LX(HL) Flexible Pin Coupling is the basic form of this series of couplings.

| Model | Old Model | Nominal Torque N ·m | Allowable Rotating Speed rpm | Shaft Hole Diameter mm d1、d2 、dz | Shaft Hole Length mm | D | S | Allowable Radial Compensation Amount | Rotational Inertia kg ·m² | Weight kg | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y型 | J、J1、Z型 | Axial | Radial | Angular Orientation | ||||||||||

| L | L1 | L | mm | |||||||||||

| LX1 | HL1 | 250 | 8500 | 12、14 | 32 | 27 | 32 | 90 | 2.5 | ±0.5 | 0.15 | ≤0°30' | 0.002 | 2 |

| 16、18、19 | 42 | 30 | 42 | |||||||||||

| 20、22、24 | 52 | 38 | 52 | |||||||||||

| LX2 | HL2 | 560 | 6300 | 20、22、24 | 52 | 38 | 52 | 120 | 2.5 | ±1 | 0.15 | 0.009 | 5 | |

| 25、28 | 62 | 44 | 62 | |||||||||||

| 30、32、35 | 82 | 60 | 82 | |||||||||||

| LX3 | HL3 | 1250 | 4750 | 30、32、35、38 | 82 | 60 | 82 | 160 | 2.5 | ±1 | 0.15 | 0.026 | 8 | |

| 40、42、45、48 | 112 | 84 | 112 | |||||||||||

| LX4 | HL4 | 2500 | 3870 | 40、42、45、48、50、55、56 | 112 | 84 | 112 | 195 | 3 | ±1.5 | 0.15 | 0.109 | 22 | |

| 60、63 | 142 | 107 | 142 | |||||||||||

| LX5 | HL5 | 3150 | 3450 | 50、55、56 | 142 | 107 | 142 | 220 | 3 | ±1.5 | 0.15 | 0.191 | 30 | |

| 60、63、65、70、71、75 | 142 | 107 | 142 | |||||||||||

| LX6 | HL6 | 6300 | 2720 | 60、63、65、70、71、75、80 | 142 | 107 | 142 | 280 | 4 | ±2 | 0.20 | 0.543 | 53 | |

| 85 | 172 | 132 | 172 | |||||||||||

| LX7 | HL7 | 11200 | 2360 | 70、71、75 | 142 | 107 | 142 | 320 | 4 | ±2 | 0.20 | 1.314 | 98 | |

| 80、85、90、95 | 172 | 132 | 172 | |||||||||||

| 100、110 | 212 | 167 | 212 | |||||||||||

| LX8 | HL8 | 16000 | 2120 | 80、85、90、95 | 212 | 167 | 212 | 360 | 5 | ±2 | 0.20 | 2.023 | 119 | |

| 100、110、120、125 | 212 | 167 | 212 | |||||||||||

| LX9 | HL9 | 22400 | 1850 | 100、110、120、125 | 212 | 167 | 212 | 410 | 5 | ±2 | 0.20 | 4.386 | 197 | |

| 130、140 | 252 | 202 | 252 | |||||||||||

| LX10 | HL10 | 35500 | 1600 | 110、120、125 | 212 | 167 | 212 | 480 | 6 | ±2.5 | 0.25 | 9.760 | 322 | |

| 130、140、150 | 252 | 202 | 252 | |||||||||||

| 160、170、180 | 302 | 242 | 302 | |||||||||||

| LX11 | HL11 | 50000 | 1400 | 130、140、150 | 252 | 202 | 252 | 540 | 6 | ±2.5 | 0.25 | 20.05 | 520 | |

| 160、170、180 | 302 | 242 | 302 | |||||||||||

| 190、200、220 | 352 | 282 | 352 | |||||||||||

| LX12 | HL12 | 80000 | 1220 | 160、170、180 | 302 | 242 | 302 | 630 | 7 | ±2.5 | 0.25 | 37.71 | 714 | |

| 190、200、220 | 352 | 282 | 352 | |||||||||||

| 240、250、260 | 410 | 330 | 一 | |||||||||||

| LX13 | HL13 | 125000 | 1080 | 190、200、220 | 352 | 282 | 352 | 710 | 8 | ±3 | 0.25 | 71.37 | 1057 | |

| 240、250、260 | 410 | 330 | 一 | |||||||||||

| 280、300 | 470 | 380 | 一 | |||||||||||

| LX14 | HL14 | 180000 | 950 | 240、250、260 | 410 | 330 | 一 | 800 | 8 | ±3 | 0.25 | 170.6 | 1956 | |

| 280、300、320 | 470 | 380 | 一 | |||||||||||

| 340 | 550 | 450 | 一 | |||||||||||

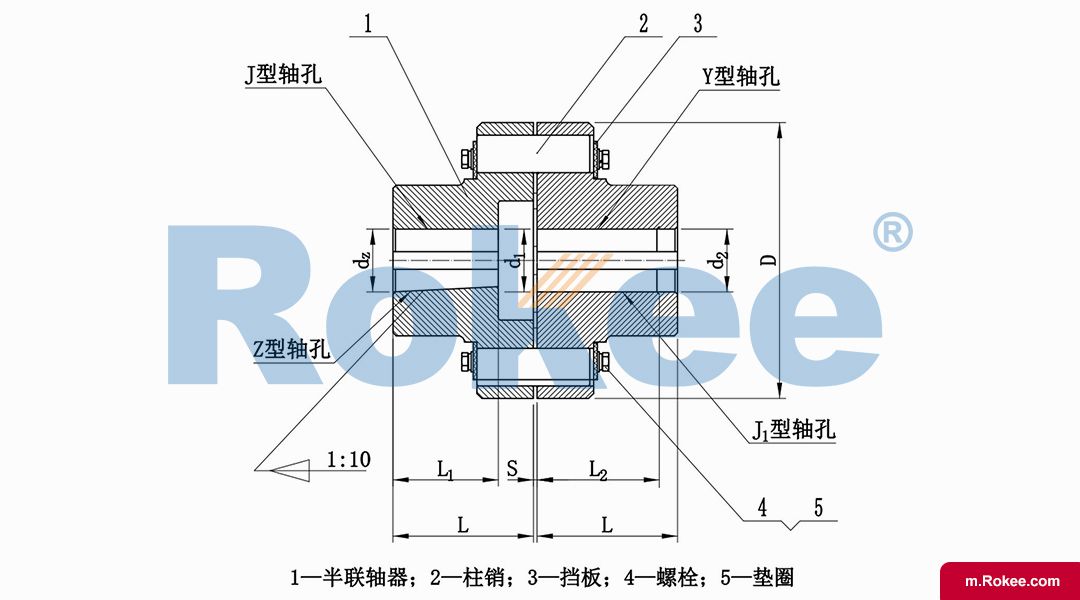

The LX elastic pin coupling is mainly used in coaxial transmission systems, and through its internal elastic element - MC nylon material pin, torque transmission is achieved. The HL elastic pin coupling has the characteristics of simple structure, easy manufacturing, convenient loading and unloading of elastic components, and can be replaced without moving the two halves of the coupling.

Structural Characteristics

Half coupling: manufactured using precision casting technology, usually made of cast iron HT20-40 or cast steel ZG35II. The shaft hole and keyway are machined and formed according to relevant standards.

Elastic element: The core component is a column pin made of MC nylon material, which has wear resistance and shear resistance properties. The column pin transmits torque through cross-sectional shear, forming a flexible connection.

Symmetrical design: The coupling is designed symmetrically at both ends, supporting quick disassembly and component interchangeability.

Application Scenarios and Limitations

- Application scenario: LX Flexible pin coupling is mainly used in high and low speed motion scenarios of coaxial transmission systems, such as gearboxes, pumps, fans and other ordinary mechanical equipment. Especially suitable for transmission systems with small axis offsets and low to medium impact conditions that require buffering and shock absorption.

Restriction: XL Flexible pin coupling is not suitable for low-speed load-bearing, strong impact vibration, and high reliability requirements of lifting machinery. Meanwhile, installation conditions where the radial or angular offset exceeds the compensation limit are also not applicable.

Installation and Maintenance

- Installation: The dimensions of the shaft hole keyway must strictly comply with relevant standards. When installing Z-shaped conical holes, a shaft end with a taper of 1:10 is required.

Maintenance: Regularly check the wear of the nylon column pin. If the wear on one side exceeds a certain limit (such as 3mm), it needs to be replaced as a whole. Elastic components can be replaced without moving the device during maintenance, resulting in short downtime for repairs.

The LX/XL Flexible pin coupling has a wide range of application scenarios and unique structural characteristics. When selecting and using, it is necessary to choose the appropriate model based on specific working conditions and requirements, and follow relevant installation and maintenance specifications to ensure its normal operation and extend its service life.

URL: https://m.rokee.com/pin-and-bush-couplings/lx-or-hl-flexible-pin-coupling.html