Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.

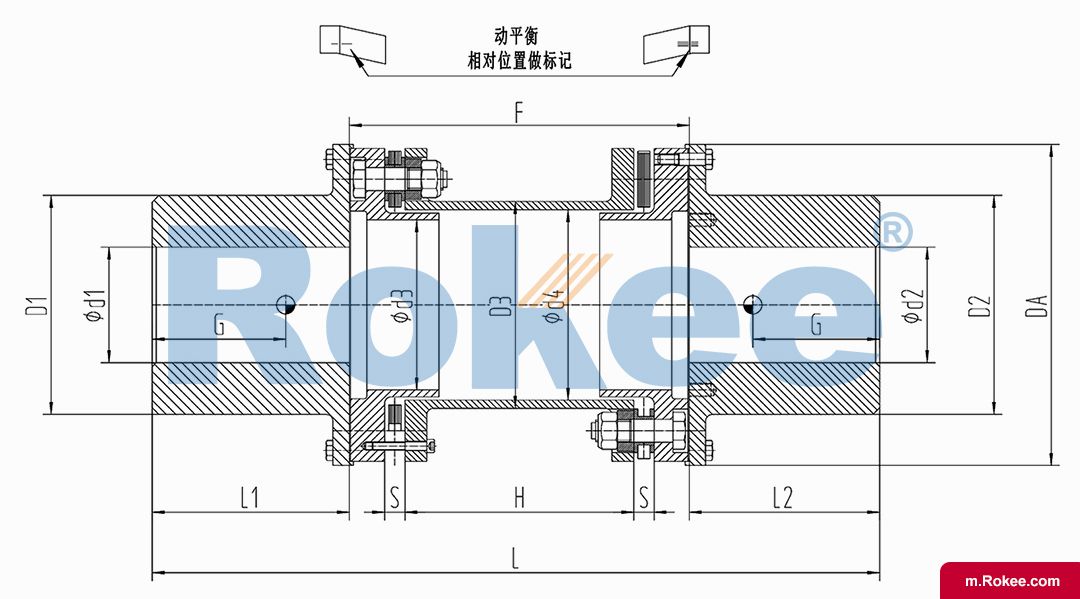

| Model | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 min | E(min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQA85-4 | 85 | 52 | 41 | 35 | 30 | 40 | 80 | 160 | 24000 | 40.5 | 310 |

| RLQA96-4 | 96 | 64 | 46 | 45 | 35 | 50 | 80 | 180 | 21000 | 67 | 420 |

| RLQA105-4 | 105 | 73 | 56 | 50 | 45 | 60 | 85 | 205 | 18900 | 150 | 750 |

| RLQA125-4 | 125 | 93 | 70 | 65 | 58 | 75 | 95 | 245 | 15200 | 205 | 1495 |

| RLQA135-4 | 135 | 103 | 80 | 75 | 68 | 85 | 100 | 270 | 14750 | 410 | 1780 |

| RLQA152-4 | 152 | 120 | 90 | 85 | 78 | 100 | 110 | 310 | 13500 | 1000 | 3100 |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQA85-4 | 24.22 | 1° | 1 | 7.2 | 4.32 | 1 | 14 | 3.1 | 26 | 2 | 10 |

| RLQA96-4 | 29.1 | 1.25 | 7.2 | 4.92 | 2 | 20 | 3.85 | 28 | 4 | 10 | |

| RLQA105-4 | 34.07 | 1.4 | 8.4 | 6.17 | 4 | 40 | 5.54 | 38 | 8 | 10 | |

| RLQA125-4 | 42.094 | 1.7 | 9.5 | 7.74 | 10 | 99 | 9.45 | 41 | 18 | 10 | |

| RLQA135-4 | 47.571 | 1.95 | 10.7 | 10.95 | 15 | 154 | 11.5 | 60 | 26 | 10 | |

| RLQA152-4 | 54.879 | 2 | 11.1 | 12.43 | 22 | 225 | 16.5 | 95 | 49 | 10 |

| Model | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 min | E(min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQA103-6 | 103 | 70 | 55 | 48 | 49 | 55 | 80 | 190 | 20000 | 400 | 1200 |

| RLQA125-6 | 125 | 90 | 65 | 60 | 58 | 70 | 90 | 230 | 17000 | 630 | 2500 |

| RLQA145-6 | 145 | 107 | 84 | 75 | 75 | 85 | 90 | 280 | 14300 | 1400 | 3300 |

| RLQA158-6 | 158 | 125 | 94 | 90 | 85 | 100 | 95 | 295 | 12200 | 2000 | 6500 |

| RLQA175-6 | 175 | 145 | 108 | 105 | 99 | 120 | 125 | 365 | 10000 | 3500 | 10500 |

| RLQA205-6 | 205 | 163 | 127 | 125 | 117 | 130 | 125 | 385 | 9800 | 4250 | 13000 |

| RLQA235-6 | 235 | 195 | 150 | 140 | 140 | 160 | 135 | 455 | 8200 | 8000 | 24000 |

| RLQA255-6 | 255 | 202 | 163 | 150 | 150 | 170 | 145 | 485 | 7500 | 11850 | 33500 |

| RLQA280-6 | 280 | 230 | 182 | 165 | 167 | 185 | 175 | 545 | 6780 | 21500 | 45000 |

| RLQA300-6 | 300 | 250 | 198 | 180 | 182 | 200 | 175 | 575 | 6300 | 26500 | 51600 |

| RLQA320-6 | 320 | 265 | 219 | 190 | 200 | 210 | 195 | 615 | 5800 | 38500 | 77000 |

| RLQA370-6 | 370 | 306 | 242 | 220 | 220 | 240 | 220 | 700 | 5100 | 40000 | 11000 |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQA103-6 | 52.41 | 0.65° | 0.8 | 8 | 3.8 | 3 | 25 | 4.5 | 47 | 5 | 10 |

| RLQA125-6 | 61.485 | 1 | 11 | 5.3 | 5 | 51 | 7.6 | 151 | 13 | 10 | |

| RLQA145-6 | 67.9 | 1.15 | 11 | 8.82 | 14 | 143 | 12.1 | 150 | 31 | 10 | |

| RLQA158-6 | 81.4 | 1.3 | 15 | 10 | 20 | 203 | 17.2 | 217 | 57 | 10 | |

| RLQA175-6 | 96.6 | 1.5 | 15 | 11.5 | 31 | 314 | 29 | 472 | 129 | 10 | |

| RLQA205-6 | 102 | 1.75 | 20 | 15 | 56 | 571 | 36.9 | 478 | 203 | 25 | |

| RLQA235-6 | 120.2 | 1.8 | 22 | 20 | 105 | 1066 | 51.4 | 894 | 483 | 25 | |

| RLQA255-6 | 132 | 1.8 | 24 | 23 | 146 | 1489 | 73.1 | 1502 | 671 | 85 | |

| RLQA280-6 | 142.7 | 1.9 | 30 | 30.1 | 232 | 2361 | 102.9 | 1517 | 115 | 85 | |

| RLQA300-6 | 149.1 | 1.9 | 32 | 33 | 301 | 3089 | 123.3 | 1562 | 160.6 | 85 | |

| RLQA320-6 | 164.3 | 2.4 | 34 | 44 | 490 | 4989 | 165.9 | 2622 | 258 | 210 | |

| RLQA370-6 | 185.5 | 3 | 34 | 57.5 | 771 | 7860 | 238.1 | 4242 | 466.7 | 210 |

| Model | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 min | E(min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQA205-8 | 207 | 168 | 135 | 120 | 123 | 120 | 125 | 385 | 9500 | 8000 | 19500 |

| RLQA235-8 | 240 | 190 | 152 | 135 | 138 | 150 | 145 | 445 | 8000 | 16000 | 47800 |

| RLQA255-8 | 258 | 207 | 164 | 145 | 149 | 160 | 175 | 485 | 7500 | 25000 | 63000 |

| RLQA300-8 | 302 | 247 | 198 | 175 | 184 | 200 | 175 | 575 | 6500 | 31500 | 73700 |

| RLQA345-8 | 346 | 295 | 234 | 210 | 217 | 240 | 195 | 675 | 5500 | 40000 | 123000 |

| RLQA370-8 | 372 | 306 | 248 | 220 | 228 | 240 | 220 | 700 | 5200 | 63000 | 165000 |

| RLQA400-8 | 402 | 327 | 257 | 240 | 232 | 270 | 240 | 780 | 4750 | 80000 | 228000 |

| RLQA435-8 | 435 | 356 | 293 | 250 | 270 | 280 | 240 | 800 | 4400 | 100000 | 254000 |

| RLQA485-8 | 485 | 406 | 327 | 290 | 300 | 320 | 295 | 935 | 3900 | 140000 | 400000 |

| RLQA540-8 | 540 | 447 | 374 | 320 | 344 | 350 | 295 | 995 | 3500 | 200000 | 448000 |

| RLQA610-8 | 610 | 517 | 410 | 370 | 375 | 410 | 320 | 1145 | 3200 | 250000 | 669000 |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQA205-8 | 116.4 | 0.5° | 1 | 20 | 19.1 | 80 | 811 | 58 | 904 | 438 | 25 |

| RLQA235-8 | 121.5 | 1.1 | 22 | 25.1 | 132 | 1344 | 63.5 | 2614 | 504 | 25 | |

| RLQA255-8 | 133.4 | 1.2 | 24 | 29 | 178 | 1810 | 88 | 3069 | 862 | 85 | |

| RLQA300-8 | 151.5 | 1.5 | 30 | 33 | 301 | 3069 | 126 | 3909 | 1597 | 85 | |

| RLQA345-8 | 174.4 | 1.9 | 32 | 42.5 | 602 | 6133 | 197.5 | 5365 | 3484 | 85 | |

| RLQA370-8 | 187.4 | 2.1 | 34 | 59 | 833 | 8485 | 235.1 | 9043 | 4677 | 210 | |

| RLQA400-8 | 207.2 | 2.4 | 34 | 75.5 | 1129 | 11509 | 316 | 9109 | 7329 | 210 | |

| RLQA435-8 | 212.5 | 2.6 | 36 | 80 | 1504 | 16140 | 372.5 | 15450 | 10010 | 410 | |

| RLQA485-8 | 245.2 | 2.75 | 38 | 105 | 2570 | 26183 | 538 | 20380 | 18490 | 410 | |

| RLQA540-8 | 262.4 | 3 | 38 | 133 | 4290 | 43682 | 696 | 23350 | 29500 | 710 | |

| RLQA610-8 | 302.1 | 3.5 | 44 | 169 | 6870 | 700033 | 1055 | 33720 | 57570 | 710 |

The biggest feature of the flange free quick installation Flexible Membrane coupling is that it abandons the flange structure in traditional couplings and instead adopts a more compact and lightweight design. This design not only reduces the overall weight of the coupling, but also greatly simplifies the installation process, making the installation and disassembly of the coupling more convenient and efficient. Meanwhile, as the core component of the coupling, the diaphragm is made of high-strength and highly elastic materials, which have good torsional rigidity and shock absorption performance, and can effectively absorb shaft vibration, protecting the transmission system from damage.

Performance advantages of flange free quick installation Plate coupling

Efficient transmission: Due to the abandonment of flange structure, the flange free quick installation diaphragm coupling reduces unnecessary energy loss and improves transmission efficiency during the transmission process. At the same time, the elastic deformation of the diaphragm can automatically compensate for the axial, radial, and angular displacement of the shaft system caused by factors such as thermal expansion and contraction, installation errors, etc., ensuring the smoothness and reliability of the transmission.

Easy to install and maintain: The quick install design eliminates the need for tedious bolt tightening processes for the installation and disassembly of couplings, greatly saving installation time and maintenance costs. In addition, the replaceability of the membrane components also ensures the ease of maintenance of the coupling during long-term use.

Strong adaptability: The flange free quick installation diaphragm coupling is suitable for various transmission systems, whether it is high-speed rotating precision machinery or heavy-duty, high impact industrial equipment, it can demonstrate good adaptability and stability.

Safe and reliable: The high-strength material and unique structural design of the diaphragm enable the coupling to maintain stable operation even under extreme working conditions, effectively preventing transmission failure or damage caused by shaft vibration or overload.

The flange free quick installation Shim Pack coupling has been widely used in various fields such as aerospace, automotive manufacturing, wind power generation, and petrochemicals due to its unique structure and excellent performance. With the continuous development of intelligent manufacturing, the performance requirements for couplings will also become increasingly high. The flange free quick installation diaphragm coupling, with its significant advantages of efficient transmission, easy installation and maintenance, strong adaptability, and safety and reliability, will undoubtedly occupy a more important position in the future market.

In short, as an innovative achievement in the field of mechanical transmission, the flange free quick installation Steel Laminae coupling provides strong support for the optimization and upgrading of the transmission system with its unique structure and excellent performance. With the continuous advancement of technology and the expansion of application fields, we believe that this new type of coupling will play a more important role in the future.