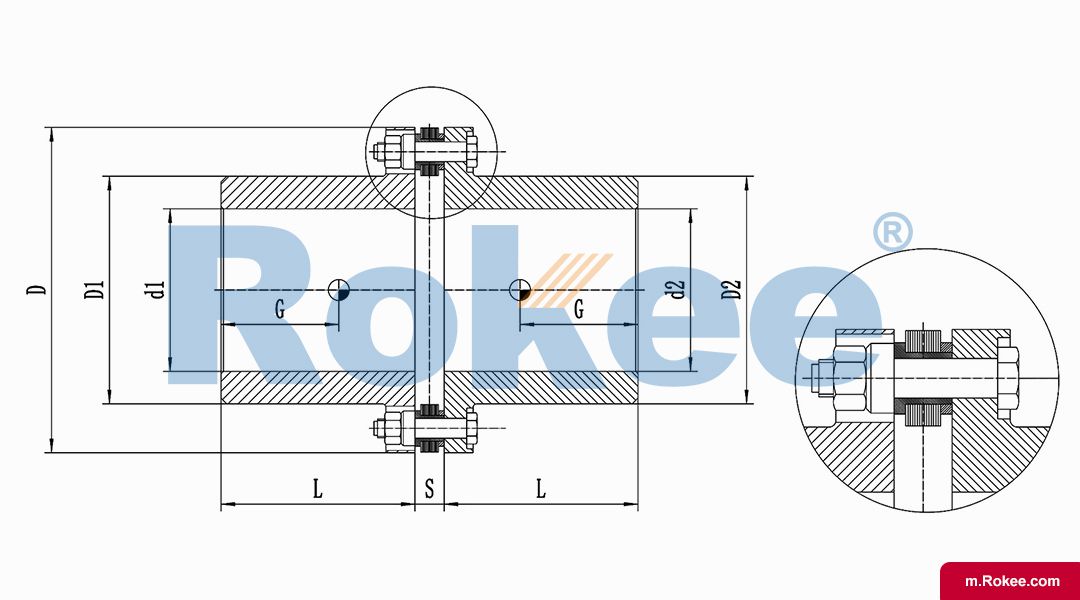

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.

| Model | D | D1 | D2 | d1(max) | d2(max) | L | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLM80-4 | 80 | 42 | 64.5 | 28 | 28 | 30 | 7.2 | 9800 | 40.5 | 220 |

| RLM92-4 | 92 | 54 | 73 | 38 | 38 | 45 | 7.2 | 8500 | 67 | 280 |

| RLM102-4 | 102 | 61 | 80 | 42 | 42 | 50 | 8.4 | 7500 | 150 | 450 |

| RLM120-4 | 120 | 78 | 98 | 55 | 55 | 65 | 9.5 | 6300 | 205 | 1050 |

| RLM130-4 | 130 | 88 | 108 | 60 | 60 | 75 | 10.7 | 5600 | 410 | 1200 |

| RLM145-4 | 145 | 98 | 120 | 70 | 70 | 85 | 11.1 | 5200 | 950 | 2200 |

| RLM178-4 | 178 | 114 | 145 | 75 | 75 | 90 | 13.6 | 4300 | 1450 | 3850 |

| RLM195-4 | 195 | 126 | 160.5 | 90 | 90 | 105 | 15.2 | 3800 | 2100 | 7100 |

| Model | Mass Point G | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Quality | Intermediate Sleeve Rotational Inertia | Quality | Torsional Stiffness | Rotational Inertia | |

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | (Kg) | Ct10E6(N.m/rad) | J(Kg.m²) | ||

| RLM80-4 | 38.1 | 0 | 0.9 | - | - | - | 2.12 | 0.021 | 0.011 | |

| RLM92-4 | 49.7 | 1 | - | - | - | 2.45 | 0.024 | 0.002 | ||

| RLM102-4 | 66.4 | 1.25 | - | - | - | 3.95 | 0.034 | 0.0035 | ||

| RLM120-4 | 66.8 | 1.4 | - | - | - | 5.8 | 0.035 | 0.0085 | ||

| RLM130-4 | 80 | 1.7 | - | - | - | 7.5 | 0.055 | 0.012 | ||

| RLM145-4 | 84.2 | 1.95 | - | - | - | 12.5 | 0.086 | 0.019 | ||

| RLM178-4 | 84.6 | 2.5 | - | - | - | 19.9 | 0.209 | 0.032 | ||

| RLM195-4 | 106.1 | 3 | - | - | - | 21.59 | 0.29 | 0.078 | ||

Small single diaphragm coupling is a type of diaphragm coupling, which has the characteristics of compact structure, light weight, and small volume, and is very suitable for situations with limited space.

The small flexible membrane coupling mainly consists of two half couplings and a metal diaphragm. Metal diaphragms are usually made of high-strength stainless steel materials, which have good elasticity and toughness. Two half couplings are connected to the diaphragm through bolts, forming a whole. This structure provides great flexibility and convenience for small single diaphragm couplings during installation and use.

The working principle of a small flexible laminated coupling mainly relies on the elastic deformation of the diaphragm to compensate for the relative displacement of the two shafts connected. When there is a deviation between the driving shaft and the driven shaft, the diaphragm will undergo elastic deformation to compensate for axial, radial, and angular deviations. At the same time, the elastic deformation of the diaphragm can also absorb vibration and impact, reducing the noise and vibration of the transmission system. This compensation function enables small single diaphragm couplings to have higher stability and reliability during transmission.

Small lamina couplings are widely used in various small mechanical equipment, such as motors, pumps, fans, etc. Especially in situations where high installation space and transmission accuracy are required, small single diaphragm couplings have unique advantages. In addition, in the automotive manufacturing industry, small shim pack couplings are also commonly used in power transmission, motion control, and precision transmission scenarios, such as conveyor system drives, electric tightening machines, spindle systems, etc.

Selection precautions

Torque requirement: Select a suitable size of small laminated membrane coupling according to the torque requirements of the equipment.

Deviation compensation capability: Consider the possible deviations that may occur during the installation and operation of the equipment, and select couplings with corresponding compensation capabilities.

Work environment: Select appropriate materials and protection levels based on factors such as temperature, humidity, and corrosiveness of the work environment.

Small metal diaphragm couplings play an important role in small mechanical equipment and automotive manufacturing industries due to their unique structural characteristics and working principles. When selecting, it is necessary to comprehensively consider the specific requirements and working environment of the equipment to ensure the selection of suitable coupling models and specifications.