Rokee is a chinese Industrial Cardan Shafts Manufacturer, provide Industrial Cardan Shafts processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Industrial Cardan Shafts selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Industrial Cardan Shafts is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

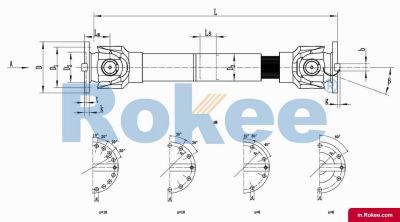

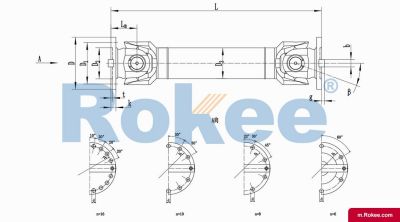

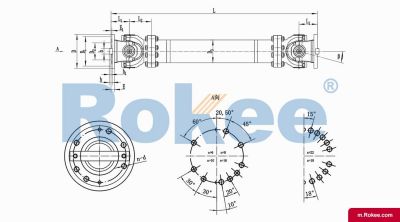

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

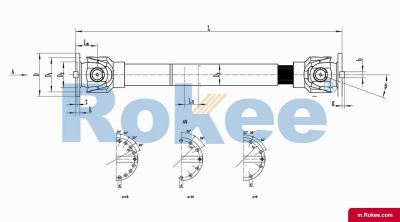

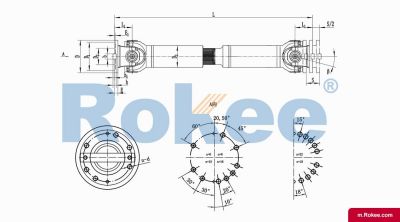

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

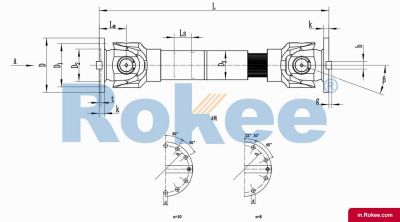

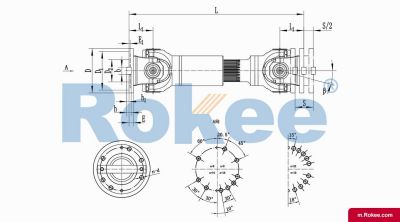

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

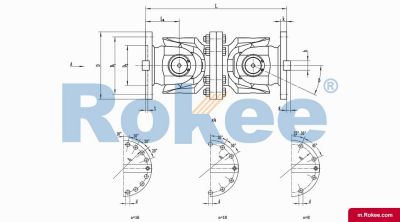

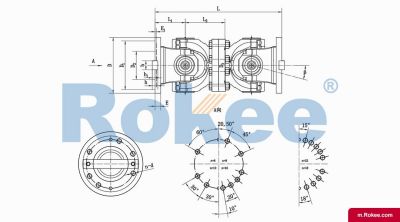

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

Industrial Cardan Shaft is a mechanism that utilizes the characteristics of its mechanism to enable continuous rotation of the two shafts connected without being on the same axis and with an angle between the axes, and to reliably transmit torque and motion. It has a large angular compensation capability, compact structure, and high transmission efficiency. There are various structural types of Industrial Cardan Shafts, such as cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type. The core component of the cross axis Industrial Cardan Shaft is the cross axis, which allows the two shafts to rotate continuously at equal angular velocities within a large range of angles. The ball cage Industrial Cardan Shaft achieves two axis transmission through components such as the outer ring of the ball cage, the inner ring of the star shape, the cage, and the transmission steel ball. It is suitable for working conditions with large inclination angles and limited radial dimensions.

According to the magnitude of the transmitted torque, Industrial Cardan Shafts can be classified as heavy, medium, light, and small. Different models of Industrial Cardan Shafts are suitable for different mechanical transmission systems. Industrial Cardan Shafts are widely used in metallurgy, heavy machinery, petrochemicals, engineering machinery, rail transportation, agricultural machinery, industrial machinery and other fields. For example, in steel rolling machinery, Industrial Cardan Shafts are used to connect rollers and transmission systems, achieving reliable torque transmission; In heavy transportation equipment, it is used to connect the wheels and transmission shaft, ensuring that the vehicle can travel smoothly in various road conditions.

Industrial Cardan Shafts have significant angular compensation capabilities and can adapt to changes in the angle between two shafts. Compact structure, small footprint, easy to install and maintain. The transmission efficiency of Industrial Cardan Shafts is high, which can reduce energy loss and improve the overall performance of mechanical transmission systems. Using high-quality materials and advanced manufacturing processes, the Industrial Cardan Shaft has high reliability and durability.

When selecting a Industrial Cardan Shaft, factors such as the magnitude of the transmitted torque, the speed of the shaft, and the magnitude and direction of the relative displacement between the two shafts need to be considered. At the same time, it is necessary to refer to the characteristics of various types of couplings and choose a suitable type of coupling. For the Industrial Cardan Shafts that have already been selected, regular maintenance and upkeep are required. For example, regular lubrication can extend its service life; When disassembling and reinstalling, it is necessary to pay attention to adjusting the position of the cross axis to balance wear and tear; In addition, it is necessary to regularly check the wear of the coupling and replace damaged components in a timely manner.

« Industrial Cardan Shafts » Post Date: 2024/5/8

URL: https://m.rokee.com/tags/industrial-cardan-shafts.html