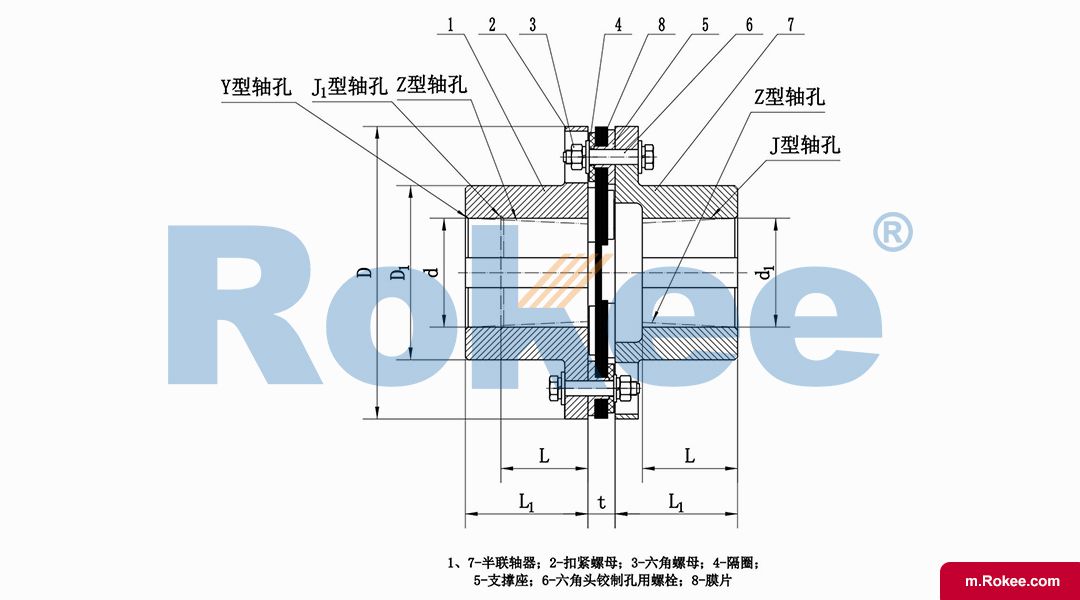

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.

| Model | Nominal Torque Tn N ·m | Instantaneous Maximum Torque Tmax N ·m | Allowable Rotating Speed [n] r/min | Shaft Hole Diameter d,d1 mm | Shaft Hole Length mm | D mm | t mm | Torsional Stiffness C N·m/rad | Quality m kg | Rotational Inertia I kg·m2 | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y 型 | J 、J1 、Z 、Z1 型 | L推荐 | |||||||||||||||||||||||||||||||||||

| L | L | L1 | |||||||||||||||||||||||||||||||||||

| JMI1 | 25 | 80 | 6000 | 14 | 32 | — | J1 型 27 Z1 型 20 | 35 | 90 | 8.8 | 1×104 | 1 | 0.0007 | ||||||||||||||||||||||||

| 16,18,19 | 42 | 30 | |||||||||||||||||||||||||||||||||||

| 20,22 | 52 | 38 | |||||||||||||||||||||||||||||||||||

| JMI2 | 63 | 180 | 5000 | 18,19 | 42 | 30 | 45 | 100 | 9.5 | 1.4×104 | 2.3 | 0.001 | |||||||||||||||||||||||||

| 20,22,24 | 52 | 38 | |||||||||||||||||||||||||||||||||||

| 25 | 62 | 44 | |||||||||||||||||||||||||||||||||||

| JMI3 | 100 | 315 | 20,22,24 | 52 | 38 | 50 | 120 | 11 | 1.87×104 | 2.3 | 0.0024 | ||||||||||||||||||||||||||

| 25,28 | 62 | 44 | |||||||||||||||||||||||||||||||||||

| 30 | 82 | 60 | |||||||||||||||||||||||||||||||||||

| JMI4 | 160 | 500 | 4500 | 24 | 52 | 38 | 55 | 130 | 12.5 | 3.12×104 | 3.3 | 0.0024 | |||||||||||||||||||||||||

| 25,28 | 62 | 44 | |||||||||||||||||||||||||||||||||||

| 30,32,35 | 82 | 60 | |||||||||||||||||||||||||||||||||||

| JMI5 | 250 | 710 | 4000 | 28 | 62 | 44 | 60 | 150 | 14 | 4.32×104 | 5.3 | 0.0083 | |||||||||||||||||||||||||

| 30,32,35,38 | 82 | 60 | |||||||||||||||||||||||||||||||||||

| 40 | 112 | 84 | |||||||||||||||||||||||||||||||||||

| JMI6 | 400 | 1120 | 3600 | 32,35,38 | 82 | 82 | 60 | 65 | 170 | 15.5 | 6.88×104 | 8.7 | 0.0159 | ||||||||||||||||||||||||

| 40,42,45,48,50 | 112 | 112 | 84 | ||||||||||||||||||||||||||||||||||

| JMI7 | 630 | 1800 | 3000 | 40,42,45,48 | 107 | 70 | 210 | 19 | 10.35×104 | 14.3 | 0.0432 | ||||||||||||||||||||||||||

| 50,55,56,60 | 142 | — | |||||||||||||||||||||||||||||||||||

| JMI8 | 1000 | 2500 | 2800 | 45,48,50,55,56 | 112 | 112 | 84 | 80 | 240 | 22.5 | 16.11×104 | 22 | 0.0879 | ||||||||||||||||||||||||

| 60,63,65,70 | 142 | 107 | |||||||||||||||||||||||||||||||||||

| JMI9 | 1600 | 4000 | 2500 | 55,56 | 112 | 84 | 85 | 260 | 24 | 26.17×104 | 29 | 0.1415 | |||||||||||||||||||||||||

| 60,63,70,71,75 | 142 | 107 | |||||||||||||||||||||||||||||||||||

| 80 | 172 | 132 | |||||||||||||||||||||||||||||||||||

| JMI10 | 2500 | 6300 | 2000 | 63,65,70,71,75 | 142 | 142 | 107 | 90 | 280 | 17 | 7.88×104 | 52 | 0.2974 | ||||||||||||||||||||||||

| 80,85,90,95,75 | 172 | — | 132 | ||||||||||||||||||||||||||||||||||

| JMI11 | 4000 | 9000 | 1800 | 75 | 142 | 142 | 107 | 95 | 300 | 19.5 | 10.49×104 | 69 | 0.4782 | ||||||||||||||||||||||||

| 80,85,90,95 | 172 | 172 | 132 | ||||||||||||||||||||||||||||||||||

| 100,110 | 212 | — | 167 | ||||||||||||||||||||||||||||||||||

| JMI12 | 6300 | 12500 | 1600 | 90,95 | 172 | 132 | 120 | 340 | 23 | 14.07×104 | 94 | 0.8067 | |||||||||||||||||||||||||

| 100,110,120,125 | 212 | 167 | |||||||||||||||||||||||||||||||||||

| JMI13 | 10000 | 18000 | 1400 | 100,110,120,125 | 135 | 380 | 28 | 19.2×104 | 128 | 1.7053 | |||||||||||||||||||||||||||

| 130,140 | 252 | 202 | |||||||||||||||||||||||||||||||||||

| JMI14 | 16000 | 28000 | 1200 | 120,125 | 212 | 167 | 150 | 420 | 31 | 30.0×104 | 184 | 2.6832 | |||||||||||||||||||||||||

| 130,140,150 | 252 | 202 | |||||||||||||||||||||||||||||||||||

| 160 | 302 | 242 | |||||||||||||||||||||||||||||||||||

| JMI15 | 25000 | 40000 | 1120 | 140,150 | 252 | 202 | 180 | 480 | 37.5 | 47.46×104 | 262 | 4.8015 | |||||||||||||||||||||||||

| 160,170,180 | 302 | 242 | |||||||||||||||||||||||||||||||||||

| JMI16 | 40000 | 56000 | 1000 | 160,170,180 | 200 | 560 | 41 | 48.09×104 | 384 | 9.4118 | |||||||||||||||||||||||||||

| 190,200 | 352 | 282 | |||||||||||||||||||||||||||||||||||

| JMI17 | 63000 | 80000 | 900 | 190,200,220 | 220 | 630 | 47 | 10.13×104 | 561 | 18.3753 | |||||||||||||||||||||||||||

| 140 | 410 | 330 | |||||||||||||||||||||||||||||||||||

| JMI18 | 100000 | 125000 | 800 | 220 | 352 | 282 | 250 | 710 | 54.5 | 16.14×104 | 723 | 28.2033 | |||||||||||||||||||||||||

| 240,250,260 | 410 | 330 | |||||||||||||||||||||||||||||||||||

| JMI19 | 160000 | 200000 | 710 | 250,260 | 280 | 800 | 48 | 79.8×104 | 1267 | 66.5813 | |||||||||||||||||||||||||||

| 280,300,320 | 470 | 380 | |||||||||||||||||||||||||||||||||||

JMI diaphragm couplings have the characteristics of strong ability to compensate for misalignment of two axes, high transmission efficiency, and adaptability to high temperatures and harsh environments.

Main characteristics

Strong compensation capability: Compared with gear couplings, JMI Membrane couplings have twice the angular displacement, smaller reaction force during radial displacement, greater flexibility, and allow for larger axial, radial, and angular displacements.

High transmission efficiency: up to 99.86%, especially suitable for medium and high-speed high-power transmission.

Strong adaptability: capable of working in high temperatures and harsh environments ranging from -80 to 300 degrees Celsius, and able to operate under conditions of impact and vibration.

Simple structure: light weight, small size, easy to assemble and disassemble, easy to maintain and replace.

Accurate transmission: able to accurately transmit speed, operate without slip, and can be used for the transmission of precision machinery.

JMI Metal diaphragm couplings are widely used in metallurgy, mining, petroleum, chemical, power, shipbuilding, lifting and transportation, textile, light industry, agricultural machinery, printing machinery, as well as mechanical equipment such as water pumps, fans, and machine tools to transmit power. Its superior performance and adaptability make it a key component in transmission systems in these fields.

When selecting JMI Flexible diaphragm couplings, it is necessary to choose the appropriate model and specifications based on the specific needs of the transmission system. At the same time, some manufacturers also provide customized services, which can be designed and manufactured according to customers' special needs. When selecting suppliers, it is recommended to prioritize manufacturers with rich production experience and good reputation to ensure product quality and after-sales service.

To ensure the long-term stable operation of JMI Steel Laminae couplings, regular maintenance and upkeep are necessary. This mainly includes checking the wear of the coupling, the looseness of fasteners, and the lubrication condition. If any abnormal situation is found, it should be dealt with and replaced in a timely manner to avoid causing greater damage to the transmission system.

JMI shim pack coupling is a mechanical transmission component with superior performance and strong adaptability, and has broad application prospects in multiple industries. In the process of selection, use, and maintenance, it is necessary to fully consider its characteristics and application requirements to ensure the stable operation of the transmission system.

URL: https://m.rokee.com/diaphragm-couplings/jmi-single-diaphragm-coupling-with-counterbore.html