Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.

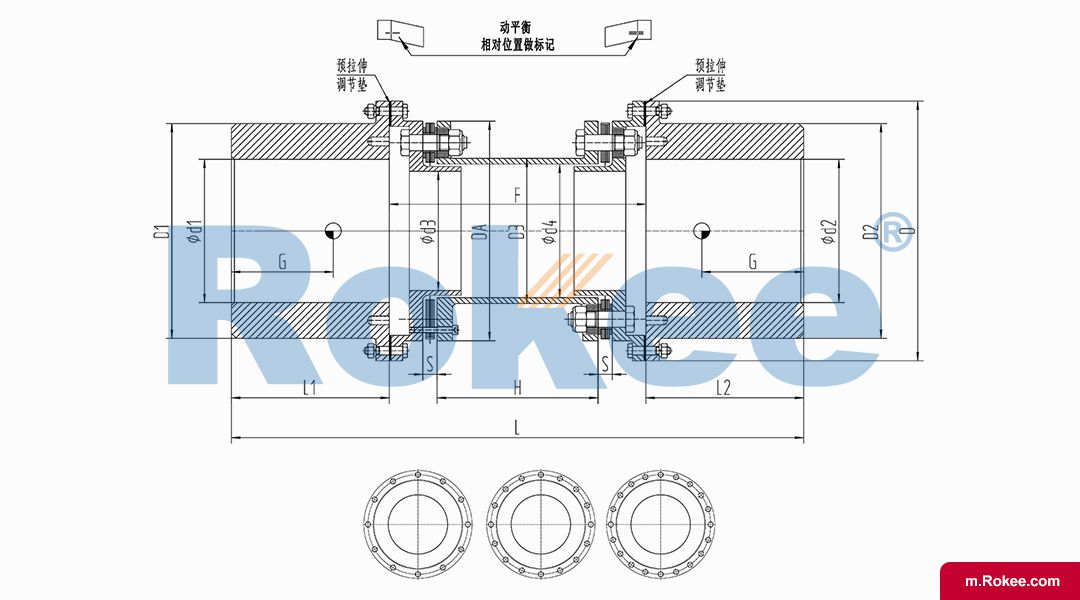

| Model | D | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 | E Standard/Minimum (min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQF103-6 | 124 | 103 | 103 | 62 | 60 | 56 | 65 | 460/120 | 260 | 38000 | 980 | 2500 |

| RLQF125-6 | 146 | 125 | 127 | 76 | 70 | 58 | 75 | 460/120 | 272 | 35000 | 1500 | 5300 |

| RLQF145-6 | 168 | 145 | 150 | 85 | 85 | 75 | 90 | 460/120 | 290 | 30000 | 2000 | 6500 |

| RLQF158-6 | 188 | 158 | 180 | 94 | 100 | 85 | 105 | 460/130 | 340 | 27500 | 3800 | 15000 |

| RLQF175-6 | 210 | 175 | 200 | 108 | 120 | 99 | 125 | 460/160 | 400 | 24500 | 6500 | 25000 |

| RLQF205-6 | 235 | 205 | 210 | 127 | 135 | 117 | 140 | 460/160 | 430 | 23500 | 9800 | 27500 |

| RLQF235-6 | 270 | 235 | 232 | 151 | 155 | 140 | 165 | 460/190 | 525 | 21000 | 13500 | 43500 |

| RLQF255-6 | 298 | 255 | 250 | 164 | 170 | 150 | 180 | 460/195 | 545 | 18500 | 19500 | 65000 |

| RLQF280-6 | 320 | 280 | 277 | 182 | 185 | 167 | 195 | 460/200 | 590 | 16000 | 26500 | 85350 |

| RLQF300-6 | 350 | 300 | 305 | 202 | 205 | 182 | 215 | 460/210 | 620 | 14850 | 32000 | 91500 |

| RLQF320-6 | 382 | 320 | 336 | 219 | 225 | 200 | 235 | 460/250 | 710 | 13500 | 43200 | 128000 |

| RLQF370-6 | 425 | 370 | 365 | 238 | 245 | 220 | 255 | 500/270 | 780 | 12500 | 70000 | 185000 |

| RLQF400-6 | 455 | 402 | 405 | 248 | 270 | 232 | 290 | 500/305 | 885 | 11000 | 98000 | 282000 |

| RLQF435-6 | 490 | 435 | 440 | 292 | 295 | 270 | 315 | 500/305 | 925 | 10000 | 125000 | 315000 |

| RLQF465-6 | 540 | 465 | 470 | 327 | 325 | 300 | 345 | 550/330 | 1000 | 8500 | 145000 | 391500 |

| RLQF540-6 | 600 | 540 | 532 | 375 | 355 | 344 | 375 | 550/330 | 1070 | 7350 | 200000 | 525000 |

| Model | d3 | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQF103-6 | 52.41 | 0.35° | 0.9*2 | 9 | 3.8 | 3 | 25 | 7.6 | 47 | 5 | 8 | |

| RLQF125-6 | 61.485 | 1*2 | 12 | 5.3 | 5.04 | 51.3 | 12.8 | 151 | 13 | 8 | ||

| RLQF145-6 | 70.6 | 1*2 | 14 | 8.82 | 14 | 143 | 19.5 | 150 | 31 | 8 | ||

| RLQF158-6 | 80.02 | 1.25*2 | 16 | 10 | 20 | 203 | 28 | 217 | 57 | 8 | ||

| RLQF175-6 | 96.6 | 1.25*2 | 17 | 11.5 | 31 | 314 | 42.5 | 472 | 129 | 8 | ||

| RLQF205-6 | 103.5 | 1.75*2 | 17 | 15 | 56 | 571 | 56.5 | 478 | 203 | 15 | ||

| RLQF235-6 | 120.2 | 1.75*2 | 21 | 20 | 105 | 1066 | 89 | 894 | 483 | 15 | ||

| RLQF255-6 | 132 | 1.8*2 | 21 | 23 | 146 | 1489 | 112.5 | 1502 | 671 | 45 | ||

| RLQF280-6 | 142.7 | 1.8*2 | 22 | 30.1 | 232 | 2361 | 138 | 1517 | 115 | 45 | ||

| RLQF300-6 | 149.1 | 2*2 | 22 | 33 | 301 | 3089 | 173.2 | 1562 | 160.6 | 45 | ||

| RLQF320-6 | 164.3 | 2*2 | 27 | 44 | 490 | 4989 | 247 | 2622 | 258 | 45 | ||

| RLQF370-6 | 185.5 | 2.25*2 | 32 | 57.5 | 771 | 7860 | 337 | 4242 | 466.7 | 45 | ||

| RLQF400-6 | 207.2 | 3*2 | 35 | 75.5 | 1129 | 11509 | 405 | 9109 | 7329 | 45 | ||

| RLQF435-6 | 212.5 | 3.25*2 | 37 | 80 | 1504 | 16140 | 515.5 | 15450 | 10010 | 45 | ||

| RLQF485-6 | 245.2 | 3.75*2 | 40 | 105 | 2570 | 26183 | 690 | 20380 | 18490 | 100 | ||

| RLQF540-6 | 262.4 | 4*2 | 42 | 133 | 4290 | 43682 | 903 | 23350 | 29500 | 100 | ||

| Model | D | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 | E Standard/Minimum (min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQF158-8 | 188 | 158 | 147 | 94 | 100 | 82 | 105 | 460/130 | 340 | 12200 | 7500 | 20000 |

| RLQF175-8 | 210 | 175 | 175 | 108 | 115 | 97 | 120 | 460/160 | 400 | 10000 | 9800 | 29200 |

| RLQF205-8 | 235 | 207 | 197 | 135 | 130 | 123 | 135 | 460/250 | 520 | 9500 | 11250 | 39375 |

| RLQF235-8 | 280 | 240 | 235 | 152 | 155 | 138 | 165 | 460/270 | 600 | 8000 | 27500 | 82500 |

| RLQF255-8 | 300 | 258 | 260 | 164 | 175 | 149 | 185 | 460/305 | 675 | 7500 | 31500 | 94500 |

| RLQF300-8 | 345 | 302 | 292 | 198 | 195 | 184 | 205 | 460/305 | 715 | 6500 | 42500 | 127500 |

| RLQF345-8 | 402 | 346 | 344 | 234 | 230 | 217 | 240 | 500/250 | 730 | 5500 | 62000 | 186000 |

| RLQF370-8 | 425 | 372 | 368 | 248 | 2445 | 228 | 255 | 500/270 | 780 | 5200 | 98000 | 264500 |

| RLQF400-8 | 453 | 402 | 396 | 257 | 270 | 232 | 290 | 500/305 | 885 | 4750 | 135000 | 364500 |

| RLQF435-8 | 490 | 435 | 435 | 293 | 290 | 270 | 310 | 500/305 | 925 | 4400 | 170000 | 459000 |

| RLQF465-8 | 540 | 465 | 474 | 327 | 315 | 300 | 335 | 550/330 | 1000 | 3900 | 215000 | 580500 |

| RLQF540-8 | 600 | 540 | 526 | 375 | 350 | 344 | 370 | 550/330 | 1070 | 3500 | 278000 | 750600 |

| RLQF610-8 | 665 | 610 | 587 | 420 | 390 | 385 | 410 | 600/385 | 1205 | 3200 | 400000 | 105000 |

| Model | d3 | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQF158-8 | 87.8 | 0.25° | 0.6*2 | 16 | 12 | 20 | 203 | 29 | 351 | 110 | 8 | |

| RLQF175-8 | 94.5 | 0.9*2 | 17 | 13 | 31 | 314 | 42.5 | 620 | 220 | 10 | ||

| RLQF205-8 | 103.8 | 1.1*2 | 17 | 19.1 | 80 | 811 | 58 | 904 | 438 | 12.5 | ||

| RLQF235-8 | 121.5 | 1.1*2 | 21 | 25.1 | 132 | 1344 | 98 | 1785 | 865 | 28 | ||

| RLQF255-8 | 133.4 | 1.4*2 | 21 | 29 | 178 | 1810 | 125.5 | 3069 | 950 | 31.5 | ||

| RLQF300-8 | 151.5 | 1.7*2 | 22 | 33 | 301 | 3069 | 174 | 3909 | 1597 | 45 | ||

| RLQF345-8 | 174.4 | 2*2 | 24 | 42.5 | 602 | 6133 | 275 | 5365 | 3484 | 63 | ||

| RLQF370-8 | 187.4 | 2.1*2 | 27 | 59 | 833 | 8485 | 332 | 9043 | 4677 | 100 | ||

| RLQF400-8 | 207.2 | 2.2*2 | 32 | 75.5 | 1129 | 11509 | 435.2 | 12300 | 13500 | 140 | ||

| RLQF435-8 | 212.5 | 2.4*2 | 35 | 80 | 1504 | 16140 | 554 | 15450 | 18780 | 180 | ||

| RLQF485-8 | 245.2 | 2.6*2 | 37 | 105 | 2570 | 26183 | 742 | 20380 | 30280 | 224 | ||

| RLQF540-8 | 262.4 | 2.75*2 | 40 | 133 | 4290 | 43682 | 956 | 23350 | 47500 | 280 | ||

| RLQF610-8 | 302.1 | 3.4*2 | 42 | 169 | 6870 | 70033 | 1325 | 37320 | 81300 | 400 | ||

| Model | D | DA | D1/D2 | D3 | d1/d2max) | d4 | L1/L2 | E Standard/Minimum (min) | L | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLQF205-10 | 235 | 207 | 190 | 135 | 130 | 119 | 135 | 460/250 | 520 | 18500 | 20000 | 54000 |

| RLQF235-10 | 280 | 240 | 225 | 152 | 155 | 132 | 165 | 460/270 | 600 | 15500 | 35500 | 113500 |

| RLQF255-10 | 300 | 258 | 255 | 164 | 175 | 140 | 185 | 460/305 | 675 | 14500 | 50000 | 145000 |

| RLQF300-10 | 345 | 302 | 286 | 198 | 195 | 176 | 205 | 460/305 | 715 | 12500 | 63000 | 165000 |

| RLQF345-10 | 402 | 346 | 345 | 234 | 230 | 217 | 240 | 500/250 | 730 | 11000 | 78500 | 245000 |

| RLQF370-10 | 425 | 372 | 368 | 248 | 245 | 228 | 255 | 500/270 | 780 | 10000 | 124500 | 348500 |

| RLQF400-10 | 453 | 402 | 400 | 257 | 270 | 232 | 290 | 500/305 | 885 | 9500 | 158500 | 518000 |

| RLQF435-10 | 490 | 435 | 435 | 293 | 290 | 270 | 310 | 500/305 | 925 | 8700 | 178000 | 575000 |

| RLQF485-10 | 550 | 485 | 480 | 327 | 315 | 300 | 335 | 550/330 | 1000 | 7500 | 245000 | 860000 |

| RLQF540-10 | 600 | 540 | 530 | 374 | 350 | 344 | 370 | 550/330 | 1070 | 6850 | 350000 | 965000 |

| RLQF610-10 | 665 | 610 | 590 | 410 | 390 | 386 | 410 | 600/385 | 1205 | 6000 | 555000 | 1450000 |

| RLQF720-10 | 800 | 720 | 725 | 495 | 500 | 435 | 650 | |||||

| Model | d3 | Mass Point G | Angular Deviation | Maximum axial deviation | S | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Tightening torque |

| (mm) | (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | Js10-6(Kg.m²/mm) | F' (N.m) | |

| RLQF205-10 | 116.4 | 0.2° | 0.8*2 | 21 | 25 | 100 | 811 | 58 | 1450 | 380 | 8 | |

| RLQF235-10 | 121.5 | 0.85*2 | 23 | 35 | 175 | 1344 | 95 | 2660 | 870 | 15 | ||

| RLQF255-10 | 121.5 | 0.95*2 | 23 | 45 | 261 | 1344 | 128 | 3930 | 1440 | 15 | ||

| RLQF300-10 | 133.4 | 1.15*2 | 26 | 48 | 445 | 1810 | 175.5 | 5405 | 2540 | 45 | ||

| RLQF345-10 | 151.5 | 1.4*2 | 31 | 51 | 602 | 3069 | 278.5 | 7921 | 5990 | 45 | ||

| RLQF370-10 | 174.4 | 1.5*2 | 33 | 59 | 833 | 6133 | 336 | 11450 | 8050 | 45 | ||

| RLQF400-10 | 187.4 | 1.505*2 | 35 | 75 | 1077 | 8485 | 445 | 15540 | 12390 | 45 | ||

| RLQF435-10 | 207.2 | 2*2 | 35 | 78.5 | 1510 | 11509 | 559 | 19950 | 18850 | 45 | ||

| RLQF485-10 | 212.5 | 2.15*2 | 38 | 104.5 | 2570 | 16140 | 748.5 | 29385 | 30500 | 45 | ||

| RLQF540-10 | 245.2 | 2.3*2 | 40 | 133 | 4285 | 26183 | 960 | 39425 | 47950 | 100 | ||

| RLQF610-10 | 262.4 | 2.8*2 | 46 | 170 | 6672 | 43682 | 1328 | 59450 | 81560 | 100 | ||

| RLQF720-10 |

The quick installation flange Steel Laminae coupling mainly consists of two half couplings, a diaphragm group, flanges, and fasteners. Among them, the diaphragm group is the core component of the coupling, which is composed of multiple layers of thin metal sheets stacked together and has good elasticity and torsional resistance. Flanges are used to connect half couplings with drive shafts, and can be quickly installed and disassembled using fasteners such as bolts.

Compared with traditional couplings, the biggest feature of quick fit flange Flexible Laminated Membrane couplings is their quick fit design. This design makes the installation and disassembly of the coupling extremely simple, without the need for complex alignment processes, greatly improving work efficiency. At the same time, the flange structure also enhances the rigidity and load-bearing capacity of the coupling, making it more suitable for harsh working conditions such as heavy loads and high speeds.

Performance advantages of quick installation flange Shim Pack coupling

High elasticity and anti torsion performance: The design of the diaphragm group enables the coupling to have good elasticity and anti torsion performance, effectively absorbing shaft vibration and impact, and protecting the transmission system from damage.

Quick and convenient installation: The quick connection design between the flange and the half coupling makes the installation and disassembly of the coupling extremely easy, reducing maintenance costs.

High load-bearing capacity: The flange structure enhances the rigidity of the coupling, allowing it to withstand greater axial, radial, and angular displacements, making it suitable for heavy-duty conditions.

Strong compensation capability: The Plate coupling has excellent compensation capability and can automatically compensate for deviations caused by manufacturing errors, installation errors, or thermal expansion in the shaft system, ensuring the smooth operation of the transmission system.

Corrosion and high temperature resistance: According to actual needs, the diaphragm group can be made of corrosion-resistant and high temperature resistant materials such as stainless steel to meet the requirements of special working conditions.

The quick installation flange Flexible Membrane coupling has been widely used in many industrial fields due to its superior performance. For example, in the mechanical manufacturing industry, it is often used to connect transmission components such as motors and reducers, pumps and motors; In the energy industry, it can be used in the transmission system of new energy equipment such as wind power and hydropower; In the chemical industry, it can be used to connect various chemical pumps, mixers, and other equipment to ensure the stability and safety of the transmission system.

The quick installation flange diaphragm coupling has become an indispensable and important component in modern industrial transmission systems due to its unique structural design and superior performance. With the continuous advancement of industrial technology and the expansion of application fields, the quick installation flange diaphragm coupling will continue to play its important role, providing strong guarantees for the stable and efficient operation of industrial transmission systems. At the same time, we also look forward to the emergence of more innovative technologies to promote the sustainable development of the coupling industry.