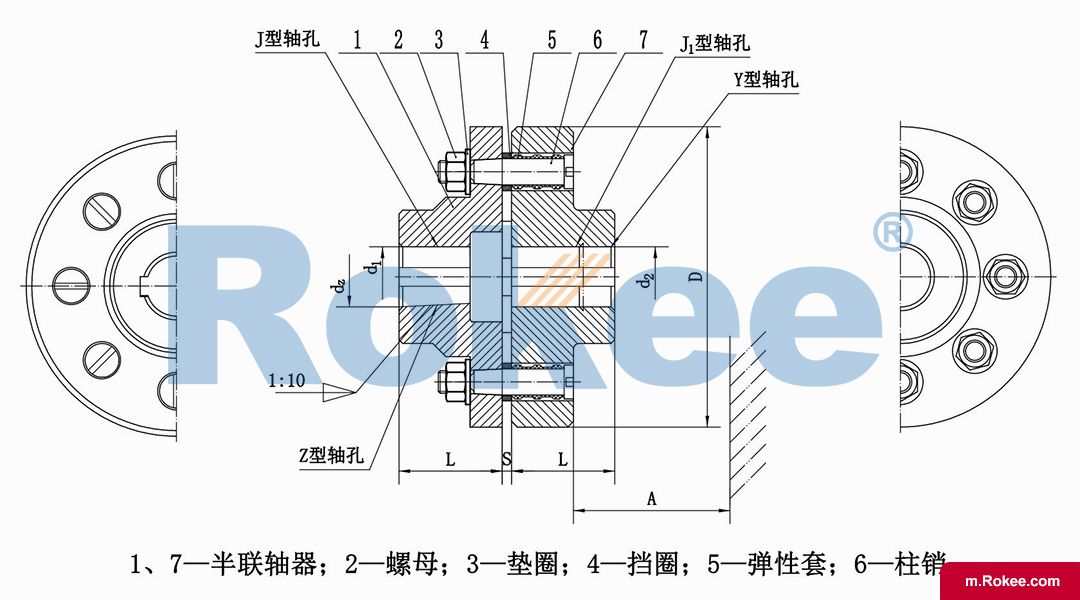

LT Elastic Sleeve Pin Coupling is the basic form of this series of couplings.

| Model | Nominal Torque N ·m | Allowable Rotating Speed rpm | Shaft Hole Diameter d1、d2 | Shaft Hole Length L | D mm | D1 mm | S mm | A mm | Rotational Inertia Kg ·m2 | Weight kg | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y型 | J、Z型 | |||||||||||

| L | L1 | L | ||||||||||

| mm | ||||||||||||

| LT1 | 16 | 8800 | 10,11 | 22 | 25 | 22 | 71 | 22 | 3 | 18 | 0.0004 | 0.7 |

| 12,14 | 27 | 32 | 27 | |||||||||

| LT2 | 25 | 7600 | 12,14 | 27 | 32 | 27 | 80 | 30 | 3 | 18 | 0.001 | 1.0 |

| 16,18,19 | 30 | 42 | 30 | |||||||||

| LT3 | 63 | 6300 | 16,18,19 | 30 | 42 | 30 | 95 | 35 | 4 | 35 | 0.002 | 2.2 |

| 20,22 | 38 | 52 | 38 | |||||||||

| LT4 | 100 | 5700 | 20,22,24 | 38 | 52 | 38 | 106 | 42 | 4 | 35 | 0.004 | 3.2 |

| 25,28 | 44 | 62 | 44 | |||||||||

| LT5 | 224 | 4600 | 25,28 | 44 | 62 | 44 | 130 | 56 | 5 | 45 | 0.011 | 5.5 |

| 30,32,35 | 60 | 82 | 60 | |||||||||

| LT6 | 355 | 3800 | 32,35,38 | 60 | 82 | 60 | 160 | 71 | 5 | 45 | 0.026 | 9.6 |

| 40,42 | 84 | 112 | 84 | |||||||||

| LT7 | 560 | 3600 | 40,42,45,48 | 84 | 112 | 84 | 190 | 80 | 5 | 45 | 0.06 | 15.7 |

| LT8 | 1120 | 3000 | 40,42,45,48,50,55 | 84 | 112 | 84 | 224 | 95 | 6 | 65 | 0.13 | 24.0 |

| 60,63,65 | 107 | 142 | 107 | |||||||||

| LT9 | 1600 | 2850 | 50,55 | 84 | 112 | 84 | 250 | 110 | 6 | 65 | 0.20 | 31.0 |

| 60,63,65,70 | 107 | 142 | 107 | |||||||||

| LT10 | 3150 | 2300 | 63,65,70,75 | 107 | 142 | 107 | 315 | 150 | 8 | 80 | 0.64 | 60.2 |

| 80,85,90,95 | 132 | 172 | 132 | |||||||||

| LT11 | 6300 | 1800 | 80,85,90,95 | 132 | 172 | 132 | 400 | 190 | 10 | 100 | 2.06 | 114 |

| 100,110 | 167 | 212 | 167 | |||||||||

| LT12 | 12500 | 1450 | 100,110,120,125 | 167 | 212 | 167 | 475 | 220 | 12 | 130 | 5.00 | 212 |

| 130 | 202 | 252 | 202 | |||||||||

| LT13 | 22400 | 1150 | 120,125 | 167 | 212 | 167 | 600 | 280 | 14 | 180 | 16.0 | 416 |

| 130,140,150 | 202 | 252 | 202 | |||||||||

| 160,170 | 242 | 302 | 242 | |||||||||

LT elastic sleeve pin coupling is a non-metallic elastic element flexible coupling that is structurally similar to a flange coupling.

The TL elastic sleeve column pin coupling consists of two halves of a coupling, which are connected by a column pin with an elastic sleeve on one end. When the coupling is working, the elastic sleeve will deform while transmitting torque, thereby compensating for the relative displacement between the two shafts (including radial, axial, and angular), and absorbing vibration and impact energy.

Performance Characteristics

Simple structure: The LT type elastic sleeve pin coupling has a relatively simple structure, is easy to manufacture, and does not require complex processing techniques.

No lubrication required: Due to the use of elastic sleeves made of rubber or leather materials, this coupling does not require lubrication during operation, reducing maintenance costs.

Easy to replace: After the elastic sleeve wears out, it can be replaced separately without disassembling the entire coupling, making maintenance convenient.

Compensation capability: It has a certain ability to compensate for the relative offset of two axes, suitable for situations with high precision requirements.

Vibration damping and buffering: The elastic sleeve can absorb vibration and impact energy, playing a certain role in vibration damping and buffering.

Application Scope:

- Suitable for small and medium power shaft transmission systems with good base rigidity, high centering accuracy, and low impact loads.

Widely used in the transmission system of equipment such as water pumps and fans.

Precautions

Regular inspection: As the elastic sleeve will wear out after long-term use, it is necessary to regularly inspect and replace the worn elastic sleeve.

Alignment accuracy: During installation and debugging, it is necessary to ensure that the alignment accuracy of the two shafts is within the allowable range to ensure the normal operation of the coupling and extend its service life.

Allowable compensation amount: The allowable compensation amount for the axis displacement of this coupling is relatively small and not suitable for situations with strict compensation requirements.

The LT elastic sleeve pin coupling is developed on the basis of the original TL type, with more diverse models covering various specifications such as TL8 to TL13. With the advancement of technology and changes in market demand, the performance parameters and application scope of this coupling are constantly expanding and improving.

TL elastic sleeve pin coupling has been widely used in small and medium power shaft transmission due to its simple structure, easy manufacturing, no need for lubrication, convenient replacement, and certain compensation ability and vibration damping performance.

URL: https://m.rokee.com/pin-and-bush-couplings/lt-or-tl-elastic-sleeve-pin-coupling.html