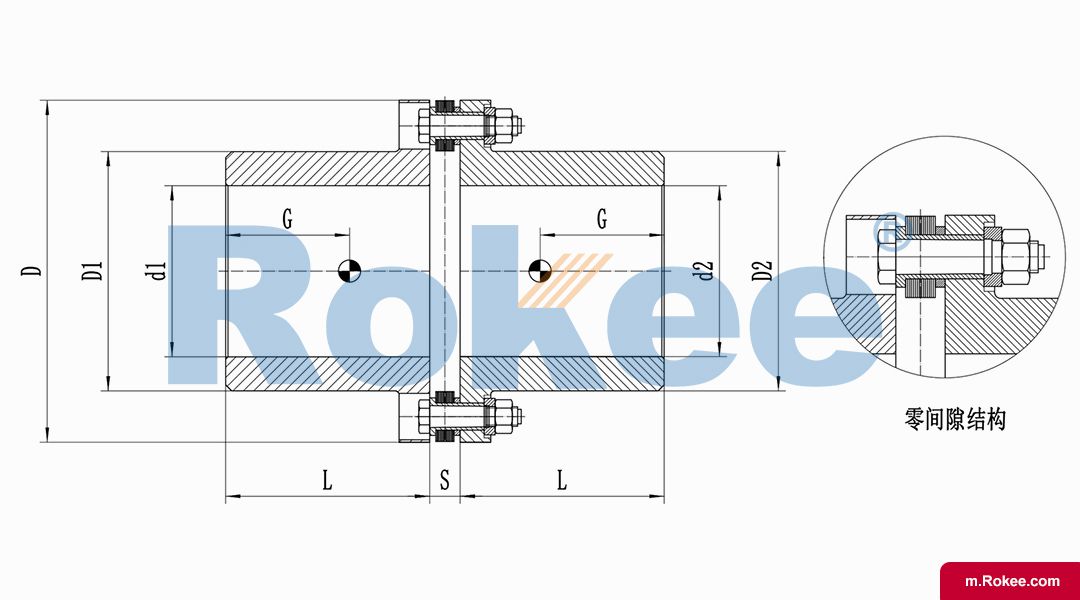

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.

| Model | D | D1 | D2 | d1(max) | d2(max) | L1/L2 | S | Nominal Torque | Maximum Instantaneous Torque | Mass Point G | Radial Deviation | Axial Deviation | DIAPHRAGM GROUP Torsional Stiffness | Quality | Torsional Stiffness | Rotational Inertia | Maximum Allowable Speed |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | T(N.m) | Tmax(N.m) | (mm) | (±△º) | (±△mm) | Ct10E6(N.m/rad) | (Kg) | Ct10E6(N.m/rad) | J(Kg.m²) | n max(r/min) | |

| RLA55-6 | 55 | 32 | 32 | 22 | 22 | 25 | 6 | 36 | 76.5 | 26.3 | / | 0.5 | 0.04 | 0.62 | 0.02 | 0.0002 | 29000 |

| RLA65-6 | 65 | 35 | 35 | 25 | 25 | 30 | 6 | 52 | 109.5 | 29.8 | 0.5 | 0.055 | 1 | 0.0275 | 0.0006 | 24500 | |

| RLA80-6 | 80 | 42 | 42 | 30 | 30 | 35 | 6 | 120 | 252 | 37.9 | 0.5 | 0.06 | 1.85 | 0.03 | 0.0012 | 21000 | |

| RLA95-6 | 92 | 50 | 50 | 35 | 35 | 40 | 8 | 230 | 483 | 39.95 | 0.5 | 0.09 | 2.17 | 0.045 | 0.00185 | 16850 | |

| RLA105-6 | 105 | 64 | 64 | 45 | 45 | 55 | 8 | 450 | 950 | 54.1 | 0.5 | 0.19 | 3.98 | 0.095 | 0.008 | 15500 | |

| RLA125-6 | 125 | 78 | 78 | 55 | 55 | 60 | 11 | 650 | 1300 | 52.1 | 0.5 | 0.34 | 5.69 | 0.17 | 0.01708 | 14000 | |

| RLA135-6 | 135 | 92 | 92 | 65 | 65 | 70 | 11 | 1180 | 2478 | 62.2 | 0.5 | 0.29 | 8.3 | 0.145 | 0.0225 | 11800 | |

| RLA160-6 | 160 | 106 | 106 | 75 | 75 | 80 | 15 | 2100 | 2780 | 64.5 | 0.7 | 0.84 | 11.92 | 0.42 | 0.05 | 10000 | |

| RLA180-6 | 180 | 127 | 127 | 90 | 90 | 105 | 15 | 3580 | 5600 | 77.6 | 0.7 | 1.1 | 17.18 | 0.55 | 0.0768 | 8500 | |

| RLA210-6 | 210 | 148 | 148 | 105 | 105 | 115 | 20 | 5000 | 7800 | 80.6 | 0.7 | 1.97 | 24.88 | 0.985 | 0.1974 | 7800 | |

| RLA230-6 | 230 | 177 | 177 | 120 | 120 | 125 | 22 | 8500 | 13200 | 96.9 | 0.8 | 3.45 | 36.17 | 1.725 | 0.2806 | 6800 | |

| RLA260-6 | 260 | 198 | 198 | 140 | 130 | 140 | 24 | 9000 | 14040 | 103.2 | 0.8 | 5.13 | 52.24 | 2.565 | 0.646 | 6200 | |

| RLA280-6 | 280 | 219 | 219 | 145 | 145 | 155 | 30 | 13500 | 21060 | 118.1 | 1 | 7.94 | 71.77 | 3.97 | 0.814 | 5500 | |

| RLA310-6 | 310 | 233 | 233 | 170 | 160 | 170 | 32 | 20250 | 31500 | 122 | 1 | 9.35 | 94.83 | 4.675 | 1.58 | 5180 | |

| RLA340-6 | 340 | 254 | 254 | 180 | 180 | 190 | 34 | 30500 | 47500 | 141.3 | 1 | 12.58 | 131.63 | 6.29 | 2.464 | 4680 | |

| RLA370-6 | 370 | 293 | 293 | 200 | 200 | 210 | 34 | 32500 | 78500 | 145 | 1 | 15.95 | 156.6 | 7.975 | 3.55 | 4200 | |

| RLA420-6 | 420 | 315 | 315 | 220 | 220 | 230 | 36 | 42000 | 95800 | 167.8 | 1 | 23.95 | 218.3 | 11.975 | 6.222 | 4000 | |

| RLA210-8 | 210 | 148 | 148 | 105 | 105 | 115 | 20 | 5750 | 8970 | 80.6 | / | 0.7 | 1.97 | 24.88 | 0.985 | 0.1974 | 7800 |

| RLA230-8 | 230 | 177 | 177 | 120 | 120 | 125 | 22 | 10250 | 17300 | 96.9 | 0.8 | 3.45 | 36.17 | 1.725 | 0.2806 | 7200 | |

| RLA260-8 | 260 | 168 | 168 | 130 | 130 | 140 | 23 | 13500 | 21060 | 103.497 | 1.8 | 10.25 | 52.651 | 5.125 | 0.629 | 6800 | |

| RLA280-8 | 280 | 196 | 196 | 140 | 140 | 150 | 25 | 20250 | 31500 | 118.425 | 1.8 | 16.15 | 72.480 | 8.075 | 0.902 | 6100 | |

| RLA310-8 | 310 | 210 | 210 | 150 | 150 | 160 | 27 | 30500 | 47500 | 123.418 | 1.9 | 18.69 | 96.239 | 9.345 | 1.589 | 5500 | |

| RLA340-8 | 340 | 238 | 238 | 170 | 170 | 180 | 32 | 32500 | 78500 | 144.162 | 1.9 | 25.15 | 135.020 | 12.575 | 2.613 | 5000 | |

| RLA370-8 | 370 | 252 | 252 | 180 | 180 | 190 | 32 | 42000 | 95800 | 146.339 | 2 | 31.91 | 158.593 | 15.955 | 3.668 | 4500 | |

| RLA420-8 | 420 | 280 | 280 | 200 | 200 | 210 | 38 | 72000 | 112500 | 169.191 | 2.1 | 47.89 | 220.412 | 23.945 | 6.458 | 4200 | |

| RLA450-8 | 450 | 330 | 330 | 220 | 220 | 230 | 38 | 95000 | 228000 | 160.652 | 2.1 | 58.46 | 303.786 | 29.23 | 10.191 | 3800 | |

| RLA500-8 | 500 | 360 | 360 | 250 | 250 | 260 | 44 | 125000 | 312500 | 187.242 | 2.25 | 71.67 | 415.856 | 35.835 | 17.063 | 3500 | |

| RLA340-10 | 340 | 238 | 238 | 170 | 170 | 180 | 32 | 40620 | 98120 | 144.162 | / | 1.9 | 25.15 | 135.020 | 12.575 | 2.613 | 5000 |

| RLA370-10 | 370 | 252 | 252 | 180 | 180 | 190 | 32 | 52500 | 118750 | 146.339 | 2 | 31.91 | 158.593 | 15.955 | 3.668 | 4500 | |

| RLA420-10 | 420 | 280 | 280 | 200 | 200 | 210 | 38 | 90000 | 140600 | 169.191 | 2.1 | 47.89 | 220.412 | 23.945 | 6.458 | 4200 | |

| RLA450-10 | 450 | 330 | 330 | 220 | 220 | 230 | 38 | 11875 | 285000 | 160.652 | 2.25 | 71.35 | 303.786 | 35.675 | 10.191 | 3800 | |

| RLA500-10 | 500 | 360 | 360 | 250 | 250 | 260 | 44 | 156250 | 390600 | 187.242 | 2.5 | 91.95 | 415.856 | 45.975 | 17.063 | 3500 | |

| RLA630-10 | 630 | 405 | 405 | 280 | 280 | 300 | 44 | 262500 | 574370 | 198.637 | 3 | 193.1 | 578.547 | 96.55 | 39.181 | 3200 | |

| RLA700-10 | 700 | 478 | 460 | 320 | 320 | 340 | 50 | 360000 | 656250 | 197.354 | 3.5 | 260.46 | 782.783 | 130.23 | 62.154 | 3000 | |

| RLA760-10 | 760 | 505 | 493 | 340 | 340 | 380 | 60 | 456250 | 1043750 | 261.444 | 4 | 331.34 | 1050.094 | 165.67 | 96.662 | 2800 | |

| RLA860-10 | 860 | 765 | 548 | 380 | 380 | 450 | 60 | 668750 | 1471250 | 267.654 | 4 | 491.07 | 1369.448 | 245.535 | 169.6 | 2500 | |

| RLA950-10 | 950 | 625 | 625 | 420 | 420 | 540 | 60 | 900000 | 1890000 | 313.875 | 4 | 658.31 | 1854.832 | 329.155 | 264.568 | 2200 | |

The core of a single shaft sleeve reverse mounted Flexible diaphragm coupling lies in the design of its diaphragm components. Diaphragm is usually made of high-strength and highly elastic metal materials, such as stainless steel or titanium alloy, to ensure good elastic deformation ability while withstanding high torque. The membrane is formed into a specific ripple shape through precision machining, which not only enhances the torsional rigidity of the coupling, but also effectively reduces radial and axial displacement compensation errors.

Reverse installation design is another highlight of the single shaft sleeve reverse installation Membrane coupling. Traditional diaphragm couplings usually install the diaphragm component outside the shaft sleeve, while reverse installation designs embed the diaphragm component inside the shaft sleeve. This structural innovation enables the coupling to have higher installation flexibility and stronger load-bearing capacity in a compact space.

The working principle of a single shaft sleeve reverse mounted diaphragm coupling is based on the elastic deformation of the diaphragm to transmit torque and absorb shaft system errors. When there is relative displacement between the two axes, the diaphragm undergoes elastic deformation to absorb these displacements and maintain synchronous rotation of the two axes. At the same time, the corrugated shape design of the membrane enables uniform stress distribution during deformation, avoiding the occurrence of local overload phenomena.

Application advantages

High precision transmission: Due to the high elastic deformation ability and precision machining technology of the diaphragm, the single shaft sleeve reverse mounted diaphragm coupling can achieve high-precision torque transmission and shaft system error compensation, which is suitable for occasions with high requirements for transmission accuracy.

High load capacity: The reverse design allows the coupling to maintain a high load capacity even in a compact structure, making it suitable for heavy-duty and high-speed transmission systems.

Good balance performance: The corrugated shape design of the diaphragm helps reduce the rotational inertia and vibration noise of the coupling, improving the smoothness and reliability of the transmission system.

Easy to install and maintain: The single shaft sleeve design simplifies the installation process of the coupling and reduces maintenance costs. At the same time, the replaceability of the membrane component enables the coupling to quickly restore use in the event of damage.

Although single shaft sleeve reverse mounted Shim Pack couplings have many advantages, the following points still need to be noted in practical applications:

Selection and matching: Select the appropriate coupling model and specifications based on the specific needs of the transmission system to ensure that the performance of the coupling can meet the system requirements.

Installation accuracy: Ensure the installation accuracy of the coupling to avoid performance degradation or damage caused by installation errors.

Regular inspection and maintenance: Regularly inspect and maintain the coupling, promptly identify and address potential issues, and extend the service life of the coupling.

Environmental adaptability: Consider the working environment of the coupling, such as temperature, humidity, corrosiveness, and other factors, and select suitable materials and protective measures.

The single shaft sleeve reverse mounted Steel Laminae coupling has a wide range of application prospects in the field of mechanical transmission due to its unique structure and excellent performance. By delving into its technical characteristics, working principles, and application advantages, and combining them with practical considerations, we can better leverage the performance advantages of this transmission component and provide strong support for the efficient operation of industrial production.

URL: https://m.rokee.com/diaphragm-couplings/rla-standard-single-section-metal-diaphragm-coupling.html