Rokee is a chinese Single Diaphragm Couplings Manufacturer, provide Single Diaphragm Couplings processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Single Diaphragm Couplings selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Single Diaphragm Couplings is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

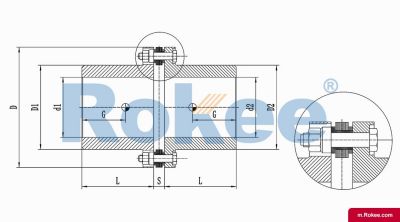

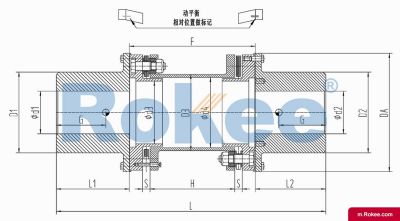

RLM Standard Single Section Small Metal Diaphragm Coupling

The RLM standard single section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working situations with a working speed not exceeding 5000rpm, and cannot compensate for radial errors.View More -

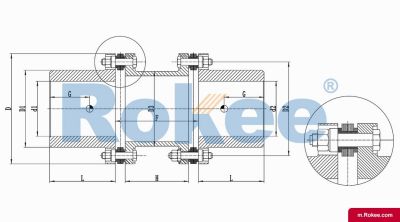

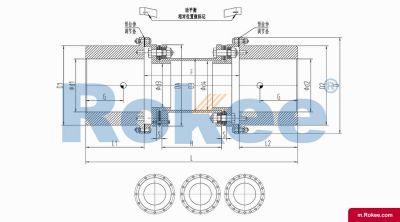

RLMD Standard Double Section Small Metal Diaphragm Coupling

The RLMD standard double section small metal diaphragm coupling is suitable for various industrial process pumps and small torque working occasions with a working speed not exceeding 5000rpm.View More -

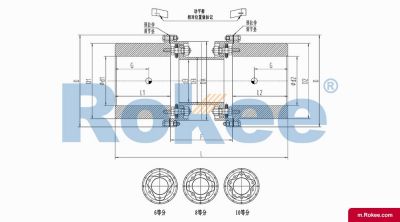

RLA Standard Single Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings,reliable choice for medium to low speed applications,but it cannot compensate for radial deviation.View More -

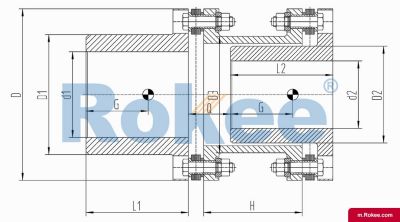

RLAD Standard Double Section Metal Diaphragm Coupling

The classic design of metal flexible diaphragm couplings is a reliable choice for medium to low speed applications.View More -

RLAR Single Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

Single side shaft sleeve reverse installation design, suitable for occasions with limited shaft head distance.View More -

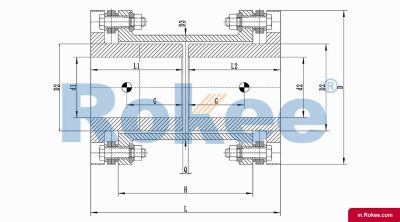

RLARD Double Shaft Sleeve Reverse-mounting Metal Diaphragm Coupling

The double-sided shaft sleeve reverse installation design is also applicable in situations where the distance from the shaft head is limited or the additional bending moment is smaller.View More -

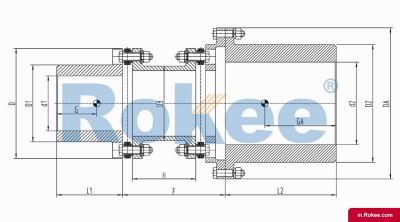

RLAF Large & Small Shaft Mounted Metal Diaphragm Coupling

The size difference design of the bilateral shaft sleeve is suitable for situations where the diameter difference between the two ends of the shaft is significant.View More -

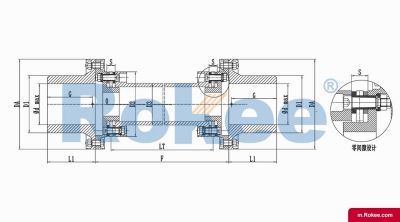

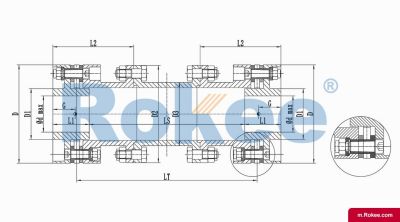

RLAT Super Long Wheelbase Metal Diaphragm Coupling

Adopting an intermediate shaft design, suitable for ultra long shaft spacing power transmission applications.View More -

RLQA No Flange Quick Installation Metal Diaphragm Coupling

Suitable for various industrial process pumps, fans, and other medium to low speed applications, with a maximum speed generally not exceeding 25000 rpm. It meets the requirements of API610/ISO14691 and is one of the first products for API applications.View More -

RLQF Flange Type Quick Installation Metal Diaphragm Coupling

Suitable for drum pressure fans, turbine compressors, and other high speed applications, with a maximum speed of up to 35000rpm.View More -

RLQU Improved Flange Quick Installation Metal Diaphragm Coupling

The improved RLQF has smaller additional bending moments and better performance. Suitable for drum pressure fans, turbine compressors, and other high speed applications.View More -

RLHD High Speed Metal Diaphragm Coupling

Suitable for higher speed applications, it also adopts a flexible component integrated assembly design, with a maximum speed of up to 42000rpm.View More -

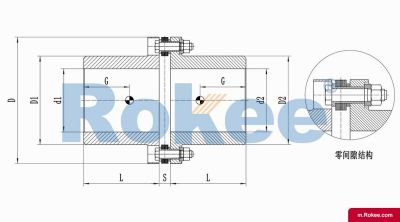

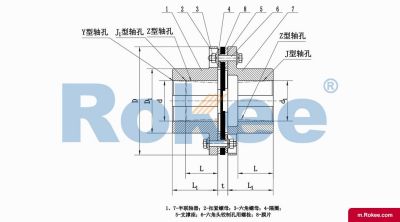

JMI Single Diaphragm Coupling With Counterbore

JMI metal diaphragm coupling adopts the single-piece design, suitable for short distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

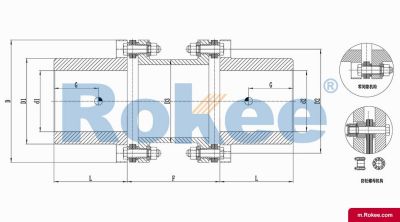

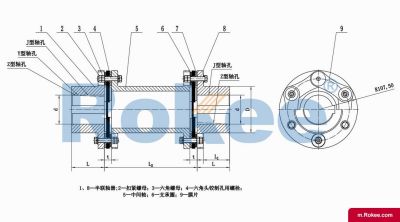

JMIJ Double Diaphragm Coupling With Intermediate Shaft

JMIJ metal diaphragm coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at one end has a counterbore, facilitating the fixing of the shaft end.View More -

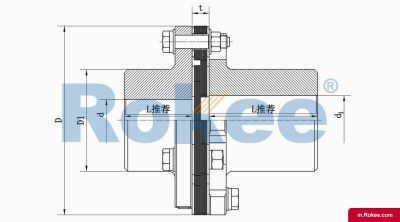

JMII Single Diaphragm Coupling Without Counterbore

JMII metal diaphragm coupling also adopts the single-piece design but has no counterbore, suitable for short distance transmission, with more compact structure.View More -

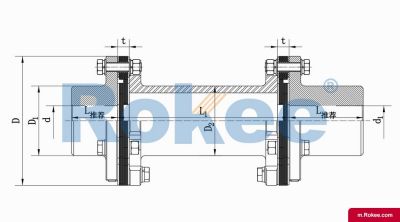

JMIIJ Double Diaphragm Coupling With Intermediate Shaft

JMIIJ Diaphragm Coupling is designed with intermediate shaft, suitable for long distance transmission. Besides, the semi-coupling sleeve at both ends have no counterbore.View More

Single diaphragm coupling is a high-performance metal elastic element flexible coupling that plays an important role in modern industrial transmission systems. As a precision mechanical component connecting two shafts, it compensates for various deviations between the shafts through the elastic deformation of metal diaphragms, while transmitting torque and motion.

The core structure of a single diaphragm coupling is relatively simple but intricately designed:

Basic composition: It mainly consists of an elastic diaphragm component and two shaft sleeves (or hubs). The diaphragm is usually made of high-strength stainless steel sheet and is fixed to the two halves of the coupling through precision bolts staggered.

Diaphragm design: Diaphragm can be divided into linkage type and integral pieces of different shapes. Each group of diaphragms is composed of several ultra-thin metal sheets stacked together, which ensures flexibility and provides sufficient strength. The membrane is usually processed into a special petal shape or with hollow patterns, which can optimize stress distribution and improve fatigue life.

Connection method: The connection between the shaft sleeve and the equipment shaft can take various forms, including keyway connection, clamping connection, or cone sleeve connection, to meet different installation requirements and shaft end forms. In terms of material selection, shaft sleeves are often made of aluminum alloy or steel, balancing lightweight and high-strength requirements.

Compared with the double diaphragm coupling, the single diaphragm type has a more compact structure and fewer parts, which makes it more advantageous in space limited applications. However, its ability to compensate for complex deviations is relatively weak.

The single diaphragm coupling achieves its core function through the elastic deformation of the metal diaphragm:

Torque transmission: When the driving shaft rotates, the torque is transmitted to the diaphragm through one shaft sleeve, and then transmitted to the other shaft sleeve through the diaphragm, ultimately driving the driven shaft to rotate. During the transmission of torque, the diaphragm will undergo slight shear deformation, which is a recoverable elastic deformation.

Deviation compensation: It can effectively compensate for three basic types of shaft system deviations:

Axial deviation: When there is displacement between the two axes in the axial direction, the diaphragm will undergo conical deformation

Radial deviation: Faced with the situation where the two axis centerlines are parallel but not overlapping, the diaphragm exhibits a bending deformation state

Angular deviation: When the two axis centerlines form an angle, one side of the diaphragm is under tension while the other side is under pressure

It is worth noting that the ability of a single diaphragm coupling to compensate for composite deviations (with multiple deviations present simultaneously) is relatively limited. It is generally recommended to control angular deviations within 1.5 degrees and small axial/radial deviations. When the deviation exceeds the allowable range, excessive alternating stress will be generated in the diaphragm, significantly reducing its service life.

The single diaphragm coupling has a series of outstanding performance characteristics, making it the preferred choice in many industrial applications:

Gap free transmission: The direct connection between metals ensures zero rotational clearance, which is crucial for servo systems that require precise positioning and can achieve seamless motion transmission.

Maintenance free design: There are no relative sliding parts in the entire transmission process, no need for lubrication and regular maintenance, saving maintenance costs and avoiding lubrication pollution, especially suitable for industries with high cleanliness requirements such as food and medicine.

Environmental adaptability: It can work stably within the extreme temperature range of -80 ℃ to+300 ℃ (depending on the specific material), and is corrosion-resistant and oil resistant, suitable for harsh environments such as chemical and marine industries.

Efficient transmission: The transmission efficiency is as high as 99.86%, with almost no power loss, which is particularly important for high-power transmission and energy-saving applications.

Dynamic performance: Although the shock absorption performance is not as good as that of rubber elastic couplings, it still has certain vibration damping characteristics and can effectively suppress high-frequency vibration transmission.

Precision: It can accurately transmit speed and operate without any slip, and is widely used in precision machinery fields such as CNC machine tools and semiconductor equipment.

In terms of technical parameters, the nominal torque transmission range of a single diaphragm coupling is usually 25-1250N · m, and the allowable speed can reach 15300-1900r/min, which can adapt to various transmission requirements from micro servo motors to large industrial equipment.

With its excellent performance, single diaphragm couplings have been widely used in multiple industrial fields:

General industrial equipment: including shaft connections for rotating equipment such as pumps (especially high-power chemical pumps), fans, compressors, generators, etc. It performs particularly well in key equipment such as boiler feed pumps and turbine drive devices.

Precision machinery: widely used in CNC machine tools, laser processing equipment, precision measuring instruments and other applications that require high-precision transmission to ensure the accuracy of motion control.

Process industry: Production line equipment in industries such as petrochemicals, pharmaceuticals, and food processing is highly favored due to its corrosion resistance and maintenance free characteristics.

Special environment: In special occasions such as nuclear power plants, ship propulsion systems, aerospace auxiliary equipment, etc., their reliability and environmental adaptability are fully utilized.

Automation equipment: The connection between servo motors, stepper motors, ball screws, encoders, especially for robots, automated production lines, etc. that require high-frequency response and high positioning accuracy.

Selection considerations

Torque requirement: Calculate the rated torque and peak torque that the system needs to transmit, ensuring that the coupling capacity has an appropriate safety margin

Speed range: Check if the allowable speed of the coupling covers the operating speed of the equipment, paying special attention to the critical speed area

Deviation situation: Evaluate the possible axial, radial, and angular deviations of the shaft system, and select a model that matches the compensation capability

Environmental conditions: Consider the influence of environmental factors such as temperature, corrosive media, dust, etc. on material selection

Space limitation: The outer diameter and length of the coupling are determined based on the size of the installation space, and the single diaphragm type is usually more compact

Inertia matching: High dynamic response systems need to pay attention to the impact of the rotational inertia of the coupling on the acceleration performance of the system

Installation precautions

Centering adjustment: even if flexible coupling is used, the shafting centering accuracy should be improved as far as possible, and the deviation should be controlled within 1/3 of the allowable range

Bolt tightening: Use a cross symmetrical method to tighten the bolts in stages, and use a torque wrench to ensure even pre tightening force

Protective measures: Install protective covers for rotating components to ensure safe operation

Trial operation inspection: After the initial operation, the machine should be stopped to check the bolt tightening status, and regular inspections should be conducted during the initial operation

Special treatment: Solid lubricants such as molybdenum disulfide can be applied between the membranes to reduce micro motion wear

Although single diaphragm couplings are generally maintenance free, the following potential issues still need to be addressed:

Abnormal vibration: usually caused by poor alignment, loose bolts, or damaged diaphragms, and should be promptly investigated

Abnormal noise: Possible causes include excessive axial spacing, excessive angular deviation, or speed fluctuations

Diaphragm fracture: often caused by long-term overload or fatigue accumulation, it is necessary to check the load condition and alignment status

Loose connection: Regularly check the fit between the shaft sleeve and the shaft to prevent wear caused by looseness

In terms of maintenance, it is recommended to conduct the following checks regularly:

Visually inspect the membrane for cracks or plastic deformation

Check all fasteners for looseness

Monitor vibration and temperature changes during operation

Regularly review the alignment of the shaft system

Compared to other types of couplings, single diaphragm couplings have unique advantages:

Compared with gear couplings: no relative sliding, no need for lubrication and sealing, no noise and maintenance, can partially replace gear couplings

Compared with elastic couplings, it has higher torsional rigidity, no creep aging problems, and a wider temperature resistance range

Compared with double diaphragm couplings: the structure is simpler and more compact, but the ability to compensate for composite deviations is weaker

Compared with bellows couplings: slightly less torque rigidity but usually stronger load-bearing capacity

The single diaphragm coupling represents the high-performance development direction of modern coupling technology, and its exquisite design and excellent mechanical performance make it occupy an important position in the field of industrial transmission. With the advancement of materials science and manufacturing technology, single diaphragm couplings will continue to develop towards higher torque density, longer lifespan, and more intelligent monitoring in the future, providing reliable shaft connection solutions for mechanical equipment in various industrial fields.

« Single Diaphragm Couplings » Post Date: 2024/5/6

URL: https://m.rokee.com/tags/single-diaphragm-couplings.html