Rokee is a chinese Cardan Drive Shafts Manufacturer, provide Cardan Drive Shafts processing and customization services, Over the years, with excellent quality, we have been continuously providing many coupling products of various categories and uses complying with multiple standards and a full range of services, from the Cardan Drive Shafts selection to final installation and operation, for the industry fields of ferrous metallurgy, nuclear power, gas turbine, wind power, ropeway construction, lifting transportation, general equipment, etc. We strictly comply with quality system requirements and implement the whole process control to become a reliable and trustworthy partner of customers.

Providing customers with better Cardan Drive Shafts is always our driving force. Our aim is to transmit power for you and generate value for both of us. We look forward to joining you and becoming your partner for common progress.

-

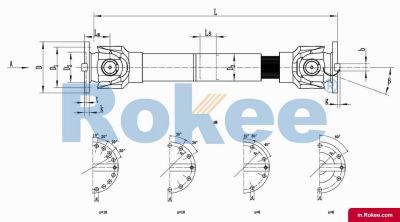

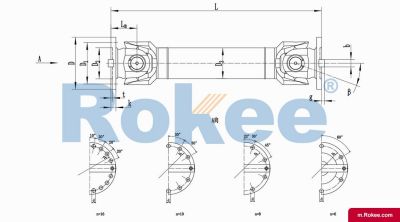

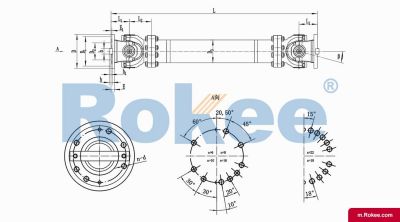

SWC-BH Cardan Shaft

SWC-BH standard telescopic welded universal joint couplingView More -

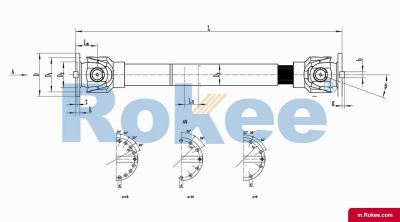

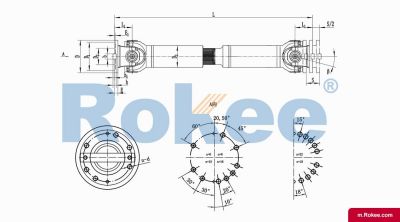

SWC-CH Cardan Shaft

SWC-CH long telescopic welded universal joint couplingView More -

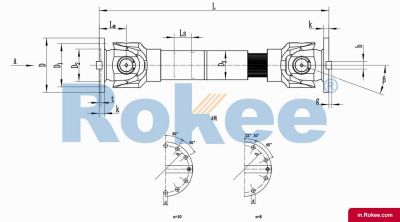

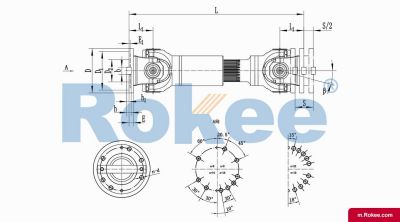

SWC-DH Cardan Shaft

SWC-DH short telescopic welded universal joint couplingView More -

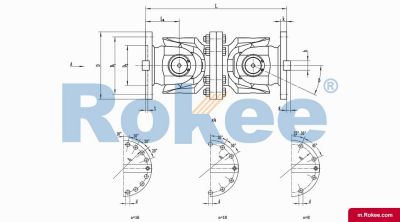

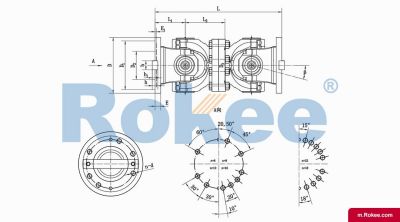

SWC-WD Cardan Shaft

SWC-WD non-telescopic short universal joint couplingView More -

SWC-WH Cardan Shaft

SWC-WH non-telescopic welded universal joint couplingView More -

SWP-A Cardan Shaft

SWP-A telescopic long type universal joint couplingView More -

SWP-B Cardan Shaft

SWP-B telescopic short type universal joint couplingView More -

SWP-C Cardan Shaft

SWP-C non telescopic short type universal joint couplingView More -

SWP-D Cardan Shaft

SWP-D non telescopic long type universal joint couplingView More

Cardan Drive Shaft is a mechanism that utilizes the characteristics of its mechanism to enable continuous rotation of the two shafts connected without being on the same axis and with an angle between the axes, and to reliably transmit torque and motion. It has a large angular compensation capability, compact structure, and high transmission efficiency. There are various structural types of Cardan Drive Shafts, such as cross shaft type, ball cage type, ball fork type, convex block type, ball pin type, ball joint type, ball joint plunger type, three pin type, trident rod type, three ball pin type, hinge rod type, etc. Among them, the most commonly used is the cross axis type, followed by the cage type. The core component of the cross axis Cardan Drive Shaft is the cross axis, which allows the two shafts to rotate continuously at equal angular velocities within a large range of angles. The ball cage Cardan Drive Shaft achieves two axis transmission through components such as the outer ring of the ball cage, the inner ring of the star shape, the cage, and the transmission steel ball. It is suitable for working conditions with large inclination angles and limited radial dimensions.

According to the magnitude of the transmitted torque, Cardan Drive Shafts can be classified as heavy, medium, light, and small. Different models of Cardan Drive Shafts are suitable for different mechanical transmission systems. Cardan Drive Shafts are widely used in metallurgy, heavy machinery, petrochemicals, engineering machinery, rail transportation, agricultural machinery, industrial machinery and other fields. For example, in steel rolling machinery, Cardan Drive Shafts are used to connect rollers and transmission systems, achieving reliable torque transmission; In heavy transportation equipment, it is used to connect the wheels and transmission shaft, ensuring that the vehicle can travel smoothly in various road conditions.

Cardan Drive Shafts have significant angular compensation capabilities and can adapt to changes in the angle between two shafts. Compact structure, small footprint, easy to install and maintain. The transmission efficiency of Cardan Drive Shafts is high, which can reduce energy loss and improve the overall performance of mechanical transmission systems. Using high-quality materials and advanced manufacturing processes, the Cardan Drive Shaft has high reliability and durability.

When selecting a Cardan Drive Shaft, factors such as the magnitude of the transmitted torque, the speed of the shaft, and the magnitude and direction of the relative displacement between the two shafts need to be considered. At the same time, it is necessary to refer to the characteristics of various types of couplings and choose a suitable type of coupling. For the Cardan Drive Shafts that have already been selected, regular maintenance and upkeep are required. For example, regular lubrication can extend its service life; When disassembling and reinstalling, it is necessary to pay attention to adjusting the position of the cross axis to balance wear and tear; In addition, it is necessary to regularly check the wear of the coupling and replace damaged components in a timely manner.

In the realm of mechanical power transmission, the cardan drive shaft stands as a fundamental component that enables efficient and reliable power transfer between non-coaxial shafts. This versatile mechanical device has been widely integrated into various industrial and transportation systems, playing a crucial role in bridging the gap between power sources and functional components. Its ability to accommodate angular deviations while maintaining stable torque transmission makes it indispensable in scenarios where shafts cannot be aligned perfectly, such as in automotive drivetrains, industrial machinery, and aerospace systems.

The core functionality of a cardan drive shaft lies in its ability to transmit rotational motion and torque between two shafts that are not in the same straight line. This is primarily achieved through the design of universal joints, which are the key components connecting the drive shaft segments. A typical cardan drive shaft assembly consists of two universal joints (also known as cardan joints) and a central shaft. The universal joint comprises two yokes and a cross shaft, with bearings installed at the intersections of the cross shaft and the yokes to reduce friction during rotation. When one shaft rotates, the cross shaft transfers the rotational motion to the other yoke, allowing the second shaft to rotate even when there is an angular offset between the two shafts. However, a single universal joint has a limitation: the output speed fluctuates slightly as the angle between the shafts changes, which can cause vibration and noise. To address this issue, most cardan drive shaft systems use two universal joints arranged in a specific configuration, ensuring that the speed fluctuations from the first joint are compensated by the second, resulting in nearly constant output speed. This constant velocity transmission is critical for maintaining the stability and efficiency of the entire mechanical system, especially in high-speed applications.

The structural design of a cardan drive shaft is tailored to meet the specific requirements of its application environment, with variations in materials, dimensions, and joint types. The central shaft, which bears the main torque load, is typically constructed from high-strength materials to ensure durability and resistance to fatigue. The choice of material depends on the application's load requirements, operating speed, and environmental conditions. For most standard applications, high-strength alloy steels such as 42CrMo and 40Cr are preferred due to their excellent tensile strength (exceeding 800MPa) and good toughness, which enable them to withstand the high torque and rotational stresses encountered during operation. In applications requiring lightweight design, such as aerospace and high-performance automotive systems, advanced materials like carbon fiber composites are increasingly being used. These composite materials not only reduce the overall weight of the drive shaft but also maintain high strength and stiffness, contributing to improved energy efficiency and performance. The universal joints also exhibit structural variations, including cross-shaft universal joints, tripod universal joints, and flexible universal joints. Cross-shaft universal joints are the most common due to their simple structure, high reliability, and high transmission efficiency, making them suitable for a wide range of industrial and automotive applications. Tripod universal joints, on the other hand, can accommodate larger angular offsets (up to 43 degrees) and are characterized by compact size, light weight, and smooth operation, making them ideal for small-displacement passenger cars with limited installation space. Flexible universal joints rely on elastic components such as rubber discs or rubber-metal sleeves to absorb torsional vibrations and reduce noise, and are typically used in applications where the angular offset is small (3-5 degrees) and axial displacement is minimal.

The manufacturing process of a cardan drive shaft is a complex sequence of operations that requires strict quality control to ensure precision and performance. The process typically begins with material selection and preparation, where the raw material (usually alloy steel bars) is inspected for chemical composition and mechanical properties using techniques such as spectral analysis and tensile testing to ensure compliance with design requirements. The next step is cutting, where the raw material is precisely cut into blanks using CNC band saws or circular saws, with strict control over the cutting length tolerance (±0.5mm) and cutting surface perpendicularity (≤0.1mm/m) to avoid insufficient machining allowance in subsequent processes. After cutting, the blanks undergo preliminary processing, including turning and milling, to form the basic shape of the shaft, such as stepped shafts and flanges. Key processes such as spline milling are also performed at this stage to ensure the drive shaft can effectively transmit torque through connections with other components. Heat treatment is a critical step in enhancing the mechanical properties of the drive shaft. The blanks are subjected to quenching and tempering processes to improve their hardness, strength, and toughness. For example, 42CrMo alloy steel is typically quenched at high temperatures and then tempered at 550℃ to achieve a hardness of HRC25-32, ensuring optimal comprehensive mechanical properties. In some cases, surface heat treatment techniques such as induction hardening are used to increase the surface hardness of key areas, improving wear resistance. After heat treatment, the drive shaft undergoes precision machining, including grinding, to achieve the required dimensional accuracy and surface roughness. The final stages of manufacturing include surface treatment, assembly, and testing. Surface treatment processes such as phosphating or epoxy coating are applied to enhance corrosion resistance, while assembly involves installing the universal joints, bearings, and other components. Testing procedures include dynamic balance testing to ensure the drive shaft operates smoothly at high speeds (with an unbalance of ≤10g·cm), as well as torque and fatigue testing to verify its reliability and service life.

The cardan drive shaft finds applications in a wide range of industries, owing to its versatility and reliability in power transmission. In the automotive industry, it is a key component of the drivetrain system, connecting the transmission to the differential in rear-wheel-drive and four-wheel-drive vehicles. As the vehicle travels over uneven terrain, the suspension system moves, causing changes in the angle between the transmission and the differential. The cardan drive shaft accommodates these angular changes, ensuring continuous power transmission to the drive wheels. It is also used in steering systems and brake systems to ensure stable operation under various driving conditions. In industrial machinery, such as cranes, excavators, and conveyor systems, the cardan drive shaft is used to transmit power between non-coaxial shafts in complex mechanical structures. These applications require the drive shaft to withstand heavy loads and harsh operating environments, making high-strength materials and robust structural designs essential. The aerospace industry also relies on cardan drive shafts in applications such as aircraft landing gear and engine mounts, where reliable power transmission and lightweight design are critical. In agricultural machinery, such as tractors and harvesters, the cardan drive shaft is used to drive working implements such as plows and mowers, enabling efficient power transfer from the engine to the tools. The marine industry uses cardan drive shafts to transmit power from the engine to the propeller, ensuring stable operation under varying sea conditions. Additionally, with the development of industrial robotics, cardan drive shafts are increasingly being used in robot joints to enable precise and flexible movement, highlighting their adaptability to emerging technological fields.

In recent years, the cardan drive shaft has undergone significant technological advancements, driven by the evolving needs of various industries for higher efficiency, lighter weight, and smarter performance. One of the key trends is the adoption of new materials and lightweight design. The use of carbon fiber composites has increased rapidly, with their penetration rate rising by 8 percentage points in the past three years, and a market share of over 15% in high-end applications. These materials not only reduce the weight of the drive shaft but also improve fuel efficiency and reduce emissions, aligning with global environmental protection trends. Another important trend is the integration of digital and intelligent technologies into the design and manufacturing process. Digital simulation technologies, such as finite element analysis and digital twin, are used to optimize the structural design of the drive shaft, reducing the number of physical prototypes and shortening the development cycle by up to 30%. Intelligent testing systems, including three-coordinate measuring machines and ultrasonic flaw detectors, are widely used to ensure product quality, reducing the defect rate to below 0.12%. The development of additive manufacturing (3D printing) technology has also enabled the production of complex-shaped drive shaft components, allowing for more efficient designs that were previously impossible with traditional manufacturing methods. In addition, there is a growing focus on predictive maintenance and lifecycle management. By integrating sensors into the cardan drive shaft, real-time data on torque, temperature, and vibration can be collected, enabling early detection of potential faults and reducing downtime. This smart maintenance approach has become a new value-added service in the industry, with its contribution to profits increasing from 8% in 2024 to 12% in 2025.

Despite the technological advancements, the cardan drive shaft still faces challenges that drive further innovation. One of the main challenges is balancing high performance with lightweight design. As industries such as automotive and aerospace demand higher power density and lower energy consumption, there is a need to develop materials and designs that can maintain high strength and durability while reducing weight. Another challenge is ensuring reliability and durability under extreme operating conditions, such as high temperatures, high humidity, and heavy loads. This requires continuous improvements in material science, heat treatment processes, and surface protection technologies. Additionally, with the trend towards electrification and automation in various industries, the cardan drive shaft needs to be adapted to work seamlessly with electric motors and intelligent control systems. For example, in electric vehicles, the drive shaft must accommodate the high torque output of electric motors and operate quietly, requiring new designs and materials to reduce vibration and noise. The development of global standards for noise, vibration, and energy efficiency also presents challenges, as manufacturers need to comply with increasingly stringent requirements across different regions.

Looking to the future, the cardan drive shaft is expected to continue evolving to meet the changing needs of global industries. The use of advanced composites and lightweight alloys will become more widespread, driven by the demand for energy efficiency and reduced carbon emissions. Digitalization and intelligentization will further deepen, with the integration of AI and IoT technologies enabling real-time monitoring, predictive maintenance, and adaptive control of cardan drive shaft systems. The application scope of cardan drive shafts will also expand into new fields, such as medical equipment, smart manufacturing, and renewable energy systems (e.g., wind turbines). In wind energy applications, the demand for large-scale cardan drive shafts that can withstand high torque and harsh environmental conditions is expected to grow, driven by the expansion of the global renewable energy sector. Additionally, the trend towards customization will continue, with manufacturers offering tailored cardan drive shaft solutions to meet the specific requirements of different applications. This will require greater flexibility in manufacturing processes and closer collaboration between manufacturers and end-users.

In conclusion, the cardan drive shaft is a vital component in modern mechanical power transmission systems, with a wide range of applications across automotive, industrial, aerospace, agricultural, and marine industries. Its ability to transmit torque between non-coaxial shafts while accommodating angular deviations makes it indispensable in complex mechanical structures. Over the years, advancements in materials, manufacturing processes, and digital technologies have significantly improved the performance, reliability, and efficiency of cardan drive shafts. Despite the challenges posed by lightweight design, extreme operating conditions, and evolving industry standards, the future of the cardan drive shaft looks promising, with continued innovation driving its adaptation to new technologies and applications. As global industries move towards sustainability, electrification, and intelligentization, the cardan drive shaft will remain a key enabler of efficient and reliable power transmission, playing a crucial role in the development of modern engineering systems.

« Cardan Drive Shafts » Update Date: 2026/1/10