Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.

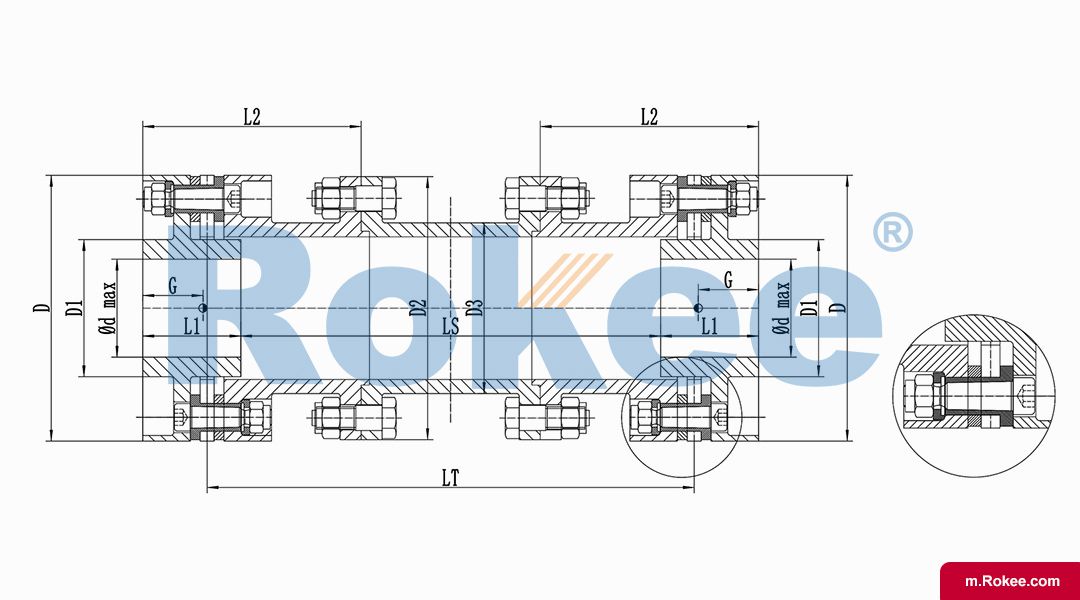

| Model | D | D1 | D2 | D3 | d(max) | L1 | LT | LS Design calculation according to 457.2(18") | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD95-6 | 95 | 49 | 94 | 61 | 35 | 35 | =LS+2*24 | Provide data according to design requirements | 40000 | 1000 | 1300 |

| RLHD125-6 | 125 | 63 | 112 | 79 | 45 | 45 | =LS+2*35 | 31500 | 2300 | 3000 | |

| RLHD145-6 | 145 | 77 | 133 | 90 | 55 | 55 | =LS+2*45 | 26500 | 4000 | 5000 | |

| RLHD175-6 | 175 | 98 | 155 | 112 | 70 | 70 | =LS+2*63 | 22000 | 6700 | 8500 | |

| RLHD205-6 | 205 | 112 | 170 | 127 | 80 | 80 | =LS+2*77 | 19000 | 10500 | 13000 | |

| RLHD220-6 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | 17300 | 14500 | 18500 | |

| RLHD250-6 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 21000 | 27000 | |

| RLHD270-6 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 26500 | 35000 | |

| RLHD295-6 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12800 | 35000 | 45500 | |

| RLHD320-6 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 41000 | 52000 | |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | L2 | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Total Mass (KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLHD95-6 | 21.5 | 0.35 | 1.6 | 78 | 3.65 | 3.09 | 31.5 | 4.9 | 0.048 | 0.006 | (3.65/1000)*(Ls-457.2)+4.9 |

| RLHD125-6 | 25.5 | 2 | 87 | 5.6 | 8.13 | 82.6 | 8.4 | 0.11 | 0.016 | (5.6/1000)*(Ls-457.2)+8.4 | |

| RLHD145-6 | 30 | 2.4 | 105 | 8.38 | 15.7 | 160 | 13.7 | 0.201 | 0.0365 | (8.38/1000)*(Ls-457.2)+13.7 | |

| RLHD175-6 | 35.5 | 3 | 118 | 11 | 31.1 | 317 | 21 | 0.378 | 0.0812 | (11/1000)*(Ls-457.2)+21 | |

| RLHD205-6 | 38.5 | 3.8 | 125 | 15.5 | 56.1 | 571 | 30.4 | 0.623 | 0.1535 | (15.5/1000)*(Ls-457.2)+30.4 | |

| RLHD220-6 | 44.5 | 4 | 142 | 17.5 | 84.7 | 863 | 42.7 | 0.896 | 0.2692 | (17.5/1000)*(Ls-457.2)+42.7 | |

| RLHD250-6 | 51.5 | 4.6 | 160 | 22 | 138 | 1404 | 57.5 | 1.354 | 0.4711 | (22/1000)*(Ls-457.2)+57.5 | |

| RLHD270-6 | 55 | 5 | 179 | 26 | 202 | 2058 | 72.8 | 1.79 | 0.6935 | (26/1000)*(Ls-457.2)+72.8 | |

| RLHD295-6 | 60.5 | 5.6 | 190 | 31 | 297 | 2962 | 93 | 2.43 | 1.0568 | (31/1000)*(Ls-457.2)+93 | |

| RLHD320-6 | 64 | 5.8 | 200 | 35.5 | 361 | 3684 | 114 | 3.02 | 1.5153 | (35.5/1000)*(Ls-457.2)+114 | |

| Model | D | D1 | D2 | D3 | d1(max) | L1 | LT | LS Design calculation according to 457.2(18") | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD145-8 | 145 | 77 | 133 | 90 | 55 | 55 | =LS+2*45 | Provide data according to design requirements | 26300 | 5700 | 7400 |

| RLHD175-8 | 175 | 98 | 155 | 112 | 70 | 70 | =LS+2*63 | 22000 | 9600 | 12300 | |

| RLHD205-8 | 205 | 112 | 170 | 127 | 80 | 80 | =LS+2*77 | 18500 | 15000 | 19000 | |

| RLHD220-8 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | 17200 | 20000 | 26500 | |

| RLHD250-8 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 29200 | 38200 | |

| RLHD270-8 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 38100 | 49000 | |

| RLHD295-8 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12500 | 49500 | 64000 | |

| RLHD320-8 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 59000 | 77000 | |

| RLHD350-8 | 350 | 196 | 308 | 235 | 140 | 145 | =LS+2*142 | 11000 | 81000 | 105000 | |

| RLHD390-8 | 390 | 224 | 335 | 260 | 160 | 165 | =LS+2*161 | 9800 | 115000 | 150000 | |

| RLHD435-8 | 435 | 252 | 370 | 295 | 180 | 185 | =LS+2*179 | 8750 | 168500 | 220000 | |

| RLHD498-8 | 498 | 294 | 415 | 335 | 210 | 215 | =LS+2*217 | 7500 | 250000 | 320000 | |

| RLHD545-8 | 545 | 322 | 464 | 370 | 230 | 240 | =LS+2*247 | 7000 | 330000 | 420000 | |

| RLHD595-8 | 680 | 350 | 494 | 400 | 250 | 260 | =LS+2*272 | 6450 | 410000 | 540000 | |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | L2 | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Total Mass (KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Ct-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLHD145-8 | 30 | 0.25 | 1.6 | 105 | 8.38 | 15.7 | 160 | 14 | 0.248 | 0.037 | (8.38/1000)*(LS-457.2)+14 |

| RLHD175-8 | 35.5 | 1.8 | 118 | 11 | 31.1 | 317 | 21.5 | 0.472 | 0.083 | (11/1000)*(LS-457.2)+21.5 | |

| RLHD205-8 | 38.5 | 2.4 | 125 | 15.5 | 56.1 | 571 | 31.1 | 0.792 | 0.159 | (15.5/1000)*(LS-457.2)+31.3 | |

| RLHD220-8 | 45 | 2.6 | 142 | 17.5 | 84.7 | 863 | 43.6 | 0.16 | 0.2797 | (17.5/1000)*(LS-457.2)+43.6 | |

| RLHD250-8 | 52 | 3 | 160 | 22 | 138 | 1404 | 58.7 | 1.77 | 0.4825 | (22/1000)*(LS-457.2)+58.7 | |

| RLHD270-8 | 55.5 | 3.2 | 179 | 26 | 202 | 2058 | 74 | 2.38 | 1.706 | (26/1000)*(LS-457.2)+74 | |

| RLHD295-8 | 60.5 | 2.6 | 190 | 31 | 297 | 2962 | 94.8 | 3.28 | 1.0912 | (31/1000)*(LS-457.2)+94.8 | |

| RLHD320-8 | 64 | 3.8 | 200 | 35.5 | 361 | 3684 | 117 | 4.08 | 1.56 | (35.5/1000)*(LS-457.2)+117 | |

| RLHD350-8 | 69 | 3.8 | 215 | 45 | 578 | 5887 | 149 | 5.83 | 2.36 | (45/1000)*(LS-457.2)+149 | |

| RLHD390-8 | 78.5 | 4.4 | 240 | 59 | 922 | 9396 | 208 | 8.73 | 4.125 | (59/1000)*(LS-457.2)+208 | |

| RLHD435-8 | 88 | 5 | 277 | 74 | 1493 | 15213 | 290 | 13.4 | 7.301 | (74/1000)*(LS-457.2)+290 | |

| RLHD498-8 | 99 | 5.8 | 312 | 97 | 2497 | 25443 | 420 | 20.8 | 13.912 | (97/1000)*(LS-457.2)+420 | |

| RLHD545-8 | 109 | 6.4 | 337 | 120 | 3777 | 38487 | 559 | 28.3 | 22.01 | (120/1000)*(LS-457.2)+559 | |

| RLHD595-8 | 116.5 | 7.2 | 357 | 135 | 4971 | 50657 | 690 | 36.3 | 32.215 | (135/1000)*(LS-457.2)+690 | |

| Model | D | D1 | D2 | D3 | d1(max) | L1 | LT | LS Design calculation according to 457.2(18") | Maximum Allowable Speed | Nominal Torque | Maximum Instantaneous Torque |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | n max(r/min) | T(N.m) | Tmax(N.m) | |

| RLHD220-10 | 220 | 126 | 200 | 145 | 90 | 95 | =LS+2*95 | Provide data according to design requirements | 17200 | 20000 | 26500 |

| RLHD250-10 | 250 | 147 | 220 | 165 | 105 | 105 | =LS+2*98 | 15300 | 29200 | 38200 | |

| RLHD270-10 | 270 | 154 | 238 | 182 | 110 | 115 | =LS+2*111 | 14200 | 38100 | 49000 | |

| RLHD295-10 | 295 | 168 | 256 | 200 | 120 | 125 | =LS+2*119 | 12500 | 49500 | 64000 | |

| RLHD320-10 | 320 | 182 | 278 | 210 | 130 | 135 | =LS+2*132 | 12000 | 59000 | 77000 | |

| RLHD350-10 | 350 | 196 | 308 | 235 | 140 | 145 | =LS+2*142 | 11000 | 81000 | 105000 | |

| RLHD390-10 | 390 | 224 | 335 | 260 | 160 | 165 | =LS+2*161 | 9800 | 115000 | 150000 | |

| RLHD435-10 | 435 | 252 | 370 | 295 | 180 | 185 | =LS+2*179 | 8750 | 168500 | 220000 | |

| RLHD498-10 | 498 | 294 | 415 | 335 | 210 | 215 | =LS+2*217 | 7500 | 250000 | 320000 | |

| RLHD545-10 | 545 | 322 | 464 | 370 | 230 | 240 | =LS+2*247 | 7000 | 330000 | 420000 | |

| RLHD595-10 | 680 | 350 | 494 | 400 | 250 | 260 | =LS+2*272 | 6450 | 410000 | 540000 | |

| Model | Mass Point G | Angular Deviation | Maximum axial deviation | L2 | Intermediate Mass m | Intermediate moment of inertia | Intermediate torsional stiffness | Weight M | Torsional Stiffness | Rotational Inertia | Total Mass (KG) |

| (mm) | (±△º) | (Max±△mm) | (mm) | 10-3kg/mm | Js10-6(Kg.m²/mm) | Cts-106(Nm.mm/rad) | (Kg) | Ct-106(N.m/rad) | J(Kg.m²) | ||

| RLHD220-10 | 45 | 0.15 | 1.6 | 142 | 17.5 | 84.7 | 863 | 45 | 1.31 | 0.248 | (17.5/1000)*(LS-457.2)+45 |

| RLHD250-10 | 52 | 2 | 160 | 22 | 138 | 1404 | 60 | 2.02 | 0.493 | (22/1000)*(LS-457.2)+60 | |

| RLHD270-10 | 55.5 | 2.1 | 179 | 26 | 202 | 2058 | 78 | 2.73 | 0.721 | (26/1000)*(LS-457.2)+78 | |

| RLHD295-10 | 60.5 | 2.4 | 190 | 31 | 297 | 2962 | 97 | 3.77 | 1.123 | (31/1000)*(LS-457.2)+97 | |

| RLHD320-10 | 64 | 2.4 | 200 | 35.5 | 361 | 3684 | 125 | 4.71 | 1.615 | (35.5/1000)*(LS-457.2)+125 | |

| RLHD350-10 | 69 | 2.4 | 215 | 45 | 578 | 5887 | 155 | 6.78 | 2.425 | (45/1000)*(LS-457.2)+155 | |

| RLHD390-10 | 78.5 | 2.8 | 240 | 59 | 922 | 9396 | 215 | 10.2 | 4.239 | (59/1000)*(LS-457.2)+215 | |

| RLHD435-10 | 88 | 3.2 | 277 | 74 | 1493 | 15213 | 305 | 15.8 | 7.463 | (74/1000)*(LS-457.2)+305 | |

| RLHD498-10 | 99 | 3.8 | 312 | 97 | 2497 | 25443 | 435 | 24.7 | 14.223 | (97/1000)*(LS-457.2)+435 | |

| RLHD545-10 | 109 | 4 | 337 | 120 | 3777 | 38487 | 578 | 33.8 | 22.543 | (120/1000)*(LS-457.2)+578 | |

| RLHD595-10 | 116.5 | 4.6 | 357 | 135 | 4971 | 50657 | 710 | 43.5 | 32.915 | (135/1000)*(LS-457.2)+710 | |

High speed diaphragm coupling is a high-performance metal component flexible coupling. The high-speed Laminated Membrane coupling is composed of several sets of diaphragms that are connected to the two halves of the coupling in a staggered manner with bolts. Each set of diaphragms is composed of several stacked pieces. The membrane itself is very thin and has various shapes, such as 6-angle, 8-angle, or multi angle, which makes torque transmission very uniform. It consists of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the shaft sleeve with a pin, which generally does not loosen or cause backlash between the diaphragm and the shaft sleeve.

Main characteristics

Strong compensation capability: High speed Plate couplings can compensate for axial, radial, and angular offsets caused by manufacturing errors, installation errors, load deformation, and temperature rise changes between the active and driven machines. Compared with gear couplings, its angular displacement can be doubled, the reaction force is smaller during radial displacement, and the flexibility is greater.

Shock absorption and noise reduction: It has a significant shock absorption effect, no noise, no wear, and is suitable for applications that require low noise and high reliability.

Strong adaptability: able to work in high temperatures and harsh environments, and can operate safely under conditions of impact and vibration. At the same time, it is not affected by temperature and oil pollution, and has the characteristics of acid resistance, alkali resistance, and corrosion resistance.

High transmission efficiency: The transmission efficiency is high, reaching 99.86%, especially suitable for medium and high-speed high-power transmission.

Simple structure: light weight, small size, easy to assemble and disassemble, no need to move the machine for assembly and disassembly (referring to the type with intermediate shaft), no lubrication required.

Accurate transmission of rotational speed: It can accurately transmit rotational speed, operate without slip, and can be used for transmission of precision machinery.

High speed Shim Pack couplings are widely used in various mechanical equipment that requires high-speed and high-precision transmission, such as paper making machinery, pump rotation systems, ventilation equipment, material processing equipment, as well as compressors, generators, force gauges, drilling equipment, boiler feed pumps, turbine drive devices, etc.

When selecting, it is necessary to comprehensively consider factors such as the torque, speed, shaft diameter, and working environment of the equipment. Meanwhile, it is important to note the following:

Installation accuracy: When the axis deviation exceeds the allowable value during installation, the coupling may deform, resulting in damage or shortened service life. Therefore, it is necessary to ensure that the axis deviation is within the allowable range under the corresponding product catalog.

Maintenance: Before installation, it is necessary to clean the end faces of both shafts and check the fit; After installation, it is necessary to regularly check whether the screws are loose and tighten them in a timely manner; In order to prevent micro motion wear of the diaphragm during high-speed operation, solid lubricants such as molybdenum disulfide can be applied between the diaphragms or the diaphragm surface can be treated with a wear-resistant coating.

Safety protection: Due to the edges of products with film, there is a possibility of injury, so it is recommended to wear protective measures such as thick gloves during installation. At the same time, protective covers and other devices should be installed around the coupling to ensure safety.

High speed Steel Laminae couplings play an important role in the field of mechanical transmission due to their unique structure and excellent performance.

URL: https://m.rokee.com/diaphragm-couplings/rlhd-high-speed-metal-diaphragm-coupling.html