The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.

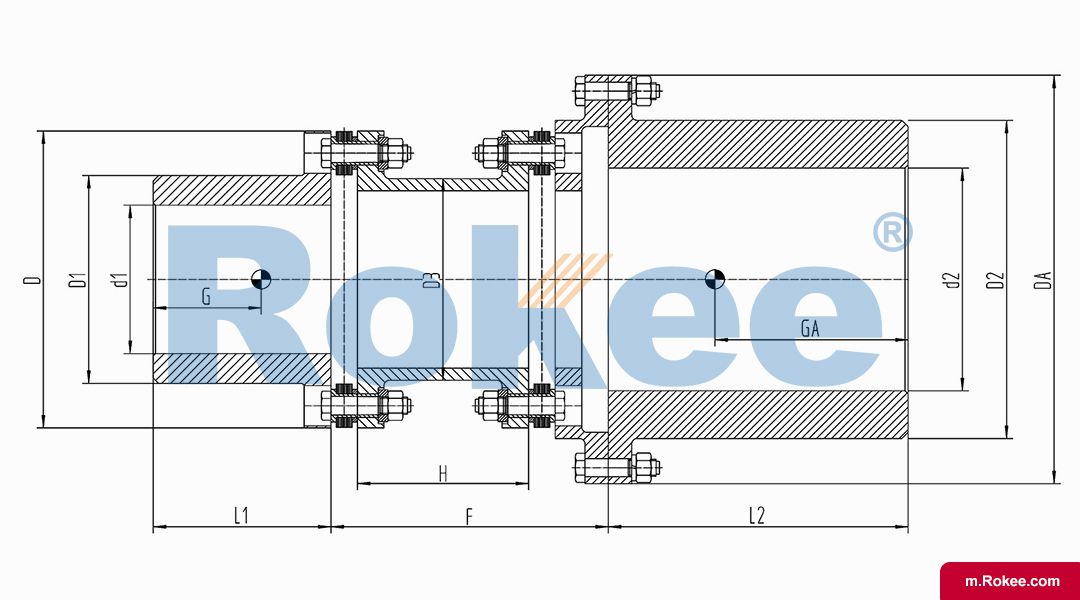

| Model | D/DA | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAF125-6 | 125/155 | 70/105 | 68 | 50 | 70 | 55/75 | 11 | 14000 | 650 | 1300 |

| RLAF135-6 | 135/168 | 92/119 | 82 | 65 | 85 | 70/90 | 11 | 11800 | 1180 | 2478 |

| RLAF156-6 | 160/190 | 105/140 | 96 | 75 | 100 | 80/105 | 15 | 10000 | 2100 | 2780 |

| RLAF178-6 | 180/218 | 119/161 | 117 | 85 | 115 | 90/120 | 15 | 8500 | 3580 | 5600 |

| RLAF210-6 | 210/258 | 140/182 | 122 | 100 | 130 | 105/135 | 20 | 7800 | 5000 | 7800 |

| RLAF225-6 | 230/276 | 154/217 | 144 | 110 | 155 | 115/165 | 22 | 6500 | 8500 | 13200 |

| RLAF255-6 | 260/295 | 168/238 | 158 | 120 | 170 | 125/180 | 24 | 5800 | 9000 | 14040 |

| RLAF280-6 | 280/320 | 196/259 | 171 | 140 | 185 | 150/195 | 30 | 5200 | 13500 | 21060 |

| RLAF305-6 | 310/356 | 210/273 | 193 | 150 | 195 | 160/205 | 32 | 4350 | 20250 | 31500 |

| RLAF340-6 | 340/400 | 238/308 | 230 | 170 | 220 | 180/230 | 34 | 3880 | 30500 | 47500 |

| RLAF365-6 | 370/425 | 258/350 | 228 | 190 | 250 | 200/260 | 34 | 3500 | 32500 | 78500 |

| RLAF420-6 | 420/495 | 278/406 | 269 | 200 | 290 | 210/290 | 36 | 3100 | 42000 | 95800 |

| Model | Mass Point G/GA | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct+10E6(N.m/rad) | (Kg) | Ct+10E6(N.m/rad) | J(Kg.m²) | |

| RLAF125-6 | 52.1/69.12 | 1 | 1 | 65 | 1.57 | 0.00644 | 0.34 | 7.8 | 0.17 | 0.01708 |

| RLAF135-6 | 62.2/83.97 | 1 | 1 | 65 | 1.82 | 0.0078 | 0.29 | 11.2 | 0.145 | 0.0225 |

| RLAF156-6 | 64.5/87.075 | 1 | 1.4 | 85 | 2.7 | 0.0163 | 0.84 | 16.1 | 0.42 | 0.05 |

| RLAF178-6 | 77.6/100.88 | 1 | 1.4 | 85 | 3.3 | 0.0224 | 1.1 | 23.2 | 0.55 | 0.0768 |

| RLAF210-6 | 80.6/104 | 1 | 1.4 | 105 | 6.16 | 0.0682 | 1.97 | 33.58 | 0.985 | 0.1974 |

| RLAF225-6 | 96.9/121.125 | 0.75 | 1.6 | 105 | 7.17 | 0.0873 | 3.45 | 47.02 | 1.725 | 0.2806 |

| RLAF255-6 | 103.2/128 | 0.75 | 1.6 | 150 | 13.64 | 0.223 | 5.13 | 67.92 | 2.565 | 0.646 |

| RLAF280-6 | 118.1/147.625 | 0.75 | 2 | 160 | 14.77 | 0.242 | 7.94 | 89.72 | 3.97 | 0.814 |

| RLAF305-6 | 122/152.5 | 0.75 | 2 | 185 | 24.43 | 0.535 | 9.35 | 118.54 | 4.675 | 1.58 |

| RLAF340-6 | 141.3/162.495 | 0.75 | 2 | 190 | 30.23 | 0.807 | 12.58 | 164.54 | 6.29 | 2.464 |

| RLAF365-6 | 145/166.675 | 0.75 | 2 | 210 | 37.4 | 1.17 | 15.95 | 195.75 | 7.975 | 3.55 |

| RLAF420-6 | 167.8/192.97 | 0.75 | 2 | 220 | 49.5 | 2.036 | 23.95 | 272.875 | 11.975 | 6.222 |

| Model | DA/D | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAF255-8 | 260/295 | 168/238 | 158 | 120 | 170 | 125/180 | 24 | 5800 | 9000 | 14040 |

| RLAF280-8 | 280/320 | 196/259 | 196 | 140 | 185 | 150/195 | 30 | 5200 | 13500 | 21060 |

| RLAF310-8 | 310/356 | 210/273 | 210 | 150 | 195 | 160/205 | 32 | 4350 | 20250 | 31500 |

| RLAF340-8 | 340/400 | 238/308 | 238 | 170 | 220 | 180/230 | 34 | 3880 | 30500 | 47500 |

| RLAF370-8 | 370/425 | 258/350 | 258 | 190 | 250 | 200/260 | 34 | 3500 | 32500 | 78500 |

| RLAF420-8 | 420/495 | 278/406 | 273 | 200 | 290 | 210/290 | 36 | 3100 | 42000 | 95800 |

| RLAF445-8 | 450/518 | 330/450 | 340 | 220 | 320 | 282/330 | 38 | 1850 | 60000 | 93600 |

| RLAF500-8 | 500/575 | 360/546 | 434 | 240 | 390 | 330/330 | 44 | 1800 | 72000 | 112500 |

| Model | Mass Point G/GA | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct10E6(N.m/rad) | (Kg) | Ct+10E6(N.m/rad) | J(Kg.m²) | |

| RLAF255-8 | 103.2/128 | 0.5 | 3.6 | 150 | 13.644 | 0.223 | 10.25 | 67.92 | 5.125 | 0.629 |

| RLAF280-8 | 118.1/147.625 | 0.5 | 3.6 | 160 | 14.769 | 0.242 | 16.15 | 89.72 | 8.075 | 0.902 |

| RLAF310-8 | 122/152.5 | 0.5 | 3.8 | 185 | 24.437 | 0.535 | 18.69 | 118.54 | 9.345 | 1.589 |

| RLAF340-8 | 141.3/162.495 | 0.5 | 3.8 | 190 | 30.234 | 0.807 | 25.15 | 164.54 | 12.575 | 2.613 |

| RLAF370-8 | 145/166.675 | 0.5 | 4 | 210 | 37.400 | 1.17 | 31.91 | 195.75 | 15.955 | 3.668 |

| RLAF420-8 | 167.8/192.97 | 0.5 | 4.6 | 220 | 49.497 | 2.036 | 47.89 | 272.875 | 23.945 | 6.458 |

| RLAF445-8 | 160.6523/184.75 | 0.5 | 4.6 | 220 | 55.760 | 2.043 | 58.46 | 364.500 | 29.23 | 10.191 |

| RLAF500-8 | 187.2418/215.328 | 0.5 | 5.5 | 230 | 73.668 | 3.509 | 71.67 | 499.030 | 35.835 | 17.063 |

| Model | DA/D | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLAF370-10 | 370/425 | 258/350 | 258 | 190 | 250 | 200/260 | 34 | 3500 | 32500 | 78500 |

| RLF420-10 | 420/495 | 278/406 | 273 | 200 | 290 | 210/290 | 36 | 3100 | 42000 | 95800 |

| RLAF445-10 | 450/518 | 330/420 | 321 | 220 | 300 | 282/330 | 38 | 1850 | 75000 | 117000 |

| RLAF500-10 | 500/575 | 360/448 | 346 | 240 | 320 | 330/330 | 44 | 1800 | 105000 | 163800 |

| RLAF630-10 | 630/710 | 405/462 | 398 | 280 | 350 | 330/450 | 44 | 1420 | 210000 | 327600 |

| RLAF700-10 | 700/785 | 460/546 | 448 | 320 | 390 | 330/520 | 50 | 1280 | 288000 | 449280 |

| RLAF60-10 | 760/850 | 493/645 | 478 | 340 | 460 | 450/580 | 60 | 1180 | 365000 | 569400 |

| Model | Mass Point G/GA | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct10E6(N.m/rad) | (Kg) | Ct+10E6(N.m/rad) | J(Kg.m²) | |

| RLAF370-10 | 145/166.675 | 0.32 | 4 | 210 | 37.400 | 1.17 | 31.91 | 195.75 | 15.955 | 3.668 |

| RLF420-10 | 167.8/192.97 | 0.32 | 4.6 | 220 | 49.497 | 2.036 | 47.89 | 272.875 | 23.945 | 6.458 |

| RLAF445-10 | 160.6523/184.75 | 0.32 | 4.5 | 220 | 55.760 | 2.043 | 71.35 | 364.500 | 35.675 | 10.191 |

| RLAF500-10 | 187.2418/215.328 | 0.32 | 5 | 230 | 73.668 | 3.509 | 91.95 | 499.030 | 45.975 | 17.063 |

| RLAF630-10 | 197.3536/226.95 | 0.32 | 6 | 245 | 130.080 | 12.453 | 193.1 | 694.250 | 96.55 | 39.181 |

| RLAF700-10 | 198.6369/228.45 | 0.32 | 7 | 250 | 217.214 | 20.778 | 260.46 | 939.340 | 130.23 | 62.154 |

| RLAF60-10 | 261.44407/300.66 | 0.32 | 8 | 265 | 197.708 | 26.842 | 331.34 | 1260.120 | 165.67 | 96.662 |

The large and small shaft mounted diaphragm coupling mainly consists of two half couplings, a diaphragm group, and connecting bolts. Its working principle is based on the elastic deformation of the diaphragm to transmit torque and compensate for misalignment of the shaft system. When there is relative displacement between the two axes, the diaphragm assembly will undergo elastic deformation to absorb and compensate for these displacements, ensuring the smoothness and reliability of the transmission.

Structural Characteristics

Large and small shaft design: The large and small shaft mounted Laminated Membrane coupling is particularly suitable for connecting two shafts with different diameters. By designing half couplings with different diameters, flexible connection of the shaft system can be easily achieved.

Diaphragm group structure: Diaphragm groups are usually made of high-strength and highly elastic materials, such as stainless steel or spring steel. This design not only improves the load-bearing capacity of the coupling, but also gives it better fatigue resistance.

Connecting bolt: The connecting bolt is used to fasten two half couplings together, ensuring the pre tightening force and transmission stability of the diaphragm group. When designing and selecting materials, it is necessary to fully consider the strength and corrosion resistance of bolts.

Performance Advantages

High precision transmission: The large and small shaft mounted Shim Pack coupling has high-precision transmission characteristics, which can significantly reduce shaft vibration and noise, and improve the operating efficiency of mechanical equipment.

Good compensation capability: This coupling has excellent shaft misalignment compensation capability, including radial, angular, and axial displacement, and is suitable for various complex working conditions.

Easy installation and maintenance: The structure of the large and small shaft mounted Flexible Membrane coupling is simple and compact, and the installation and maintenance process is relatively simple, reducing operating costs and time costs.

Strong adaptability: This coupling is suitable for various transmission systems, including high-speed, heavy-duty, and harsh environments, and performs excellently.

The large and small shaft mounted Steel Laminae couplings are widely used in various mechanical equipment, such as wind turbines, ship propulsion systems, heavy machinery, and automated production lines. Especially in situations where high-precision transmission and shaft compensation are required, this coupling demonstrates its unique advantages.