The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.

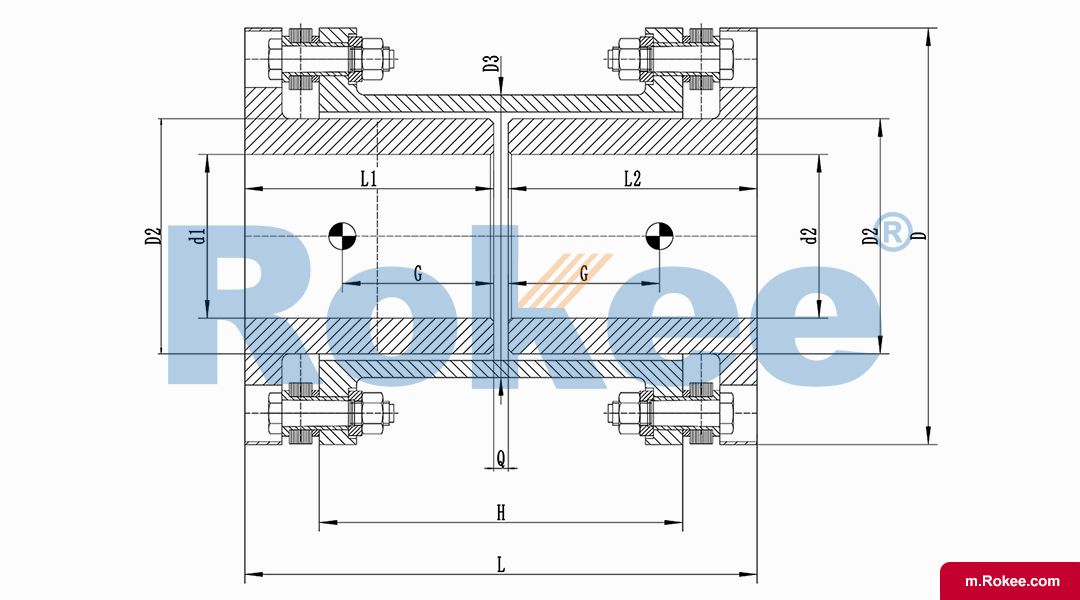

| Model | D | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLARD125-6 | 125 | 70/56 | 68 | 50 | 40 | 55/50 | 11 | 14000 | 650 | 1300 |

| RLARD135-6 | 135 | 92/70 | 82 | 65 | 50 | 70/55 | 11 | 11800 | 1180 | 2478 |

| RLARD156-6 | 160 | 105/84 | 96 | 75 | 60 | 80/70 | 15 | 10000 | 2100 | 2780 |

| RLARD178-6 | 180 | 119/105 | 117 | 85 | 70 | 90/80 | 15 | 8500 | 3580 | 5600 |

| RLARD210-6 | 210 | 140/112 | 122 | 100 | 80 | 105/90 | 20 | 7800 | 5000 | 7800 |

| RLARD225-6 | 230 | 154/119 | 144 | 110 | 85 | 115/90 | 22 | 6500 | 8500 | 13200 |

| RLARD255-6 | 260 | 168/133 | 158 | 120 | 95 | 125/105 | 24 | 5800 | 9000 | 14040 |

| RLARD280-6 | 280 | 196/147 | 171 | 140 | 105 | 150/110 | 30 | 5200 | 13500 | 21060 |

| RLARD305-6 | 310 | 210/160 | 193 | 150 | 115 | 160/120 | 32 | 4350 | 20250 | 31500 |

| RLARD340-6 | 340 | 238/182 | 230 | 170 | 130 | 180/140 | 34 | 3880 | 30500 | 47500 |

| RLARD365-6 | 370 | 258/210 | 228 | 190 | 150 | 200/160 | 34 | 3500 | 32500 | 78500 |

| RLARD420-6 | 420 | 278/238 | 269 | 200 | 170 | 210/180 | 36 | 3100 | 42000 | 95800 |

| Model | Mass Point G | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct10E6(N.m/rad) | (Kg) | Ct10E6(N.m/rad) | J(Kg.m²) | |

| RLARD125-6 | 52.1 | 1 | 1 | 65 | 1.57 | 0.00644 | 0.34 | 5.69 | 0.17 | 0.01708 |

| RLARD135-6 | 62.2 | 1 | 1 | 80 | 1.82 | 0.0078 | 0.29 | 8.3 | 0.145 | 0.0225 |

| RLARD156-6 | 64.5 | 1 | 1.4 | 90 | 2.7 | 0.0163 | 0.84 | 11.92 | 0.42 | 0.05 |

| RLARD178-6 | 77.6 | 1 | 1.4 | 90 | 3.3 | 0.0224 | 1.1 | 17.18 | 0.55 | 0.0768 |

| RLARD210-6 | 80.6 | 1 | 1.4 | 105 | 6.16 | 0.0682 | 1.97 | 24.88 | 0.985 | 0.1974 |

| RLARD225-6 | 96.9 | 0.75 | 1.6 | 135 | 7.17 | 0.0873 | 3.45 | 36.17 | 1.725 | 0.2806 |

| RLARD255-6 | 103.2 | 0.75 | 1.6 | 150 | 13.64 | 0.223 | 5.13 | 52.24 | 2.565 | 0.646 |

| RLARD280-6 | 118.1 | 0.75 | 2 | 160 | 14.77 | 0.242 | 7.94 | 71.77 | 3.97 | 0.814 |

| RLARD305-6 | 122 | 0.75 | 2 | 185 | 24.43 | 0.535 | 9.35 | 94.83 | 4.675 | 1.58 |

| RLARD340-6 | 141.3 | 0.75 | 2 | 190 | 30.23 | 0.807 | 12.58 | 131.63 | 6.29 | 2.464 |

| RLARD365-6 | 145 | 0.75 | 2 | 210 | 37.4 | 1.17 | 15.95 | 156.6 | 7.975 | 3.55 |

| RLARD420-6 | 167.8 | 0.75 | 2 | 220 | 49.5 | 2.036 | 23.95 | 218.3 | 11.975 | 6.222 |

| Model | D | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLARD225-8 | 230 | 154/119 | 139 | 110 | 85 | 115/90 | 23 | 6500 | 9000 | 15050 |

| RLARD255-8 | 260 | 168/133 | 158 | 120 | 95 | 125/105 | 24 | 5800 | 13500 | 21060 |

| RLARD280-8 | 280 | 196/147 | 196 | 140 | 105 | 150/105 | 27 | 5200 | 20250 | 31500 |

| RLARD310-8 | 310 | 210/160 | 210 | 150 | 115 | 160/120 | 32 | 4350 | 30500 | 47500 |

| RLARD340-8 | 340 | 238/182 | 238 | 170 | 130 | 180/140 | 32 | 3880 | 32500 | 78500 |

| RLARD370-8 | 370 | 258/210 | 258 | 190 | 150 | 200/160 | 38 | 3500 | 42000 | 95800 |

| RLARD420-8 | 420 | 278/238 | 273 | 200 | 170 | 210/180 | 38 | 3100 | 72000 | 112500 |

| RLARD445-8 | 450 | 340/280 | 340 | 240 | 200 | 250/210 | 41 | 2880 | 95000 | 228000 |

| RLARD500-8 | 500 | 420/336 | 434 | 270 | 240 | 300/250 | 44 | 2740 | 125000 | 228000 |

| Model | Mass Point G | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct10E6(N.m/rad) | (Kg) | Ct10E6(N.m/rad) | J(Kg.m²) | |

| RLARD225-8 | 103.497 | 0.5 | 3.6 | 150 | 13.644 | 0.223 | 10.25 | 52.651 | 5.125 | 0.629 |

| RLARD255-8 | 103.2 | 0.75 | 1.6 | 150 | 13.64 | 0.223 | 5.13 | 52.24 | 2.565 | 0.646 |

| RLARD280-8 | 118.1 | 0.75 | 2 | 160 | 14.77 | 0.242 | 7.94 | 71.77 | 3.97 | 0.814 |

| RLARD310-8 | 123.418 | 0.5 | 3.8 | 185 | 24.437 | 0.535 | 18.69 | 96.239 | 9.345 | 1.589 |

| RLARD340-8 | 144.162 | 0.5 | 3.8 | 190 | 30.234 | 0.807 | 25.15 | 135.020 | 12.575 | 2.613 |

| RLARD370-8 | 146.339 | 0.5 | 4 | 210 | 37.400 | 1.17 | 31.91 | 158.593 | 15.955 | 3.668 |

| RLARD420-8 | 169.191 | 0.5 | 4.2 | 220 | 49.497 | 2.036 | 47.89 | 220.412 | 23.945 | 6.458 |

| RLARD445-8 | 160.652 | 0.5 | 4.2 | 220 | 55.760 | 2.043 | 58.46 | 303.786 | 29.23 | 10.191 |

| RLARD500-8 | 187.242 | 0.5 | 4.5 | 230 | 73.668 | 3.509 | 71.67 | 415.856 | 35.835 | 17.063 |

| Model | D | D1/D2 | D3 | d1(max) | d2(max) | L1/L2 | S | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLARD370-10 | 370 | 258/210 | 258 | 190 | 150 | 200/160 | 38 | 3500 | 32500 | 78500 |

| RLARD420-10 | 420 | 278/238 | 288 | 200 | 170 | 210/180 | 38 | 3100 | 75000 | 117000 |

| RLARD445-10 | 450 | 340/280 | 330 | 240 | 200 | 250/210 | 44 | 2600 | 105000 | 163800 |

| RLARD500-10 | 500 | 420/336 | 434 | 270 | 240 | 300/250 | 44 | 2740 | 125000 | 228000 |

| RLARD630-10 | 630 | 430/378 | 434 | 310 | 270 | 460/300 | 46 | 2450 | 210000 | 327600 |

| RLARD700-10 | 700 | 476/434 | 475 | 340 | 310 | 490/460 | 50 | 2380 | 288000 | 449280 |

| RLARD760-10 | 760 | 525/475 | 525 | 375 | 340 | 520/490 | 60 | 2100 | 365000 | 569400 |

| RLARD860-10 | 860 | 585/518 | 584 | 420 | 370 | 570/520 | 60 | 1850 | 535000 | 834600 |

| RLARD950-10 | 950 | 658/592 | 658 | 470 | 420 | 620/570 | 60 | 1430 | 720000 | 1123200 |

| Model | Mass Point G | Angular Deviation | Axial Deviation | Intermediate Joint Sleeve H | Intermediate Sleeve Weight | Intermediate Sleeve Rotational Inertia | Torsional stiffness of diaphragm group | Weight | Torsional Stiffness | Rotational Inertia |

|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (±△º) | (±△mm) | min(mm) | kg | Jh(Kg.m²) | Ct10E6(N.m/rad) | (Kg) | Ct10E6(N.m/rad) | J(Kg.m²) | |

| RLARD370-10 | 146.339 | 0.5 | 4 | 210 | 37.400 | 1.17 | 31.91 | 158.593 | 15.955 | 3.668 |

| RLARD420-10 | 169.191 | 0.5 | 4.2 | 220 | 49.497 | 2.036 | 47.89 | 220.412 | 23.945 | 6.458 |

| RLARD445-10 | 160.652 | 0.32 | 4.5 | 220 | 55.760 | 2.043 | 71.35 | 303.786 | 35.675 | 10.191 |

| RLARD500-10 | 187.242 | 0.32 | 5 | 230 | 73.668 | 3.509 | 91.95 | 415.856 | 45.975 | 17.063 |

| RLARD630-10 | 198.637 | 0.32 | 6 | 245 | 130.080 | 12.453 | 193.1 | 578.547 | 96.55 | 39.181 |

| RLARD700-10 | 197.354 | 0.32 | 7 | 250 | 217.214 | 20.778 | 260.46 | 782.783 | 130.23 | 62.154 |

| RLARD760-10 | 261.444 | 0.32 | 8 | 265 | 197.708 | 26.842 | 331.34 | 1050.094 | 165.67 | 96.662 |

| RLARD860-10 | 267.654 | 0.32 | 8 | 290 | 284.050 | 52.988 | 491.07 | 1369.448 | 245.535 | 169.6 |

| RLARD950-10 | 313.875 | 0.32 | 8 | 290 | 333.215 | 73.988 | 658.31 | 1854.832 | 329.155 | 264.568 |

The double axis reverse mounted Flexible Membrane coupling is a high-performance metal elastic element flexible coupling, which has a unique structure and excellent performance, and plays an important role in the shaft transmission of various mechanical devices.

The double axis reverse mounted Laminated Membrane coupling consists of several sets of stainless steel thin plates connected in a staggered manner to the two halves of the coupling, with each set of diaphragms consisting of several stacked pieces. The characteristic of this coupling lies in its dual axis sleeve design and reverse installation structure, which enables it to better adapt to complex transmission environments and provide higher transmission efficiency and stability.

The double axis reverse mounted Metal Diaphragm coupling compensates for the relative displacement of the two connected shafts by the elastic deformation of the diaphragm. When there is axial, radial, or angular displacement between the two axes, the diaphragm will undergo elastic deformation to absorb these offsets and ensure smooth transmission. The ability of this elastic deformation enables the dual axis reverse mounted diaphragm coupling to maintain excellent performance in various working conditions and environments.

Performance Characteristics

High strength and long life: Due to the use of stainless steel thin plates for the diaphragm, the double axis sleeve reverse mounted diaphragm coupling has the characteristics of high strength and long life. It can withstand high torque and load while maintaining good elastic deformation ability.

No rotational clearance: The structural design of the dual axis reverse mounted diaphragm coupling ensures that there is no rotational clearance during use, thereby improving the accuracy and stability of the transmission.

Acid and alkali resistance and corrosion resistance: Diaphragm couplings have the characteristics of acid, alkali and corrosion resistance, and are suitable for working environments with high temperature, high speed and corrosive media.

Shock absorption and noise reduction: The dual axis reverse mounted Plate coupling also has good shock absorption and noise reduction performance, which can reduce vibration and noise during the transmission process and improve the operating efficiency of the equipment.

Double axis reverse mounted Shim Pack couplings are widely used in shaft transmission of various mechanical devices, such as water pumps, fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, etc. In addition, it is also suitable for shaft transmission in high-temperature, high-speed, and corrosive medium working environments, such as high-speed power transmission systems for aviation and naval vessels, as well as high-speed and high-power mechanical transmission systems for generator sets.

When installing a double axis reverse mounted Steel Laminae coupling, it is necessary to ensure that the axis deviation of the two shafts is within the allowable range to avoid deformation or damage to the coupling. At the same time, attention should be paid to keeping the coupling clean and lubricated during installation to ensure its normal operation. In terms of maintenance, the fastening bolts of the coupling should be regularly checked for looseness and tightened in a timely manner to maintain its stability. In addition, the diaphragm should be regularly inspected and maintained to avoid affecting transmission performance due to wear or damage.