft and spline sleeve should be checked for alignment during installation to ensure that the phase difference between the axis lines of the fork head bearing holes at both ends does not exceed a certain range. Otherwise, the angular velocities of the main and driven shafts cannot be equal, resulting in unnecessary impact during operation.

After the installed Cardan Coupling is operated under load, the connecting bolts should be checked for looseness and tightened again to the specified torque until the bolts are no longer loose.

The angular compensation of Cardan Couplings has strict regulations and must not exceed its compensation range arbitrarily.

Overloading of couplings should be avoided to reduce their service life and lifespan, and prevent operational accidents from occurring.

In the complex network of mechanical transmission systems, the cardan coupling stands as a fundamental component that enables the seamless transfer of rotational motion and torque between shafts that are not aligned in a straight line. Also known as the universal joint coupling, this mechanical device has evolved over centuries to become an indispensable part of numerous industrial, automotive, agricultural, and aerospace applications. Its unique ability to accommodate angular misalignment between connected shafts while maintaining efficient power transmission has made it a cornerstone of modern machinery design. From the heavy-duty transmissions of commercial trucks to the precision mechanisms of agricultural equipment and even the intricate systems of aerospace vehicles, the cardan coupling plays a critical role in ensuring operational reliability and performance.

At its core, the cardan coupling is a spherical mechanism designed to transmit rotational motion between two shafts that may have varying angles relative to each other during operation. The basic structure of a conventional cardan coupling consists of two yokes (fork-shaped components) attached to the ends of the input and output shafts, and a cross-shaped element, known as the cardan cross or spider, which connects these two yokes. The cardan cross features four trunnions, each of which is fitted with a bearing that allows the cross to rotate freely within the yokes. This configuration enables the input shaft to drive the output shaft even when the axes of the two shafts are not collinear, as the cross can pivot within the yokes to compensate for angular misalignment. The bearings mounted on the trunnions are crucial for reducing friction and wear during operation, ensuring smooth rotation and extending the service life of the coupling. In some designs, a telescopic section is integrated into one of the shafts to accommodate axial displacement, which may occur due to thermal expansion or contraction of the shafts during operation or changes in the relative position of the connected components.

The working principle of the cardan coupling is rooted in kinematic mechanics, specifically the transmission of rotational motion through a spherical joint. When the input shaft rotates, it drives the connected yoke, which in turn imparts rotational motion to the cardan cross. The cross then transfers this motion to the output yoke, causing the output shaft to rotate. A key characteristic of a single cardan coupling is its inherent non-uniform velocity transmission. This means that when the input shaft rotates at a constant angular velocity, the output shaft experiences periodic fluctuations in its angular velocity, especially as the angle between the two shafts (referred to as the operating angle) increases. This non-uniformity arises from the geometric relationship between the yokes and the cardan cross: as the cross rotates, the effective radius of the trunnions relative to the yoke's axis changes, leading to variations in the output speed. These velocity fluctuations can generate vibration, noise, and additional dynamic loads on the transmission system, which may affect the performance and durability of other components. To mitigate this issue, engineers often use a double cardan coupling configuration, which consists of two single cardan couplings connected by an intermediate shaft. When properly aligned, the non-uniform velocity variations from the first coupling are canceled out by the second coupling, resulting in nearly uniform velocity transmission between the input and output shafts. This makes the double cardan coupling suitable for applications where smooth, constant-speed transmission is critical.

Over time, several variations of the cardan coupling have been developed to meet the specific requirements of different applications. The most common types include the cross-type (universal) cardan coupling, the double cardan coupling, the constant velocity (CV) cardan coupling, and the flexible cardan coupling. The cross-type cardan coupling, which is the most basic and widely used variant, features a simple structure with high torque transmission capacity and can accommodate operating angles of up to 15-20 degrees in general applications, and even up to 30 degrees in specialized off-road or heavy machinery. However, as mentioned earlier, its non-uniform velocity transmission limits its use in high-speed or precision applications. The double cardan coupling, as an improved version, addresses the velocity fluctuation issue by using two cross joints and an intermediate shaft, ensuring more consistent speed transmission and making it suitable for long-distance shaft connections, such as in multi-axle vehicles. The constant velocity cardan coupling, also known as the CV joint, is a specialized type designed to eliminate velocity fluctuations entirely, even at large operating angles. This is achieved through the use of spherical grooves and steel balls that maintain a constant velocity ratio between the input and output shafts. CV cardan couplings can accommodate operating angles of up to 45-50 degrees and are widely used in front-wheel-drive vehicles, where they connect the transmission to the front wheels and allow for both power transmission and steering movement. The flexible cardan coupling, on the other hand, incorporates elastic elements such as rubber or composite materials into its design. These elastic elements help absorb vibration, reduce noise, and compensate for minor angular and axial misalignments, making them suitable for applications where shock absorption and smooth operation are prioritized, such as in small motors or precision equipment.

The selection of materials for cardan couplings is a critical aspect of their design, as it directly impacts their strength, durability, performance, and suitability for specific operating environments. The choice of materials depends on factors such as the torque capacity required, the operating speed, the environmental conditions (e.g., temperature, humidity, corrosive substances), and the weight constraints of the application. For most standard applications, the yokes and cardan cross are typically made from high-strength carbon steels or alloy steels. Carbon steels such as 45 steel are cost-effective and offer good mechanical properties when heat-treated, making them suitable for medium-torque applications. Alloy steels, such as 40Cr, 20CrMnTi, and 42CrMo, are preferred for high-torque or heavy-duty applications due to their superior strength, toughness, and wear resistance. These alloy steels are often subjected to heat treatment processes such as carburizing, quenching, and tempering to enhance their surface hardness and core toughness, ensuring they can withstand the high stresses and impact loads encountered in heavy machinery. In applications where corrosion resistance is a priority, such as marine environments, food processing equipment, or chemical plants, stainless steel materials like 304 or 316 stainless steel are used. These materials offer excellent resistance to rust and chemical corrosion, ensuring the coupling's performance and longevity in harsh environments. For lightweight applications such as aerospace or high-speed machinery, aluminum alloys or composite materials like carbon fiber-reinforced polymers are sometimes employed. These materials significantly reduce the weight of the coupling without compromising its strength, which is crucial for improving fuel efficiency and reducing overall system inertia.

The versatility of the cardan coupling makes it applicable across a wide range of industries and machinery types. One of the most prominent applications is in the automotive industry, where cardan couplings are essential components of the transmission system. In rear-wheel-drive and four-wheel-drive vehicles, cardan couplings (often in the form of universal joints) are used to connect the transmission to the drive shaft and the drive shaft to the differential. This allows the drive shaft to transmit power from the engine to the wheels even as the suspension moves, causing changes in the angle between the shafts. In front-wheel-drive vehicles, CV cardan couplings are used to connect the transaxle to the front wheels, enabling both power transmission and steering. Heavy-duty vehicles such as trucks, buses, and off-road vehicles rely on robust cardan couplings to handle the high torque loads and large angular misalignments encountered during operation. Beyond the automotive industry, cardan couplings are widely used in industrial machinery. In manufacturing plants, they are employed in conveyor systems, pumps, compressors, and machine tools, where they facilitate power transmission between motors and various machine components. In construction and mining machinery, such as excavators, loaders, and bulldozers, cardan couplings are used to transmit power to the hydraulic systems and drive trains, withstanding the harsh operating conditions and heavy loads typical of these applications. The agricultural industry also relies heavily on cardan couplings, which are used in tractors, harvesters, and other farm equipment to connect engines to implements such as plows, mowers, and seeders. These couplings must accommodate the constant changes in angular alignment as the equipment moves over uneven terrain while maintaining efficient power transmission. Additionally, cardan couplings find applications in aerospace, where they are used in aircraft landing gear systems and engine components, and in marine engineering, where they connect ship engines to propellers, handling the dynamic misalignments caused by wave motion.

Despite their widespread use and proven reliability, cardan couplings face several challenges that drive ongoing research and development efforts. One of the primary challenges is addressing the issues associated with non-uniform velocity transmission in single cardan couplings, which can lead to vibration, noise, and premature wear of system components. While double cardan couplings and CV joints mitigate this issue, they add complexity and cost to the system, requiring precise manufacturing and alignment. Another challenge is improving the durability and maintenance requirements of cardan couplings, especially in harsh operating environments. The bearings and trunnions of the coupling are prone to wear and damage due to friction, contamination, and inadequate lubrication. To address this, manufacturers are developing advanced bearing materials and lubrication systems, such as sealed bearings that prevent the ingress of dirt and moisture, and long-lasting lubricants that reduce the frequency of maintenance. The trend toward electrification and automation in various industries, particularly in the automotive and manufacturing sectors, is also driving changes in cardan coupling design. Electric vehicles, for example, have different torque and speed characteristics compared to internal combustion engine vehicles, requiring cardan couplings that can handle higher torque loads and operate at higher speeds with minimal vibration. Additionally, the need for lightweight and compact components in electric vehicles is pushing the development of cardan couplings made from advanced composite materials and optimized designs that reduce weight without sacrificing strength. The growing focus on sustainability and environmental protection is another factor influencing the evolution of cardan couplings. Manufacturers are exploring eco-friendly materials and manufacturing processes that reduce energy consumption and minimize waste. This includes the use of recycled materials, as well as the development of couplings that are more energy-efficient, reducing power loss during transmission.

Looking to the future, the cardan coupling is expected to continue evolving to meet the changing demands of modern engineering. Advances in materials science, such as the development of new high-strength, lightweight alloys and composites, will enable the design of more efficient and durable cardan couplings. Precision manufacturing technologies, such as additive manufacturing (3D printing), will allow for the production of complex coupling designs with tighter tolerances, improving performance and reducing production costs. The integration of smart technologies into cardan couplings is also a promising area of development. Sensors embedded in the coupling could monitor key parameters such as temperature, vibration, and wear, providing real-time data to maintenance teams and enabling predictive maintenance. This would help reduce downtime, extend the service life of the coupling, and improve overall system reliability. Additionally, the trend toward electrification and autonomous systems will drive the development of specialized cardan couplings tailored to the unique requirements of these technologies, such as high-torque capacity, low noise, and compact design. In the automotive sector, the shift to electric and hybrid vehicles will continue to increase the demand for CV cardan couplings and other advanced variants that can handle the high-performance requirements of these vehicles. In industrial automation, cardan couplings will play a key role in enabling the precise and efficient operation of robotic systems and automated production lines, where smooth power transmission and reliability are critical.

In conclusion, the cardan coupling is a vital component in mechanical transmission systems, enabling the efficient transfer of rotational motion and torque between misaligned shafts across a wide range of applications. Its simple yet effective design, combined with its versatility and durability, has made it an indispensable part of modern machinery. From its basic cross-type design to advanced CV joints and flexible variants, the cardan coupling has evolved to meet the specific needs of different industries, from automotive and industrial to agricultural and aerospace. The selection of appropriate materials and the ongoing development of new designs and technologies are crucial to addressing the challenges faced by cardan couplings, such as non-uniform velocity transmission, wear, and maintenance requirements. As industries continue to evolve toward electrification, automation, and sustainability, the cardan coupling will undoubtedly play a key role in supporting these advancements, with future designs focusing on lightweight materials, smart monitoring, and enhanced performance. The enduring relevance of the cardan coupling in mechanical engineering is a testament to its fundamental importance in enabling the reliable and efficient operation of the machinery that powers our modern world.

« Cardan Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/cardan-couplings.html