Rokee is a chinese Shim Couplings Manufacturer, provide Shim Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Shim Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Shim Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

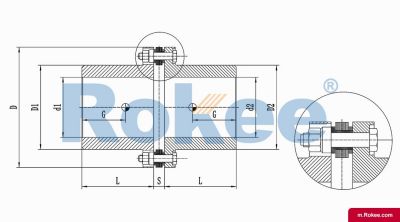

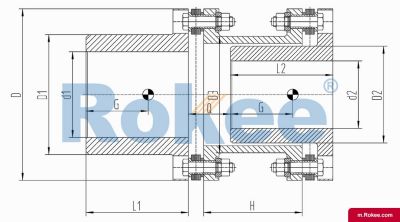

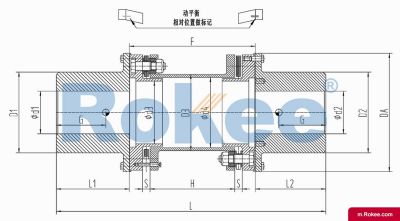

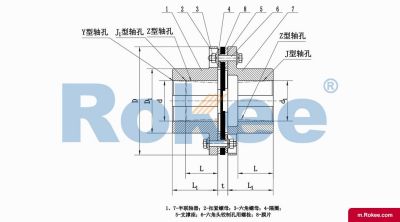

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

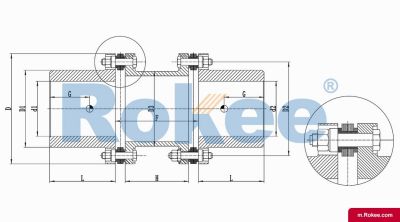

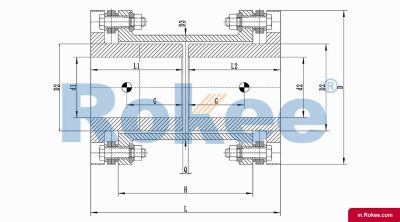

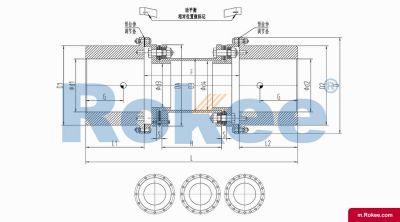

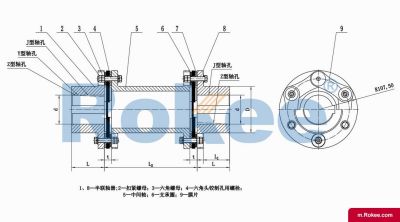

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

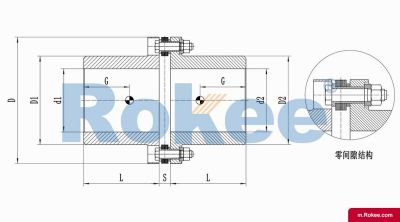

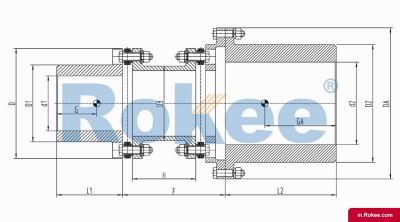

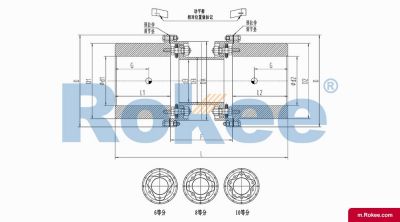

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

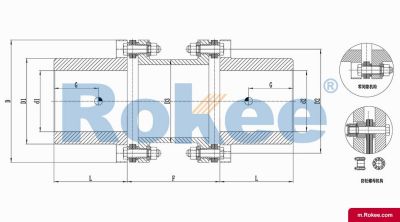

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

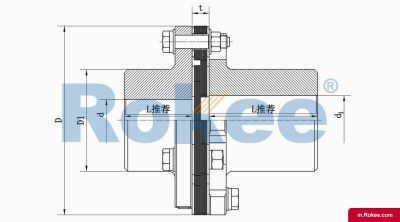

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

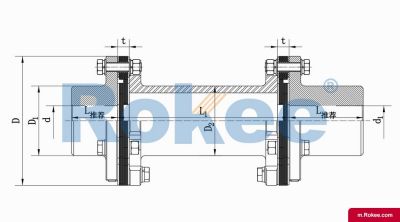

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

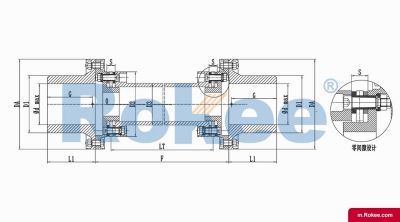

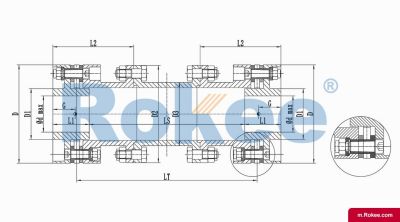

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

A shim coupling is a flexible coupling that connects two shafts and transmits power through elastic elements (laminated groups), while compensating for a certain degree of shaft system deviation. This type of coupling plays a crucial role in mechanical transmission systems and is widely used in various industrial fields.

Core structure: The shim coupling is mainly composed of two half couplings, multiple sets of spring plates, and connecting components. Each set of spring plates is carefully placed between the teeth of the two halves of the coupling, forming a discontinuous elastic connection. This design cleverly utilizes the elastic properties of metal materials, allowing for small relative displacements while transmitting torque.

Manufacturing process: In order to simplify the processing flow, the teeth on the two halves of the coupling are usually separately made as cylindrical pins with tooth grooves. Each set of spring plates is precisely embedded in the tooth slots of two cylindrical pins and fixed into independent spring components through pins. These components are then installed into the holes of the two halves of the coupling flange, completing the entire assembly process.

Displacement compensation mechanism: The coupling design specifically considers the compensation of shaft deviation. The toothed cylindrical pin on one end of the spring component is fitted with a clearance on the hole on the flange, which allows for small axial, radial, and angular displacements and effectively alleviates additional stress caused by installation errors or working deformations. The other end is fixed with an elastic retaining ring to ensure that the component will not accidentally fall off during operation.

Wear resistant treatment: In order to improve the service life of the coupling, a lining made of wear-resistant material is usually pressed into the pin hole on the flange, and a lubrication structure is designed. This treatment significantly reduces the wear between the pin hole and the cylindrical pin, allowing the coupling to maintain stable performance under harsh working conditions.

The shim coupling has a series of significant performance characteristics due to its unique structural design, which make it an irreplaceable transmission component in specific application scenarios. Understanding these performance parameters is crucial for proper selection and use.

Excellent compensation capability: The allowable radial displacement range of shim couplings is usually between 0.5-1.3mm, depending on the model and size. This compensation capability enables it to effectively absorb installation errors and shaft deformation generated during operation, protecting the transmission system from damage.

High load-bearing capacity: Due to the design of multiple sets of spring plates working in parallel, the shim coupling can transmit larger torque and has significantly higher load-bearing capacity than many other types of flexible couplings. This makes it particularly suitable for working conditions with heavy loads and high impact loads.

Convenient maintainability: The assembly and disassembly process of shim couplings is relatively simple, without the need for special tools or complex procedures. The modular spring component design enables quick replacement of damaged parts during maintenance, greatly reducing downtime and maintenance costs.

Size and load distribution: It is worth noting that one disadvantage of shim couplings is their relatively large external dimensions, which may pose challenges in compact equipment design. In addition, when there is relative displacement between the two axes, it will cause significant additional loads on the elastic elements, and the distribution of these loads between the laminations is often uneven, which may affect the service life.

Backless transmission: The shim coupling has almost no transmission clearance during normal operation, which makes it suitable for situations that require precise transmission relationships, such as servo systems. However, its transmission accuracy is generally lower than that of diaphragm couplings, which may not be the best choice in scenarios requiring ultra-high precision.

In industrial applications, shim couplings are often compared to other common types of couplings, especially diaphragm couplings. Understanding these differences can help engineers make the best choices based on specific operating conditions.

Comparison with diaphragm couplings: Diaphragm couplings are composed of single-layer or multi-layer metal diaphragms, which have the characteristics of compact structure and high transmission accuracy. In contrast, shim couplings are composed of multiple independent spring plate groups, which typically have a higher load-bearing capacity but slightly lower accuracy. Diaphragm couplings are suitable for high-precision and low to medium torque applications, such as precision instruments and medical equipment; However, shim couplings are more suitable for heavy-duty and impact load conditions, such as metallurgical equipment and heavy machinery.

Differences in maintenance requirements: Diaphragm couplings require minimal maintenance, while shim couplings require regular inspection of laminated status and lubrication. This difference makes the diaphragm coupling more advantageous in situations where it is difficult to access or maintenance free is required.

Comparison with gear couplings: Gear couplings transmit torque through the meshing of inner and outer teeth, allowing for larger angular and radial deviations, but requiring lubrication and potentially creating clearances. Stacked couplings do not require lubrication and have seamless transmission, but their compensation capability is usually not as good as toothed couplings.

Comparison with elastic couplings: Elastic couplings (such as plum blossom couplings) buffer vibration through non-metallic elastic elements, but their load-bearing capacity and temperature adaptability are usually not as good as metal shim couplings. Stacked couplings are more suitable for high temperature and heavy load conditions, while elastic couplings have advantages in small and medium power applications that require good vibration isolation performance.

Differences in stiffness characteristics: shim couplings typically have higher torsional stiffness, which enables precise transmission of motion, while some elastic couplings are designed with lower torsional stiffness to better absorb torsional vibrations. This characteristic makes shim couplings widely used in servo systems that require precise position control.

The shim coupling has been widely used in many industrial fields due to its unique performance characteristics. Understanding these typical application scenarios can help make informed choices when designing transmission systems.

Heavy industrial equipment: It performs excellently in high torque applications in the metallurgical industry and can withstand the enormous impact loads of equipment such as rolling mills. Mining machinery such as crushers and ball mills also widely use shim couplings because they can adapt to harsh working conditions and withstand vibrations and impacts.

In the field of energy, it is used to connect the turbine and generator in gas turbine and steam turbine generator sets, compensating for shaft deviation caused by thermal expansion. In rotating equipment such as pumps and compressors, it can effectively solve the problem of shaft misalignment caused by thermal deformation or installation errors.

Ship propulsion system: The propulsion shaft system of a ship is usually very long and prone to installation deviations and deformations. Stacked couplings can compensate for these deviations and ensure reliable power transmission. In diesel engine driven systems, it can effectively alleviate engine torsional vibration and protect the transmission system.

High speed applications: Stacked couplings with precision dynamic balancing can be used for high-speed rotating machinery, such as centrifugal compressors and high-speed pumps, with speeds up to thousands of revolutions per minute. In these applications, the weight and balance level of the coupling are crucial.

Special environmental applications: In high-temperature environments, such as metallurgical and glass manufacturing equipment, shim couplings have more advantages than non-metallic elastic couplings. In corrosive environments, shim couplings made of special materials such as stainless steel can be used to extend their service life.

« Shim Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/shim-couplings.html