Rokee is a chinese Geared Couplings Manufacturer, provide Geared Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Geared Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Geared Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

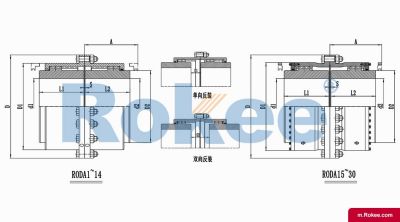

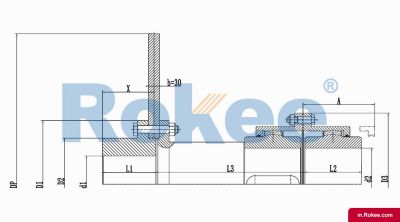

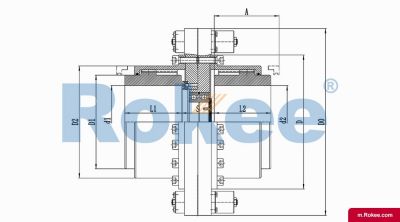

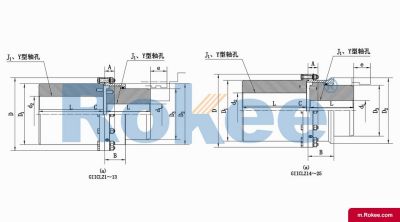

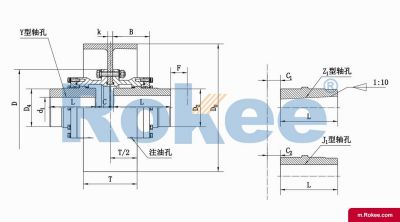

RODA Basic Drum Gear Coupling

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.View More -

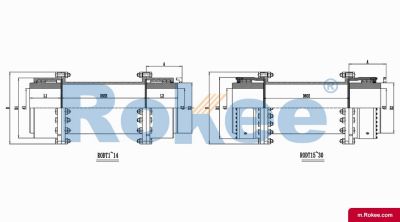

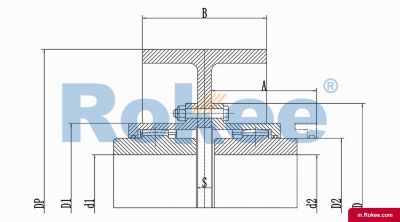

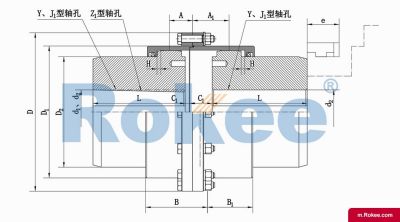

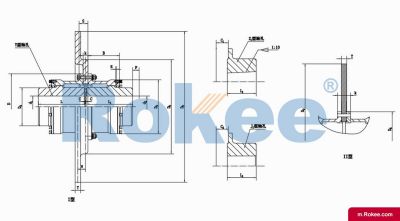

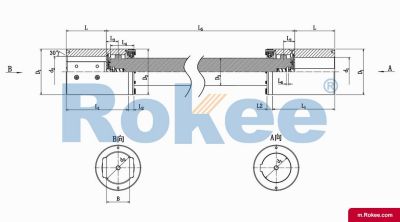

RODT Drum Gear Coupling With Intermediate Tube

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.View More -

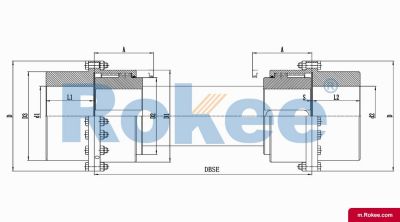

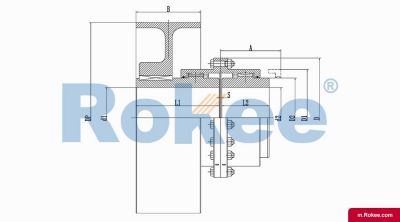

RODX Drum Gear Coupling With Intermediate Shaft

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.View More -

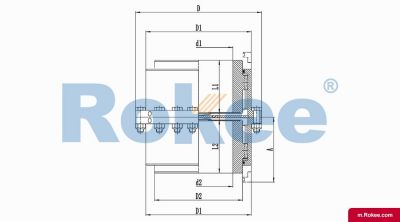

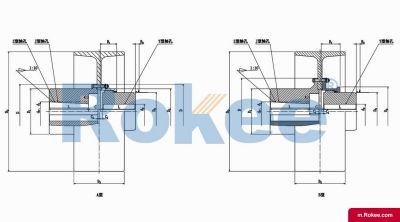

RODP Drum Gear Coupling With Brake Disc

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.View More -

RODF Drum Gear Coupling With Split Brake Discs

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.View More -

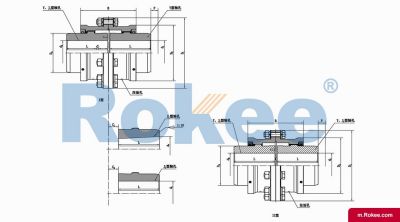

RODW Drum Gear Coupling With Brake Wheel

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.View More -

RODU Drum Gear Coupling With Brake Wheel

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.View More -

RODV Vertical Installation Drum Gear Coupling

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.View More -

RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.View More -

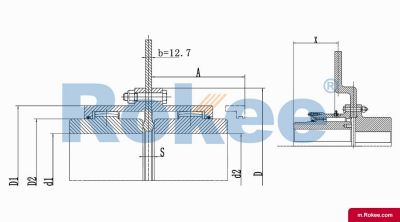

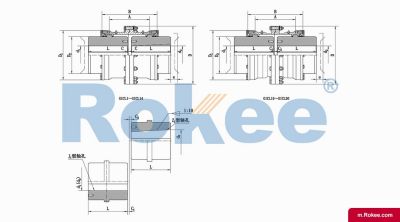

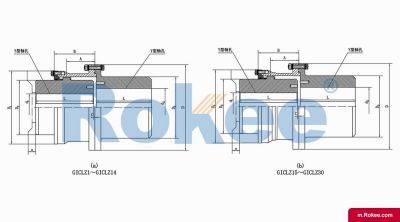

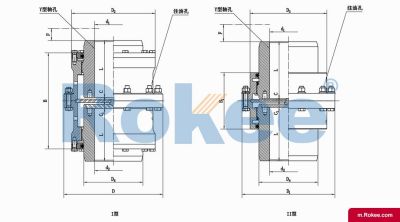

GICL Wide Type Drum Gear Coupling

GICL Drum Gear Coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.View More -

GICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.View More -

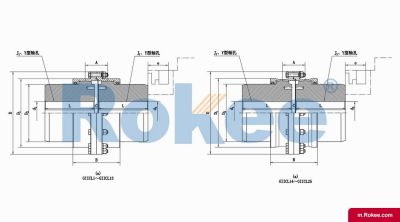

GIICL Narrow Type Drum Gear Coupling

GIICL Drum Gear Coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.View More -

GIICLZ Drum Gear Coupling With Intermediate Shaft

Half of the GIICLZ Drum Gear Coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.View More -

GCLD Drum Gear Coupling For Motor

GCLD Drum Gear Coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.View More -

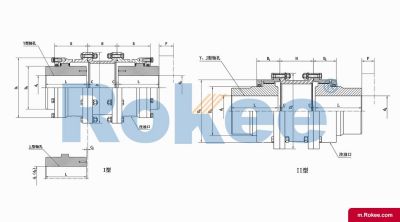

NGCL Drum Gear Coupling With Brake Wheel

NGCL Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required.View More -

NGCLZ Drum Gear Coupling With Brake Wheel

NGCLZ Drum Gear Coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.View More -

WG Drum Gear Coupling

The overall characteristics of WG Drum Gear Coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.View More -

WGZ Drum Gear Coupling With Brake Wheel

WGZ Drum Gear Coupling is designed with a brake wheel, suitable for shoe type braking.View More -

WGP Drum Gear Coupling With Brake Discs

WGP Drum Gear Coupling is designed with a brake disc, suitable for disc type braking.View More -

WGT Drum Gear Coupling With Indirect Tube

WGT Drum Gear Coupling is designed with indirect tube, suitable for long distance torque transfer.View More -

WGC Vertical Installation Drum Gear Coupling

WGC Drum Gear Coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.View More -

WGJ Drum Gear Coupling With Intermediate Shaft

WGJ Drum Gear Coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.View More

As the core component of industrial transmission systems, geared couplings occupy an important position in the field of heavy machinery due to their excellent torque transmission capability and outstanding deviation compensation performance.

The geared coupling is composed of three precision components that work together:

External gear shaft sleeve: usually forged from 42CrMo alloy steel, treated with carburizing and quenching (surface hardness HRC58-62), with tooth profile accuracy reaching GB/T10095 level 6 standard

Internal gear ring: ZG35CrMo cast steel is commonly used, and the internal teeth are subjected to ion nitriding treatment after hobbing, with the tooth surface roughness controlled within Ra0.8

Sealing system: including fluororubber skeleton oil seal (temperature resistance -30 ℃~200 ℃) and labyrinth sealing structure, ensuring grease retention rate>95%

The unique feature of torque transmission through involute gear meshing principle is that:

Drum shaped tooth design: The curvature radius of the outer tooth spherical surface is R=(1.2~1.5) d (d is the diameter of the indexing circle), allowing for an axial deflection angle of up to 2.5 °

Dynamic compensation: At a speed of 3000rpm, it can automatically compensate for radial deviation of ± 1.2mm and axial float of ± 0.8mm

Overload protection: When the torque exceeds 30% of the rated value, controllable slip occurs between the tooth surfaces to avoid equipment damage

Application field

Heavy industry sector

Metallurgical equipment: The main transmission system of the hot rolling mill can withstand instantaneous impact torque up to 5-8 times the rated value

Mining machinery: ball mill drive device, with a lifespan of over 30000 hours under continuous working conditions

Shipbuilding industry: Promote shaft connections and compensate for axis offsets caused by hull deformationEnergy and Transportation

Wind power gearbox: equipped with a 5MW unit, achieving dynamic yaw compensation of ± 1 °

High speed rail drive: applied to high-speed trains with a speed of 350km/h, with vibration acceleration controlled within 0.8m/s ²

Gas turbine: high-speed type (12000rpm) with dynamic balancing treatment, residual unbalance less than 1g · mm/kg

In the realm of mechanical power transmission, the efficient and reliable transfer of torque between rotating shafts stands as a fundamental requirement for countless industrial operations. Among the diverse array of coupling devices designed to fulfill this critical function, the geared coupling has emerged as a robust and versatile solution, particularly suited for demanding applications where high torque, misalignment compensation, and durability are paramount. Unlike flexible couplings that rely on elastic elements for torque transmission and misalignment absorption, geared couplings leverage the meshing of gear teeth to establish a rigid yet adaptable connection between shafts. This unique design confers upon them distinct advantages in terms of load-carrying capacity and torsional stiffness, making them indispensable components in heavy machinery, industrial drives, and power generation systems.

At the core of a geared coupling's functionality lies its intricate structural design, which is meticulously engineered to balance torque transmission efficiency with the ability to accommodate various forms of shaft misalignment. A typical geared coupling consists of two main components: a pair of toothed hubs (also known as semi-couplings) and an outer sleeve (or housing) with internal teeth. Each toothed hub is securely attached to the end of the respective shafts that need to be connected, usually via keys, splines, or interference fits to ensure a tight and slip-free connection. The outer sleeve, which encloses the meshing teeth of the hubs, serves dual purposes: it maintains the alignment of the meshing gears and provides protection against external contaminants such as dust, dirt, and moisture. The gear teeth on both the hubs and the sleeve are precision-machined to ensure smooth meshing, with common tooth profiles including involute and cycloidal designs. These tooth profiles are selected based on the specific application requirements, with involute teeth being the most prevalent due to their ability to distribute load evenly and accommodate slight misalignments without excessive wear. In some designs, the coupling may also incorporate a flexible element or a floating sleeve to enhance misalignment capacity, though the primary source of flexibility remains the meshing of the gear teeth themselves.

The working principle of a geared coupling revolves around the transfer of torque through the meshing of the gear teeth on the hubs and the outer sleeve. When one shaft rotates, it imparts rotational motion to its associated toothed hub. This rotational force is then transmitted to the outer sleeve via the meshing teeth, which in turn drives the second toothed hub and its connected shaft. The key advantage of this gear-based transmission is its ability to handle extremely high torque levels, far exceeding those of many other coupling types. Additionally, the meshing gear teeth allow for a certain degree of misalignment between the two shafts, including angular misalignment (where the shafts are not colinear but intersect at a point), parallel misalignment (where the shafts are parallel but offset from each other), and axial misalignment (where the shafts move along their axial direction). The amount of misalignment that a geared coupling can accommodate depends on several factors, including the design of the gear teeth, the number of teeth, the backlash between the meshing components, and the overall size of the coupling. While geared couplings are not as flexible as elastic couplings, their ability to combine high torque capacity with moderate misalignment compensation makes them ideal for applications where both factors are critical.

The performance characteristics of geared couplings are defined by a range of key parameters that determine their suitability for specific applications. Torque capacity is perhaps the most prominent of these parameters, with geared couplings capable of transmitting torques ranging from a few hundred newton-meters to several thousand newton-meters, depending on their size and design. This high torque capacity is attributed to the large contact area between the meshing gear teeth, which distributes the load evenly and reduces the stress on individual teeth. Another important performance parameter is torsional stiffness, which refers to the coupling's resistance to twisting under torque. Geared couplings exhibit high torsional stiffness, meaning that they experience minimal angular deflection when transmitting torque. This stiffness is crucial in applications where precise shaft synchronization is required, such as in conveyor systems, pumps, and compressors, as it prevents loss of power and ensures efficient operation. Additionally, geared couplings are known for their durability and long service life, particularly when properly lubricated and maintained. The use of high-strength materials and precision machining ensures that the gear teeth can withstand repeated cycles of loading without premature wear or failure.

The selection of materials for geared couplings is a critical aspect of their design, as it directly impacts their performance, durability, and suitability for different operating environments. The most common materials used for the toothed hubs and outer sleeves are high-strength alloy steels, such as 40Cr, 42CrMo, and 35CrMo. These alloys offer excellent mechanical properties, including high tensile strength, hardness, and fatigue resistance, which are essential for withstanding the high stresses encountered during torque transmission. The gear teeth are often heat-treated through processes such as carburizing, quenching, and tempering to further enhance their surface hardness and wear resistance, while maintaining the toughness of the core material to prevent brittle fracture. In applications where corrosion resistance is a concern, such as in marine environments or chemical processing plants, stainless steel or alloy steels with corrosion-resistant coatings may be used. The choice of material also depends on the operating temperature, with special heat-resistant alloys being employed for high-temperature applications, such as in power generation systems where couplings are exposed to elevated temperatures from engines or turbines.

Geared couplings find widespread application across a diverse range of industries, owing to their high torque capacity, torsional stiffness, and durability. One of the primary application areas is in heavy machinery, including mining equipment, construction machinery, and steel mills. In mining operations, for example, geared couplings are used to connect the shafts of large crushers, conveyors, and excavators, where they must transmit high torques under harsh operating conditions involving dust, vibration, and frequent starts and stops. In steel mills, they are employed in rolling mills, where they ensure the precise synchronization of shafts driving the rolls, which is essential for producing uniform steel products. Another major application domain is power generation, where geared couplings are used in thermal power plants, hydroelectric plants, and wind turbines. In thermal power plants, they connect the turbine shafts to the generator shafts, transmitting the high torque produced by the turbine to the generator to produce electricity. In wind turbines, they play a crucial role in connecting the rotor shaft to the gearbox, and in some cases, directly to the generator, ensuring efficient power transfer from the rotating blades to the electrical system.

The industrial sector also relies heavily on geared couplings in various types of rotating equipment, such as pumps, compressors, and fans. In pump systems, particularly those used in oil and gas exploration, water treatment, and chemical processing, geared couplings connect the pump shaft to the motor shaft, enabling the transfer of torque required to move fluids under high pressure. Compressors, which are used to compress gases in industrial processes and refrigeration systems, also utilize geared couplings to ensure efficient power transmission between the motor and the compressor rotor. Additionally, geared couplings are used in material handling systems, such as conveyor belts and overhead cranes, where they provide the necessary torque to move heavy loads and ensure smooth and reliable operation. Even in some automotive and aerospace applications, albeit on a smaller scale, geared couplings are used in transmissions and drive systems where high torque capacity and precision are required.

Proper installation and alignment are critical to the performance and service life of geared couplings. Misalignment beyond the coupling's designed capacity can lead to excessive wear on the gear teeth, increased vibration, reduced efficiency, and premature failure. The installation process typically involves several key steps, starting with the preparation of the shaft ends. The shaft surfaces must be clean, free of burrs, and properly machined to ensure a tight fit with the toothed hubs. The hubs are then mounted on the shafts using the appropriate method, such as keyway connections or interference fits, and secured with locking nuts or bolts. Once the hubs are in place, the outer sleeve is installed over the meshing teeth, ensuring that it is properly aligned and seated. The next crucial step is the alignment of the two shafts, which can be performed using various tools and techniques, such as straightedge and feeler gauge methods, dial indicators, or laser alignment systems. Laser alignment systems are increasingly preferred for their high accuracy, particularly in applications where precise alignment is essential. The alignment process must address both angular and parallel misalignment, ensuring that the shafts are within the coupling's specified misalignment limits.

Lubrication is another essential aspect of geared coupling maintenance, as it reduces friction between the meshing gear teeth, minimizes wear, dissipates heat, and protects against corrosion. The type of lubricant used depends on the operating conditions, including temperature, load, and speed. Common lubricants for geared couplings include mineral oils, synthetic oils, and greases. Mineral oils are suitable for most standard applications, while synthetic oils are preferred for high-temperature or high-speed operations, as they offer better thermal stability and oxidation resistance. Greases are used in applications where oil leakage is a concern or where the coupling is not easily accessible for frequent oil changes. The lubrication interval depends on the operating conditions, with couplings operating under heavy loads or in harsh environments requiring more frequent lubrication. Regular inspection of the lubricant level and condition is also important, as contaminated or degraded lubricant can lead to increased wear and component failure. Additionally, the coupling's seals should be inspected regularly to ensure that they are intact and functioning properly, preventing the ingress of contaminants and the leakage of lubricant.

Regular maintenance and inspection are essential to ensure the long-term reliability and performance of geared couplings. Routine maintenance activities include checking for signs of wear, such as pitting, scuffing, or excessive tooth wear, which can indicate misalignment, inadequate lubrication, or overloading. Vibration analysis is also a useful tool for detecting potential issues, as increased vibration can be a sign of misalignment, worn gear teeth, or loose components. The coupling's fasteners, such as bolts and locking nuts, should be checked regularly to ensure that they are tight, as loose fasteners can lead to misalignment and increased stress on the gear teeth. In addition to routine inspections, periodic disassembly and overhaul may be required for couplings operating under severe conditions. During overhaul, the gear teeth are inspected in detail, and any worn or damaged components are replaced. The coupling is then reassembled, realigned, and re-lubricated to ensure optimal performance.

Despite their many advantages, geared couplings do have certain limitations that must be considered when selecting a coupling for a specific application. One of the main limitations is their relatively high cost compared to other types of couplings, such as flexible pin couplings or jaw couplings. This higher cost is attributed to the precision machining required for the gear teeth and the use of high-strength materials. Another limitation is their limited misalignment capacity compared to elastic couplings, which can absorb larger amounts of misalignment through the deformation of elastic elements. Geared couplings also require regular lubrication and maintenance, which can add to the overall operating costs. Additionally, the meshing of gear teeth can generate noise, particularly at high speeds, which may be a concern in applications where noise levels are critical. However, these limitations are often outweighed by the geared coupling's high torque capacity, torsional stiffness, and durability, making them the preferred choice for many demanding applications.

The future development of geared couplings is likely to be driven by advancements in materials science, manufacturing technology, and digital monitoring systems. The use of new high-performance materials, such as composite materials and advanced alloys, may further enhance the strength, durability, and corrosion resistance of geared couplings, while reducing their weight. Advances in manufacturing technologies, such as additive manufacturing (3D printing), may enable the production of more complex gear tooth profiles and coupling designs, optimizing their performance and reducing production costs. Additionally, the integration of digital monitoring and predictive maintenance systems is expected to become more prevalent, allowing for real-time monitoring of coupling performance parameters such as temperature, vibration, and lubricant condition. These systems can detect potential issues before they lead to failure, enabling proactive maintenance and reducing downtime. The development of more efficient lubricants and sealing technologies may also contribute to improving the reliability and service life of geared couplings, particularly in harsh operating environments.

In conclusion, geared couplings play a vital role in mechanical power transmission, offering a unique combination of high torque capacity, torsional stiffness, and moderate misalignment compensation. Their robust design and durability make them indispensable components in a wide range of industries, from heavy machinery and power generation to industrial equipment and material handling systems. The proper selection, installation, alignment, and maintenance of geared couplings are critical to ensuring their optimal performance and long service life. While they have certain limitations, ongoing advancements in materials, manufacturing, and monitoring technologies are expected to further enhance their capabilities and expand their range of applications. As industrial operations continue to demand higher efficiency, reliability, and performance, the importance of geared couplings in power transmission systems is likely to remain unchanged, solidifying their position as a key component in modern engineering.

« Geared Couplings » Update Date: 2026/1/10

URL: https://m.rokee.com/tags/geared-couplings.html